How SMED Can Turn Back Time

Dr Anthony Kenneson-Adams. DBA. MA. BSc(Hons). FIoL, Head of Learning and Knowledge Transfer, Project7 Consultancy

Posted 11/7/2023

This article will describe the Lean Manufacturing methodology of Single-Minute Exchange of Die (SMED), explain its value to your business, and outline the SMED process as a series of simple steps that you can replicate in your organization. I will detail examples from actual SMED events where SMED has given time back to the business turning wasted time into productivity and revenue.

What is SMED?

SMED is a methodology we use in lean manufacturing to reduce the time it takes to perform equipment changeovers or setups. The goal of SMED is always to minimize the downtime between the production of one product and the start of the next product, thereby increasing efficiency and productivity. Ideally this process is reduced to ‘single minutes.’

History of SMED

Malcolm Jones, in his article in Maintenance World on the ‘Power of SMED¹’ discusses in detail the history of SMED and I encourage you to read Malcom’s comprehensive article for background on the development of SMED.

Today, SMED continues to be a valuable methodology in manufacturing and is widely practiced across industries from automotive to packaging and medical and food production to extruders for plastics. In recent years SMED’s principles and techniques have also been adapted and applied to various operational processes beyond equipment changeovers, including setup time reduction in service operations, office processes, and even operating theatres and other healthcare settings.

Wherever it is practiced SMED process follows a simple set of repeatable steps:

1. Gathering data: Firstly, collect the best data available on the current setup process. This includes recording the time taken for each step, identifying bottlenecks, and understanding the sequence of tasks involved.

It is important to take time in selecting which project to begin with on a SMED campaign. Always look for the project with the greatest potential to reduce waste and time and also be of the greatest value to the business. Creating a spaghetti diagram that records the team’s movement during the setup is a great way to collect this data. I will discuss how to collect this data and map your process using a spaghetti diagram later in the article.

2. Separating internal and external setup tasks: Internal setup tasks are those that can only be performed when the machine is stopped, while external setup tasks can be done while the machine is still running. The aim is to identify and convert as many internal setup tasks as possible into external tasks, thereby reducing the downtime required. In addition, there should be an absolute minimum of serial tasks on a change over and those that do remain should not involve anymore that removing one item and replacing it with another with the minimum of set up and calibration. If a part needs to be worked on, particularly away from the machine do a cost analysis to ascertain if there is merit in buying another part or several others if you require several different settings. In my experience a business case invariably shows that the purchase of at least one spare is a force multiplier to maximise the potential of a SMED event.

Using a motor sport example, the pit crew would never take a tyre off a wheel in a pitstop, it makes no sense, they have a new tyre and wheel already assembled and standing by, so no internal tasks.

3. Streamlining internal setup tasks: For the remaining internal setup tasks, the focus is on finding ways to simplify and optimize the process. This can involve redesigning components for easier installation, standardizing tools, and equipment, or implementing quick-change mechanisms. A good example is replacing bolts holding covers in place with quick release mechanisms. Seconds count in SMED remembering it is ‘single minutes’ that are always your aim.

A further opportunity is removing all serial tasks where they can be turned into parallel tasks. Using the same motor sport wheel change as an analogy, in the 1950s one man changed all four wheels one after the other, today, all four wheels get changed at the same time by four different people. Within budget constraints, we too have to move to new creative solutions.

4. Standardization: The final step is to document the optimized setup process and create standard operating procedures. This ensures that everyone follows the same process to ensure repeatability and sustainability, both of these being essential in any lean methodology to drive out variation and sustain the gains.

The Spaghetti Diagram

A spaghetti diagram is a visual tool used to analyse the flow of people, materials, or information within a workspace. It gets its name from the way lines representing the movement of these elements resemble a tangled plate of spaghetti. The diagram helps identify inefficiencies, redundancies, and unnecessary movement in a process.

To create a spaghetti diagram, follow these steps:

1. Select the process: Choose a process or area that you want to analyse. This should be focused on a bottle neck, a product of a pareto of downtime, a process that takes different lengths of time on different shifts or just where it is acknowledged that a process is taking longer than it should but particularly where the team doesn’t know how long the process should take. As examples, I have used this process on many manufacturing lines, in a logistics transportation office and a Finance Department with equal effectiveness.

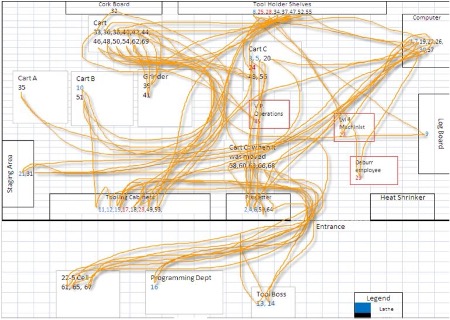

2. Observe and map movements: Track the movement of people, materials, or information involved in the process over a period of time. Use a floor plan or a grid to draw the path taken by each element, marking their starting and ending points for every journey or movement. Below is an example of a first stage spaghetti diagram².

