TPM and RCM: Whirled Class

Paul V. Arnold, MRO Today

-TPM and RCM at Whirlpool mean: “We are all responsible for the equipment.”-

When a piece of production machinery broke down at the Whirlpool plant in Findlay, Ohio, several years back, it was accepted practice for the machine operator to call maintenance and then sit back and wait for the problem to be fixed. Critical information and knowledge was not shared between the operator and maintenance technician.

Like many companies, these workers were stuck in traditional roles – operators run the machines, maintenance fixes the machines, and the two do not cross. As a result, productivity opportunities were missed.

In the mid-1990s, the maintenance leadership at Findlay decided there was a better, more progressive way. It planted the seeds that bear fruit today as the Total Productive Manufacturing and Reliability-Centered Maintenance (TPM and RCM) components of the facility’s overall Maximized Manufacturing initiative.

In one sentence, TPM and RCM at Whirlpool mean: “We are all responsible for the equipment.”

That means . . .

- Operators do maintenance work, some of it technical in nature.

- Skilled tradespeople train operators in various maintenance subjects, including the use of predictive technologies.

- Maintenance and operations employees work together in teams to uncover the root cause of problems that hinder overall equipment effectiveness (OEE).

“When you’re in maintenance and see a need for change, you have to take the lead sometimes,” says senior reliability engineer Richard Word.

It’s not always comfortable to do so, but the results can be huge.

TPM and RCM: Dishing it out

While then-maintenance manager Kirk Wolfinger and other department leaders were indeed revolutionary in deciding to open up communication and the machines to operators, there were some extenuated circumstances that confirmed that this was the right way to go.

First, demand for Whirlpool dishwashers was at an all-time high.

“If we aren’t producing dishwashers, we’re disappointing customers,” says division vice president John Haywood.

Second, Whirlpool’s corporate office challenged its plants to boost throughput with minimal capital investment. In other words, maximize the production equipment you have.

Third, with the development of a Maintenance Master Plan, one of the primary focus areas was preventive maintenance (PM).

“Upon review of our PM program, we discovered there were many more PMs than we could actually accomplish, and many of the tasks were generic, and some even irrelevant for certain equipment,” says plant engineering manager Thomas Meyer. “Adding more people to do the tasks wasn’t an option, so we knew the PMs had to become more effective, and we had to involve equipment operators in maintaining their equipment.”

Operator involvement (as individuals and as part of cross-functional, problem-solving teams) essentially enabled more than 1,000 people to help develop a better way to care for plant assets.

That is not to say, however, that maintenance and production workers universally saw the plan’s pluses at first. Some operators felt they had enough to do during a shift, let alone take on “the maintenance guy’s work.” History also played a role.

“In the past, there would be conflict if anyone caught you doing someone else’s job,” says Grade 4 operator Mike Verhoff.

Some maintenance technicians felt shifting the responsibilities was setting them up for pink slips.

“There were many skilled tradespeople worried that they were giving our work away,” says reliability technician Dave Erwin.

Word was among those that quickly calmed maintenance workers’ fears. “That cracks me up,” he says. “When have we ever had too little to do?”

The Marshall Institute, a training firm based in North Carolina, also helped prepare Whirlpool employees for change by leading sessions of The Manufacturing Game. This role-playing board game gets players to “walk in someone else’s shoes” and provides the basic tools to move an organization from reactive operations and poor reliability to a proactive approach and high reliability.

Spelling out TPM

The rollout of Total Productive Manufacturing in 1996 was the first major step toward real-world results.

TPM (also known as Total Productive Maintenance) is a team-based approach to maintaining the condition of equipment. It relies heavily on operator ownership of equipment, continuous identification and implementation of improvements, and the development of planned maintenance.

A TPM team is made up of approximately 10 area operators and maintenance personnel across the various shifts and is led by a process engineer or area supervisor. After receiving instruction on the principles of TPM and OEE (a metric that tracks sources of operating loss, including equipment availability, performance and quality), the team starts identifying opportunities in their area.

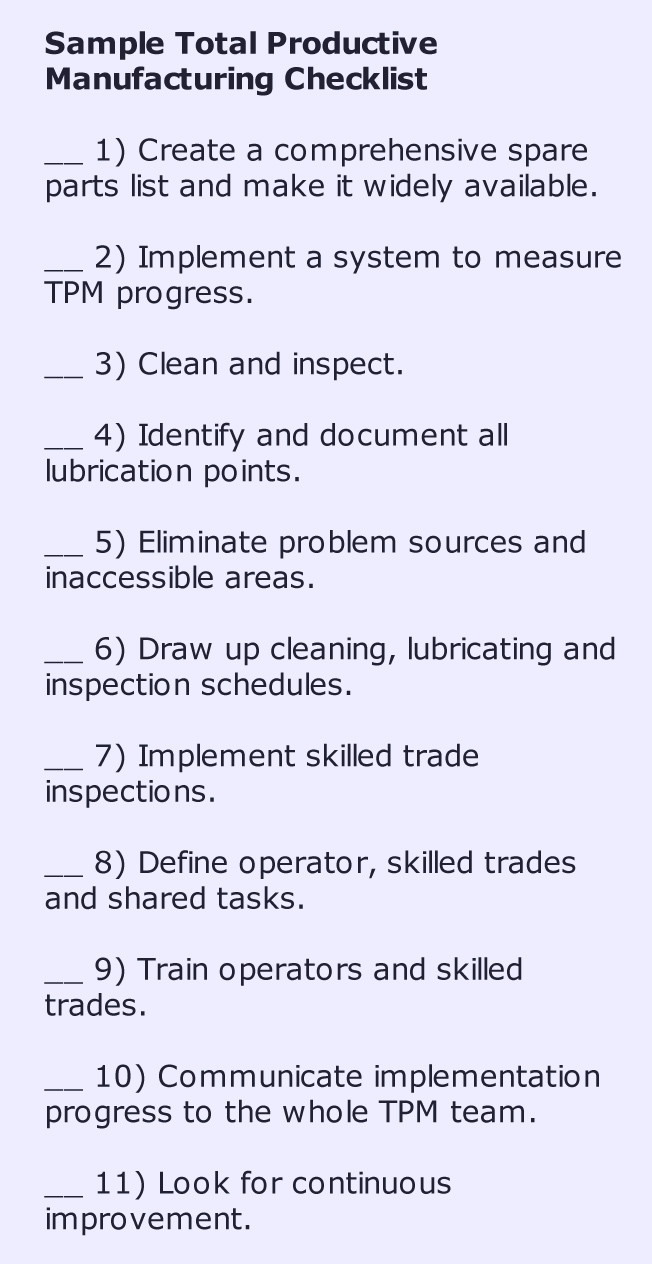

The team then looks for and implements solutions to eliminate identified sources of loss. One useful tool is a TPM checklist that contains standard actions to drive out losses. Core activities like clean-to-inspect are now done in the context of the losses identified so that the people doing the cleaning understand the purpose. On this checklist, some maintenance tasks are shifted to operators. This helps build their ownership and ensure that problems are detected and dealt with earlier.

Each of the plant’s 33 teams meet regularly (they do not disband) to identify projects that improve OEE, processes or people’s jobs.

Accomplishing goals puts TPM teams on the road to certification. Certified teams incorporate more advanced tools (tied to lean manufacturing) in order to be recertified on an annual basis.

“TPM gives a person working on the equipment the means to get things taken care of,” says senior TPM facilitator Jim Dray. “It takes away frustration and makes you feel like you’re making things better.”

In regard to maintenance tasks, operators take on as much as they are capable and trained to perform. While most operators do the routine tasks (general cleaning, lubricating, tightening bolts, and monitoring heat strips and gauge tape), others identify loose wires and air leaks, and change belts and hoses. Some operators go further after taking classes in topics such as electricity and pneumatics. Many of the classes are led by skilled tradespeople such as electricians and millwrights.

