Common Mechanisms of Failure & Preventive Methods

Ray Garvey, Reliability Consultant, CRL, CLS, Spectro Scientific, AMETEK

Posted 01/31/2023

Why do components fail? – This article explains common failure mechanisms, component types to which each applies, and suggests non-intrusive monitoring techniques to discover components in various stages of progressive failure.

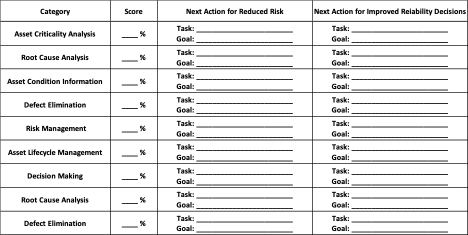

What can we do to prevent it? – This article recommends periodic reliability assessments for continuous improvement in line with organizational objectives. The initial or baseline assessment compares asset reliability with standard practice from an industry body of knowledge (BOK) and identifies near and long term areas for continuous improvement. Each assessment considers asset criticality analysis, root cause analysis, asset condition information, defect elimination, risk management, asset lifecycle management, and organizational decision making.

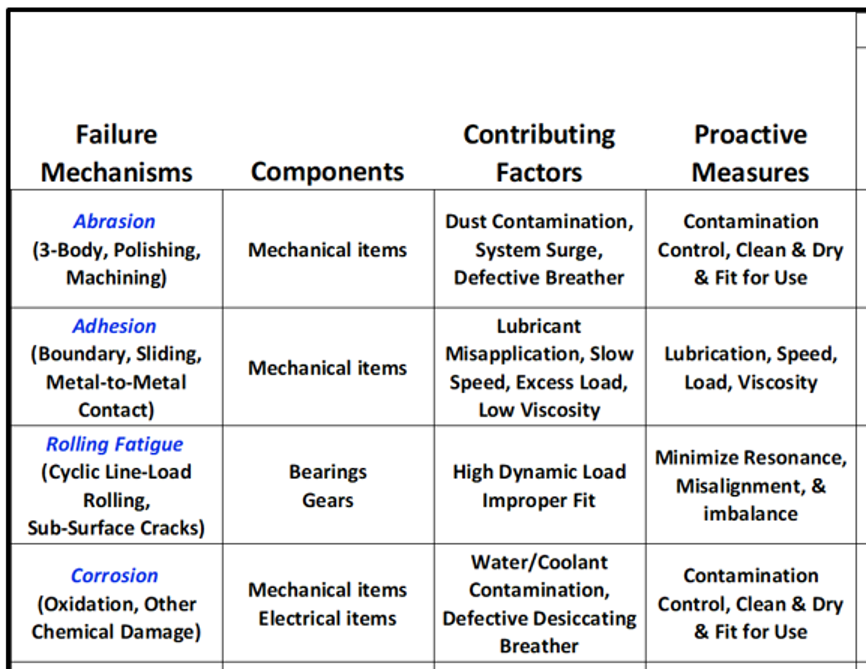

Common proactive measures intended to exclude root causes from initiating failure mechanisms included in continuous improvement activities often include contamination control, misapplication elimination, and defect elimination.

Each periodic assessment concludes with a short list of aligned priority task assignments for completion during the next assessment interval.

Periodic Assessments of Lubrication and Oil Analysis

Periodic reliability assessments provide key milestones for continuous improvement of reliability. The initial assessment establishes both a baseline and a gap. The baseline is intentional comparison of actual with a desired or best practice level to achieve organizational objectives. Organizational objectives provide focus and aim for allocation of limited resources during each interval between periodic assessments. Example organizational goals for reliability:

- Improved risk management with less reactive maintenance

- Improved decision making with better communication

- Improved reliability program including baseline assessment, goal, gap, improvement opportunities.

