Safety First: Preventing Lead Contamination in Food and Beverage Manufacturing

Elizabeth Ruiz

Posted 11/15/23

Recent incidents such as lead found in Hershey’s chocolate products and WanaBana applesauce pouches are shining the light on lead contamination in the food and beverage industry.

According to Food Dive, Consumer Reports found “concerning” amounts of heavy metals, including lead, in 16 out of 48 Hershey chocolate products that were tested. AP News reports that illness was reported for at least 22 toddlers in 14 states due to lead in packages of WanaBana cinnamon apple puree and applesauce.

What are the risks that lead exposure (and other heavy metals) pose to people who consume the products – and to those in the manufacturing facilities who make the products? What can be done at a facility level to promote safety for maintenance crews?

Dangers of Lead Contamination in Food and Beverage Manufacturing

The Food and Drug Administration warns that as lead is toxic, it is dangerous for people of any age and level of health. It often gets into food products through soil, air, water, or industrial processes. Other common sources of exposure are house dust and consumer products (American Academy of Pediatrics). OSHA has assessed that adults are mainly exposed to lead by breathing in lead-containing dust and fumes at work or from hobbies that involve lead.

Effects of exposure due to lead contamination in food and beverage manufacturing:

- Lead exposure can lead to serious learning, developmental, and behavioral problems in children and fetuses.

- Consistent/long-term exposure to heavy metals has been linked to health problems including nervous system and immune system problems, hypertension, kidney damage, reproductive, and neurocognitive issues.

- The long-term damage from consuming lead varies depending on the level in the food or water, length of time of exposure, the person’s age, and other simultaneous exposures.

(List information courtesy AP News, Food Dive, OSHA, and the FDA)

Lead Safety Tips for Plant Personnel

Now that we know the damage lead contamination in food and beverage manufacturing can cause, what are some things your organization can do to protect personnel?

The National Institute for Occupational Safety and Health (NIOSH)/Centers for Disease Control and Prevention has provided detailed instructions on how to protect your maintenance crew from lead exposure.

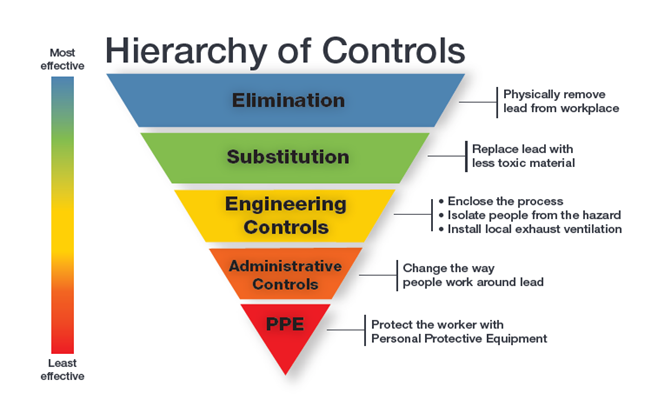

When opening a facility, the organization and qualified safety professionals should inspect the work area and determine if tasks performed expose the personnel to lead. If lead is present, use the hierarchy of controls (pictured below) to decide on the best way to protect the crew.

Elimination: Remove lead-containing materials or equipment from the process if possible.

Substitution: Replace the lead source with a less toxic material or a material with lower lead content.

Engineering Controls: Make sure that areas and equipment are designed to protect personnel from lead.

Administrative Controls: These are ways to modify the way people work to promote safety.

- Establish SOPs for tasks that put workers at risk of lead exposure.

- Strict cleaning procedures to minimize lead dust contaminating air and surfaces. This can include using HEPA vacuums and wet sweeping methods (no dry).

- Ensure that personnel are thoroughly trained on hazards and safe work practices with lead.

- Follow good hygiene such as using lead removal products, washing hands, showering, and avoid taking contaminated clothing home (protecting families). Use both types of NIOSH wipes – one to test for and one to remove 90% of lead residue from skin.

Personal Protective Equipment (PPE): Provide PPE to personnel. This includes eye protection, gloves, boots, coveralls, and respiratory protection. Make sure personnel know how to properly dispose of contaminated PPE.

Tips on How to Protect Equipment/Product from Lead Contamination

Preventing lead contamination in food and beverage manufacturing is essential for public safety. What are some things you can do in your organization to reduce the dangers and health concerns caused by heavy metals in food products?

- Consistently test of product to make sure levels are not exceeded.

- Avoid using food sources grown in geographical areas with higher levels of lead.

- Be aware of and make sure you are following FDA recommended levels for heavy metal exposure in food and beverage.

- Use proper cleaning practices for equipment and areas – read these recommendations from the NC Department of Environment and Natural Resources

Conclusion – Preventing Lead Contamination in the Food and Beverage Industry

In conclusion, the recent instances of lead contamination in popular food and beverage products highlight the pressing need for comprehensive safety measures in manufacturing facilities. The documented risks associated with lead exposure underscore the urgency of addressing this issue systematically.

Organizations must adhere to guidelines outlined by regulatory bodies and safety experts, employing strategies such as elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE). By implementing thorough inspection protocols during facility setup, enforcing strict operating procedures, and providing comprehensive training to personnel, manufacturers can significantly mitigate the risk of lead exposure for both workers and consumers.

Additionally, safeguarding product integrity through regular testing, avoiding high-risk sourcing regions, and adhering to FDA-recommended thresholds is crucial. Ultimately, prioritizing safety in the food and beverage industry is imperative for maintaining public trust and ensuring the well-being of everyone involved in the process.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you by the Maintenance World Crew.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill