6 Simple Tips for Lubrication Success

Mike Sondalini, PWW EAM System Consultant

Posted 2/1/2024

6 simple tips for lubrication success. Grease and oil are the key lubricants used throughout industry to reduce friction between metal parts. Lubricants can only reduce friction if their immediate environment sustains their lubricating properties. Once the operating conditions are known, a suitable lubricant with the right properties can be used. When the lubricant is in place it is necessary to maintain the environment and the machine to the specified design standards and protect it from changes to the design conditions. There are six key factors to address for trouble-free life where grease or oil lubrication is used on machinery.

How do you get Trouble-free Lubrication?

Only one of the trouble-free lubrication secrets is lubricant dependent! Amazingly the other five have to do with how well the bearing is treated and cared for.

1. Practice Contamination

The greatest destruction of lubrication is done through poor handling and storage practices. Hospital-quality cleanliness is the best protection against introduced contamination.

The storage room must be spotless. Transfer and drainage equipment must be as clean as restaurant knives and forks. The lubricant containers, lids and seal tops must be dinner plate finish. Keep the lubricant covered. Don’t place unused, excess lubricant back in a container – it is too late, it is already contaminated! Absolutely no dirty hands and dirty tools with clean lubricant or when touching bearings! Clean the lube point nipple on the machine spotless before inserting more clean lubricant. Unless the lubricant is clean and the bearing is spotless, the machine’s early destruction is certain.

If necessary, start your lubricant store over again. Get everyone together and explain the life-and-death requirements for clean oil and grease. Research and write lubricant storage and handling procedures, and then train everyone. Make your supervisors responsible for cleanliness of the store and the use of the procedures.

Only lubricant that is completely clean is allowed to go into bearings.

2. Moisture Contamination

The job of a lubricant is to keep metal surfaces apart. If the lube layer thins because of the presence of moisture, the surface roughness projections from the metal surfaces will smash together and rip each other to pieces. This will introduce solids contamination and make the lube film hot. The lube film becomes filled with solid metal particles, the heat thins it further and the metal shearing gets worse. The metal surfaces can even weld together from the heat caused by the friction.

Moisture must never be allowed into a bearing. Keep it clean and dry! Totally ban hosing down and compressed air blow down. Replace it with brush down and wipe cloths. To win people over to the change, trial it on the machine with the worst failure record after it has been overhauled. Record how long it lasts before the next bearing failure and compare it to the old failure history.

3. Wrong or Degraded Lubricant

The right lube viscosity at the operating temperature for the load and shaft speed is a must! Only clean lube with the correct specification for the bearing at operating conditions is acceptable. When the bearing lube deteriorates get rid of it and replace it or clean it up. Keep process chemicals out!

How do you know the lubricant’s condition, contaminants, and quality at any point in time? You don’t unless you sample it and test it for suitability to continue in service. If you are not sure whether it should continue in service, you are right! Get rid of it or clean it up. The cost of doing either is a lot less than a breakdown.

Shaft sealing is critical to success. Do everything necessary to keep moisture, process chemicals, dirt and dust from getting into the lubricant. Some options are to add more seals, change styles of seal, flush with grease using automatic dispensers, or put positive air pressure in the seal area.

4. Misalignment

Bearings and shafts are designed to run perfectly true to their axis. The first thing a designer does when designing a machine part is to draw the centerline of the shaft and bearings. Then she draws in the shaft and the bearings. In doing that she has assumed perfect alignment! P-E-R-F-E-C-T A-L-I-G-N-M-E-N-T! Unbelievable but true!

As soon as the alignment of shafts is not perfect, orbital motion occurs. Each shaft starts throwing its weight about against the other. The bearings get unexpected loads fluctuating at different positions. Instead of the load being carried in the load zone of the bearing where lubrication is present, the loads may occur at the top unlubricated part of the bearing. Or the hammering ruptures the film and squashes the lube out from the load zone. The thinner lubricating film then allows metal to metal contact.

5. Imbalance

This is a sister to misalignment. Rotating out-of-balance parts produces vibration. The vibration produces unplanned forces throughout the bearing. And like misalignment, the bearing experiences loads in unlubricated locations. The shaft begins to rattle and bounce about. In the case of roller bearings, the rollers are smashed into the raceways and start hammering the metal. The metal surfaces dimple and roughen (brinell) and failure happens soon after.

6. High Temperatures

Temperature rise causes lubricant viscosity to fall and lube films to thin. External sources may also cause temperature rise. Is the process radiating heat onto the bearing housing, or is there hot, direct sunshine on the bearing housing, preventing internally generated heat from dissipating (shedding) out of the bearing? Is the process heat being transferred down the shaft and into the bearing? Is the bearing housing covered in dust, dirt, rags or rubbish so the heat cannot escape? Does it need an extra flow of cooling air to remove the heat? If oil lubrication is used should an oil cooler be installed? Does the housing need more surface area for radiation and convection cooling?

Keep the lubricant cooled to the temperature of the required viscosity.

Do all these six things right and you won’t have problems due to poor lubrication. It will need constant vigilance, but the pay-off is long-lived plant operating with few problems. We hope these 6 tips for lubrication success will be helpful.

References for 6 simple tips for lubrication success:

Dingo-Noria Oil Analysis Training Seminar Notes 2001 – Fundamentals of machine and lubrication degradation.

Machine Design Theory and Practice, A D Deutschman, W J Michels, C E Wilson, Macmillan Publishing.

Mike Sondalini

Mike Sondalini is a Senior Consultant at PWWEAM System-of-Reliability. BEng(Hons), MBA, CPEng. As a consultant and trainer, Mike was able to present his insights to his clients, suggesting innovative approaches to plant and equipment reliability. Their feedback was resoundingly positive. Efforts which earned him an international reputation for articulate, out-of-the-box articles on plant and equipment reliability, life-cycle EAM, maintenance management, work quality assurance, and team building. After decades of dedicated research, Mike authored “Industrial Manufacturing Wellness: The Complete Guide to Successful Enterprise Asset Management” a revolutionary approach on how maintenance and physical asset management systems should be run, the book detailed who, what, where, when, why, and how outstanding reliability could be achieved. Each step based in scientific and mathematical understanding to ensure repeatability of results and optimal outcomes.

