What is Preventive Maintenance? A Comprehensive Guide

Nivedha Sridhar, Director of Marketing and a founding team member at Facilio Inc. – originally published on Facilio Blog

Posted 11/11/2022

The primary goals of any organization’s maintenance management program are standard:

- to reduce asset deterioration,

- reduce unplanned downtime,

- and save costs on expensive run-to-failure maintenance

Reactive maintenance (also known as run-to-failure maintenance) is the oldest and, to date, a popular maintenance strategy. It is an easy start since it doesn’t require complex maintenance plans or implementation.

In this “don’t fix it if ain’t broke” approach to Operations & Maintenance, technicians attend to assets/equipment only in the event of fault/failure. This approach may work perfectly for SMEs with few properties and assets to track.

A recent report by Senseye found that large facilities lose an average of 27 hours a month to machine failures, and $532,000 for each hour of unplanned downtime.

Enterprises need a “fix it so it stays healthy” strategy to avoid unexpected failures that result in costly unplanned downtime. This is precisely what preventive maintenance (PM) helps achieve.

What is preventive maintenance?

Preventive maintenance is a strategy that helps plan regular and routine maintenance to maximize the longevity of assets, equipment, and buildings.

It also helps reduce the chances of unexpected equipment failures, costly unplanned downtimes and reactive maintenance.

Businesses implement PM strategies by planning and scheduling maintenance activities based on real-time operational data using a computerized maintenance management system (CMMS). The four main types of preventive maintenance are:

- Time-based maintenance

- Usage-based maintenance

- Predictive maintenance

- Prescriptive maintenance

The number of types of preventive maintenance is not universally agreed upon; they are applied differently for each unique maintenance scenario.

What are the different types of preventive maintenance?

The concept of planned maintenance lies at the heart of preventive maintenance strategies.

The goal of planned maintenance is to reduce downtime and costs, as well as to increase asset and equipment lifespans.

Under planned maintenance, you can schedule preventive or unscheduled maintenance depending on the needs of the asset, and its impact on operations. .

- Planned unscheduled maintenance is usually applied to inexpensive and easy to replace equipment that do not have a major impact on operations in case of failure.

- Preventive maintenance is typically performed on critical equipment that have high impact and associated downtime costs.

To safeguard and future-proof critical equipment, businesses use these four major types of preventive maintenance concepts:

Time-based maintenance

Time-based maintenance occurs at scheduled calendar intervals to comply with manufacturer recommendations. This system creates necessary work orders as the due date approaches, after which the maintenance action is triggered.

Consider adding major utilities, equipment, tools, and technology your business depends on for its success to create a time-based maintenance plan for your business.

Usage-based maintenance

Usage-based maintenance considers both, the time elapsed since the last maintenance and the average number of operational hours to schedule PM tasks.

With time-based maintenance, you know that your equipment is due for an oil change, say after every 200 operational hours. It is difficult to line up resources for the change if you don’t know when the equipment is going to complete 200 operational hours.

Say the equipment is used for an average of 10 hours daily. So,

- the ideal time between oil changes (200 hours)

- time elapsed since the last change (100 hours)

- and the average usage of equipment (10 hours)

So, the next change is due in 10 days.

The biggest benefit usage-based maintenance offers over just time-based schedules is the ability to calculate the date of next maintenance, and line up resources accordingly.

Predictive maintenance

Predictive maintenance gathers information from various sensors such for vibration, gas, humidity, temperature, security, and pressure sensors.

These sensors are typically found on sensitive equipment, which send data to a predictive maintenance software that can trigger maintenance work orders in case the equipment needs inspections, repairs, or upgrades.

Predictive maintenance helps monitor the health of essential machinery, track their performance, and detect defects in advance to prevent unexpected equipment failures.

Prescriptive maintenance

The objectives of prescriptive maintenance are the same as predictive maintenance. Only, this cutting-edge technology uses advanced analytics and machine learning to not just predict, but to hypothesize potential outcomes that could lead to equipment failures.