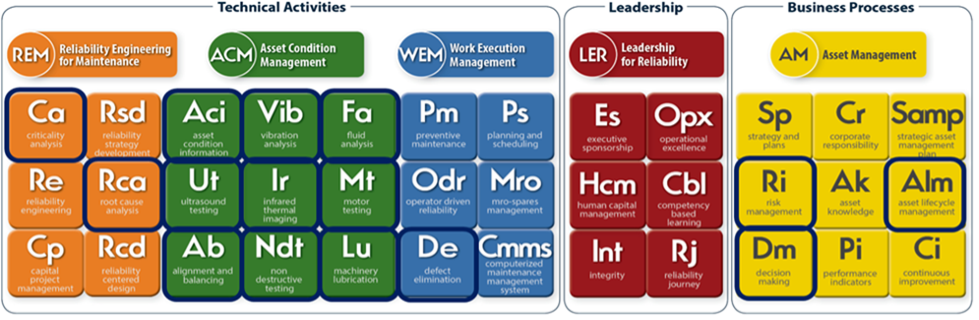

Excellent reliable industrial manufacturing requires alignment of effort. The 36-element framework diagram in Figure 1 is used by Certified Reliability Leaders (CRL) to represent functions that must work collectively in an industrial plant or mill to achieve reliability. Some or all of the blue outlined elements in Figure 1, for example, may be evaluated during periodic reliability assessments.

Each periodic assessment should follow consistent evaluation criteria based on industry body of knowledge (BOK) comprising the following published reference materials:

- Introduction to Nondestructive Testing, The American Society for Nondestructive Testing:

- Audit it. Improve it!, Reliabilityweb.com, 2015

- “Best Practices in Bulk Lubricant Storage and Handling”, Machinery Lubrication July 1999,

- “Identifying Root Causes of Failure with Condition Monitoring”, Machinery Lubrication Magazine, December 2012,

- ISO 14224

- ISO 55000

- Uptime® Elements Body of Knowledge, Reliabilityweb.com, 2019

- “Why Equipment Fails and What You Can Do to Prevent It”, Machinery Lubrication, Dec 2019.

Each reliability assessment is structured to identify common failure mechanisms, root causes, contributing factors, and proactive measures. The above BOK references are selected in support of improved reliability through failure mechanism, root cause, and defect elimination.

Based on the organizational objectives, a periodic reliability assessment will comprise evaluating asset criticality analysis, root cause analysis, asset condition information, defect elimination, risk management, asset lifecycle management, and organizational decision making consistently using a prescribed list of assessment questions based on the relevant BOK. A complete assessment including all categories is likely to cover many dozens of assessment questions and BOK references. Table 1 shows a structure for consistent assessment questions and associated BOK references.

The following table lists 58 questions and relevant Body of Knowledge references for assessing effectiveness and measuring progress and improvement with industrial lubrication and fluid analysis programs.

| Lubrication and Oil Analysis Assessment Questions | Body of Knowledge References for Assessment Questions | |

| Q1 | Is the process for designating critical assets documented, is it being practiced? | ISO 14224 does failure consequences block diagrAsset Management and Table 1, Reliability Engineering for Maintenance domain, Criticality Analysis element, pg. 10; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q2 | Does the organization have asset decision making strategies/process in place that take into account expected life, age, condition, etc.? | See Asset Management decision-making approach, Asset Management domain Decision Making element, pg.137. |

| Q3 | Are likely failure mechanisms for critical assets understood? | Reliability Engineering for Maintenance domain, Reliability Strategy Development element, Principles, pages 27-43. Identify failure modes that can defeat functions. |

| Q4 | Are likely root causes of failure for critical assets understood? | Reliability Engineering for Maintenance domain, Reliability Strategy Development element, Fig 4, page 41; and Root Cause Analysis element, page 71. Identify root causes of faults or failures that cause failure events. |

| Q5 | Is someone in the organization a root cause analysis champion who tracks recurring faults for defect elimination? | Work Execution Management domain, Defect Elimination element, pg. 87, notice defects when they are very small and remove them before they generate other defects or cause failure events. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q6 | Is abrasion (or other cutting wear typically due to particulate contamination) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q7 | Is adhesion (or other boundary or sliding wear typically due to inadequate lubricaiton) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q8 | Is fatigue (or other rolling contact deterioration of bearings and gears due to cyclic loading) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q9 | Is corrosion (or other chemical deterioration of typically due to moisture or other corrosive fluid contamination) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. |

| Q10 | Is cavitation (or other repetitive void formation and sudden collapse typically associated with impellers, pumps, pipes, and valves) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q11 | Is electrical discharge (electrical arc or spark mechanism typically associated with electric powered or static charged components) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q12 | Is deposition (a an accumulation of substances on a surface typically due to precipatate, varnish, eletrostatic attraction, or mechanical attachment) detected with condition monitoring and is defect elimination effective? | “Why Equipment Fails and What You Can Do About It”, Machinery Lubrication, Nov-Dec 2019. Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 21 & 24, focus on condition directed (CD) and fault finding (FF) tasks for efficient and effective maintenance. |

| Q13 | For lubrication program, are there documented practices to capture, store, manage & update relevant asset information? | Asset Condition Management domain, Asset Condition Information element, pg. 6, automating the consolidation and analysis of data collected; Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation.; and Audit it. Improve it! Pages 79-142. |

| Q14 | For lubrication program, have all of these distractions to success been eliminated: A) not clear goals, B) lack KPI or financial metrics, C) not well structured, D) lack skill, E) lack motivation, F) inadequate tools, G) stagnant, H) lack accountability. | Asset Management domain, all elements, and ISO 55000, aligned objectives, transparent and consistent decision making, long term strageic view, and risk-based decision-making from a position of knowledge. Audit it. Improve it! Pages 7-14. |

| Q15 | Alarm – for lubrication technology are alarm structures, thresholds, and types appropriate for the assets? | Asset Condition Management domain, Vib element, pages 36 to 42, alarm types; and Audit it. Improve it! Pages 105-133. |

| Q16 | Alarm – for lubrication programs are parameter alarms are used for detecting specific failure modes? | Asset Condition Management domain, Vib element, pages 36 to 42, alarm types; and Audit it. Improve it! Pages 112-121. See “Simple Alarms” page 112. |

| Q17 | Alarm – for lubrication program are visual alarms or baselines presented with each condition measurement? | Asset Condition Management domain, Vib element, pages 36 to 42, alarm types; and Audit it. Improve it! Pages 115-121. |

| Q18 | Alarm – for lubrication program do analysts have confidence in software alarm limits (e.g., software alarms are maintained, relevant and NOT ignored)? | Asset Condition Management domain, Vib element, pages 36 to 42, alarm types; and Audit it. Improve it! Pages 115-121. |

| Q19 | For lubrication program are there periodic assessments and is the program improving? | Asset Management domain, Ci element, pg. 167. |

| Q20 | For lubrication program is there a procedure for statistical assessment of results including faults detected, types of faults, severity levels, many WO were created, and which faults were not addressed? | Asset Management domain, Ci element, pg. 181, measure performance, audit, management review for improvement; and Audit it. Improve it! page 155, improve it. |

| Q21 | For lubrication program, are assets grouped (e.g., “alarm limit sets” or other statistical populations) into sets of similar equipment operating under similar conditions may be easily compared with each other? | Audit it. Improve it! Pages 112-121. ASTM D7720 Standard GuiDefect Elimination for Statistically Evaluating Measurand Alarm Limits when Using Oil Analysis to Monitor Equipment and Oil for Fitness and Contamination. |

| Q22 | For lubrication program are data collection and analysis cost effective (e.g., reasonable cost considerations, excellent ROI, cost effective data collection, cost effective analysis)? | Audit it. Improve it! Pages 40-44, quantify the problem in financial terms; and page 63, are roles divided to make progrAsset Management more cost-effective. |

| Q23 | For lubrication program, does the organization use findings make value driven decisions (give examples)? | Asset Management domain, all elements, and ISO 55000, aligned objectives, transparent and consistent decision making, long term strageic view, and risk-based decision-making from a position of knowledge; and Asset Management domain, Defect Elimination element, pages 129-142. |

| Q24 | For lubrication program data is consistent, repeatable and effective to detect and measure typical failure mechanisms and root causes for each measurement location | Asset Condition Management domain, Asset Condition Information element, pg. 21, Data Quality. |

| Q25 | For lubrication program are appropriate types of data being collected to detect fault and root cause and root cause indications from more than one sensory perspective? | Asset Condition Management domain, Asset Condition Information element, pg. 6; and Vib, Fa, Ut, Mt, Ab, Ndt elements. |

| Q26 | For lubrication program are numbers, types, and configurations of measurements sufficient to detect applicable failure mechanisms and root causes? | Reliability Engineering for Maintenance domain, Reliability Strategy Development and Root Cause Analysis elements. |