Related Articles

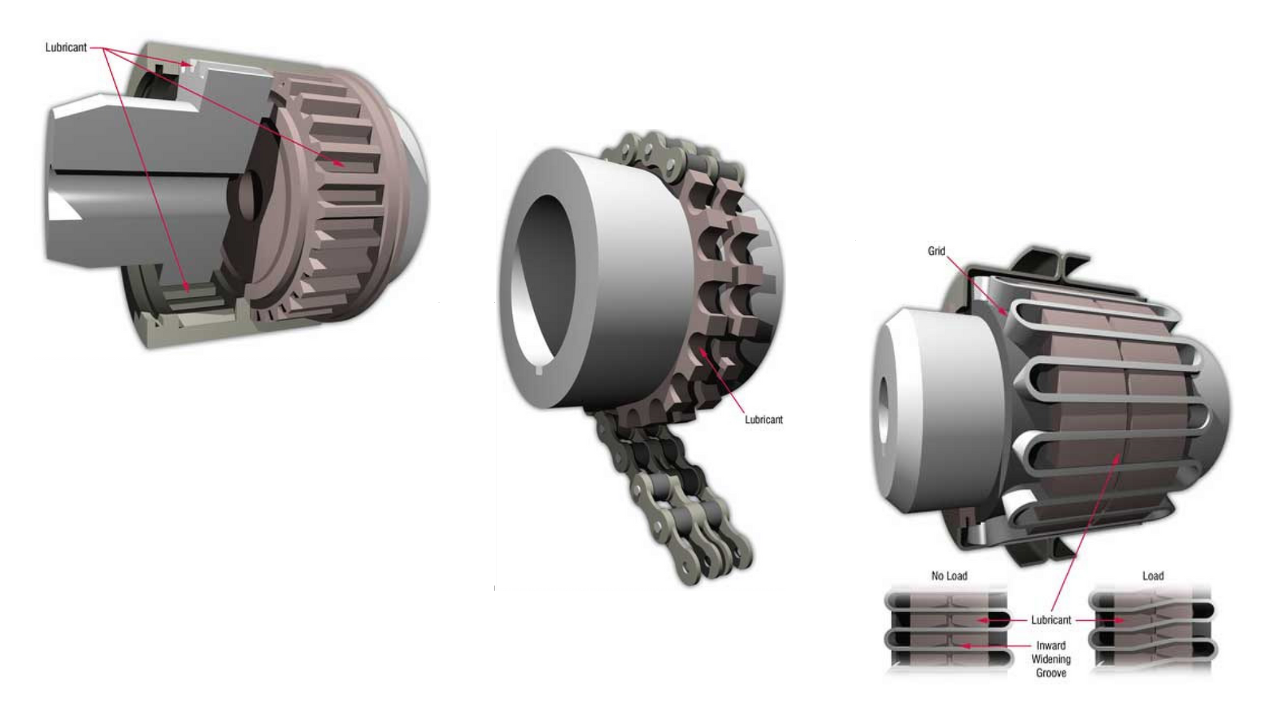

The Lubrication Requirements of Couplings

Arc Flash/Arc Blast Review with Safety Suggestions for Design & Maintenance

Electrical Hazards

Eliminating Conveyor Concerns

Fluid Power Safety Alert

Hydraulic Systems Safety

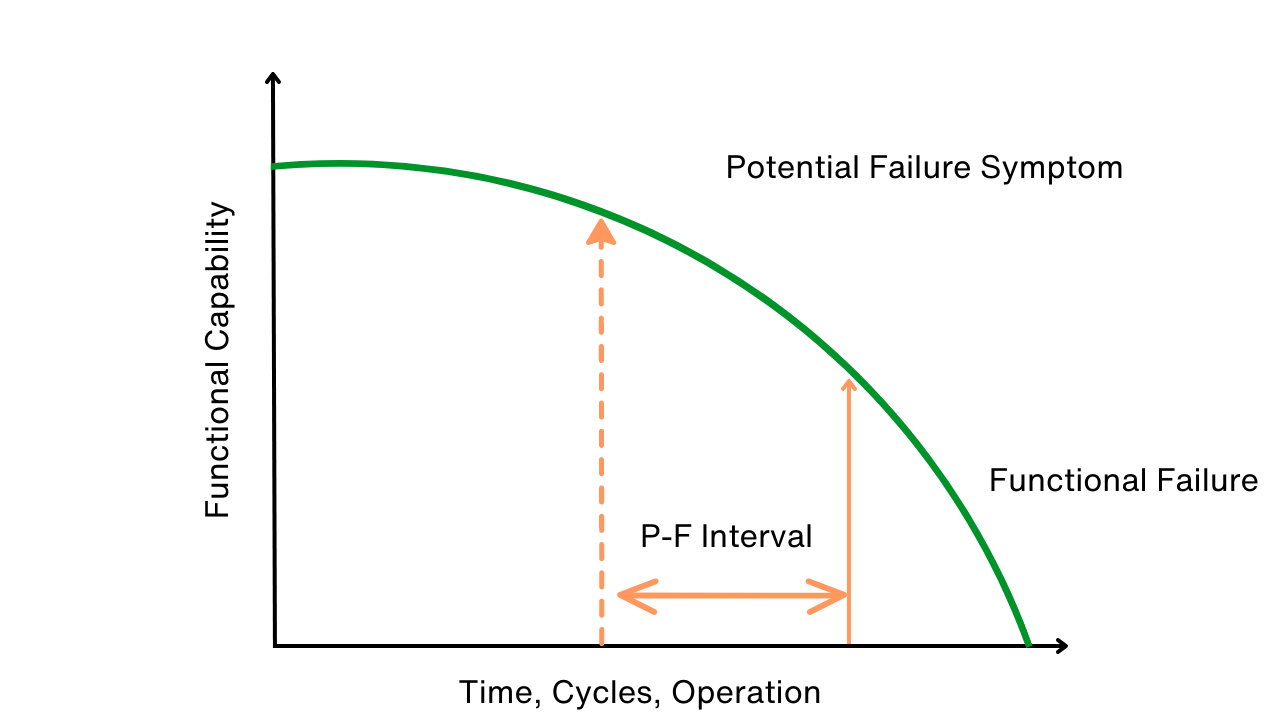

Use P-F Intervals to Map, Avert Failures

OEE: Overall Equipment Effectiveness

Tips for Maintenance Planning