Recycled Copper: Turning Scraps into Sustainability

Elizabeth Ruiz, Maintenance World Editor

Posted 6/12/24

The manufacturing industry is increasing its efforts in reusing and recycling copper scraps due to a projected doubling in copper demand by 2035. (1)

What applications can copper be used for? Why is the demand for copper growing? How is recycled copper used and what are the environmental benefits of recycling more copper? Find out in this week’s Maintenance World newsletter.

What is copper used for?

Copper has many applications in manufacturing, electronics production, and clean energy. Copper wiring is widely used in semiconductor manufacturing as well. Copper wire in silicon chips allows microprocessors to operate faster while using less energy, creating a device that is more efficient and environmentally friendly. Copper tubes and wires are also becoming more common in medical equipment due to their antibacterial and antiviral properties.

It’s high ductility and electrical conductivity made copper useful in electrical conductors, switches, transformers, and telecommunications equipment. Copper’s high thermal conductivity works well with heat exchangers, radiators, heat sinks, cookware, and kitchen appliances. Copper contains antimicrobial properties which are good for doorknobs, railings, handrails, and jewelry. It’s resistance to corrosion and weather makes it ideal for roofing, spouting, architectural accents, signage, plumbing, and other household applications. (4)

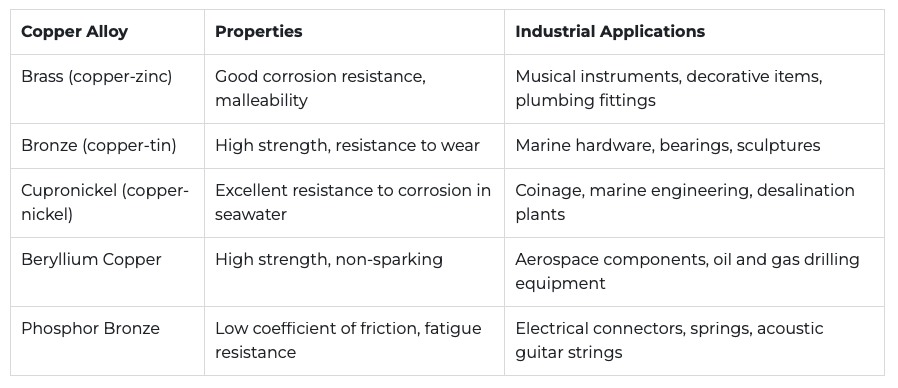

Copper alloys are also commonly used in industrial applications:

Why the demand for copper is growing

There are a number of reasons why demand for copper is growing in the manufacturing industry. One reason is the current trending away from fossil fuels towards clean electronic power to cut greenhouse gas emissions. Copper is used in making products that enable these cleaner solutions. Another increase in demand is related to new construction, cell phone production, and data centers. (1) Copper is also a key material in production of electric vehicles, power grids, and wind turbines (promoting clean energy). (2)

Because copper is integral to the energy transition, the lack of mine supply growth is being felt throughout industries. (2) Existing mines are only able to produce lower and lower grade copper ore, which adds to cost. Another issue is that opening a new mine can take over 10 years. Increasing regulations related to environmental concerns and safety are also causing a strain on copper supply, (3) (even though they are necessary and create positive outcomes in the long run).

This is where recycling comes in.

How is copper recycled?

In simple terms, copper scraps are recycled by remelting the copper down and adjusting the composition as needed. High-quality product can be produced if the scrap copper is pure and uncontaminated. If the scrap copper only consists of one allow composition, it can still be remelted into a good quality product with some composition adjustment when remelting. This grade of recycled copper can be used superfine enameled wires which require purity. The requirements are slightly less strict for recycled copper used for power cables.

If the scrap copper is mixed, contaminated, or contains other materials, it will be more difficult to adjust the composition within the specified limits when it is remelted. If it is just lead or tin, but no harmful contaminants, it is typically possible to adjust the composition by adding more lead or tin to produce leaded bronzes. This recycled copper is good to use in plumbing tube, roofing sheet, and heat exchangers.

If the scrap copper is contaminated with undesirable impurities, it is sometimes possible to dilute it during remelting to adjust the impurity level to an acceptable specification. Copper that has been tinned or soldered can be recycled to use in gunmetals and bronzes, which require the presence of lead and tin.

All the techniques retain much of the value of the scrap copper.

If the scrap copper contains beyond the acceptable limit of contaminants, it will be necessary to refine it again back to pure copper using conventional secondary metal refining techniques which provide a useful supplement to primary copper supplies. (5)

What are the environmental and business-related benefits of recycling copper?

Copper is one of the most frequently recycled and easily recycled metals available. The demand for recycled copper is always present and is currently growing, so any scraps or chips have financial value when they are recycled. These processes can be done on site if the proper equipment is available, but scraps can also be sent out to a contractor for remelting. (4)

The economy of the copper industry depends on recycling surplus products. Using the most appropriate and least expensive feedstock for producing components results in the most economic price for the material. (5)

Every ton of copper that is recycled equals around 200 tons of rock that won’t need to be mined, depending on how rich the ore is. This is important because mining can cause erosion, air pollution, contamination of soil and water, and threaten local biodiversity.

Copper is a very good candidate for reuse because it can be recycled over and over without losing value or performance. (1)

Conclusion

The manufacturing industry’s intensified focus on recycling copper scraps is a strategic response to the projected doubling of copper demand by 2035. This effort not only supports the growing need for copper in electronics, clean energy, and construction, but also reduces the environmental impact associated with mining new copper. By efficiently recycling copper, industries can produce high-quality materials while conserving natural resources and minimizing ecological damage. As a result, the shift towards recycling copper scraps not only meets rising demand but also aligns with broader sustainability goals.

Sources:

1) “As Need for Copper Rises, Cable Manufacturers Recycle More.” Jennifer McDermott. June 10, 2024. Published online by Manufacturing.net.

2 “Copper prices climb to 2024 high as Citi calls the start of the metal’s second bull market this century.” Sam Meredith. April 10, 2024. Published online by CNBC.

3) “Copper prices at 2-year highs thanks to green energy transition.” Article written from Marketplace Morning Report podcast. Caleigh Wells. April 29, 2024. Published online by Marketplace.

4) “Copper Uses in Industry.” IMS Team. June 8, 2021. Updated March 9, 2024. Metal University. Posted online by Industrial Metal Service.

5) “Recycling of Copper.” published online by Copper Development Association, Inc. from CDA UK publication of the same name. Includes “Copper: Infinitely recyclable” video by International Copper Association.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you every Wednesday by the Maintenance World crew.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill