Communications: The OEM Partnership

mt-online.com

When maintenance is allowed to interact with the plant and production Original Equipment Manufacturer (OEM), a prosperous relationship for both parties will often ensue. This OEM partnership results in first-hand information for maintenance to set up its maintenance approach, and valuable operational and design feedback for the OEM.

There are seven main circumstances in which maintenance will interact or communicate with an OEM and form an OEM partnership. These are:

- New facility or plant process/equipment design

- Equipment warranty claims

- PM task and schedule generation for original equipment installation

- RCM (Reliability Centered Maintenance) analysis of existing and new equipment installations

- Implementation and use of proprietary software and diagnostic tools

- OEM training

- Equipment and operational systems updates

New production equipment design

With increased awareness of life-cycle management costs and the validity of the maintenance process, many purchasing and engineering departments now invite their maintenance departments to assist in the development of new equipment design and operational specifications. Allowing maintenance a voice in this development stage can translate into an improved design focused on delivering increased reliability and quick maintenance turnaround.

Specifying and building equipment with known reliable components (power transmission, electrical, fasteners, etc.) could marginally increase initial build expense—but will pay back over the equipment’s life span through reduced downtime caused by premature component failure and reduced component stocking expense. Equipment designed to be maintained with visual management systems that give instant tangible feedback on the equipment’s condition, as well as for quick access and component change capability, will drastically reduce set-up time and minimize the Mean Time To Repair (MTTR).

Production equipment warranty claims

Many corporations lose out on new equipment warranties. Misunderstanding of warranty commencement date, warranty duration and terms and poor documentation of failure occurrences during the warranty period often result in maintenance paying for a premature failure that should have been back-charged to the OEM as a warranty claim.

Establishing usable warranty parameters requires the OEM and maintenance user to agree upon and document the warranty start date; is this a defined time period from the date of shipment, date of arrival on site or date of signed-off commissioning? Most companies believe it to be the commissioned date and are shocked to find out later it was the shipping date! This is even more disconcerting when the equipment is commissioned past the warranty time period.

The OEM fully understands it has a responsibility to support the equipment user at different levels. Maintenance is one of those levels.

Although most equipment typically operates under a one-year warranty period on all mechanical components, electronic components may carry only a 90-day warranty. The maintenance department must be part of the warranty discussions so such items can be marked in the CMMS equipment register and acted upon. Otherwise, maintenance might have to pay for a repair that is not its responsibility.

When exercising a warranty claim, maintenance can facilitate the process by providing the OEM with an up-to-date work log account and relevant digital photos or video of the warranty claim component or area. This information can be immediately relayed electronically to the OEM and an accelerated warranty decision can be made.

PM tasks and schedules for existing equipment

When setting up a preventive job task for an existing piece of equipment that has no maintenance manual on file, the maintenance department can contact the OEM to request a copy of an original manual and typical PM task information. If the equipment is old, the OEM will at the very least have the knowledge to assist in the setting up of basic PM routines for the equipment.

RCM (Reliability Centered Maintenance) analysis of both existing and new equipment installations

A preferable approach to the previous scenario when setting up a PM program for existing or new installations is to adopt a Reliability Centered Maintenance approach and invite the OEM to take part in the RCM analysis process to build PMs based on the ambient condition factors and consequences of failure.

Implementation and use of proprietary software and new tools

Most of today’s equipment will use some form of computer control accompanied with proprietary software that can help in diagnosing equipment breakdowns and slow-downs. OEMs can also provide other specialty tools to operate, troubleshoot and repair equipment failures. Tools such as diagnostic meters, hand tools (wrenches, screwdrivers) and power tools will all carry a warranty—and some will require ongoing support from the OEM through the learning phase of product use.

Training

With the purchase of a new product comes a need for training. In the case of maintenance diagnostic tools and maintenance software, the training requirement is best addressed before the equipment arrives on site. Unfortunately, many corporations wrongly believe that because a machine is built up from a selection of electrical and mechanical components that the maintenance staff does not require training. (These same decision-makers would shudder if their car dealers’ auto mechanics were not trained on their latest automobile purchases!)

Equipment is made up of independent and interdependent systems that the maintenance staffs must first understand before moving to the component level they understand so well. An excellent opportunity for maintenance training is during the commissioning process. By allocating a maintenance representative to the commissioning team, valuable “on the job” relevant training can be attained at no extra cost. The designated maintainer can later be used to train other maintainers.

Equipment and operational systems updates

Periodically, equipment will receive updates to both its mechanical, and more specifically, its electronic/electrical systems. Updates and improvements could mean a change to the PM task and require additional training.

Remember

Once a piece of equipment is sold, the OEM fully understands it has a responsibility to support the equipment user at different levels. Maintenance is one of those levels—and a very important one. It is up to maintenance, however, to communicate its need to the OEM and begin to form the valuable OEM partnership.

Ken Bannister is lead partner and principal consultant for Engtech Industries, Inc.

Related Articles

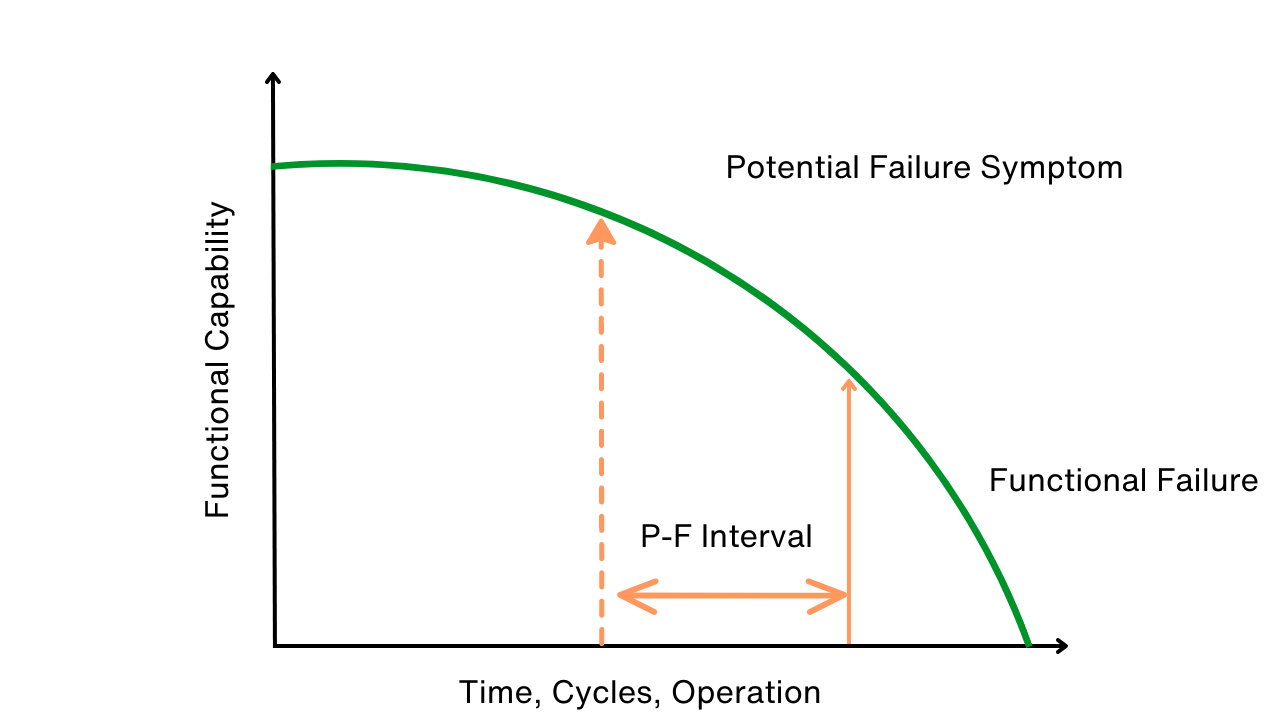

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?