| Q27 | For lubrication and analysis program, are there documented practices to capture, store, manage, analyze and use condition data information from lubrication program to make value driven decisions (provide examples)? | Asset Condition Management domain, Aci, Vib, Fa, Ut, Mt, Ab, Ndt elements. |

| Q28 | For lubrication and analysis program, are goals stated, realistic, attainable, clearly understood? | Asset Management domain, all elements, and ISO 55000, aligned objectives, transparent and consistent decision making, long term strageic view, and risk-based decision-making from a position of knowledge. |

| Q29 | For lubrication program are case history records created, stored, and accessible? | Asset Condition Management domain, Asset Condition Information element, page18, historic asset condition; and Audit it. Improve it! pages 147-152, after the repair. |

| Q30 | For lubrication technology, are the WO creation, execution, and closure processes documented, effective, easy, and is it working like it should? | Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation; Work Execution Management domain, Ps element, page 19 planning process and pages 25-28, schedule flows. |

| Q31 | For lubrication program are data collection intervals adjusted as needed to achieve intended results? | Asset Condition Management domain, Asset Condition Information element, page 5 determining when to monitor – the frequency of monitoring any condition should be determined; Asset Management domain, Decision Making eleiment, page 134, risk-based decision-making; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pages 27-32, reliability-centered maintenance principles and standards, Principle 2 identify failure modes and Principle 3 prioritize. |

| Q32 | For lubrication program is there adequate manpower and time committed? | Leadership for Reliability domain, Hcm element, page 35, ensure the right people with the right compentencies are available to deliver value from the assets; and Audit it. Improve it! page 63, is there adequate manpower. |

| Q33 | For lubrication program are sample/test point and collection methods following documented best practices? | Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation; and Audit it. Improve it! pages 99-133. |

| Q34 | For lubrication program, are there any online measurements, and if so, are they effective? | Asset Condition Management domain, Asset Condition Information element, page 5, determining when to monitor – the frequency of monitoring any condition should be determined; and page 10, on-line data. |

| Q35 | For lubrication and analysis program, is the organization prepared for an absence of any key individual? | Leadership for Reliability domain, Hcm element, page 38, succession planning; and ; and Audit it. Improve it! page 64, is the progrAsset Management dependent on one particular person. |

| Q36 | For lubrication program, are reports effective (format, severity designation, data presentation, etc.) and relevant to the WO creation process? | Work Execution Management domain, PS element, pages 25-28, schedule flows; and Audit it. Improve it! pages 135-142, report generation. |

| Q37 | For lubrication program, is there a report review process? | Audit it. Improve it! Chapter 17, follow-up and review – reports, work orders, and as-found condition results should be documented in a searchable way to detrmine how many reports were correct based on as-found conditions. |

| Q38 | For lubrication program, are the reports used and understood by the people receiving them? | Audit it. Improve it! page 142, do the people receiving the reports value them and use them? |

| Q39 | For lubrication and analysis program, is there clearly “profitable” ROI or similar measure? | Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40 cost reduction and pg. 41 efficiency and productivity. |

| Q40 | For lubrication program, does the organization calculate and communicate ROI, savings, and/or cost avoidance based on findings? | Audit it. Improve it! Pages 40-44, quantify the problem in financial terms. |

| Q41 | For lubrication program are there safety issues with any of the test points or data collection procedures, or with other activities or tasks? | Asset Management domain, Asset Condition Information element, page 27, safety considerations – ensuring the risks in data collection are managed; and Audit it. Improve it! page 94, safety and accessibility. |

| Q42 | For lubrication program, are scorecards being used; and if so, are they effective? | Asset Management domain, Pi element, page 155, The balanced scorecard is a framework that aligns an organization’s strategy at a level above the KPIs. It pulls together the measures of the organization from four perspectives (financial, internal business process, customer, and learning and growth) and allows monitoring performance. |

| Q43 | For lubrication program is (are) the sensor(s) correct and are mounts, attachments, or other sensory engagements following best practices? | Audit it. Improve it! page 91, sensors and sensor mounting. |