It analyzes equipment performance, assesses operational breakdowns and risks to forecast potential timing of an asset failure and possible operational conditions up to the time of failure. Therefore, the more Artificial Intelligence becomes familiar with your machines, the less you spend on expense reactive maintenance.

Software for prescriptive maintenance helps analyze asset performance, make recommendations and project outcomes, and trigger and monitor maintenance work orders all by itself.

These concepts are tweaked, organized, and scheduled differently to suit the unique maintenance needs of businesses.

The effective implementation of preventive maintenance can offer certain common benefits, regardless of the concept you adopt.

Benefits of preventive maintenance

PM strategies enable you to directly improve your bottom line by avoiding unexpected and expensive downtimes. Besides, preventive maintenance systems also help:

- Boost asset performance with regular repairs before failure

- Reduce equipment downtime

- Increase asset lifecycle

- Improve compliance with OSHA and workplace safety

- Prevent excessive or abnormal energy consumption

- Maximize cost savings on maintenance work

- Efficient resource allocation and utilization

- Better inventory tracking and planning

When to use preventive maintenance?

The best practice to determine inspection and schedules is to follow manufacturer guidelines for each asset/equipment. Preventive maintenance schedules help businesses tend to assets before they run to failure.

PM is used to monitor equipment like HVAC (heating, ventilation, and air conditioning), water, sanitation, electrical, safety and other mechanical equipment. PM ensures they are functioning optimally and within safety and compliance guidelines.

Requirements for preventive maintenance scheduling differ depending on the equipment you want to track and maintain.

Steps to make a preventive maintenance plan

The secret to an effective preventive maintenance plan is to get the frequency of maintenance scheduling right. When overdone, preventive maintenance can result in increased costs, wasted time and work hours, and may lead to post-maintenance breakdowns.

More isn’t always better.

Setting up customized preventive maintenance schedules for equipment vital to your operations is the best way to get started with proactive maintenance.

Here’s how you can create an effective preventive maintenance schedule:

Step 1: Prioritize assets for preventive maintenance

If you’re putting together a preventive maintenance plan for the first time, it is best to identify critical equipment that can benefit from preventive maintenance.

The types of equipment that generally benefit from preventive maintenance are those that

- are crucial to operations and business success,

- bring high repair and replacement costs,

- are likely to deteriorate with time, and

- have failure modes that regular maintenance can prevent.

Choosing assets that will benefit most from preventive maintenance schedules is an important step toward showing your team the RoI of implementing preventive maintenance programs.

Remember, preventive maintenance helps maintain and extend the life cycles of new equipment but doesn’t avoid the need to replace already old equipment.

Step 2: Get historical data for each asset

Once you have a list of equipment for preventive maintenance, you will need to understand what types and frequency of problems each asset presented in recent years.

In addition, each asset’s unplanned downtimes and maintenance work orders, along with its age and depreciation rate, help better estimate its preventive maintenance needs.

