Use the Right Grease for the Job

Peter Haig, Solvent Extract (SX) Consultant – with permission of BIN95 Business Industrial Network

Posted 10/10/2024

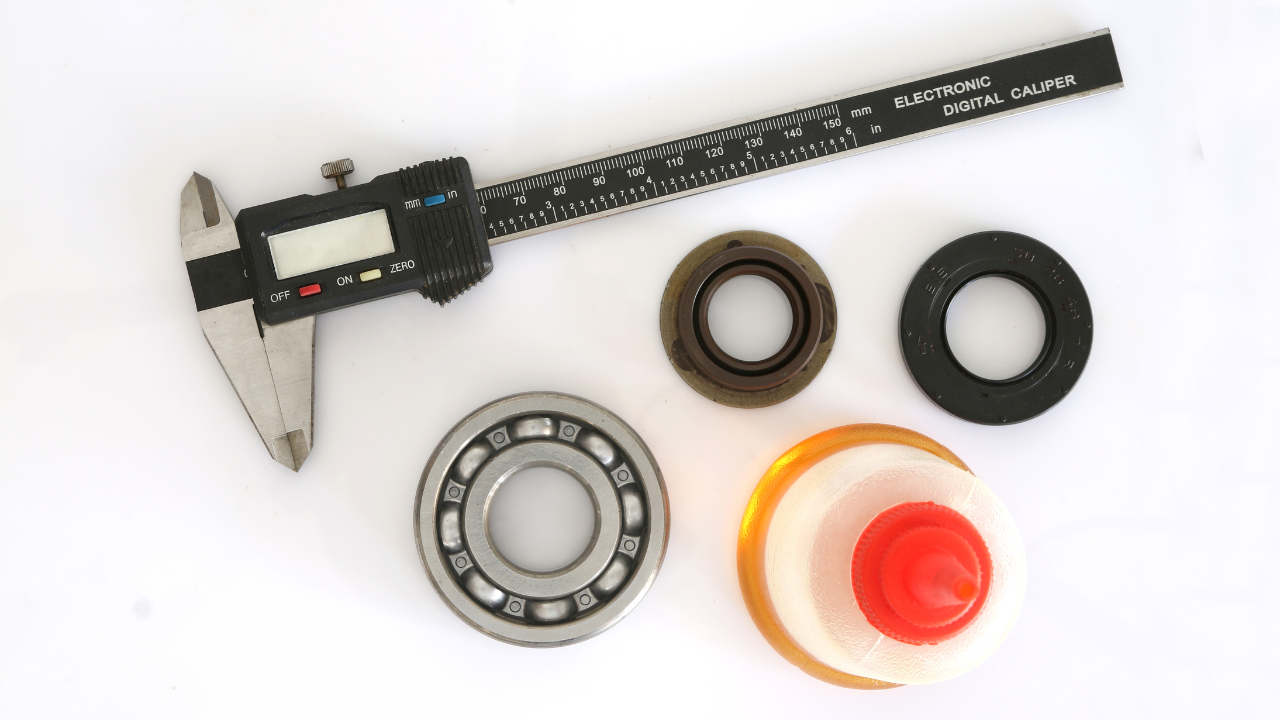

Grease – use the right one for the job. The classification, selection, and application of greases is included in this article. Greases are designed for specific applications and if used in the wrong service they will not be effective. Compare the properties of greases and check those used in your equipment are suited to the service.

Video: A Brief History of Grease – watch before reading on!

Classification, Selection, and Application of Lubricating Greases

The classification of lubricating greases is not uniformly regulated. Because of the versatility and the variations in their composition, greases are essentially classified on the basis of their base oil or thickener.

Base Oils

The oil present in a lubricating grease is referred to as its base oil. The proportion of base oil can vary depending on the type and quantity of thickener and the intended application of the grease. For most greases, the base oil content is between 85% and 97%. The type of base oil gives a grease some of its typical characteristics.

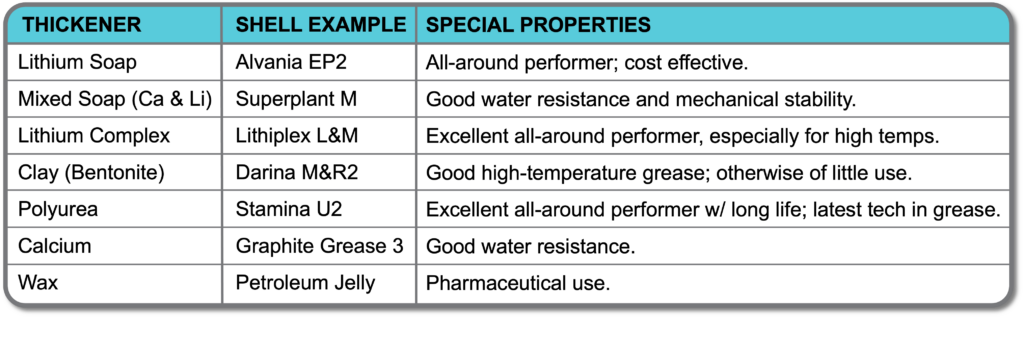

Thickeners

Thickeners are divided into soaps and non-soaps and give lubricating greases their typical properties as well. Soap greases can be divided into simple and complex soap greases, each of which are referred to by the name of the cation on which the soap is bases (e.g. lithium, sodium, calcium, barium, or aluminum soap greases).

These metal soaps are made from fatty acids, which are products obtained from animal or vegetable oils and fats.

These fatty acids are a mixture of a wide variety of chemically defined fatty acids. They are split into fatty acids and glycerides by hydrolytic decomposition. The fatty acids are then combined with the corresponding metal hydroxides to form the metal soaps used as thickeners for lubricating grease production.

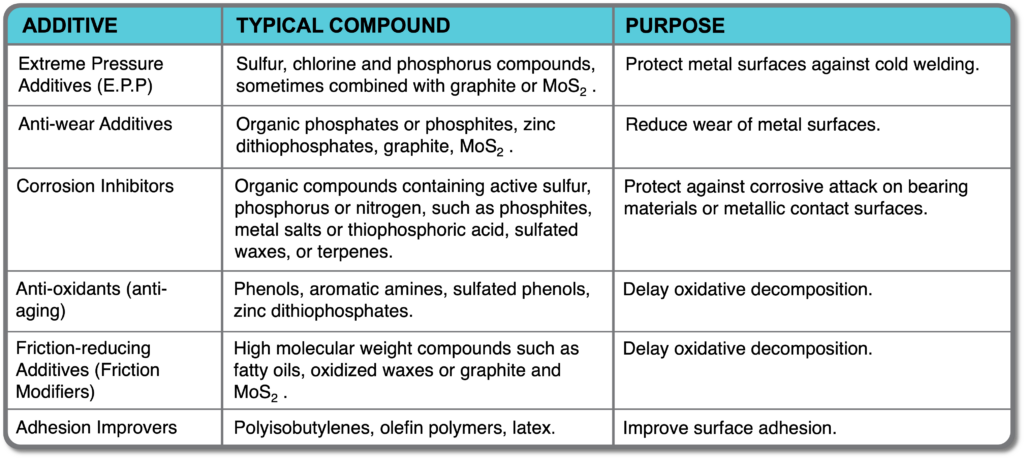

Additives

Additives counteract wear and corrosion, provide additional friction reducing effects, improve the adhesion of the grease, and prevent damage under boundary and mixed friction conditions.

Additives therefore affect the quality, potential applications, and ultimately the practical value of the grease. Additives can be solid, polar, or polymeric.

Solid Additives

Graphite, Molybdenum Disulfide, Zinc Sulfide, talc, polytetrafluoroethylene, etc. are incorporated into greases in powder form or as pigments. They act in the boundary and mixed friction regions. Solid additives improve running-in and emergency operating characteristics.

Polar Additives

Polar substances are hydrocarbon molecules which behave in an electrically non-neutral way because of their molecular structure (i.e. by incorporating other elements such as oxygen, sulfur, or chlorine), and are retained on metal surfaces as if they were magnetic. The presence of polar substances increases adhesion of the lubricant film, since pure hydrocarbons are “non-polar”.

Polymer Additives

The correlation between temperature and the viscosity of mineral oils can be influenced by additives. These additives consist of organic polymers with molecular weights of between 10,000 and 200,000. At moderate temperatures their chain-like molecules are tangled together, but at high temperatures they extend into elongated threads. By simultaneously switching to a low-viscosity base oil with a higher viscosity index (VI), the viscosity-temperature curve can be flattened. The presence of polymers makes the viscosity of a base oil dependent on the shear rate.

Polymers generally improve the wear protection offered by lubricants. Polymers used as adhesion additives for greases include polyisobutylenes, olefin polymers, and others. They improve the grease’s adhesion to surfaces.

Advantages Of Grease Lubrication Over Oil Lubrication

- Reduced design complexity

- Less maintenance is often required, since lifetime lubrication is possible.

- Less risk of leakage and simpler seal design

- Sealing effect is reinforced by used grease overflow (“grease collaring” or labyrinth).

- With high-speed greases, metered grease quantities, and a running-in period, low bearing temperatures can be achieved at high revolutions.

Disadvantages Of Grease Lubrication Compared with Oil Lubrication

- Less heat dissipation possible

- Contaminants are captured by the grease film and not removed, especially with grease lubrication of minimal quantity.

- At present, limiting speeds or speed factors are lower than with oil injection and oil/air lubrication.

Peter Haig

Peter Haig is a Solvent Extraction (SX) Consultant formerly working with both BASF and Shell Chemicals. He is known as one of the most respected engineers in the solvent extraction field. Specialties in this field include Diluent and SX Chemistry, Process Control, Equipment Advice and most importantly, SX Safety. Also has experience with mine visitations, configuration modeling, plant trials, training and arranging laboratory testing when required.

Related Articles

Use the Right Grease for the Job

How to Fix the 70/30 Phenomenon

Keys for Effective Troubleshooting

A Planner's Tool Kit

All About Eye Protection

Analyzing Semiconductor Failure

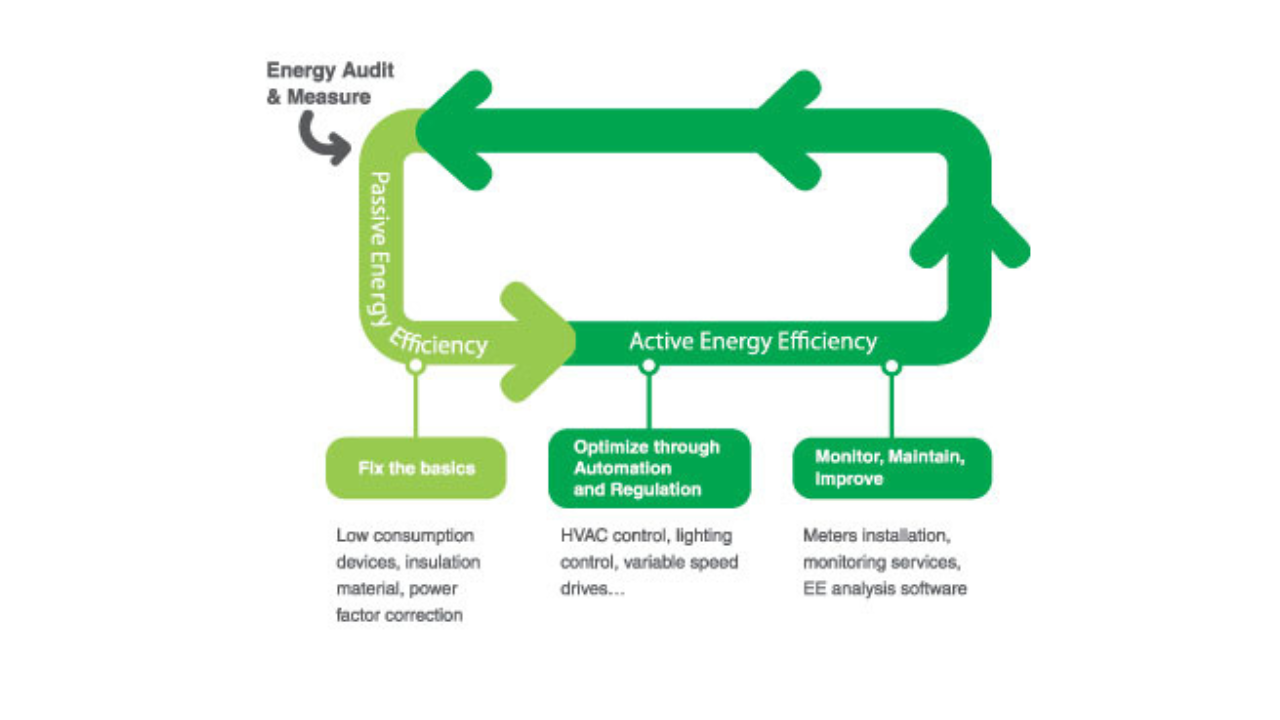

Achieve Energy Savings in Plant Facilities

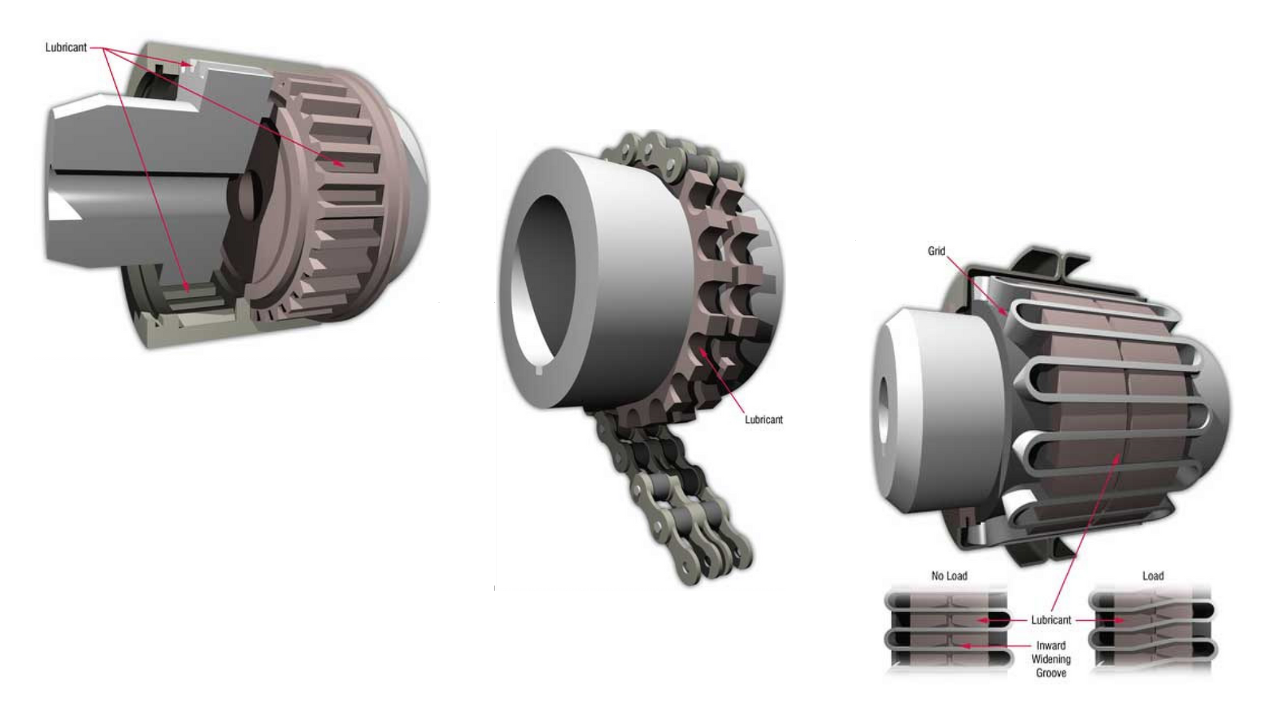

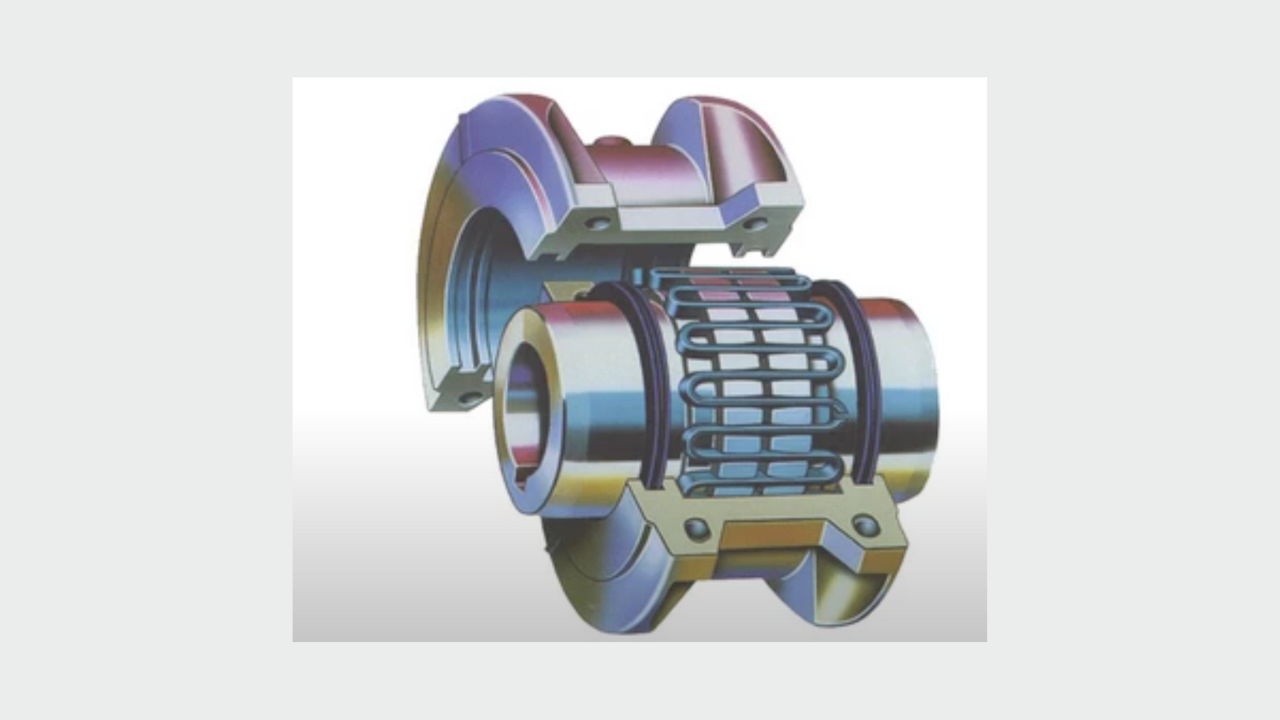

The Lubrication Requirements of Couplings

Zen and the Art of Managing Maintenance

Why do maintenance improvement initiatives fail to deliver? (Hedgehog or Fox?)

Why Maintenance Improvement Efforts Fail

Arc Flash/Arc Blast Review with Safety Suggestions for Design & Maintenance

CSA Launches First Confined Spaces Standard in Canada

Do You Need NFPA 70E?

Electrical Hazards

Eliminating Conveyor Concerns

Eye Injuries are a Serious Threat to American Workers

Fluid Power Safety Alert

Human Factors: Beyond the "Dirty Dozen"

Hydraulic Systems Safety

TPM and RCM: Whirled Class

Where Do Maintenance Professionals Come From?

What is the True Downtime Cost (TDC)?

Improvement: What Comes First?

Machine Safety: Machinery Friend or Foe?

How Maintainers Can Work More Safely

Plant Deaths Fall 14.0%

Plant Safety - Avoid Pitfalls of New and Untrained Plant Employees

Prevent Injuries: Workplace Safety is Everyone’s Job

Preventing Workplace Eye Injuries

Protective Clothing: The Hazard of Selection

Quality Control of the Inspection Process

Improved Safety

Safe Use of Clamps Through Proper Selection

Safety and Reactive Maintenance

Safeguarding: Hoops, Health & Harmonization: Design Standards Do it All

Symbiosis of Maintenance and Safety in Process Industry

The New ISO 12100 – Safety of Machinery

The Safety Catalyst: Handling Stubborn Safety Problems

What to do When you Receive an OSHA Citation

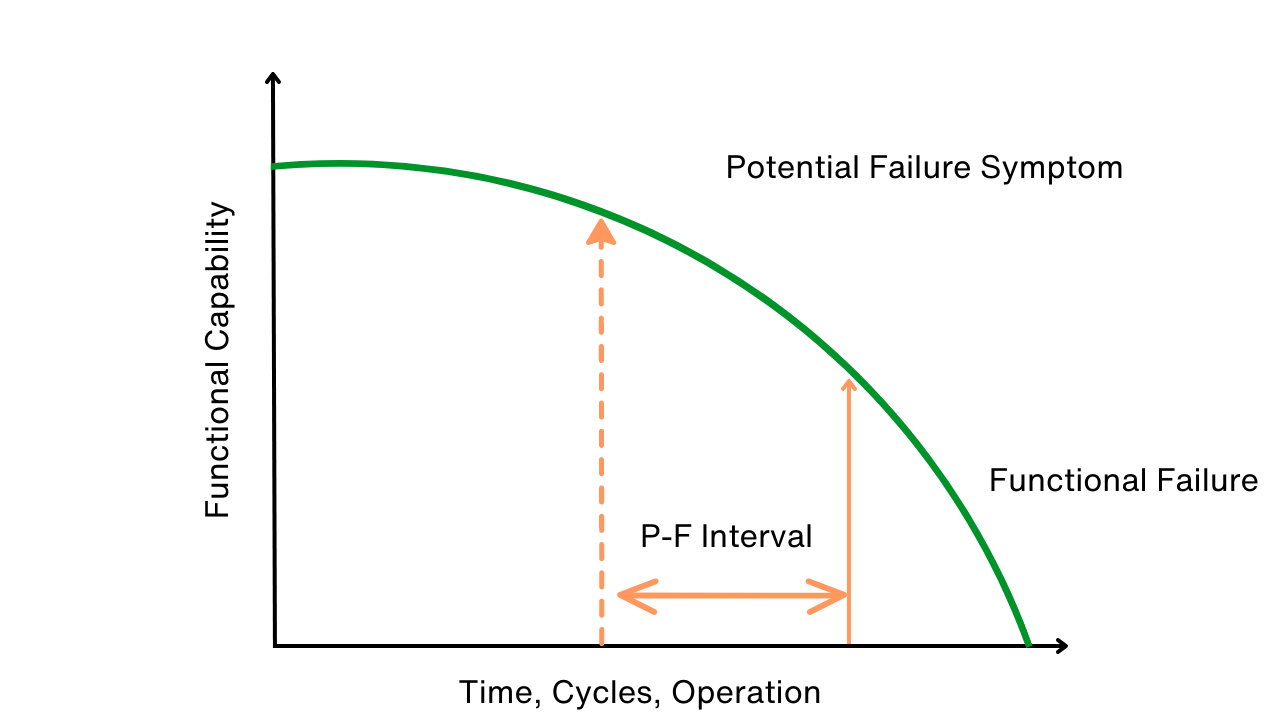

Use P-F Intervals to Map, Avert Failures

Use this Game Plan to Justify an Investment in Maintenance and Reliability

Uptime: Fill Out Work Orders? Who's Got Time for Paperwork?

TPM and Tecate: The New Translation

The Totally Responsible Individual: Dealing with Chaotic Events

The Reliability Paradox

The Real Value of the Plant You're Buying

The RCM Trap

The Japanese Path to Maintenance Excellence

The Face of Effective Reliability Management

What the Emperor’s New Clothes Says to Plant Reliability and Maintenance Professionals

The Cost of Doing Nothing

Switch in Contract, Maintenance Proves Costly

Spare Parts Management Indicators

6 Ways Outsourced Maintenance Saves

Reliability Improvements Drive Down Maintenance Costs

Reliability Centered 'Workforce' Maintenance

Reliability and Current Best Practices - An Educational Journey

Reliability and Maintenance Implementation Model

Reducing Maintenance Costs in a Tough Economic Climate

Properly Aligning Projects to Corporate Strategy

Professional Development: Driving the Economic Engine

People Management - Workforce Shortage: Acceptance is the First Step

OEE: Overall Equipment Effectiveness

Novozyme Leverages Results Oriented Maintenance and Highly Motivated Staff to Win the North American Maintenance Excellence (NAME) Award 2000

Need of Motivation for Maintenance Staff

Mechanical Quality Assurance: The Next Progression of Reliability

Maintenance Business: Managing Maintenance as a Business

Maintenance Standards at Weyerhaeuser Company

Tips for Maintenance Planning

Maintenance Outsourcing: A Step Towards Product Service Systems

Maintenance Management - Defining, Clarifying "Reliability"

Maintenance Management Legends

Maintenance Management as a Quality Process

Maintenance Key Performance Indicators (KPIs)

"Lean" on your Maintenance Materials

How to Cut Your Maintenance Budget (Without Cutting Your Throat)

Hiring of Maintenance Management Personnel – Top 10 Mistakes

The Danger of the Reduction of Workforce

Global Indicators for Maintenance, Availability Performance

Key Performance Indicators and Frontline Maintenance Leaders

The Building Blocks to Creating an Effective Lubrication Program

Evolution of the "Grease Monkey" to the Maintenance Professional

All Win - A Maintenance Partnership in Three Pulp Mills: Reasons, Results and Lessons

Maintenance Training - The Backbone of Cultural Change

Too Small for a CMMS? Think Again

The Role of Information Technology in Plant Reliability

The Maintenance Storeroom: Keys to Efficient Maintenance Operation

The Future of CMMS

The 8 Key Elements to Look for in Maintenance Software

Skimping on the Training Puts your CMMS Project at Risk

Elastopipe: Safety Pipe for Oil Rigs

Reaping the Benefits of CMMS

RCM Success Starts with CMMS

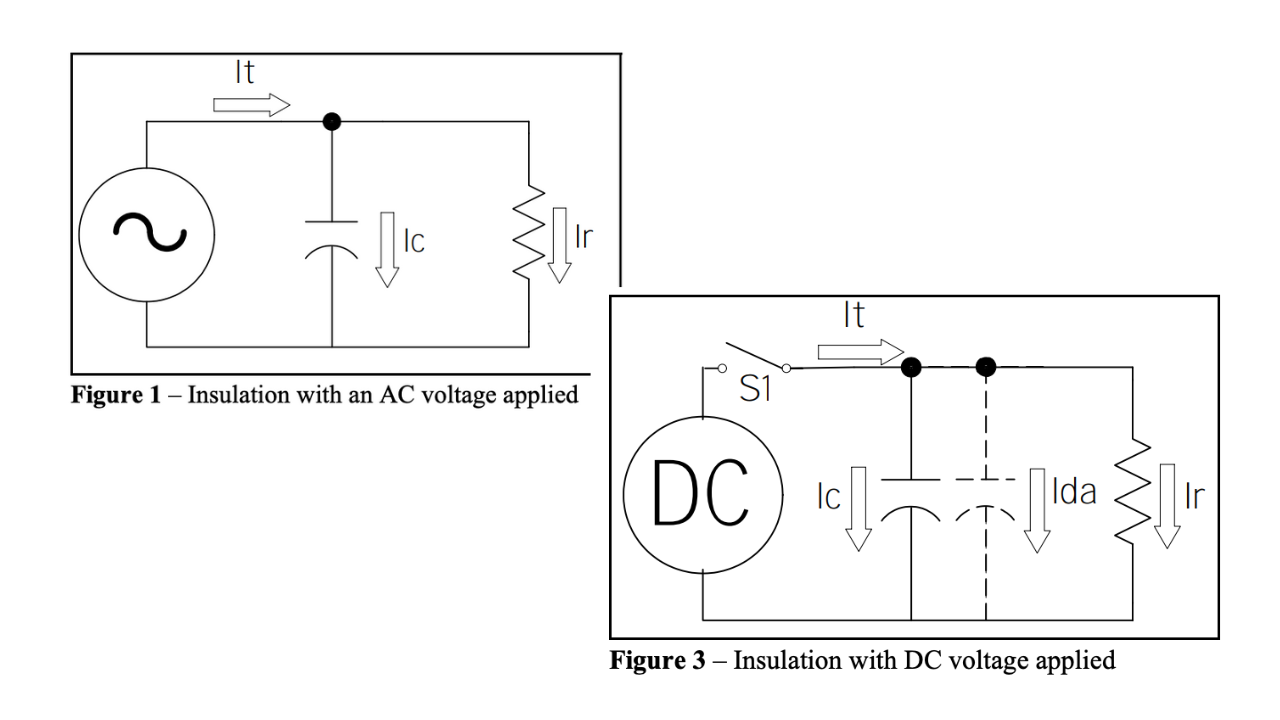

Principles of Insulation Testing

Open Warehouse System

Mobile CMMS: The Future Maintenance Team's BFF

Managing Spare Parts

Managing an EAM / CMMS Selection

Managing an EAM/CMMS Implementation

Fixing Maintenance

Few Make the Most of Their CMMS

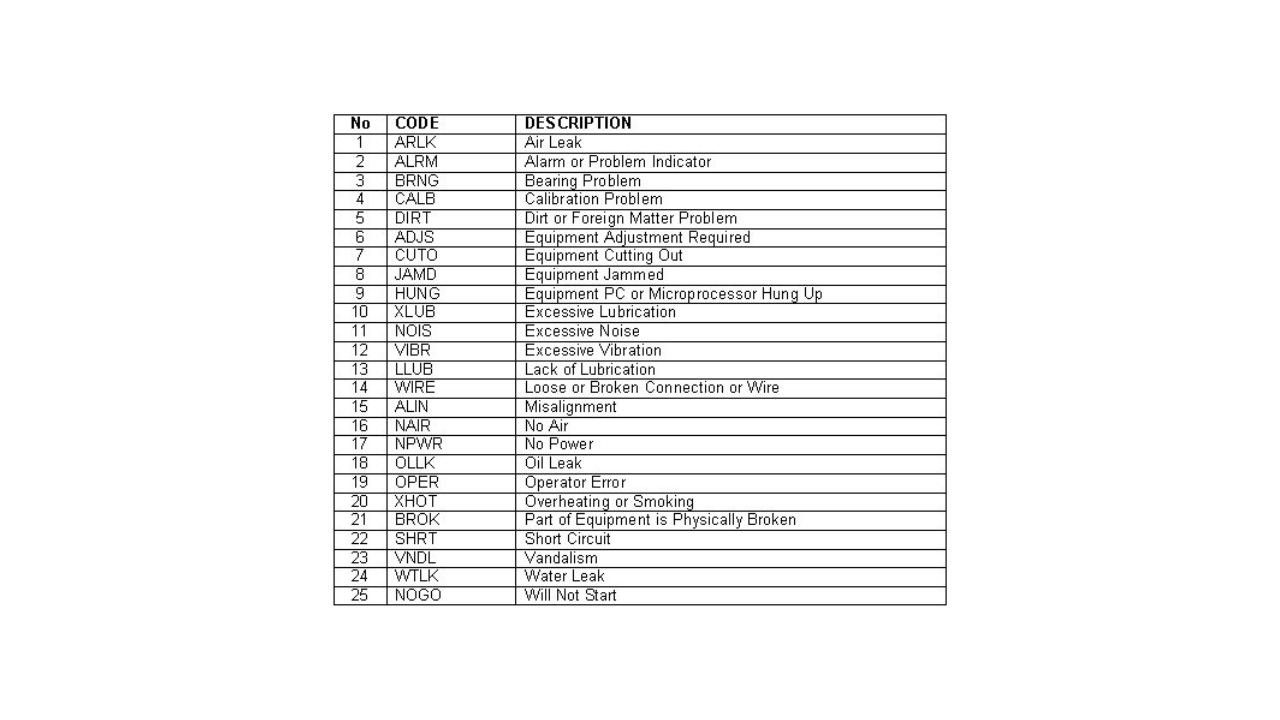

Failure Codes in Maintenance Systems - CMMS

Effective Maintenance Management at Doe Run

Eat an Elephant - Implement a CMMS

Does Lubrication Belong in the CMMS?

Developing CMMS Implementation Templates

Define the Need Before Software Installation

Collaborative Production Management in the Process Industries

CMMS Software - Selecting the Right CMMS

CMMS: Integrating Real-Time Information for Condition-Based Maintenance

Calculating the Savings from the Implementation of a CMMS

Barcode-Driven Tracking System Coordinates Toolrooms

Balancing CMMS User Configurability with Centralised Control

An Integrated Process for System Maintenance, Fault Diagnosis and Support

Maintenance Software Implementation

Maintenance Control - from Zero to Hero

Enhancing Overall Equipment Effectiveness Through TPM

Corrective Maintenance Task Generation

Centralized Maintenance vs. Decentralized

Can You Really Justify Reliability Centered Maintenance (RCM)?

Avoid Waste: Lean Maintenance Can Reduce Overall Costs

Availability in a Supply Constrained Environment is the #1 Issue for Refinery Executives

What the Pump Was Designed to Do and Why it Doesn't Do it

What is Wrong with the Modern Centrifugal Pump?

Weibull Point Process Applied to Repairable Subsystems

Using Reliability Importance Measures to Guide Component Improvement Efforts

Top Tips for Selecting Pressure Measurement Transmitters

The Full Circle of Engineering Education

The Achilles Heel of Modern Electronics

Developing Marketable Engineering Skills

Sorting Out Flexible Couplings

Safety Circuits, Force Guided Relays vs. General Purpose Relays

Preheater Points Out the Value of Cooling Off

Mining Maintainability

Maintainability Design Checklist

Engineered Building Maintenance

Energy Savings Through Pump Refurbishment and Coatings

Digging Up Savings: Go with the Flow

Design for Maintainability: The Innovation Process in Long Term Engineering Projects

Design for Maintainability

Communications: The OEM Partnership

Chain Drive Design Recommendations

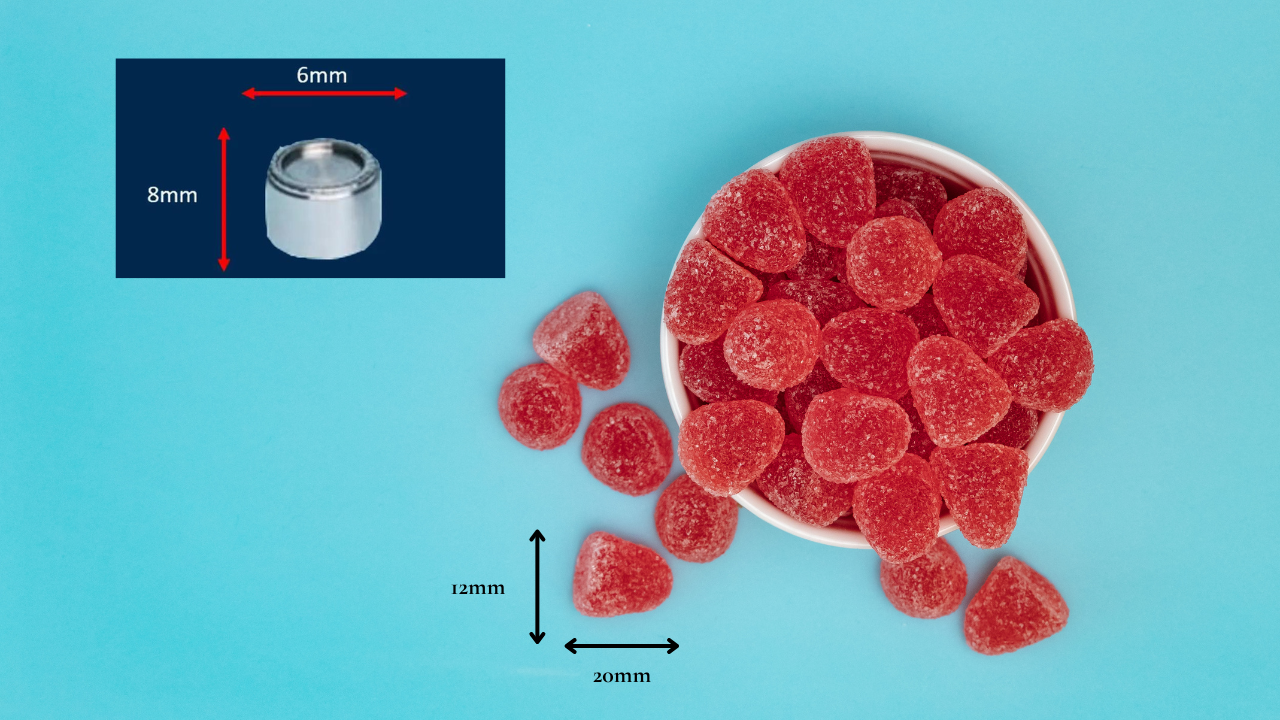

Carbon in a Metal Holder

Classifying Chemicals to Assure Effective Sealing

A Guide to Matching Electric Motors with Hydraulic Power Units

The Cost of Producing Electricity

Anatomy of a Boiler Failure—A Different Perspective

Anatomy of a Hydraulic Pump Failure

Are We Willing to Hear What “Failure” Has to Say?

Causes of Overheating in Cartridge Mechanical Seals

Centrifugal Pump Troubleshooting

PLC Troubleshooting

Electrical Troubleshooting in 7 Steps

Reduced Wear and Failure of Machine Components: Failure Analysis of Mechanical Components

Gearbox Diagnostics Fault Detection

Getting Root Cause Analysis to Work for You

How to Conduct Effective Root Cause Analysis

A Framework for Achieving Best Practice in Maintenance

An Introduction to the Maintenance Scorecard

You Cannot Maximize Production or Reduce Costs Without the use of an Effective Planned Maintenance System

Wrench Time

Work Order Prioritization

Work Order Execution and Data Capture

Work Flow Concepts

Why Planned Maintenance?

The What, Why, How of Wrench Time

Smart Shutdowns: Avoid Costly Mistakes with Your Outages

Setting Disciplined Priorities when Prioritizing Maintenance Work

Proactive Approach to Shutdowns Reduces Potlatch Maintenance Costs

Planned Work Predominance: Contribution to the Bottom Line

Planned Hours: What's a good total?

Mining Planning Department: Planning for Profits

No-no’s for the Maintenance Planner Role

Maintenance Planning in Underground Mining Operations

Maintenance Planning and Scheduling

Maintenance Management - The Planned State

'Ja, maar' Mentality Can Hurt Planning

Improving Estimating Quality

Improve Basic Work Systems First

How Project Management Software Can Smooth the Way

Cutting Maintenance Cost Through Effective Shutdown Management

Critical Component of the CMMS: The Repair Work Order

Backlog Management

Accurately Estimating Labor Hours

Ceramics Win the War on Erosion

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera

Web Based Vibration Analysis Programs

Water Contamination

Vibration & Ultrasound Technologies: A Possible Integrated Inspection Tool?

Vibration Pen, Shock Pulse Measurement (SPM), & Vibration Analysis - What's the Difference?

Vibration Analysis Reveals Poor Motor Mounting Structure

Ultrasonic Leak Detection in Heat Exchangers

Using Corrective Maintenance Work Plans to Improve Plant Reliability

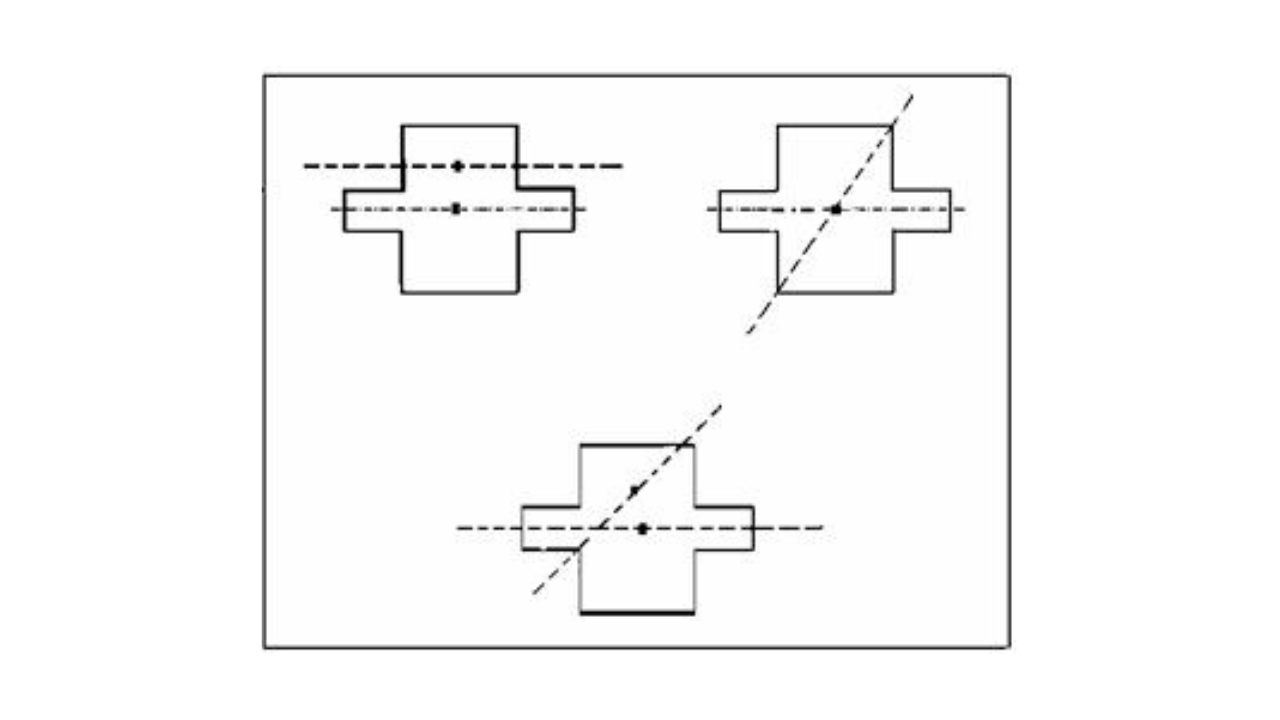

Understanding The Basics Of Balancing & Measuring Techniques

Understanding Shaft Alignment: Thermal Growth

Ultrasound for Better Lubrication

Top Ten Ways Not to be World Class at Machinery Lubrication

Tips For Blower Maintenance

3 Important Words for Success in Lubrication and Oil Analysis

The Truth Behind Misalignment Vibration Spectra of Rotating Machinery

The Hidden Cost of Oil Changes

The Effectiveness Equation for Infrared Predictive Maintenance Programs

The Case of Successful Filtration and Oil Analysis Implementation

The Basics of Lubrication PM Procedures

Vibration Standards and Damage Factors for Machinery

Standard Practices vs. Right Practices

Solving Electrical Problems with Thermal Imaging

Smurfit-Stone Pursues Profitable Path with Fernandina Maintenance Program

Corrective Maintenance | Smart Methods in Maintenance

6 Easy Steps to Maintain Your Hydraulic Equipment

Silent Assumptions of Bearing Reliability

Should Jack Screws be tight or backed off?

Maintenance Crisis Song

Shock Pulse Goes Spectrum

Selecting the Proper Offshore Lubricant

Reliability Of Critical Turbo/Compressor Equipment

Refrigerated Air Dryers Can Be the Solution to Getting the Water and Moisture Out of your Compressed Air System

Reducing Motor Bearing Failures: Modified Lubrication Procedures Improve Reliability at TVA

Protecting Mission Critical Electronics

Proactive Maintenance for Hydraulic Cylinders

Protection of Equipment During Storage, Standby and Decommissioning

Practical Condition Monitoring for Preventive Maintenance

Power Transmission: Select Proper Re-Lubrication to Extend Bearing Life

Power Company Foresees Failures

Power Quality Testing Can Reduce Costs

Outsourced Condition Monitoring Services

Optimizing Lube PMs

Online Condition Monitoring Reaps Benefits for Borealis

Nine Lubrication Systems that Keep Chains Up and Running

New Generation IR Cameras

Measure to Improve Bearing Lubrication

Management Aspects on Condition Based Maintenance: The New Opportunity for Maritime Industry

Maintaining Process Control Field Devices

LubeRight: A New Tracking System for Manual Greasing

Longer Lasting Lubricants for The Aluminum Industry

Keeping Things Moving… Capture Problems Faster With High-Speed Video Technology

Is Air a Contaminant?

Integrating Vibration and Wear Debris Analysis for Machine Condition Monitoring

Inspecting Seals with IR Thermography

In-Process Motor Testing Results Using Model Based Fault Detection Approach

Infrared Thermography and Distribution System Maintenance

Infrared Thermography

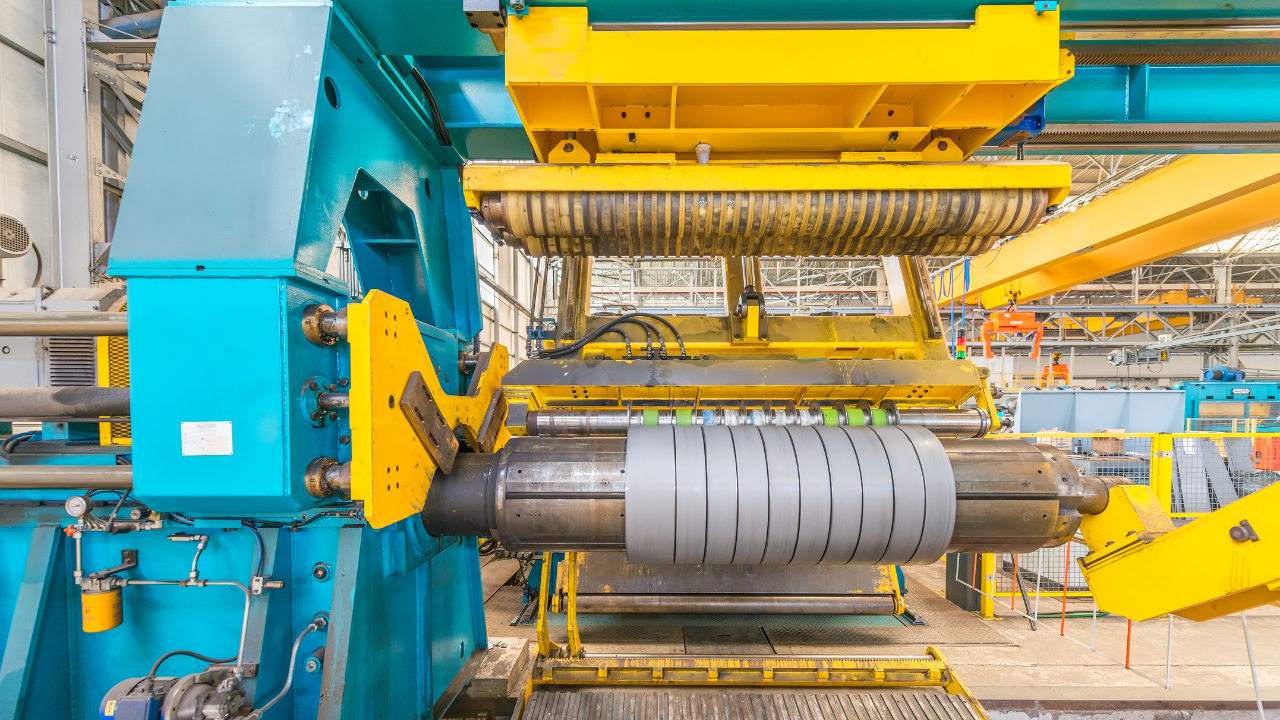

Improving Rolling Mill Lube Oil Performance and Useful Life

Implementing an IR Thermography Maintenance Program

How Unbalance Affects Bearing Life

How to Use Condition Monitoring to Optimize Grease Lubrication

How to Read an Oil Can Label

How The Eyes (and IR camera) Can Be Misled

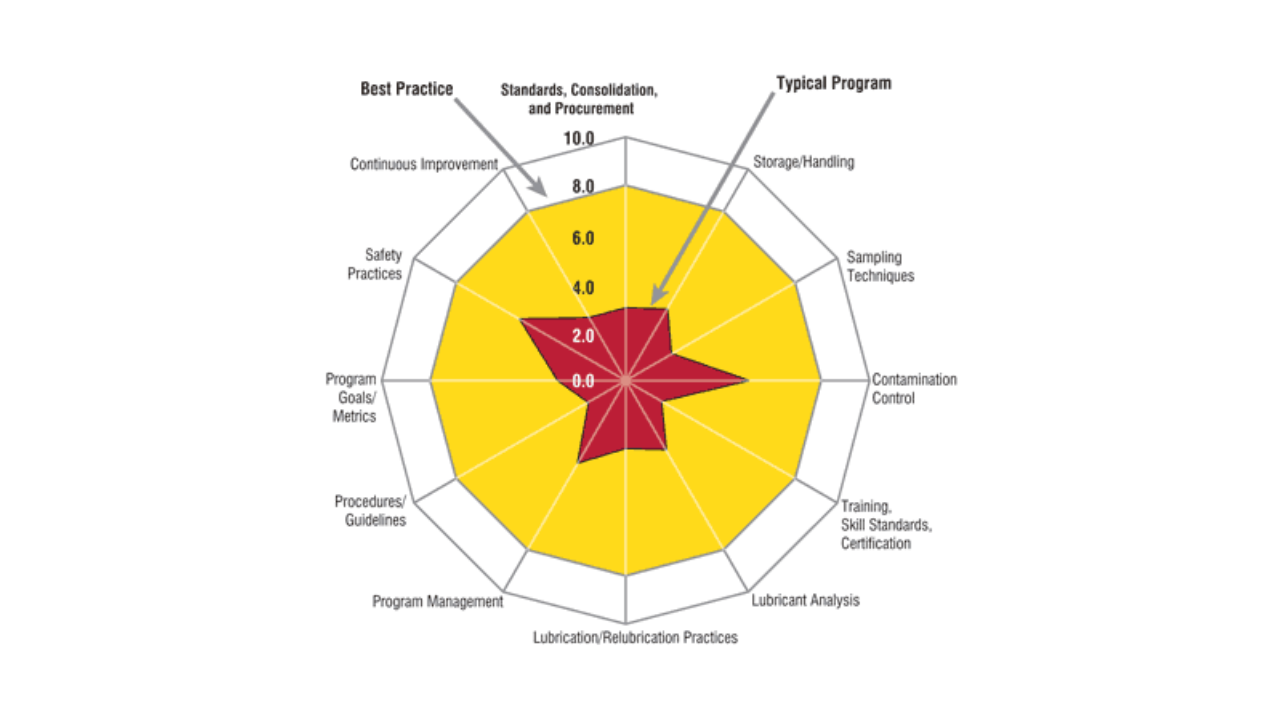

How Effective is Your Lubrication Program?

Ultrasonic Testing: Heeding the Screams of Sick Machines

Handling, Storing and Dispensing Lubricants

Greasing Bearings: It's a Whole New Ball Game

Fast, Reliable Measurements Give Us An Effective Way of Planning Preventive Maintenance In Advance

Everyone Needs a Playbook of Lube Procedures

Energy Waste You Didn't Know About...Do You Care?

Dynamic Movement White Paper

Documentation Tip – Document “As Found” Condition

Developing and Implementing an Infrared Predictive Maintenance Program

Data Analysis Tip 3 – Compare Identical Machines

Data Analysis Tip 2 – Create a Vibration Test and Analysis Guide

Data Analysis Tip 1 – Consider the Machine First and Then the Graphs

Electrical Corona & Testing

Condition Monitoring of Steam Turbines by Performance Analysis

Hydraulic Cylinder Failure Caused by the Diesel Effect

Hydraulic System Troubleshooting - Check the Easy Things First

Implement a Cost Effective Root Cause Problem Elimination (RCPE) Process

Keeping Up to Date - Human Behavior Analysis Without a PhD

Problem Analysis to Manage and Enhance Customer-Supplier Relationships

Productivity Improvement Through Operational Reliability and Knowledge Workers

RCFA of Bearing Failure

Condition Monitoring based on Acoustic Emission

Condition Monitoring at Norske Skog

Coal Plant O & M: Condition Monitoring Cuts Mirant Mid-Atlantic’s Costs

Clean Oil Reduces Engine Fuel Consumption

Change Your Lubrication Culture, Not Your Oil

Certification of Vibration Analysts in a Dynamic Job Market

How to Achieve Results Using Infrared Technology

Beyond the Usual Applications for Infrared Thermography

Better Mixer Maintenance Ensures Cleaner Effluent at Smurfit-Stone

Bearing Failures Dry Up at Weyerhaeuser

Ball Bearing Lubrication in Centrifugal Pumps

Automated Bearing Wear Detection

Analyzing Mechanical Systems Using Infrared Thermal Imaging

Machine Alignment: Alignment Pitfalls - How to Identify and Eliminate Them

Motor Condition Monitor and its Applications in Foundry Industry

Adjusting Packed Centrifugal Pumps with Open Impellers

A Team Approach to World Class Lubrication at Eli Lilly

Magnetic Plug Inspection Enhances Condition-Based Maintenance

Leaders in Maintenance: Parts 1 - 4

Visible and Invisible Maintenance Cost Savings

Can Maintenance and Operations Coexist? A Radical Process Change Story

Contractor Management Controls

Effective Benchmarking in Pursuit of Better Maintenance Operations

Energy Optimization

Focus On Results and Change the Culture Along the Way

Four on the Floor: Training Strategies - Many Paths, One Goal

Get Where You Want to Go: Operator Driven Reliability

Go Execute the Continuous Improvement Plan!

How to Make TPM Everyone's Priority

Is Your Plant Organization Ship Shape?

Kinda, Sorta Lean…So What Comes Next?

Manufacturing Operations Management: How Processors can take a New Approach to Raw Material Price Inflation

MRC Bearings' TPM Journey: From Totally Painted Machines to Taking Pride in Our Machines

Mentoring

Operations and Maintenance = Production - Parts 1 through 5

Operator Driven Reliability — Who Owns Your Mill’s Equipment?

Process Improvements: Cutting Costs with OEM Parts

Repowering or Replacement: What Is the Solution?

Reliability Business Case: Conversion Costs

Resistance to Change: Meet the ´Tators´

The Bad News Has Arrived: Your Plant is Undergoing Severe Curtailment/Closure

The Fuzzy Side of Equipment Reliability

Skills Shortage: The Perfect Storm Intensifies

The Pitfalls of Planning and Scheduling

The Power of Single Minute Exchange of Dies (SMED)

TPM Concept and Implementation Approach

Writing a Set of Seal Specifications

7 Costly Causes of Nozzle Wear

Adhesives Assure Fastener Reliability

API Plans that I Use. 15-05

Bearings for High Temperatures

Bearing Repair: An Alternative to Replacement

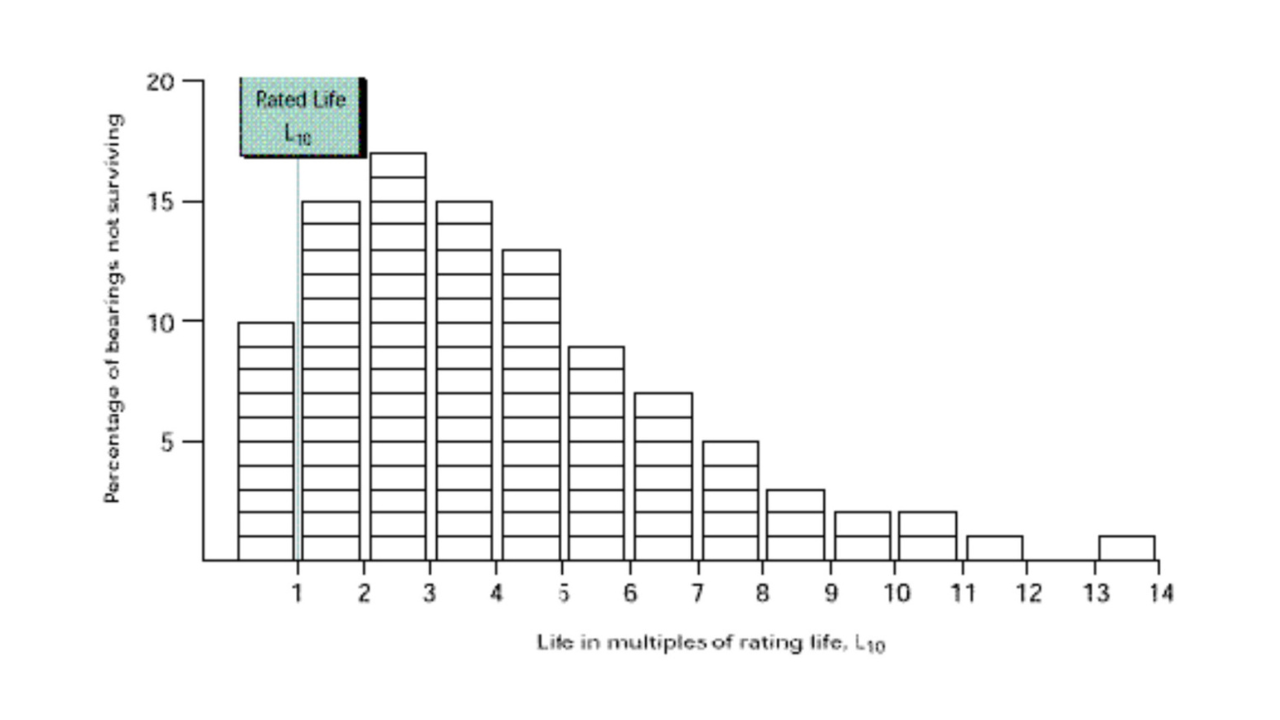

Basis for Bearing Life Calculation

Cavitation

Creating Reliable Electrical Connections

Comparing the Value of Single- and Double-Layer Insulation on Boiler Walls

DC Motor Brush Holder and the Performance of Carbon Brushes

DC Motor Carbon Brushes for Elevators: Composition, Function, Solutions

Double the Drive Life at One-Third of the Cost

Drying Your Compressed Air System Will Save Real Money

Effects of Aeration on Industrial Lubrication Equipment

Energy and Life Cycle Cost Savings in Pumping Systems

Eliminate Belt Drive Problems

Examining an Oil Purification System

Extending Pump Motor Life in Liquid Level Applications

Gear Pump Operation and Maintenance

Growing Reliability Down on the Wind Farm

How Can I Extend the Performance Range of Standard Cartridge Mechanical Seals?

How the Carbon/Graphite Seal Face is Manufactured and Where Carbon/Graphite Cannot be Used

How to Get the Best from Expansion Joints

How Water Causes Bearing Failure

Huge Cost Avoidance Using Oil Analysis at LTV Steel

HVAC Attack - How to Select the Right HVAC Filter for the Job

Hydraulic Filters that Do More Harm than Good

Hydraulic Pump Life Cut Short by Particle Contamination

Hydraulic Valves - Preventing Cavitation Damage

Electrical Motor Diagnostics: Impact of Electric Motor System Maintenance and Management

Increasing Pump Reliability and Life

Steam Maintenance: Inspect Steam Traps for Efficient System

Installation Errors Shorten Bearing Life

Is a Repaired Motor Less Reliable?

Keeping Compressed Air Dry

Leaky Shaft Seals

Magnifying Mini: Microelectronics Miniaturization

Maintain Pumping Systems Effectively

Maintenance and Troubleshooting of Electric Motors

Maintenance Equipment: Basic of Centrifugal Pumps

Maintenance Management of Your Company's PLC

Maintenance of Bearing Seals

Maintenance Theory: How do Motors Work?

Non-Destructive Exposing of Buried Energized Lines

Pitfalls of Pump Piping

PLC: Programming in List on a Mitsubishi PLC – Part 1

Pump Cavitation Solutions: Polymeric Solutions for Pumps Suffering from Cavitation

Practical Automation: Understanding Pneumatic Power Circuits

Pump and Driver Alignment 14-3

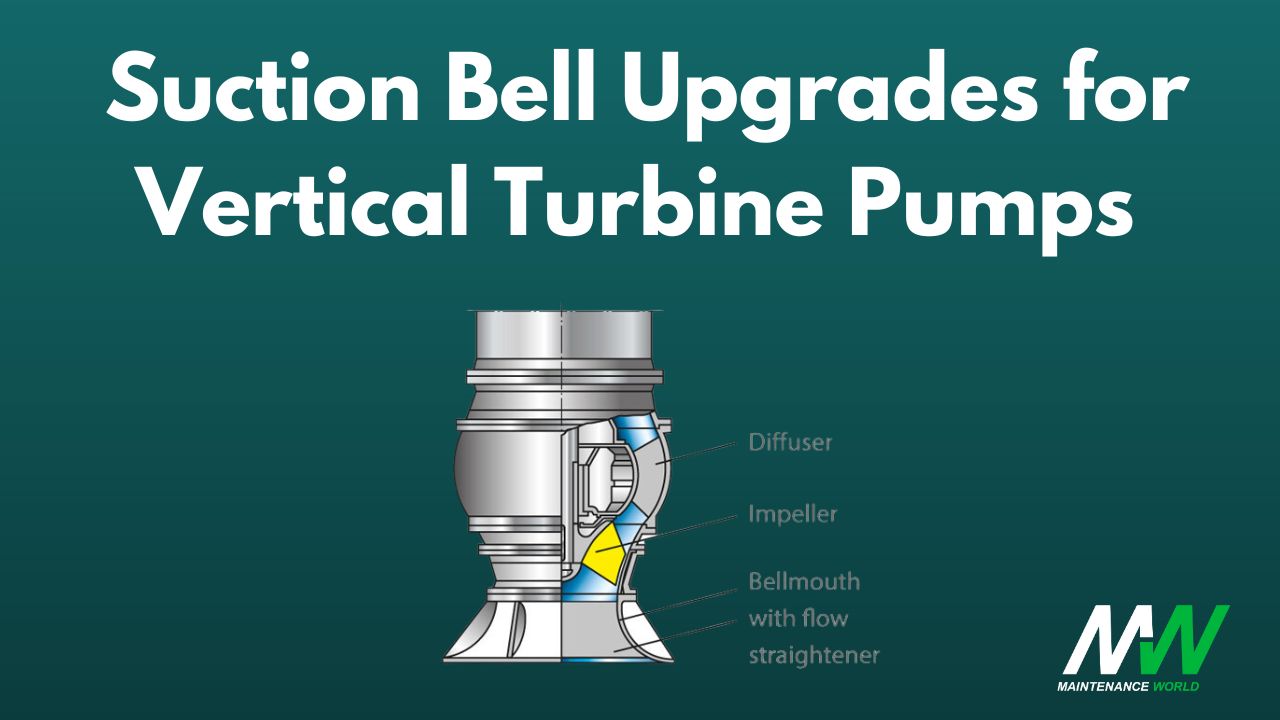

Suction Bell Upgrades for Vertical Turbine Pumps

Refurbishing Aged MCCs Proves Beneficial

Barrier or Buffer Fluid: The Liquid we Circulate Between Dual Seals

Revitalizing an Aging Grounding System

Saving Energy with Bearing Isolators

Skills Development of Craftspeople

Solving Hydraulic System Overheating Problems

Some Dangers of Batch Processes

Strive to Improve Your Gearbox Performance

Let's Clear Up the Confusion About Flushing Seals 3-6

Temperature Shock of Hydraulic Components and How to Avoid it

Test for Pumping System Efficiency

The Affinity Laws for Rotary, Positive Displacement Pumps 13-6

The ANSI Pump Standard 14-5

The API Gland

The Dual Seal Arrangement

The Non Seal Pump

The Pump Affinity Laws 2-1

The Role of Fireside Corrosion on Boiler Tube Failures

The Role of Fireside Corrosion on Boiler Tube Failures: Part 2

The 7 Secrets of Pump Reliability

The Trouble with Torque in Electrical Connections

Fire Sprinkler Corrosion: The True Threat of a High Corrosion Problem to a Fire Sprinkler Line

Understanding the 'Diesel Effect' and How it Damages Hydraulic Cylinders

Understanding Shaft Alignment: Basics

What is a valve?

Who Should Recondition My Seals?

Why Should I Upgrade to a Programmable Logic Controller (PLC)?

World Standard Maintenance Skills through Assessment and Multi-Skilling

Pumps: You Get What You Pay For... Or Do You?

RCFA: How to Select the "RIGHT" Root Cause Failure Analysis

Developing a Root Cause Analysis Work Process - Part 1

Developing a Root Cause Analysis Work Process - Part 2

Developing a Root Cause Analysis Work Process - Part 3

Root Cause Analysis Chronic Events: Panning For Gold

RCM for Medium Sized and Lean Organizations

Examples of Root Cause Analysis

Root Cause Analysis Guidance Document

Root Cause Analysis: Will It Find the Weak Link?

Case Study: Root Cause on Seal Failure in Refinery

7 Points to Successful Root Cause Analysis (RCA)

The Latent Causes of Industrial Failure

Troubleshoot AC Motors

Troubleshooting Hydraulics

Troubleshooting Paper Machine Problems Through Thermal Imaging

Troubleshooting Valves

Martin Sprocket and Gears: Maintenance and Troubleshooting Guide

The Process of Troubleshooting Mechanical Seals - Part 1

Troubleshooting Mechanical Seals | Wide Wear Track | Part 2

Troubleshooting Mechanical Seals | Centered/ Miscentered | Part 3

Troubleshooting Mechanical Seals | Even/Uneven Wear Track | Part 4

Troubleshooting Mechanical Seals | Scoring | Part 5

Troubleshooting Mechanical Seals | Chipping | Part 6

Troubleshooting Mechanical Seals | Coking | Part 7

Troubleshooting Mechanical Seals | Heat Checking or Cracking | Part 8

Troubleshooting Mechanical Seals | Mechanical Seal Blistering | Part 9

Troubleshooting Premature Bearing Failure

The Top 10 Reasons Why Root Cause Analysis Sucks in the United States

Why Do Pump Bearings Fail?

Why Some Root Cause Investigations Don't Prevent Recurrence

Lube Routes vs. Combo PMs: What's Best? What are the Issues?

Brinelling of Bearings

Hydraulic Troubleshooting

Factors which Influence the Speed of an Air Cylinder

Hydraulic Testing & Diagnostics

Logical Troubleshooting in Hydraulic Systems

Hydraulic Filter Condition Monitoring

Three Simple RCA (Root Cause Analysis) Facilitation Tips

Planning and Scheduling in the Process Industry

How Do Variable Speed Drives Impact Mechanical Seals?

The ‘Maintenance Crisis’ and Innovations that are Changing it

Flow through Orifices

Carbon Brushes for DC Motors and Generators

Matching a Hydraulic Motor to the Load

Creating Reliable Equipment Information

Figure Out the Dollars Behind CMMS Automation

Disc Couplings Dump Downtime

Leading Change: Why Transformation Efforts Fail

What is Vibration? Linear and Non-Linear Systems

How Green is Green When it Comes to Using Everyday Industrial Cleaning Products for Plant Maintenance?

How to Build Your ISO 55001 Asset Management System Quickly and make ISO 55001 Certification Easy

PLC: Programming in List on a Mitsubishi FX PLC - Part 2

Rethinking the Decision Factory

What Do Your Preventive Maintenance Tasks Really Do For Your Asset Care Strategy?

The New Productivity Challenge

Leadership in Maintenance Weekly/Daily Operations and Maintenance Meetings

Focusing RCM on Equipment Critical to Electrical Safety

Failure Teaches Success

Ten Steps to Pump Reliability - Part 1

Shining a Black Light on Coating Inspections

7 Ways Leaders Fail

Fluorescent Cleaning Non-Destructive Testing

A Twist on Particle Evaluation: Redefining the ISO Cleanliness Code

You Cannot Lose With Training

The Financial Benefits of Reliability

Safety Incidents: Is Safety a Backseat Driver?

10 Reasons Why You Should Audit Your Vibration Monitoring Program NOW!

Optimizing your Shutdown Program in 5 Steps

3 Keys to Improved Bolted Flange Joint Integrity

Beginning a Maintenance and Operations Partnership

10 Steps to Pump Reliability - Part 2

Wrench Time - Why the “FEAR” to Measure Maintenance Productivity?

Maintenance Planning and Scheduling Basics

Cost-Benefit Analysis and Projecting Project Payback

4 Ways To Break Free From Being ‘Too Busy’

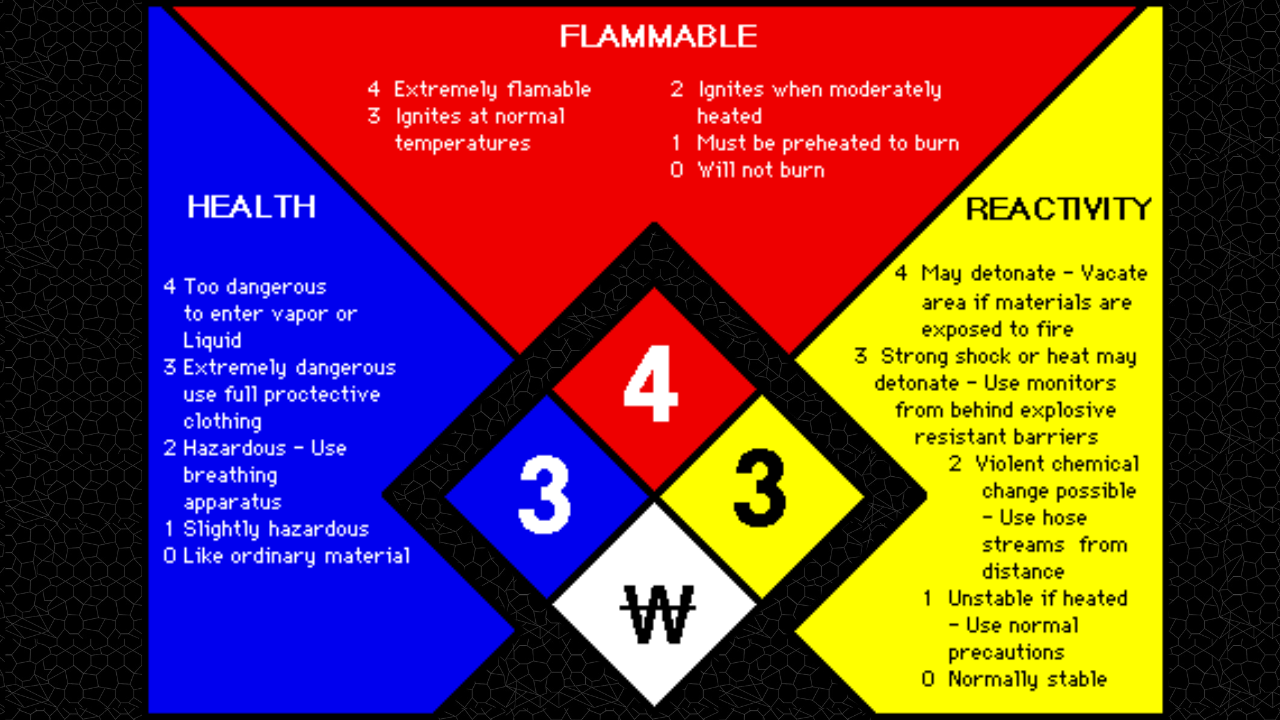

NFPA’s Hazard Diamond

Workforce Development

Can a CMMS/EAM Solution Really Solve All Your Problems?

21st Century Oil Analysis – Fantastic Gains – Still More to Learn and Do

Maintenance Cost and Estimated Replacement Value

Whose Job Is Leadership, Anyway?

Pump Technology Balancing Tradition & Innovation

A Sustainable & Effective Approach to Vibration Analysis

Victor Wowk: Field Balancing Standards - How Good Is Good Enough?

Lubrication Audit, Develop and Implement

Should You Contract Out Maintenance?

Cost of Unreliability

Fire Prevention and Emergency Action Plans: Are you ready to handle emergencies?

Air Canada takes a 'pit crew' approach to 787 maintenance

How do you measure reliability?

Lifetime Coating Systems: Major Problem When Product Life Exceeds Coating Life

Corporate Maintenance Reliability: Certification & Job Performance

What is Reliability?

Contamination Control Can Reduce Costs

How a Photoelectric Sensor Saved My Job

Identify the Reliability Gap

Developing Leaders: To Train or Not to Train?

10 Components of a Successful Vibration Program - Part 1

Definition of Maintenance

You Think a Computerized Maintenance Management System Is an Option?

10 Components of a Successful Vibration Program - Part 2

Industry Insight with Christer Idhammar of IDCON INC

Corrosion Prevention a New Market Niche?

Visual Inspection: A Necessary Component of Infrared Inspections

RPM Method + RCM = Reliability

Human Capital and the Internet of Things

Three Ways to Reduce Maintenance Cost

Evidence Based Asset Management: Actionable Intelligence in the Era of Big Data

ERP and EAM: Partners, Not Competitors

Does Your Company Need a Maintenance Culture Intervention?

M2M Strategies for Machine Tool Maintenance

Practical Maintenance Strategy Design For Capital Expansions

Maintenance Cost and Reliability

10 Components of a Successful Vibration Program: Part 3

Asbestos Risk in Manufacturing Plants

How to Extend Bearing Life

Reliability: Concepts and Trends

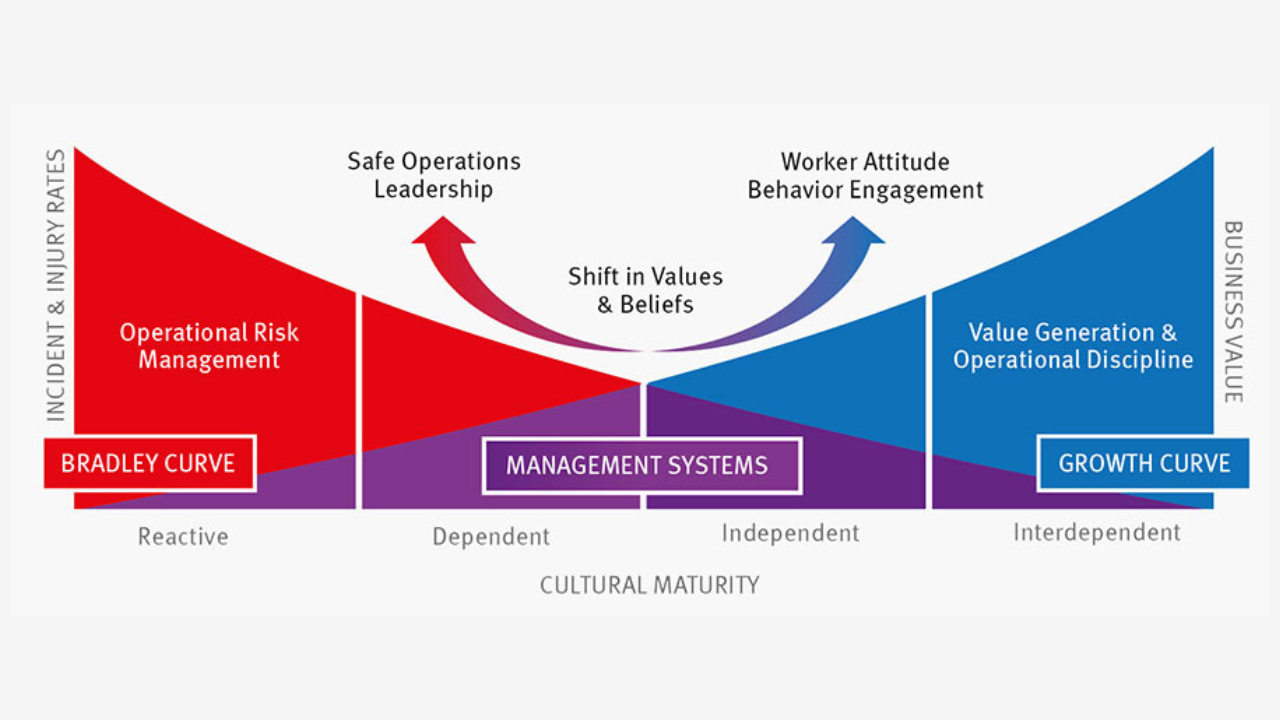

The True Value of Reliability: A Look at the DuPont Bradley Curve

Breakthrough Technology for Maintenance Inspections

What are Current Best Practices (CBPs)?

CMMS - Computer Maintenance Management System

The True Cost of Bearing Lubrication

Vibration Analysis Using ADCs Keeps Industrial Equipment Working

Reliability, Resilience and Damage

Cooling the Industrial Workplace

Systematizing Your Asset Management Operation

The Meaning of Bearing Life

Using Performance and Development to Sustain Performance Improvement

Power Plant Maintenance: Which Strategy Is Best?

Maintenance is Really Not the Problem

10 Ways to Reduce Reactive Maintenance

Standard Job Plans

Unleash the Potential of Your Reliability Function

Costs and Capabilities of Pneumatic, Electric Actuators

How to Build a High Performance Maintenance Team

The Story of a Work Order

Preventive Maintenance - Visible Change

Releasing Asset Value Sustainably - An Analysis of ISO55000x

10 Steps to Achieve World-Class Manufacturing Maintenance Practices

Internal Clearance & Its Effect on Bearing Fatigue Life

Using Effective EAM to Improve Asset Utilization & Reduce Costs

Job Interviews: The 4 Levels of Fit

Operations Maintenance Coordinator Role (OMC)

Making a Successful Case for Maintenance

Principles of Measuring Performance

Start Designing a Planning and Scheduling Program

Asset and Maintenance Managers: Key Decision Makers

Gear Pump Operation and Maintenance

RCPE: What vs. Who

The Key to Unlocking the Full Potential of Your CMMS

Hydraulic Systems Hack! Preventative Maintenance Checklist

Bad Salesmanship Hinders Reliability

The Most Definitive Test of a Hydraulic Pump

Vibration Analysis: Interpreting the Vibration Signature of Plant Equipment

How the Industrial Internet of Things (IIoT) Is Shaping Manufacturing

MEMS Accelerometer Performance Comes of Age

The Secret to Making Your Deferred Maintenance Backlog Manageable

Do We Really Want to Be Proactive?

Debunking the Myths Around Bearings

The Evolution of Performance Measurement

Condition Monitoring in the 21st Century

Asset Performance: Wiring Your Assets for Success

What is Total Productive Maintenance?

Setting Techniques for Tapered Roller Bearings

Grid Coupling: How Does a Component Fail?

Normalization of Deviance and the Perception of Defects

The Challenge: Developing a Reliability Culture

Back to Basics for True Operational Excellence

Hydraulic System FMEA Made Easy

The Top 10 Improvements to Pursue in Your MRO Spare Parts Program

How to Determine Lubricant Mixing

Acceleration Enveloping: Opening the Envelope on Bearing Vibration

11 Tips for Effective Workplace Housekeeping

From Screwdrivers to Testers: Vibration Testing and Analysis Comes of Age

How to Make the Most of Predictive Maintenance

Why Organizations Leave Money on the Table

Cleanliness is Indicative of Quality

Engineers Need a Nap

Improving Safety: 10 Tips, Tricks, Rules and Suggestions

Safety Tips for Handling Petroleum Products

The Golden Rules for Machinery Reliability

Justification of Planners

An Introduction to Machine Vibration

3 Outlooks on What's Trending and What's Important in Industrial Lubrication and Oil Analysis

How to Use Condition Monitoring as a Proactive Equipment Reliability Improvement Strategy

Why You Should Avoid Using Oil Funnels

Creating a Spare Parts Holding List with Confidence

Why Oil Goes Bad

Some Plain Talk About Nuts and Bolts: Part 1 of 2

Drone Based Inspections and their Use in the Future of Facility Maintenance

How to Get the Resources and Support You Need

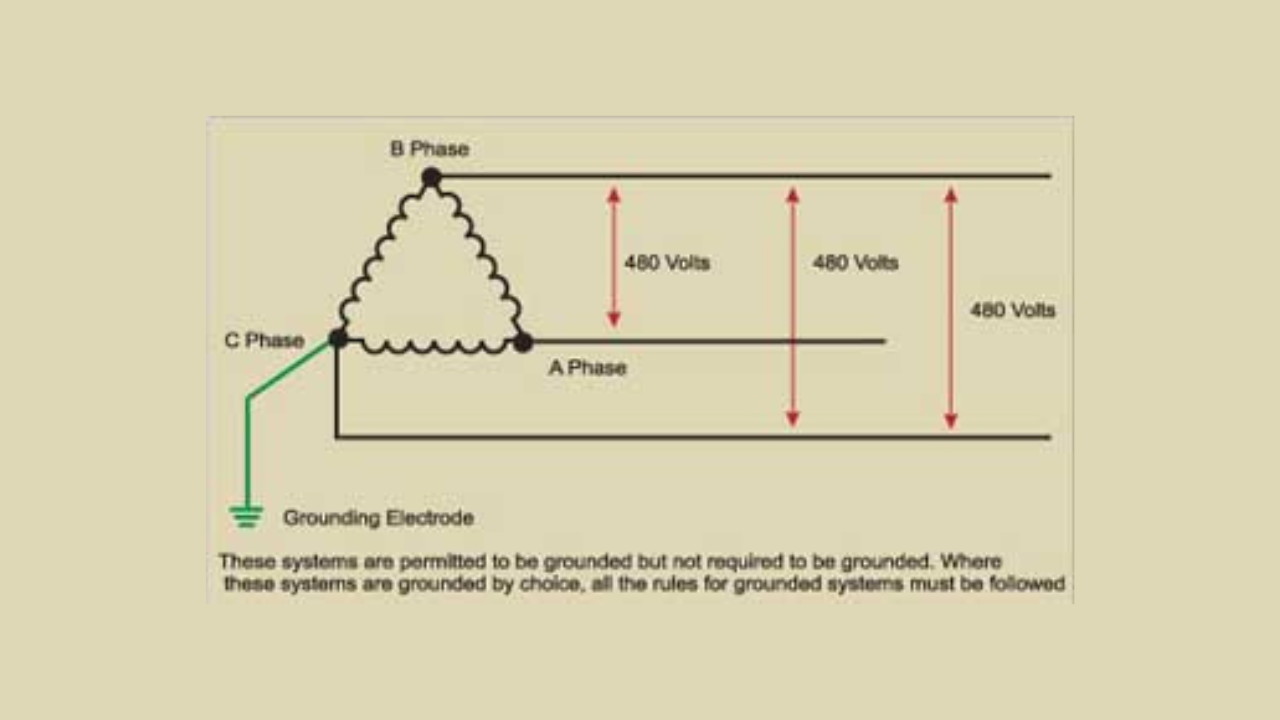

Installations and Inspections of Corner-grounded Systems

Building a Reliable Plant Through Constant Evolution

Best Practices for Lubricating Paper Machines

Failure vs. Breakdown: What is the difference between a failure and breakdown?

Vibration Analysis as a Diagnosis Tool for Health Monitoring of Industrial Machines

Why Temperature Affects Lubricants

Five Pillars for a Maintenance and Reliability Program

Best Practices for Compressor Storage

Three Levels of Condition-Based Maintenance

Your Maintenance Debt Dictates Your Maintenance Cost

Developing an Effective Electric Motor Testing Program

Common Sense: Is It Common?

Indoor Air Quality Increases Workforce Productivity

Highly Effective Maintenance Training is to “Know Why”

The 5 Habits of Great Reliability Engineers

Back to Leadership Basics

Reliability Tips: The Layers of Root Cause

How to Optimize Big Data in Factory Maintenance

90% of all Training is Wasted!

10 Things Your Management Needs to Know Now

How many Planners and Supervisors do we need?

Did you Review Your Last Shutdown/Turnaround?

No Part Left Behind: 4 Simple Rules for Efficient Inventory Management

3 Techniques for Optimizing Preventive Maintenance

Can Operations Manage Maintenance?

The Past and the Future of Industrial Maintenance Management

How Service Parts Planning Impacts Machine Uptime

A Driving Lesson for Plant Management

Continuous Predictive Maintenance Is the Way Forward

Importance of Flooring for Food Processing Plant Hygiene

Why Online Oil Quality Monitoring is a Best Practice for Reliability Programs

A Plan for Breaking Out of Maintenance Budget Jail

7 Steps to Trouble-free Grease Lubrication

On-Site Fluid Intelligence: A Revolution to Advance Machinery Reliability

Leadership is Vital to Success

Planning and Scheduling: Planners Should Not

Asset Strategy Management: The Missing Piece in the Asset Management Puzzle

3 Ways to Improve Motor Health with Vibration Testing

Are Most Maintenance Organizations Overstaffed?

The New Industrial Culture: Journeys Toward Collaboration

Technologies That Make Asset Monitoring Boring...in a Good Way

Best Practices in Lubrication

Can Your Mill Produce the Right Results?

Avoid Oil Sampling Pitfalls

Sustaining Life Span of Rotating Equipment in Plants

Work Safety - Part 1

Work / Job Safety – Part 2

The Keys to Solving Fatigue: The Silent Killer

Self-paced: Work Management Training

Equipment Inspections: Who is Doing Them?

Maintenance Apps for Smartphones

How to Improve Your PM Program in 10 Steps

How to Use Mechanical Integrity Inspections

Does Operations Know Their Role?

Maintenance Work Orders in the Age of Industrial Internet of Things

Checking Best Practices for Preventive Maintenance

The Industrial Internet: Disruptive, Innovation, Readiness

Nondestructive Testing for Protective Coatings: Implementing a Lifetime Corrosion Prevention Program

Why Machine Learning and AI Are the Future of Oil Analysis

Fatigue Failure 101

Artificial Intelligence vs. Reliability Studies

Achieving "Near Zero" Refrigerant Emissions in HVAC Systems

Creating a Culture of Manufacturing Reliability

How Building Managers Can Save On Energy Purchasing Through Changing Paradigms

CAT I - Introduction to Machinery Vibration

CAT II - Basic Machinery Vibration

CAT III - Machinery Vibration Analysis

BRM - Balancing of Rotating Machinery

VAO - Vibration Analysis Overview

Sources of data for AI Empowered Maintenance – Manufacturing Execution System

What Is Facilities Management? Challenges, Solutions, & More

What is Preventive Maintenance? A Comprehensive Guide

10 Steps to Getting More From Your Equipment Lubricants

How a Platform Approach Can Transform Your Building Operations

Develop and Manage Preventive Maintenance

Root Cause Problem Elimination

Essential Care and Inspection Techniques

Is the Objective Reliable Availability?

Determining Accurate Alignment Targets

Plant Numbering and Asset Identification

Introduction to MCEMAX*

MCEMAX Data Analysis

Electric Motor Testing Certification**

Communications: The CMMS Setup in a Maintenance Partnership

Piping Vibration - Causes, Limits and Remedies

Achieving TPM Excellence the Fast Jet Way

The Trifecta of Motor Maintenance

Definition of Root Cause Analysis (RCA)

Managing Today's Castles with InMapz

Improve Your Year End Inventory Results

Direction is Not Supervision: Tips for Supervisors

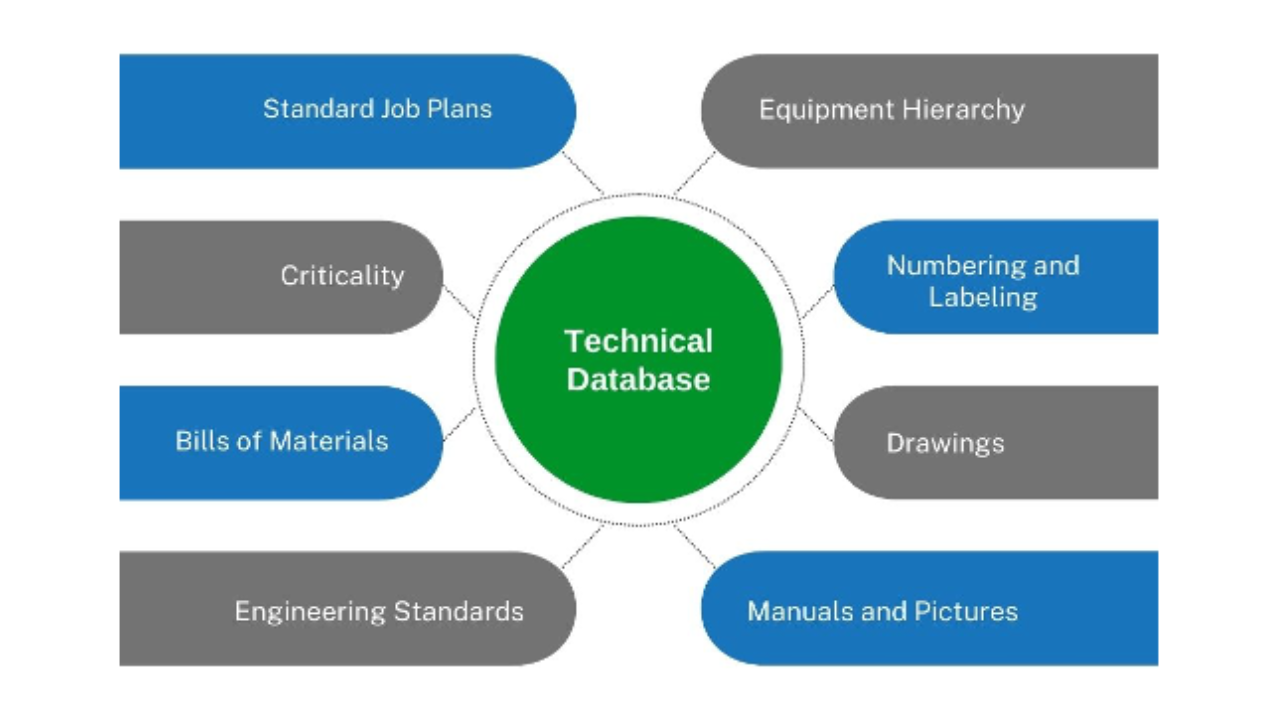

What is the Technical Database and How Does it Affect Planning and Scheduling?

3 Trends That are Set to Shape Property Ops in 2023

How to Mitigate Risk with Your Mobile Solution Proof of Concept

Gaps in Your Electric Motor Reliability Program

Linear and Nonlinear Vibrations

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

Allocating and Analyzing Downtime

RFID: Is It the Right Solution for your Problem?

South Carolina Ranked as the #1 State for Manufacturing

Practical Guide to Equipment Hierarchy

Facilities Management Technology for 2023

The Decade of American Reshoring

Electric Motor Problems

Common Mechanisms of Failure & Preventive Methods

Vibration Institute 46th Annual Training Conference and Expo

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

The Missing Link Between OEE and TPM

Brinelling and False Brinelling

HBD Condition Monitoring Devices at the center of Ohio Derailment

Install, Maintain Single-Packaged Units for Optimal IAQ

The Edison Principal - More Science than Guesswork for Corrosion Prevention

Failure Analysis Uncovers the Cause of the Keystone Oil Spill

How do I Test Relays and Contactors?

Asset Performance Management Improvement by the Numbers

Ohio Foundry Explosion

How to Label and Number Equipment for Easy Identification

The Pump Impeller: Pump Life Extension

Oil and Gas Layoffs

Get Your Bearing on Brinelling

Studying Fractures: Recognizing and Understanding Failure Modes

DOJ Files a Lawsuit against a Neoprene Manufacturing Plant in Louisiana

Put Your Equipment Drawings, Manuals and Pictures to Work for Cost Savings

Managing Models

Ohio Files Federal Lawsuit over Norfolk Southern Derailment

New Challenges in Maintenance Management

Transitioning from Military to Industrial Maintenance: 2nd Times-a-Charm

Ohio Manufacturing Plant Producing Refurbished Tanks

Why Might your Business Need a CMMS?

Happy Retirement Tim! But Don't Forget About the New Employees

Biden kicks off his ‘Investing in America’ Tour in NC

Metal Fatigue Failure

Maintenance, Lean Processes and the Drive to Net Zero

The Eco Edison is Making Waves in Louisiana

Growing Old: 6 Risks of Aging Facilities

Engineering Standards to Help Lower Cost

EPA Tightens Mercury and Air Toxics Standards for Coal Plants

Physical Asset Management: Turning your Vision into Reality

What is the Role of a Maintenance Storeroom?

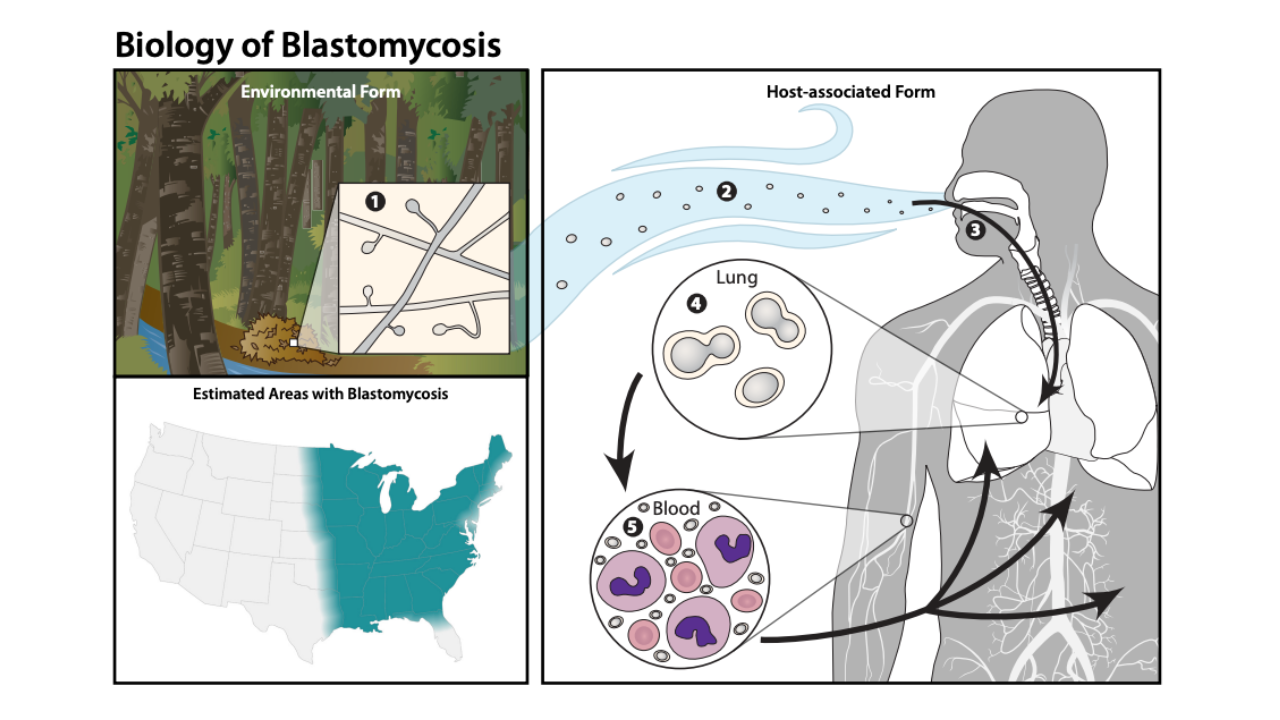

Industrial Outbreak of Blastomycosis at Michigan Paper Mill

Controlling Materials Returned to Maintenance Stores

Navigating O&M’s new responsibilities with Connected CMMS

Dr. Yellow: More than just good luck, it’s good maintenance

5 Key Maintenance Manager Skills Needed in 2023

The Maintenance Leader’s Journey from ‘Command and Control’ to ‘Mission Command’

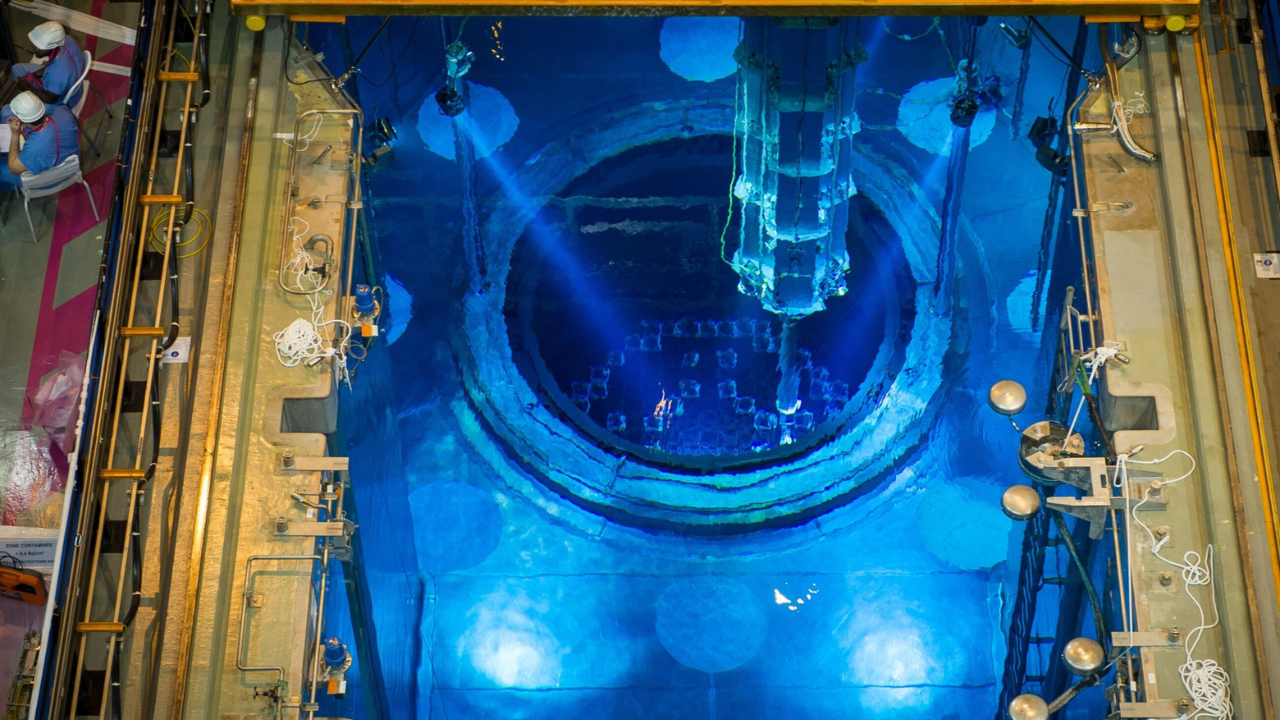

France Struggling with Nuclear Reactor Maintenance

The Godfather of Reliability: Christer Idhammar

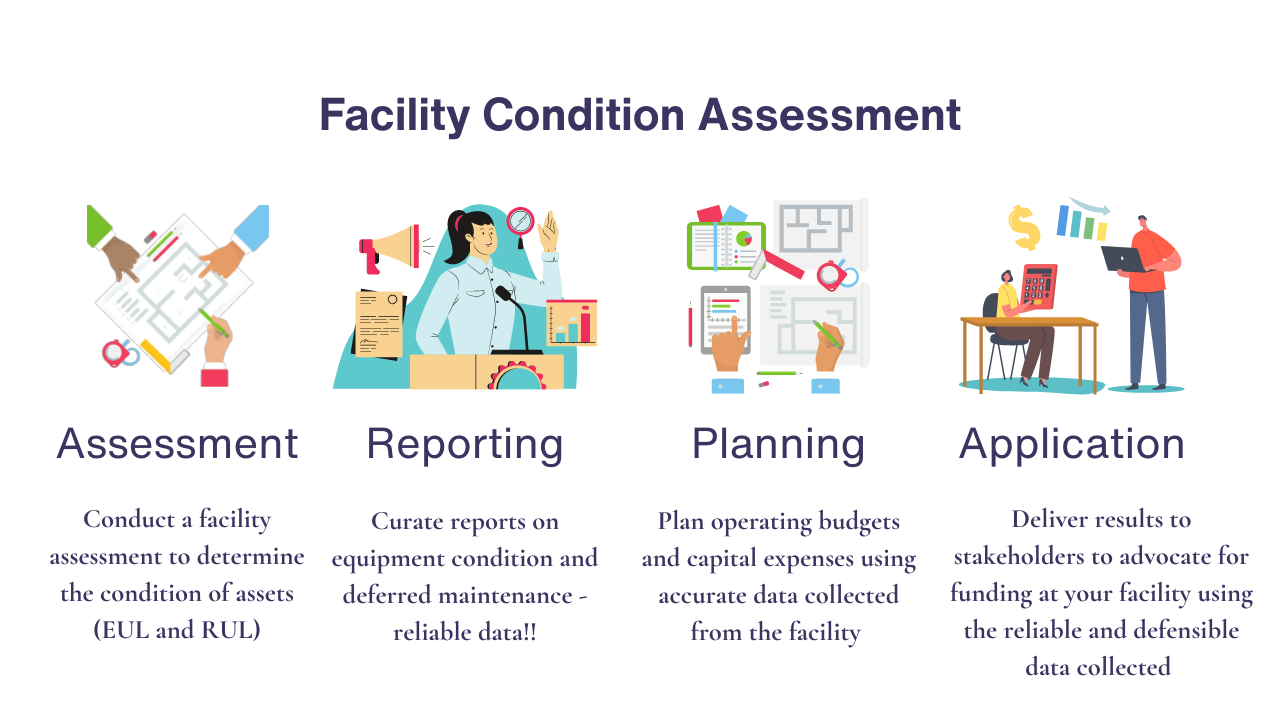

How to Navigate the Facility Condition Assessment Industry

Russian Ball Bearing Shortage

Bill of Materials: A List of Parts to Streamline Maintenance Work Management

What is ISO 55000?

Panama Canal Maintenance to Extend Life Another 100 years

The Benefits of a Modern CMMS for Solar Power Farms

Heating Solutions: Avoid Heating Concerns with Preventative Maintenance

Semiconductor Industry Facing Worrisome Talent Shortage

Motor Brush Facts and Maintenance

Making These 8 Simple Changes in Your CMMS Will Give You Surprising Results

Potable Water Contamination aboard US Naval Ships

IDCON Talks: Christer Idhammar

The Lost Recipe of Self-Healing Concrete: A Maintenance Dream

Industrial Coaching

Critical Gaps in the Sky: The Looming Aviation Maintenance Technician Shortage

Embracing the Power of Computer Aided Facility Management

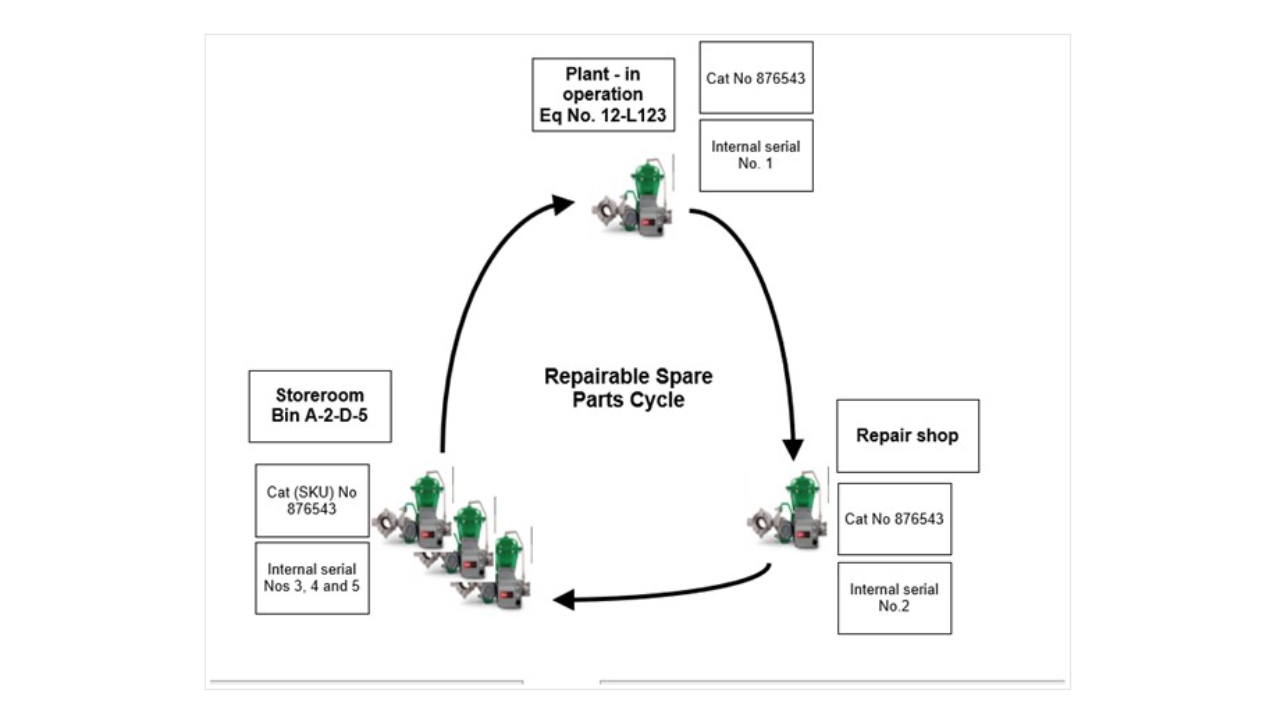

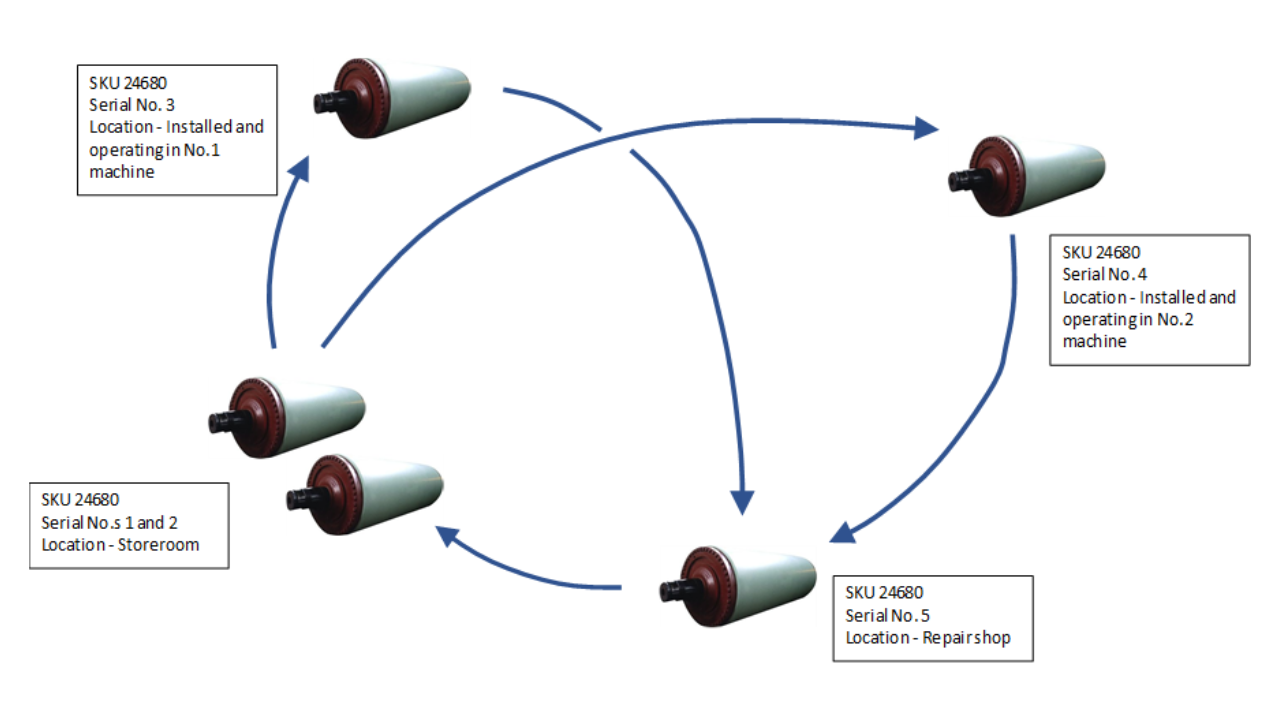

Managing Repairable Spares

Serialized Spare Parts

Lathered in Valor: Saluting the Maintenance Heroes of Operation Ivory Soap

The 8 Pillars of TPM

Root Cause Failure Analysis of Bearings According to ISO 15243

Balasore Train Crash: Urgent Need for Maintenance and Safety Upgrades

Maintenance Management: The Perfect Role for Critical Thinkers

The Journey to Operational Excellence

The Unfilled Seats: Exploring the School Bus Technician Gap

The Journey to Operational Excellence | Improvement Plan

The Journey to Operational Excellence | Continuous Improvement

Scaling New Heights: Innovative Solutions aid Navy's Maintenance Efforts

The Journey to Operational Excellence | Commitment

Nuclear Weapons Release Systems & Your Electrical Reliability Program

Superior Refinery Wisconsin to Reopen in 2023

Why Condition Based Maintenance Should Be Considered a Critical Component of Any Business’s Asset Maintenance Strategy

Why You Should Become a Certified Vibration Analyst

Watching the Horizon with Criticality Analysis

Condition Monitoring Matters: Lessons Learned from Fury 325

How a CMMS Can Reduce Downtime

Repair, Don't Waste: The Solution to Our E-Waste Problem

NTSB Report Points to Natural Gas Leak as Catalyst in Chocolate Factory Explosion

The Fight to Repair Industrial Electronics

The Hard Edge to Soft Skills

Beyond the Headlines: Embracing Positivity in Industrial Safety – OSHA’s Voluntary Protection Programs Shine

Industrial Steam Cleaning

The 5 Pillars of A Comprehensive Maintenance Strategy

Fighting Back Against the US Manufacturing Workforce Shortage: Specialized Programs and Nonprofits

Are You Reliability?

What are the Differences between CMMS, EAM, and APM?

Why did the Ohio Foundry Explosion Happen?

Embracing the Power of Predictive Maintenance in Industrial Manufacturing

Equipping Crews for Cost Savings with Standard Job Plans

Revolutionizing Train Maintenance: 3D Printing Redefines Spare Parts Procurement

Unmanned Aircraft Systems and the Future of Autonomous Inspection

You Want to See Through Walls?

Landscape to Lambscape: How Sheep are Reshaping Solar Farm Maintenance

Challenging the P-F "Curve"

2023 DCMUG: Mapping a Road to MAS

Equipment Criticality Analysis and Managing Storeroom Assets

Design for Reliability: Facility Upgrades

3 Things You Should Not Be Doing As A Facility Manager

Every Interaction is an Opportunity: Maximizing Business Potential

Preparing Facilities for Extreme Weather

AAA Best Practices Make the Difference

8 Tips for Getting Maintenance Technicians to Adopt CMMS Software

The Switch to Swiss: Why are Manufacturers Swapping out Traditional CNC Turning Machines for Swiss Lathes?

Best Practices for Preventive Maintenance on Unit Heaters

Harmonics and Sidebands

Glasses on, Troubles Gone: Augmented Reality Takes Flight in Maintenance

Innovative Thinking + Standards = Ubiquity

A Discussion about Root Cause

Navigating the Depths: The US Navy's Quest for Submarine Spare Parts

Experiences with Magnetic Drive Pumps

The Essential Role of Psychological Safety in Building High Performance Teams

Harnessing the Flow: The Potential of Hydropower for a Cleaner Tomorrow

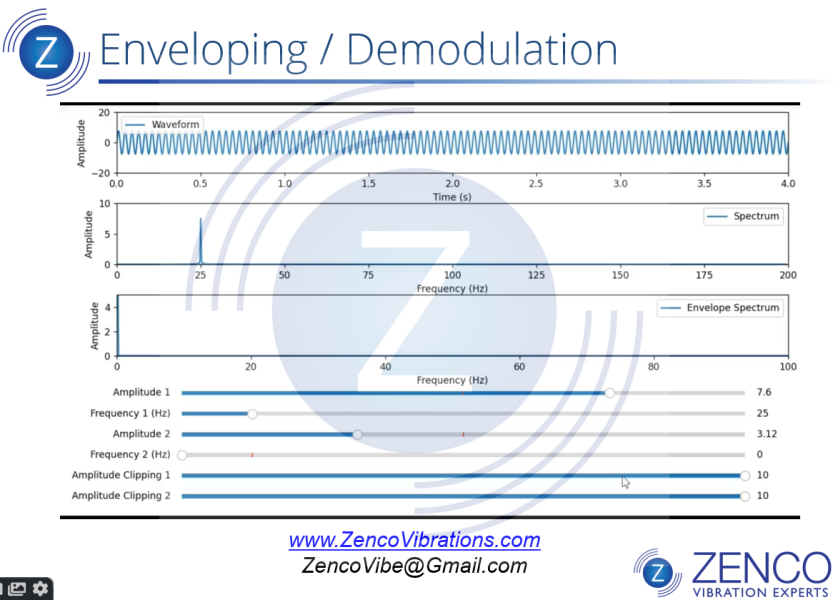

Demystifying Demodulation and Enveloping

Realistic Goals During the First Year of a CMMS Implementation

Optimizing Operations: Conveyor Belt PM and Advances in Fabrication

Technical Database Performance Survey: Get the Full Picture

Trade-Offs in Drone Technology: High-Performance vs. Data Security

Spare Parts Management Trends and Essential Tips

How to Turn the Right People into the Wrong People

Good Equipment Health = Good Business Health

Ammonia Safety Precautions: How to Incorporate Predictive Maintenance and the CMMS for Safe Ammonia Use

Asset Management Strategy: Detail Doesn’t Come from a Summary

How SMED Can Turn Back Time

Under the Hood: Unraveling the Diesel Technician Shortage

Breaking Tech Barriers to Excel in a Competitive FM Arena

Diagnosing a Bent Shaft

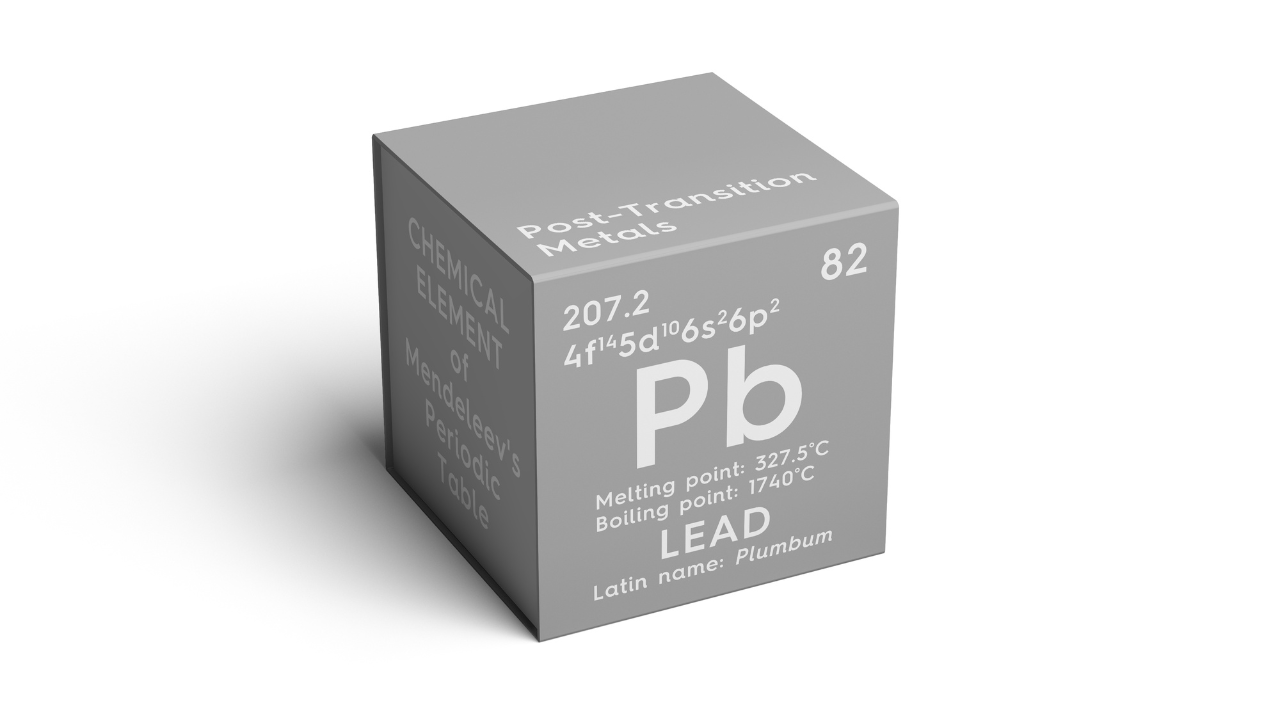

Safety First: Preventing Lead Contamination in Food and Beverage Manufacturing

The CMMS: Where Data Goes to Die – Unleashing the Potential of Your Maintenance Digital Backbone

6 Tips for Getting Executive Approval for CMMS Software

The Benefits of Participating in Manufacturing Apprenticeships

Find the Hidden Value of the Technical Database

A Better Convention Navigation Experience

Charging Up: The Resurgence of Battery Manufacturing in the US

What is Plant Maintenance?

How to Avoid Losing Retiring Employees’ Business Experience

Preventing Failures and Extending Equipment Life: The Key to Increasing Uptime

Zero-Based Budgeting in SAP

Does Condition Based Maintenance (CBM) Improve Reliability?

Offshore Wind Farms for Renewable Energy

Predictive Maintenance in the Aftermarket: Extending Machine Lifespan and Sustainability

Five Ways CMMS Software Helps Transform Maintenance Managers into Leaders

Guide to 2024 Reliability and Maintenance Conferences

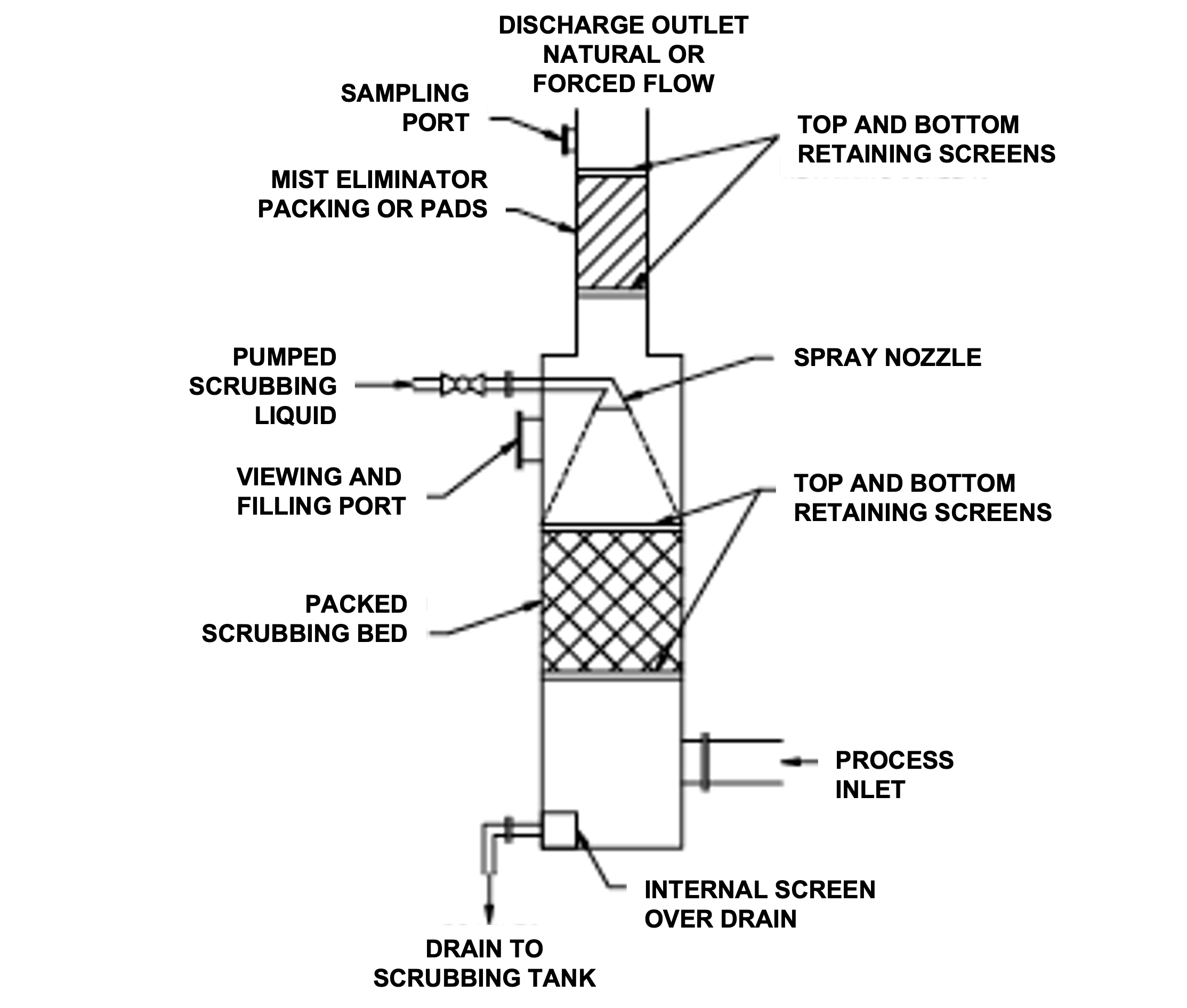

Is Your Wet Scrubbing Tower Working?

Who is Driving Your Leadership Career?

Making Sense of NIST & Cybersecurity Requirements for Maximo

Failed Business Metrics

Forging into the Future: A Brief Overview of the Metal Forging Industry

How to Optimize Operations and Maintenance for Success

Property Operations in 2024: Navigating a Transformative Landscape with Integrated Solutions, Automation, and Purposeful Innovation

Guide to 2024 European Reliability and Maintenance Conferences

Pump Selection – Key Considerations

The Impact of Lower Quality Process Materials on Manufacturing Equipment Downtime

The Power of Machine Condition Monitoring 2024

Innovations in Maintenance Safety: Tools and Techniques for Safer Work Environments

Gas or Electric: Which Fuel Source is Right for You?

Mining Industry 2024: Focusing on Safety, Reliability, and Reducing Greenhouse Gases

Leveraging Maximo for Inventory Management

The Benefits of Floating HRSG Duct Liners

Textile Industry 2024

6 Simple Tips for Lubrication Success

Continuous Improvement Leadership – Accelerating Your Success

10 Reliability and Maintenance Books to Read in 2024

Unlocking Growth: Overcoming the 6 Tech Roadblocks to Scale Your FM Services

How to Choose the Most Effective PPE for Maintenance Workers

Condition Monitoring & Preventive Maintenance for Die Cutters & Tooling

Maintenance in the World of Pumps

Cloud-Based vs. On-Premise CMMS Compared

New EPA Soot Pollution Standard 2024

Revolutionizing Reliability and Maintenance through Production Automation

Preventive vs. Reactive Maintenance: Don’t Neglect Makeup Water and Condensate Return Treatment

Tool Inventory Management: How and Why?

CSV vs. CSA: Moving from Software Validation to Assurance

Continuous Improvement Leadership: Accelerating Your Success Part II

33 Reliability Engineering Certifications to Further Your Career

Oil vs. Latex Paint: Which is Best for Your Commercial or Industrial Painting Needs?

Spending Money to Save Money – How Investing in Technologies Can Reduce Maintenance Costs

Engineering Degrees Around the World

What is a Shaft Centerline Diagram?

Proactive Over Reactive: IoT's Role in Redefining Industrial Maintenance

The Fern Hollow Bridge Collapse: A Wake-Up Call for Bridge Maintenance Programs

Artificial Intelligence: The Future of Searching for Spare Parts in the Maintenance of Large Industrial Enterprises

Preventive vs. Reactive Maintenance: Don’t Neglect Makeup Water and Condensate Return Treatment – Part 2

Heat Transfer Basics

What is the Value of Failure Prediction - Early Warnings?

Continuous Improvement Leadership – Accelerating Your Success Part III

How to Protect Your Business from Cybercrime

Optimizing Maintenance: The Power of Metrics and KPIs

A Guide to Understanding Project Management in Engineering

A Simple Fault Finding Technique

Additive Manufacturing 101

Mobile vs. Desktop: Differences in CMMS Features

How to Minimize Environmental Waste in Mines

Grease, Gears, and Great Insights: Essential Reliability and Maintenance Podcasts and YouTube Channels

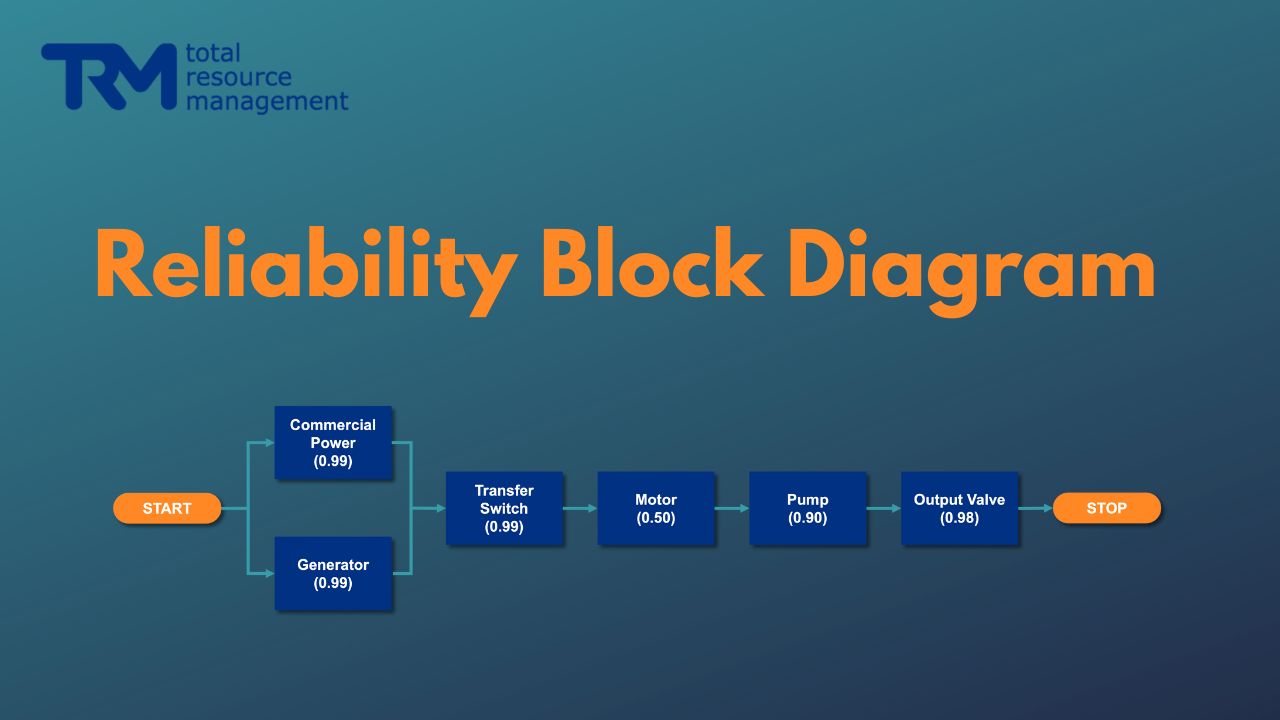

Back to Basics: Understanding Reliability Block Diagrams (RBD)

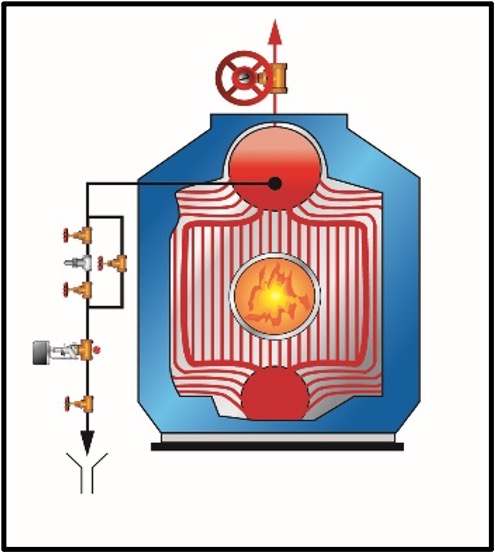

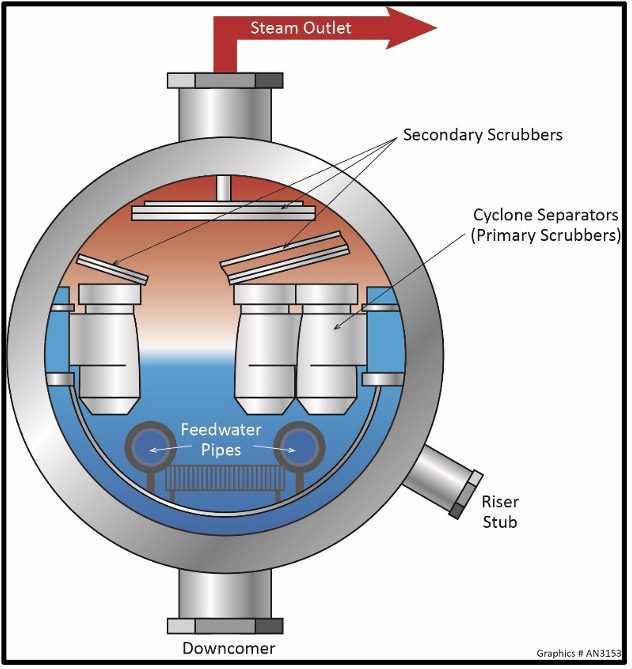

Boiler Water Chemistry Control: Preventive vs. Reactive Maintenance

Heat Illness Prevention

Essential First Aid Skills for Maintenance Workers

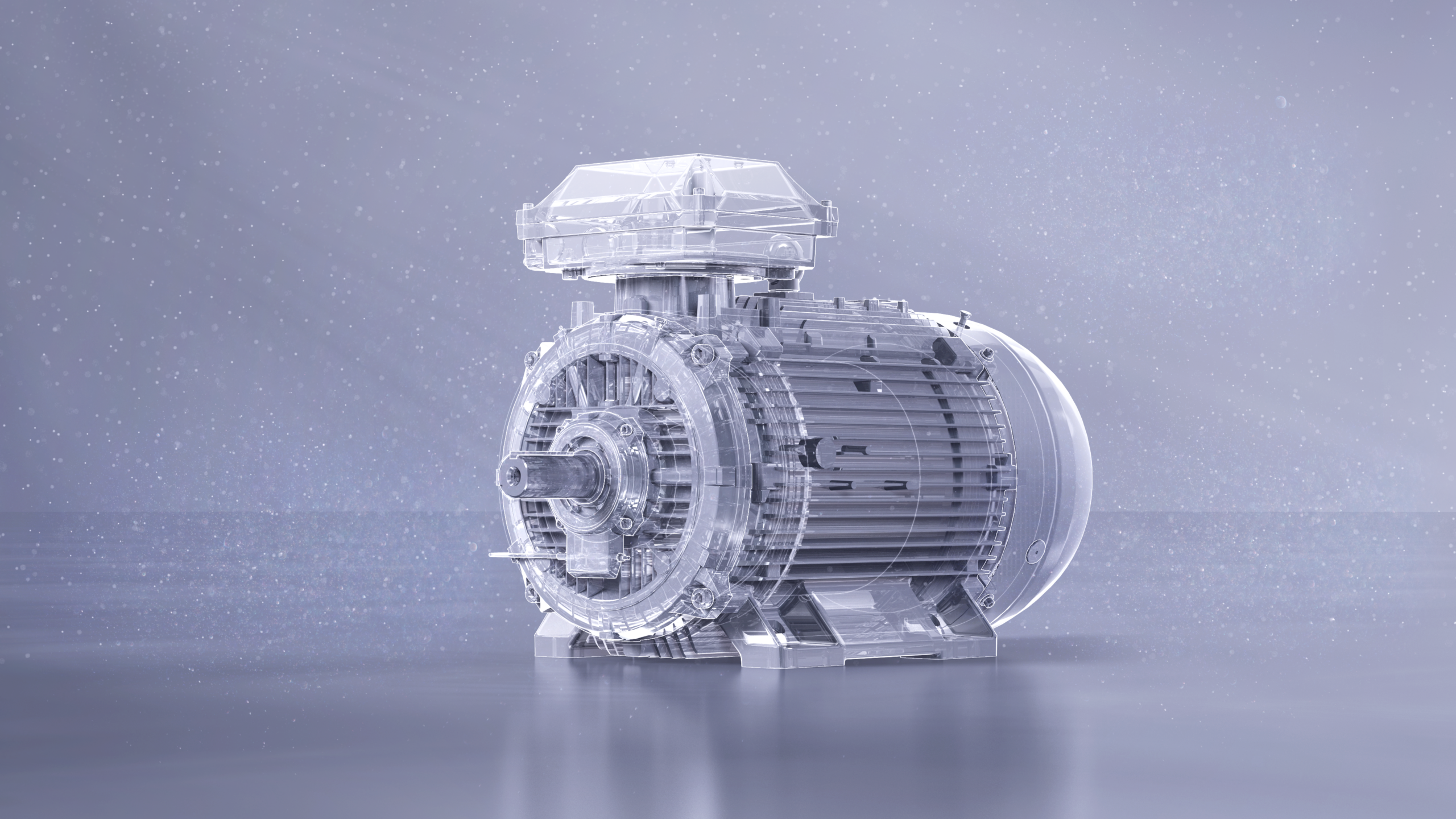

High-efficiency SynRM motors, a game changer in potentially explosive environments

Happy World Facilities Management Day!

Understand Your Goals with New Maintenance Technology

Leveraging BIM for Enhanced Maintenance: A New Era in Facility Management

Maintaining Heating Solutions in The Off Season

Leadership of Industry 5.0 and ‘New Quality 5.0’ - A Paradigm Shift

Supply Chain Issues 2024: How Good Reliability and Maintenance Helps

How Can Control Systems Trick Operators?

Preventive vs. Reactive Maintenance Part 4: Steam Generation Series

Working with SAP Master and Transactional Data

Coating Care: Erosion vs. Corrosion

Mechanical Insulation for the Manufacturing Industry

The Role of Maintenance and Reliability Teams in Infectious Waste Management

CMMS System: Integration for Off-site Operations

Recycled Copper: Turning Scraps into Sustainability

Balancing Continuous Operation and Root Cause Troubleshooting: Maximizing Production

Does Investing in CMMS Software Make Sense During a Tough Economy?

2024 Trench Safety Stand Down Week

National Safety Month 2024: Ensuring Worker Safety Through Proactive Facility Maintenance

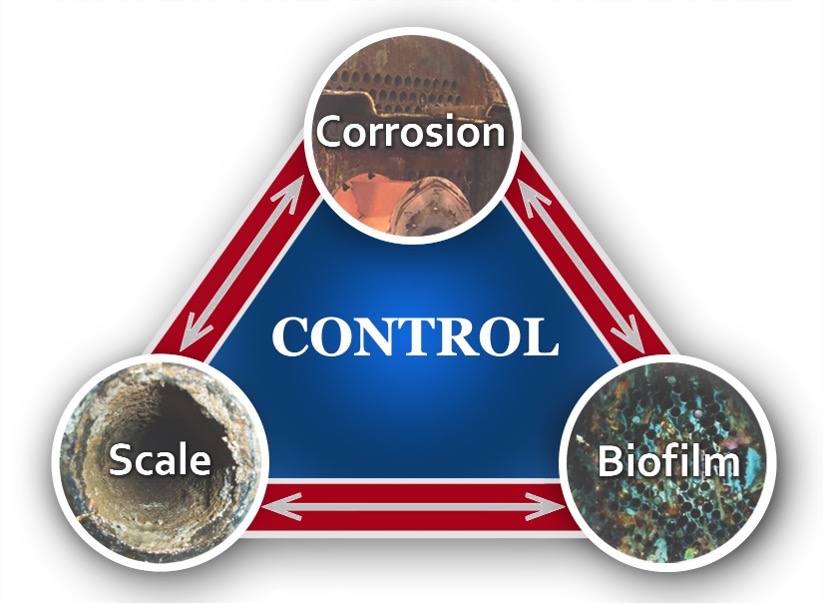

Protecting Cooling Water Systems – Part 1

How to Protect Bearings from Dust and Water

Data Preparation Strategies & AutoAI Advancements: Watson Studio Essentials

Digital Maps for Plants and Factories

Firework Manufacturing Safety

Utilizing Decision Intelligence Technology Across Industries

Autonomous Maintenance: Maximize Equipment Uptime with CMMS

Embracing the Sun: How VR/AR is Revolutionizing Follow-the-Sun Maintenance

Robotics in Manufacturing

Unpacking Lean Leadership: Part 1

30-60-90 Day Plan for New Maintenance Managers

Resources for Essential Reliability and Maintenance Case Studies

The Critical Connection Between Digital Transformation and Sustainable Continuous Improvement

Protecting Cooling Water Systems – Part 2

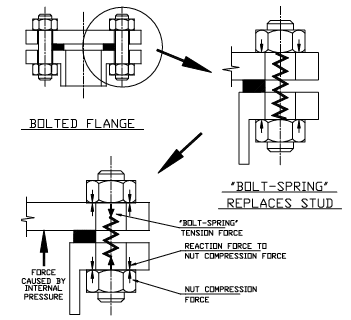

Prevent Flange Leaks with Proper Bolting Practices

The Evolution of AI in Maintenance: From Expert Systems to Intelligent Agents

Safe + Sound Week 2024

Building A Diverse Lean Leadership Team: Unpacking Lean Leadership Part 2

Fault Reporting: How to Improve Workflows in Maintenance Operations

Optimizing Preventive Maintenance Activities

Metal Corrosion Basics

CMMS Features that Maintenance Teams Should Use to Improve Maintenance Performance

SAP for Asset and Service Management Conference 2024

The Integrity Test Advantage

Scale Formation in Cooling Water Systems: Protecting Cooling Water Systems, Part 3

Maintenance in the Era of Industry 4.0

How to Make the Most of S/4HANA Asset Management

AI-Powered Maintenance: AI Models and Possible Use Cases

How to Develop Inclusive Lean Leadership Training

Using a CMMS for Root Cause Analysis (RCA)

Define and Measure KPIs and Goals for Condition Based Maintenance

Durability Meets Innovation: Exploring BRUTE’s Toughest Solutions for Manufacturing & Industrial Settings

Shifting Maintenance Perspectives from a Cost Center to a Critical Business Asset

Guide to Manufacturing Plant Hurricane Preparation

Get Mechanical Seals Working Properly

Corrosion Fundamentals: Protecting Cooling Water Systems – Part 4

Reliability Strategies Function for MAS 9.0 (MAS RS)

Navigating the AI Frontier: Balancing Innovation and Caution in Maintenance

National Manufacturing Day 2024

Asset Data Configuration - A Journey from Concept to Value Extraction (Part 1: Structuring an Asset Register)