| Q44 | For lubrication program is there an accurate test guide for the machine, measurement point, identification, and measurement method? | Audit it. Improve it! pages 79-89, does the test guiDefect Elimination contain all the information a person would need to verify correct machine, locate test points, take measurements, verify configuration, understand machine components? |

| Q45 | For lubrication program are tools appropriately matched, considering data collection, software, database, analyses, etc.? | Asset Management domain, Asset Condition Information element page 4, what to monitor with what method, when to monitor, how to automate the consolidation and analysis of data collected to make timely and accurate decisions. |

| Q46 | For lubrication program are personnel trained and certified in at least minimum skill level for data collection and analysis? | Leadership for Reliability domain, Hcm element, page 42, align skills with organizational needs. |

| Q47 | For lubrication program, are training and certification opportunities offered on regular basis? | Leadership for Reliability domain, Hcm element, page 42, align skills with organizational needs. |

| Q48 | Contamination control – are housekeeping practices documented and used for contamination control: clean, dry, fit for use? | Asset Condition Management domain, Fa and Machinery Lubrication elements; Best Practices in Bulk Lubricant Storage and Handling, Machinery Lubrication, July 1999; and Why Equipment Fails and What You Can Do About It, Machinery Lubrication, Nov-Dec 2019. |

| Q49 | Condition based changes – does fluid analysis enable condition based fluid changes; if so, is it functioning well? | Asset Condition Management domain, Fa element, page 53, lubricant suitability for continued use. |

| Q50 | Contamination control – does the documented lubrication program specify best practices for contamination control? | Asset Condition Management domain, Machinery Lubrication element; and Why Equipment Fails and What You Can Do About It, Machinery Lubrication, Nov-Dec 2019. |

| Q51 | Contamination control – are best practices, including desiccating air breathers, used for most oil compartments and storage tanks? | Asset Condition Management domain, Machinery Lubrication element; and Why Equipment Fails and What You Can Do About It, Machinery Lubrication, Nov-Dec 2019. |

| Q52 | Contamination control – Are bulk oil suppliers required to pass on-site acceptance tests before delivery including: viscosity, moisture, neutralization number, and particle count? | Asset Condition Management domain, Fa and Machinery Lubrication elements; Best Practices in Bulk Lubricant Storage and Handling, Machinery Lubrication, July 1999; and Why Equipment Fails and What You Can Do About It, Machinery Lubrication, Nov-Dec 2019. |

| Q53 | Misapplication control – does lubrication program specify and use best practice grease and oil lubricant selection? | Asset Condition Management domain, Machinery Lubrication element; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q54 | Misapplication control – does lubrication program specify and use best practice grease lubricant application methods for all grease types? | Asset Condition Management domain, Machinery Lubrication element; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q55 | Misapplication control – does lubrication program specify and use best practice oil lubricant application methods for all oil types? | Asset Condition Management domain, Machinery Lubrication element; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q56 | Misapplication control – are all of the following tagged and configured to avoid misapplication: sample ports, apparatus, transfer containers, compartments, and storage containers? | Asset Condition Management domain, Machinery Lubrication element; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q57 | Misapplication control – does lubrication program specify and use best practice grease lubricant transfer and storage options? | Asset Condition Management domain, Machinery Lubrication element; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

| Q58 | Sampling – does the documented lubrication program specify and use best practices for lubricant sampling and inspection options? | Asset Condition Management domain, Fa and Machinery Lubrication elements; and Reliability Engineering for Maintenance domain, Reliability Strategy Development element, pg. 40, documentation. |

Assessment findings and follow on actions to achieve continuous improvement documented as shown in Table 2. For this example, organizational objectives are: 1) risk reduction and 2) improved decision making. Note that the category, Asset Condition Information, is typically divided into several parts including vibration analysis, alignment and balance, fluid analysis, lubrication, infrared thermal imaging, and nondestructive testing, for example.

The interval between periodic assessments is used to accomplish continuous improvement. A short list of three to five priority categories with three to five tasks and assigned responsibilities focuses teams on organizational aim and alignment. For example, lubrication and fluid analysis categories for an interval between periodic assessments might include:

- Machinery lubrication with tasks pertaining to contamination control and misapplication elimination.

- Oil analysis with tasks pertaining to measuring ferrous density, particle counting including particle shape classification, and water contamination.

Failure Mechanisms

Abrasion, corrosion, fatigue, and adhesion, cavitation, erosion, electrical discharge and deposition are common failure mechanism from the referenced literature. Characteristics of these failure mechanisms are stated below and listed in the first column of Tables 3 and 4.

Abrasion

Abrasion affects nearly all mechanical systems. It begins when silica dust particles are transported by the lubricant to a narrow clearance between moving surfaces. Hard particles that are too large to pass through embed into one surface and cut the other. The shear force between the lubricated hard particles and the moving surface cut a V-notch into the moving metal surface.

This cutting process emits a spectrum of mechanical vibration from the point of abrasion and generates abrasive wear debris which is carried away by the lubricant. This mechanism generally is not self-propagating and is easily offset by contamination control. It can be triggered by a surge in the circulating system or by a defective breather.

Corrosion

Corrosion impacts almost all electrical and mechanical systems and is synergistic with all other failure mechanisms. It occurs when a corrosive substance attacks metal and changes the surface from being strong, thermally and electrically conductive metal into soft, electrically and thermally resistive oxide.

The resulting oxide is easily rubbed off by shear, which exposes fresh metal for sustaining oxidation. This mild rubbing emits stress waves and spreads soft metal oxides into the lubricant, exposing metal to the oxidation process. This mechanism may be prevented by moisture contamination control. It can be triggered by process contamination, a coolant leak or defective desiccant breather.

Fatigue

Fatigue affects mechanical systems with loaded bearings and gears. Roller bearings and gears often fail due to the process of rolling contact, which eventually leads to material fatigue cracks and spalling. Compression between the rollers and races and between gear teeth produces subsurface Hertzian contact shear that eventually work-hardens the metal until microcracks form, grow, interconnect and then release metal debris.

This generates stress waves from the impacts and releases debris into the lubricant. Fatigue can be offset by minimizing dynamic loading from imbalance, misalignment and resonance, as well as by static load reduction and other maintenance practices. It can be triggered by an improper fit or thermal growth. Cavitation can also cause cyclic subsurface shear resulting in material fatigue cracks and spalling.

Adhesion (or boundary wear)

Adhesion impacts nearly all mechanical systems with loaded components. Adhesive wear and other boundary wear damage is progressive and self-propagating while also accelerating corrosion. Metal-to-metal contact occurs when the lubricant film designed to eliminate friction and separate a roller from a race or a journal from a shaft fails due to inadequate lubrication. The increase in friction and shear causes mixed and boundary lubrication regimes.

The contact emits stress waves. Compression with mixed and boundary lubrication leads to shear and friction, which results in intense heating, melting and discoloration. Metal debris and oxides are released into the lubricant, and a spectrum of vibration is emitted. This mechanism can be prevented by maintaining the proper lubricant at the correct level and by operating at the designed speed and load. It may be triggered by a slow speed, high load, low viscosity or inadequate lubricant delivery.

Example Mechanism/Cause Condition Monitoring Techniques

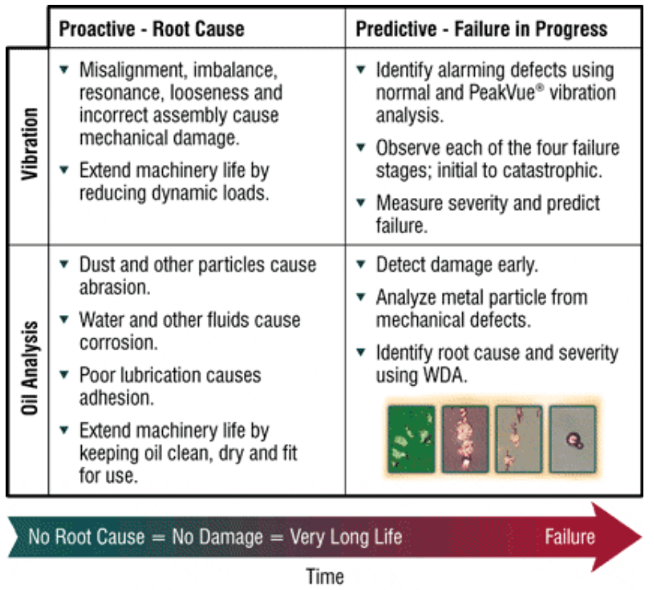

Proactive and Predictive Condition monitoring

It is best to use a plurality of condition monitoring techniques when practical to assess a fault condition. The following diagram from Machinery Lubrication, March 2003 article, “How Machinery Wear Rates Impact Maintenance Priorities”, demonstrates how oil analysis and vibration analysis are complementary proactively finding root cause issues and predictively finding failure mechanisms in progress.

Elemental Spectroscopy

X-ray fluorescence (XRF) elemental spectroscopy of filter patch specimens is preferred for large particle failure mechanisms including abrasion, fatigue and severe adhesion. Optical emission spectroscopy and XRF are both suitable for corrosion and mild adhesion mechanisms.

Particle Count and Shape Classification

Particle counts greater than 4, 6 and 14 microns enable condition monitoring for contamination control. Direct-imaging automatic particle shape classification or microscopic wear particle analysis can help distinguish the failure mechanism.[iv]

Inspect and Special Test

Electrical discharges in oil-filled compartments may benefit from dissolved gas analysis (DGA) looking for evidence of turn-to-turn arcing. Deposition and accumulation of matter on flow controls, filters, screens, valves, fans and oil compartments are failure mechanisms resulting from a variety of operational conditions. The inspection and testing protocol will depend on these factors. For example, membrane patch colorimetry (MPC) is a preferred testing technique to identify varnish precursors.

Total Ferrous

A magnetometer is preferred for determining the total ferrous concentration of all ferrous oxide and ferrous metal particles from the molecular to abrasive wear particle size ranges. This tool is useful for quantifying wear and severity for ferrous debris in lubricating fluids.

Viscosity

Lubricant misapplication, e.g., wrong oil, is frequently identified by verifying the correct viscosity for in-service lubricants. This directly relates to monitoring for inadequate lubrication associated with adhesion.

Water, Coolant, and Neutralization Number

A convenient onsite method for monitoring water, coolant and the acid or base number is transmission infrared spectroscopy of the in-service lubricant. Laboratory titration methods such as Karl Fischer are also effective. Water, coolant and acid are all related to corrosive wear mechanisms.

Tension, Compression and Shear

“Nothing – well almost nothing – fails in compression,” said John Googin, chief scientist for the Department of Energy’s Y-12 National Security Complex, when asked about failure mechanisms. Googin suggested that at times when he thought compression was a primary cause of failure, a closer study of the evidence would reveal either a tensile or shear mechanism was initiating the progressive failure sequence.[v] Three decades later, I still have not found an exception to this statement. I also have discovered that shear force is nearly always a contributing factor from incipient to catastrophic failure mechanisms.

Lubricated load-bearing surfaces allow machines to work by way of compression through a lubrication film. Mechanical systems are designed to have a long life and perform work through applied tension and compression. The intended long life can be cut short by shear. Failure mechanisms of abrasion, corrosion, fatigue, adhesion, cavitation, erosion and electrical discharge each have a common failure element of shear.

Conclusion

This article attempts to describe how equipment fails and what may be done to improve overall reliability. The article identifies common mechanisms of failure: abrasion, corrosion, fatigue, adhesion, erosion, cavitation, electrical discharge, and deposition. Each mechanism has contributing factors, proactive measures, and affects various kinds of equipment. Several preferred non-intrusive monitoring techniques are identified to enable proactive and preventive efforts for improved reliability. Periodic reliability assessments based on industry standard criteria may be used reduce risk, improve decision making, eliminate defects, and achieve continuous improvement.

References

[i] A Reliability Framework for Asset Management System™ and Uptime® Elements™ trademarks of Reliabilityweb.com and the graphic image in Figure 1 is copyright of Reliabilityweb.com.

[ii] “Why Equipment Fails and What You Can Do to Prevent It“, Ray Garvey, Machinery Lubrication Magazine, December 2019

[iii] “How Machinery Wear Rates Impact Maintenance Priorities”, Ray Garvey, Machinery Lubrication, March 2003

[iv] “Converting Tribology Based Condition Monitoring into Measurable Maintenance Results”, by Ray Garvey and Grahame Fogel, Computational Systems Inc., 1998

[v] “Composite Hull for Full-Ocean Depth”, R. E. Garvey, Marine Technology Journal, Volume 24, Number 2, June 1990

Ray Garvey

Ray Garvey is an engineer and inventor named on more than 20 U.S. patents associated with oil analyzers, infrared thermography, machine monitoring, and composite structures. Ray has been an employee of Emerson Process Management for 22 years, and is known for his participation in the development of Emerson’s CSI 5100 and CSI 5200 Minilab analyzers. Ray received his BS degree from West Point and MS degree from the University of Tennessee. His professional certifications include Professional Engineer (PE), Certified Lubrication Specialist (CLS), and U.S. Army Engineer ( Lt. Col. retired). Ray worked for the U.S. Army Corps of Engineers (five years active, 20 years reserve), U.S. DOE Uranium Gas Centrifuge Program (11 years), and is currently employed with Emerson Process Management.

Related Articles

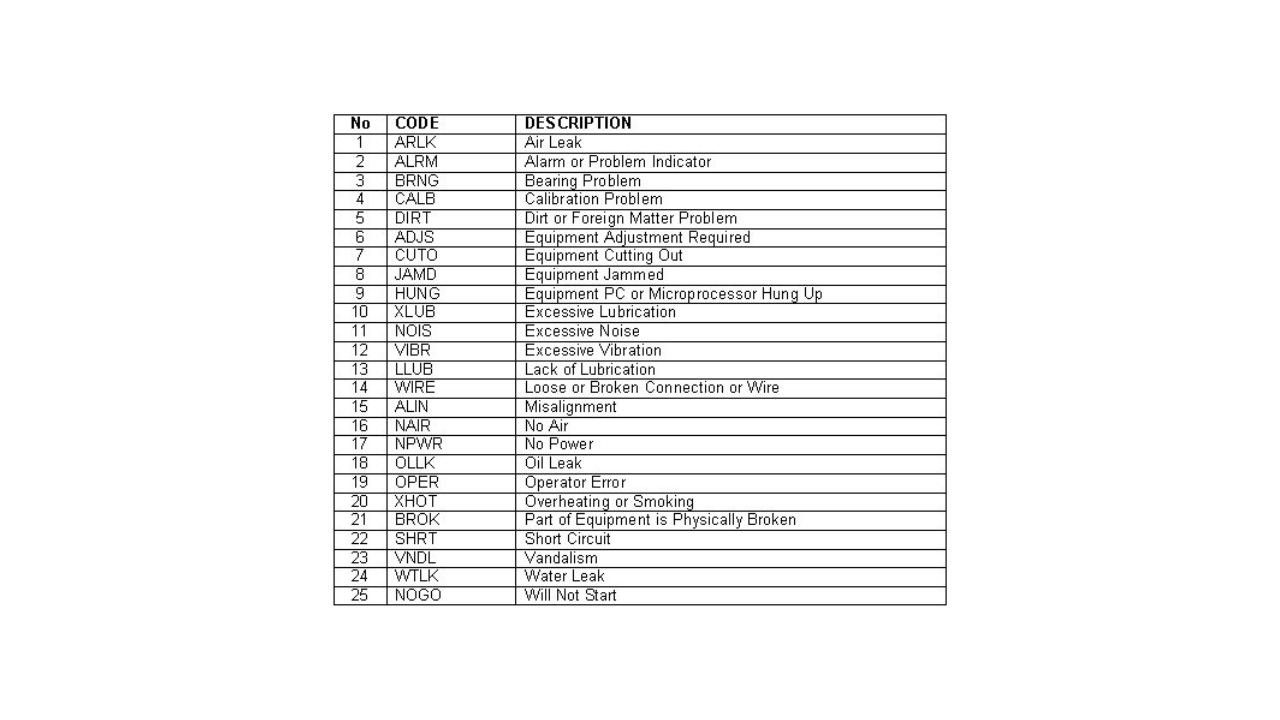

Failure Codes in Maintenance Systems - CMMS

Are We Willing to Hear What “Failure” Has to Say?

Reduced Wear and Failure of Machine Components: Failure Analysis of Mechanical Components

Fatigue Failure 101

RCFA: How to Select the "RIGHT" Root Cause Failure Analysis

The Latent Causes of Industrial Failure