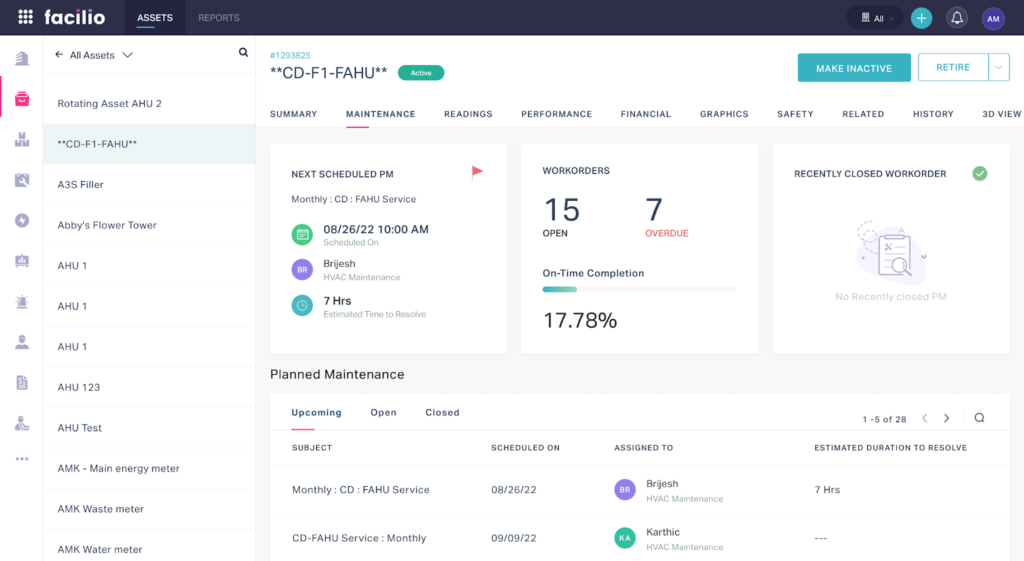

The above screenshot shows detailed maintenance history along with PM tasks for a particular asset. While such detail is easy to achieve with a CMMS, you can also use an excel, or CSV file to store this information.

If you do not have historical data, fret not – you can still make a PM schedule by projecting asset maintenance needs.

Step 3: Project maintenance needs for chosen assets

Each asset has its unique operation lifetime and maintenance needs. When in doubt, it is best to refer to recommendations from the Original Equipment Manufacturer (OEM) manual.

The manufacturer’s manual contains schedules for necessary maintenance actions and the usage of critical spare parts.

Additionally, talking to operators, technicians, and other maintenance personnel who directly operate the equipment can give you performance insights that can help optimize PM.

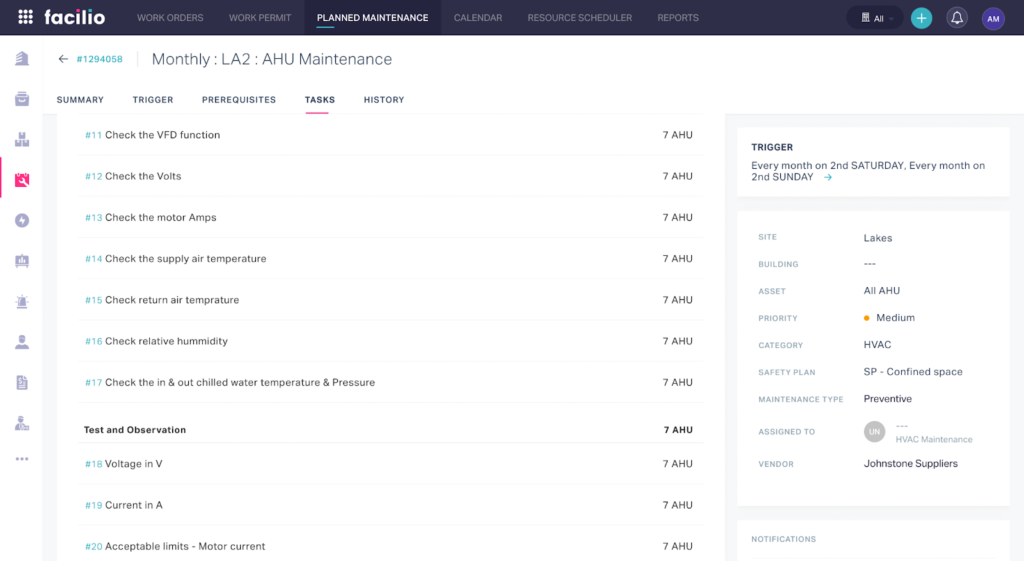

Once you have this information on hand, you will be able to make checklists of tasks and inspections to perform for each asset, as illustrated in the screenshot.

Step 4: Create a pilot preventive maintenance plan

After considering the historical data and manufacturer recommendations for your chosen assets, you have everything you need to create a preventive maintenance plan.

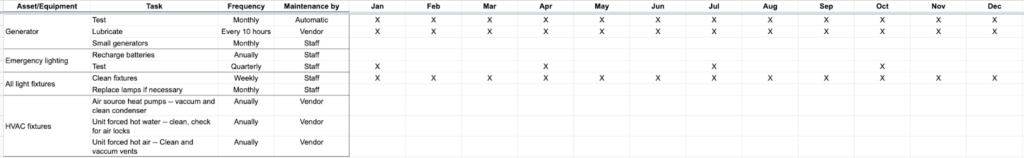

You will need to write down maintenance tasks for each asset and determine the maintenance frequency. It would be best if you had an asset management plan that looks like this –

It is also a good idea to add any relevant asset information or notes from technicians as comments wherever necessary. With this basic asset management plan, you are ready to kickstart your preventive maintenance system!

Step 5: Track, measure, and optimize

Congrats! You have created a preventive maintenance schedule, and your team is getting used to optimized workflows. What’s next?

It is critical to track and monitor the progress and performance of each asset being regularly maintained. This way, you always know if a particular asset needs more or less preventive maintenance to perform optimally.

As we discussed earlier, the greatest pitfall in preventive maintenance is overscheduling of preventive maintenance tasks.

- If an asset works ideally and without any failures, its preventive maintenance schedule works well. Maybe, it is getting more maintenance than it needs. In such a case, you can tweak its maintenance frequency without affecting its operational efficiency.

- If a piece of equipment has seen post-maintenance breakdowns, you can increase the frequency of maintenance for that one. It is also a good idea to understand the root cause of breakdowns in such cases.

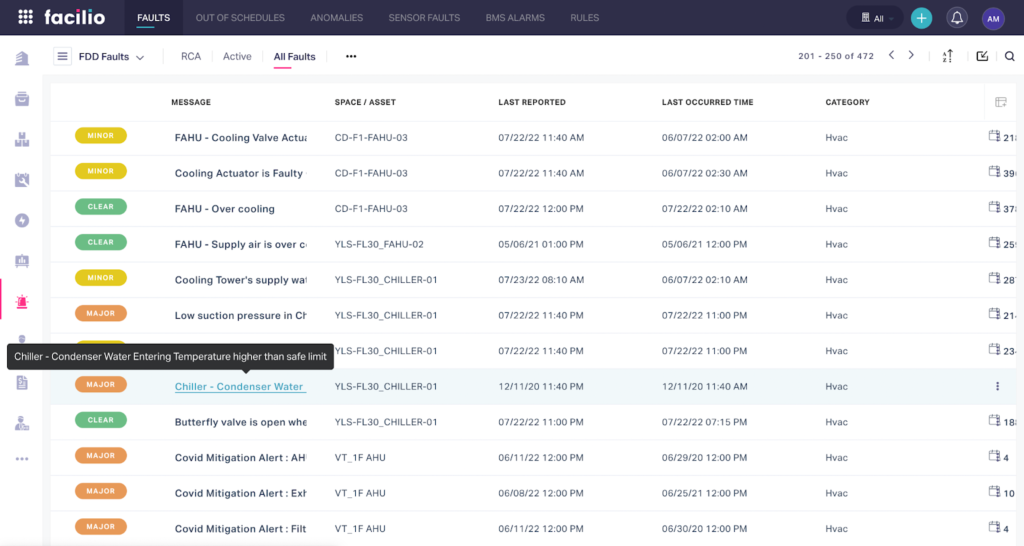

A preventive maintenance software or CMMS houses detailed logs on each maintained asset. This helps maintenance teams quickly perform root cause analysis, understand the asset’s maintenance needs, and empower businesses to make repair or replace decisions confidently.

Step 6: Determine KPIs

Defining KPIs (Key Performance Indicators) when getting buy-in for preventive maintenance or after listing critical assets helps measure the effectiveness of your PM plan.

Common maintenance management KPIs are:

- 99% annual uptime for critical assets

- Zero unplanned downtime for three years

- 90% accuracy for inventory and spare parts stock

- Annual workplace accidents under 2%

In 2022, the best way to achieve all this and more is by automating the process with robust maintenance management software.

What is preventive maintenance software?

Preventive maintenance software is an application of CMMS that helps businesses collect extensive asset information in real-time, schedule maintenance tasks, create work orders, and easily track performance.

As a result, optimizing maintenance schedules helps maximize asset performance and lifespan, lower unplanned downtime, and save repair-based costs.

The primary objectives of a preventive maintenance plan are to maximize asset life cycles and prevent downtimes while saving time, costs, and resources for all stakeholders. A CMMS solution helps achieve these in two significant ways:

- Data-driven asset management: CMMS software captures all information about an asset that PM programs require. This includes its repair calendar, asset priority, repair history, breakdowns and downtime, and equipment manufacturer standards.

Using this data, maintenance technicians can quickly diagnose the performance of each asset before repair or replacement decisions are made. - Implementing proactive maintenance strategies: If you’ve relied chiefly on reactive maintenance in the past, switching to proactive maintenance can bring up many unforeseen challenges.

Common challenges are scheduling, resource allocation, performance analysis, and strategic decisions for future operations.

Thankfully, modern-day CMMS software uses technology like IoT and Machine learning to make the entire process intuitive and seamless.

CMMS features that make preventive maintenance simple

A CMMS plays a pivotal role in the success of a preventive maintenance plan. The functions and tasks it helps streamline, automate, and simplify are:

- Set up preventive maintenance schedules for assets based on time or usage.

- Track and manage all maintenance work with a simple maintenance calendar.

- Create preventive maintenance checklists and attach them to relevant work orders.

- Automate work order creation and log all work records in the CMMS.

- Access to maintenance data for any asset from anywhere and any device.

- Enable greater accuracy in managing and spare part inventory with automatic usage tracking.

- Optimize your preventive maintenance program with metrics and KPIs tracking.

Further, CMMS software collects all relevant data from people, processes, and assets to act as a centralized platform for all things building operations.

It uses the data points it contains at each stage to empower businesses with real-time operational insights to improve their maintenance programs.

Suggested read: How a CMMS Helps Boost Your Property Operations: A Comprehensive Guide

The future of preventive maintenance

IoT (Internet of Things) and Machine Learning technologies have only made their way to real estate property operations in the recent past. And since have shown extraordinary results in continually optimizing assets and maintenance activities.

For instance, consider the case of Al Fajer, a facilities management company widely regarded as an industry leader with over 300 buildings in the UAE.

Al Fajer depended on legacy CMMS and rigid facilities management software to manage all maintenance activities. However, legacy software’s limitations in functionality, customer experience, and real-time data analytics resulted in costly reactive maintenance.

After partnering with Facilio, a connected platform for building operations, here’s what they were able to achieve:

- 6864 assets connected from across the portfolio

- 80+ proactive planned maintenance using a 52-week PPM calendar

- 13% increase in workforce productivity

Here’s what the General Manager at Al Fajer, Ms. Sangeetha had to say about maintenance management with Facilio –

The use of remote monitoring and analytical modeling capabilities enables businesses to realize the true potential of their maintenance management programs.

Not only do CMMS like Facilio help track, optimize, and report asset performance, but they also help decrease the net amount of resources allocated to executing maintenance tasks, saving time, costs, and resources for the business.

Wondering which CMMS software might be best for your business? We’ve put together a handy list of considerations to make before choosing a CMMS for you, hope it helps!

Things to consider before choosing a CMMS software

Here are a few CMMS features that help your maintenance management team realize the full RoI of your CMMS investment.

- Asset management

- Work order management

- Inventory management

- Program management

- Preventive maintenance management

- Procurement management

- Reporting and Business Intelligence Analytics

- Integrations with BMS, HCM, Accounting, and other essential software

Most maintenance managers agree that these features are the most important. However, every organization has different operations and maintenance needs. Therefore, you should be very well-versed with the features and benefits of CMMS for your use case.

By the way, we’d love to learn more about your proactive maintenance management needs! The friendly faces at Facilio love enabling businesses to get building operations and maintenance just right.