Think about how a Formula 1 pitstop has gone from minutes in the 1950’s to just a few seconds today. This reduction of time did not happen overnight but was the product of mapping the process, practicing the process and continuous iterative improvement and refinement then re-mapping the process and starting the cycle over again.

3. Analyse the diagram: Examine the spaghetti diagram to identify patterns, long distances travelled, bottlenecks, and areas of congestion. Look for unnecessary backtracking, crisscrossing paths, or excessive movement. Constantly pose the question ‘Why?’ to yourself and your team. In one analysis, I found that the same operator went to the tool store 14 times in 45 minutes collecting one tool at a time. In another example the operator went to the maintenance department 5 times in 50 minutes to ask for help. In another example the operator undertook 3 visits to an oil store on one changeover for 3 different products; something they did on every product change on the machine.

4. Identify improvements: Based on the analysis, brainstorm ways to streamline the process and reduce movement. This could involve rearranging workstations, eliminating unnecessary steps, or improving communication and material flow. Practical examples I have seen are having point of use tools on lanyards to avoid trips away from the machine, having maintenance standing by at the machine or on radios ready for a change over and having flammable cabinets on the line to house oils and greases that were frequently needed.

Another major improvement is removing serial tasks such as rebuilding a component such as a blade bar or travel guides as part of the set up. Have spares ready at the side of the machine for at least the top 80% of the products that you will run. Keep the Formula 1 pitstop in mind, have everything on-hand and ready before the event. 5. Re-run the process three or four times to optimise the process to the point that there are the absolute minimum number of spaghetti lines left on the page before deciding on the standard task time. This is really valuable because the team will learn lessons on top of the changes that you make. Don’t expect this exercise to be once and done.

By utilizing the SMED methodology and the insights gained from the spaghetti diagram, businesses can achieve benefits that include:

1. Reduced setup time: SMED helps eliminate non-value-added activities and streamline the setup process, leading to a significant reduction in the time it takes to change over equipment on a production line. This allows for more frequent changeovers and increased production flexibility. In one example I facilitated in a packaging plant the set-up time using this process was reduced from 93 minutes to just 19 minutes. Only 9 minutes to reduce to achieve the SMED definition.

2. Increased productivity: By reducing downtime and improving efficiency, SMED enables more time for value-added production, leading to increased output and productivity. On one machine the successful SMED event meant that sales could now look for more orders and the business could cut out weekend working for a staff that previously could not plan family time. On a printing press the reduction in SMED time enabled the business to take on a new client 3 months ahead of schedule.

3. Cost savings: Shorter setup times mean less idle time and lower labour costs. Additionally, increased productivity can result in cost savings through economies of scale. In one high end specialist printing company this enabled the changeover time to be shorter than the production run time which was a first for the business.

4. Improved quality: SMED emphasizes standardization and the use of quick-change mechanisms, reducing the likelihood of errors and defects during the setup process. Examples are using wing nuts rather than traditional nuts that need a wrench, or attaching rulers and coloured marks for setups to the machine rather than having to measure every time, or piping grease nipples outside of a machine to avoid removing covers, etc. Don’t think that you have to come up with all the ideas yourself. The team will be a fount of knowledge when they engage with SMED and see how it makes their life easier. When I engage the team in SMED events optimising setups and changeovers I am constantly surprised at their innovation and creativity. The time taken always pays dividends.

Summary

In summary, SMED and the spaghetti diagram process provide valuable tools and insights to optimize processes, minimize waste, and enhance profitability in manufacturing and other operational environments. A SMED exercise well executed with an engaged team can literally turn back time and in my experience has turned back the time previously taken for setups and changeovers by an hour or more in some cases; this creates business opportunity.

Once you have your setups and changeovers running like a Formula 1 pitstop then it is time for the implementation of Autonomous Maintenance, but that is for another article.

References:

- The Power of Single Minute Exchange of Dies (SMED) (maintenanceworld.com). Accessed 5 June 2023

- Use a Spaghetti Diagram to Capture Motion – American Lean Consulting. Accessed 5 June 2023

Dr Anthony Kenneson-Adams

Dr. Anthony Kenneson-Adams had a 30-year career in the Royal Air Force, becoming a Senior Engineering Officer, Project Manager and Engineering Authority responsible for multiple fast jets and large-body aircraft in peace and war operations. On retiring from the Royal Air Force, he became a Corporate Operational Excellence Consultant in the Paper Manufacturing and Packaging Industries and is now the Head of Learning and Knowledge Transfer for the international Project 7 Consultancy. You can contact Anthony at www.project7consultancy.com or [email protected]

Related Articles

OEE: Overall Equipment Effectiveness

Mechanical Quality Assurance: The Next Progression of Reliability

Tips for Maintenance Planning

Global Indicators for Maintenance, Availability Performance

Skimping on the Training Puts your CMMS Project at Risk

Elastopipe: Safety Pipe for Oil Rigs

RCM Success Starts with CMMS

Maintenance Software Implementation

Enhancing Overall Equipment Effectiveness Through TPM

Can You Really Justify Reliability Centered Maintenance (RCM)?

Safety Circuits, Force Guided Relays vs. General Purpose Relays

Design for Maintainability

Work Order Prioritization