Tradespeople assigned to the plant’s Reliability Lab also offer training on the basics of predictive technologies such as infrared thermography and ultrasound.

“By doing that, the lab guys focus on the ‘fun’ stuff – examining components that have failed or are failing – instead of only collecting condition data,” says Word.

When it comes to predictive tools or machine issues, a “Lines of Defense” hierarchy controls who does the work. It tracks from operator to semi-skilled operator to area maintenance technician to Reliability Lab technician to an outside expert.

“Operators are in the best position to monitor the daily condition of the equipment,” says reliability technician Jim Stone. “Give me the stuff where I can really use my skills and my knowledge.”

Spelling out RCM

While many companies stop at TPM, or give up while trying to adopt TPM, the Whirlpool plant kept going, adding Reliability-Centered Maintenance to its toolbag in 2000.

In Findlay, RCM bonds a structured thought process to the expertise of a cross-functional team. The goal is to develop a complete maintenance strategy for a process or piece of equipment. The genesis of this program was instruction from Doug Plucknette, a former Eastman Kodak veteran and one of the true gurus on RCM. (Plucknette currently runs a consultancy business called Reliability Solutions).

An RCM team – made up of the facilitator (Word), a co-facilitator, implementation leader, operators, skilled trades, maintenance and production supervisors, and process and control engineers – analyzes the process or machine, pinpoints faults or areas of opportunity, and implements fixes to make the process/machine more robust.

A system must have one or more of the following attributes to be a target for an RCM analysis.

- It is a critical piece in need of an improved maintenance strategy.

- It is a system that immediately impacts production and/or has immediate negative economic consequences from poor reliability.

- It is a critical system that may be totally automated and is, therefore, not a candidate for a TPM team.

- It is a system that has become a constraint for product flow.

- It is equipment that has recently encountered reliability problems.

- It is a system that will become more reliable from ownership or operator awareness of the functions.

- It has a TPM team that needs revitalization or several new members.

After finding an appropriate target, the team follows a rigorous 14-step analytical process:

- Review the equipment’s operational history.

- Detail the parameters for consequence of failure.

- List the main functions.

- List the sub-functions.

- List the failure modes.

- List the failure effects.

- List the downtime.

- List the consequence.

- Navigate a decision tree.

- Determine the proper maintenance task.

- Determine the need for stocking a spare part.

- Review the completeness of the analysis for the time scheduled.

- Do a reality check.

“We take some of the poor performing pieces of equipment and, together, we bring them back to life,” says Word. “If we start giving a challenging machine some special care, pay attention to it and treat it right, it will work fine.”

RCM analyses can be generally accomplished in one week. After that, team members are assigned specific tasks to complete. Most of the implementation involves reviewing and transferring a detailed maintenance task into the PM system.

Through early April, the plant completed 27 RCM analyses, which identified 3,066 failure modes and 2,225 tasks. To show the teamwork in this process, operators received 53 percent of the tasks and maintenance technicians received the rest.

In addition to those leading indicators, OEE is tracked on all equipment that has had an RCM analysis to ensure that the process is working.

TPM and RCM Create a Productive and Reliable Organization

What overall effects have TPM and RCM had on the Findlay plant?

Thanks in part to these tools:

- Production has increased 27 percent since 1996.

- OEE in some production areas has increased to 97 percent.

- Production and maintenance workers are continuously looking for improvements.

“It’s become part of our culture,” says reliability technician Dick Klingler. “Everyone is responsible for our equipment.”

And, they are all responsible for driving the culture change to improved productivity.

Related Articles

How to Fix the 70/30 Phenomenon

Zen and the Art of Managing Maintenance

Why do maintenance improvement initiatives fail to deliver? (Hedgehog or Fox?)

Why Maintenance Improvement Efforts Fail

Where Do Maintenance Professionals Come From?