Pick a time that works for you, and we’ll explore how to supercharge proactive maintenance management for your business together!

Discover the power of PM for your business with Facilio

Facilio is a unified platform for connected building operations. It brings data from properties, people, processes, and systems to a centralized command center to give real-time and complete visibility of your buildings portfolio’s performance.

Explore what Facilio’s Connected CMMS can do for your business:

- Maintenance management

- Contractor management

- Vendor management

- Workplace management

- Visitor management

- Connected Optimization

Nivedha Sridhar

Nivedha Sridhar is the Director of Marketing and a founding team member at Facilio Inc., an enterprise-wide facilities O&M software platform provider headquartered in New York. Nivedha’s career spans over 8 years of product, growth, and corporate marketing focused on enterprise IoT software and business cloud applications. Before starting with Facilio in 2017, she managed Global Marketing for an enterprise brand at Zoho Corporation.

Related Articles

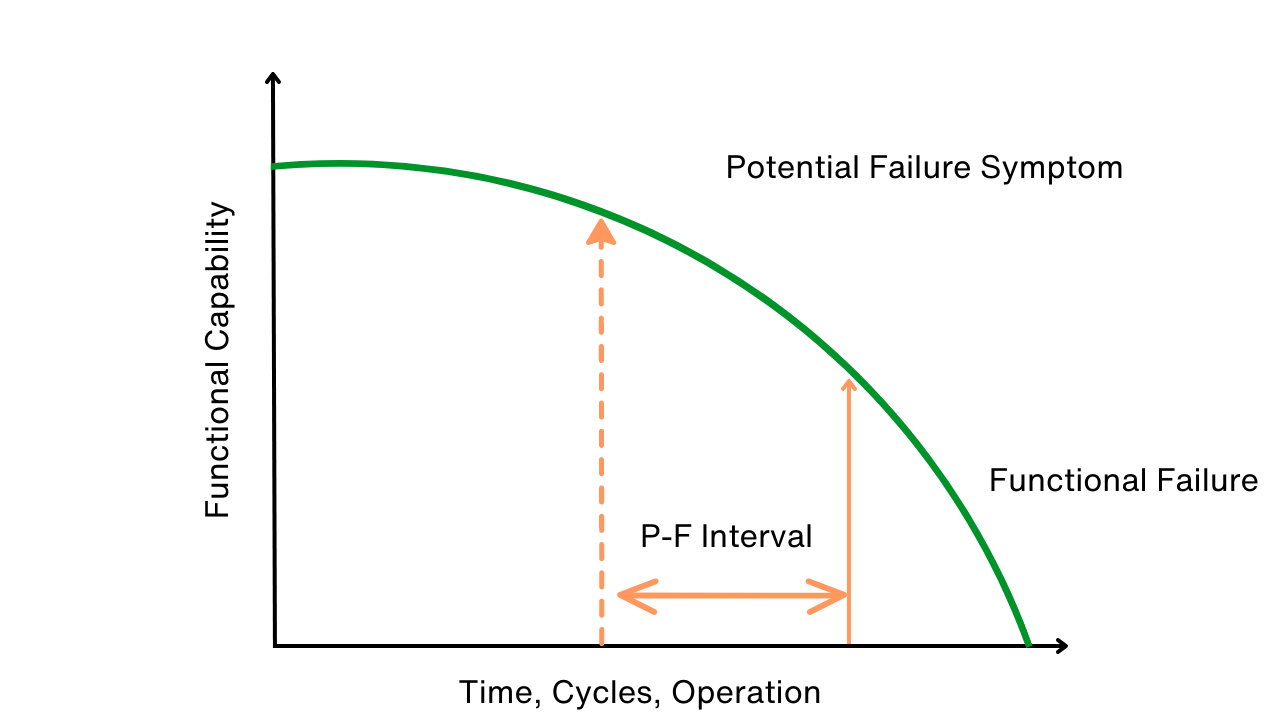

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability