Optimizing Operations: Conveyor Belt PM and Advances in Fabrication

Elizabeth Ruiz

Posted 10/18/23

Introduction

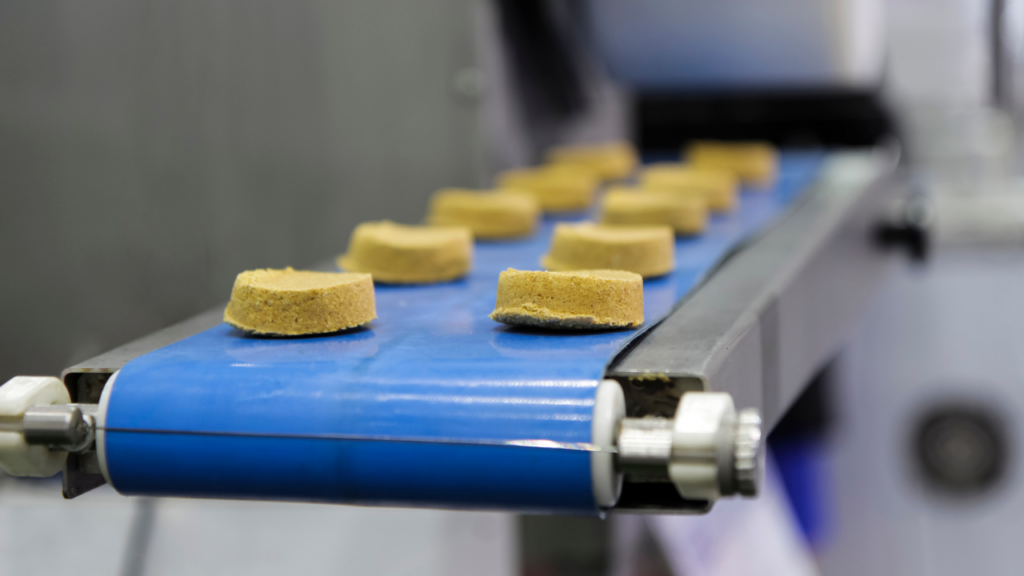

Advances in conveyor belting fabrication abilities and materials in recent years are improving processes related to the food industry. They allow for easier repair, more efficiency, and most importantly, better food safety. What are the recent changes to belts? What are the best ways to improve reliability and perform conveyor belt PM?

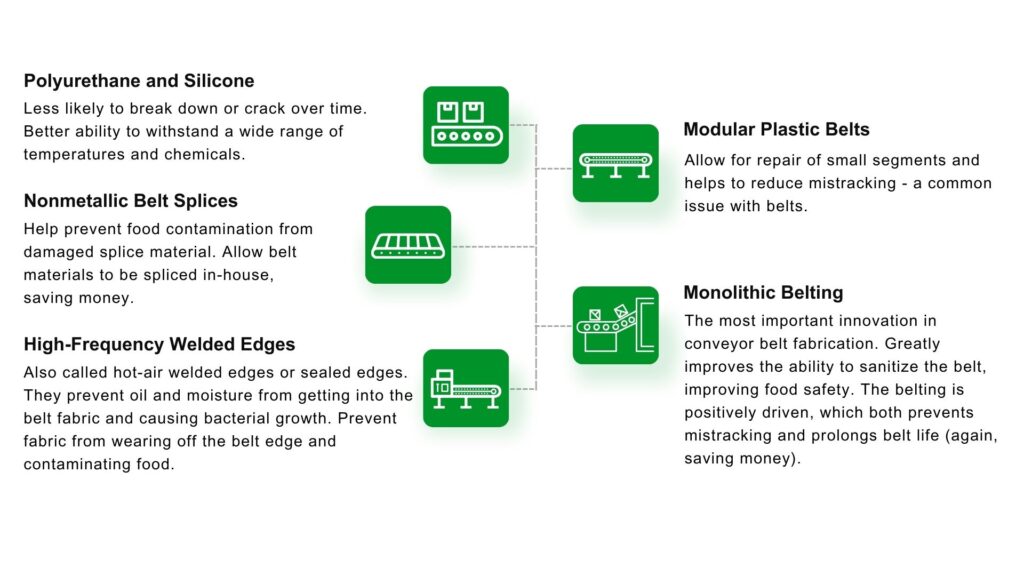

Conveyor Belt Improvements

According to manufacturing.net, these recent advances in conveyor belt fabrication are improving reliability, saving costs, and enhancing food safety:

Set Yourself Up for Exceptional Conveyor Belt Reliability

The first thing to do is make sure you are working with the correct conveyor belt for your organization’s needs. Accurate Industrial suggests these tips to correctly select a conveyor belt for your organization:

- Consider the size, weight, dimensions, and other characteristics of the load the belts are handling.

- Set the conveyors to pull instead of push. The belt can lose up to 50-70% of its load capacity when pushing.

- Take flow rate into consideration. A fast flow rate likely requires special equipment such as fasteners, endless splicing equipment, segmented transfer plates, and maintenance tools.

- Choose the right belt according to your industry. Different industries such as food and pharmaceutical require different materials and sanitation factors.

Conveyor Belt PM Checklist

When you have determined that your conveyor belt is the right one, it is important to perform conveyor belt PM to make sure it continues to function correctly.

Conveyor systems that are operated safely and maintained properly are very efficient pieces of equipment that can streamline processes for a productive organization. A conveyor belt malfunction creates an extremely disruptive and chaotic environment—causing workflow bottlenecks, material pile-up, product damage, and potential danger to personnel.

What are some conveyor belt PM steps we can take to make sure they are running properly?

Take a look at this Conveyor Belt PM Checklist of suggested PMs from the conveyor belt experts at Accurate Industrial and Richards-Wilcox Conveyor.

- Follow belt manufacturer’s recommendations for routine weekly, monthly, and quarterly inspections of bearings, pulleys, etc. Make sure the maintenance team records details of every inspection.

- Inspect the tracking of the conveyor belt for signs of wear and tear. Quickly replace any damaged segments before they cause further damage.

- Monitor tension to make sure the belt isn’t held too tightly or loosely. Incorrect belt tension can cause costly and lengthy breakdowns.

- Inspect lacing to make sure there are no abnormalities. Conveyor chains fail when lacing is off.

- Make sure a routine cleaning and lubrication regimen is in place for the belts.

- Use predictive maintenance to replace parts before they break. Have critical parts in stores ready to go when needed.

Conveyor Belt Operation Safety Tips

Safety of personnel when operating belts and performing conveyor belt PM is of the utmost importance. Worker safety should be part of the mission of every organization. Accurate Industrial and Richards-Wilcox Conveyor have put together safety tips according to their conveyor belt expertise:

- Make sure that the machine guard placement is in proper condition and placed correctly.

- Routinely check the functionality of emergency stops and safety mechanisms (for example pull stops, housings, warning labels) to ensure they work properly and immediately.

- Calibrate and adjust conveyors to manufacturer’s standards.

- Ensure that workstations are designed with safety and efficiency in mind – think ergonomics.

- Create a strong safety culture in your organization. Encourage personnel to report safety concerns and make suggestions for improvement.

- Make sure emergency processes are in place and visible/well-communicated.

- Put a zero-tolerance policy in place for any misuse of conveyors.

Conclusion

Recent improvements in conveyor belt fabrication are boosting efficiency and food safety in the food industry. Selecting the right belt for specific organizational needs and implementing routine conveyor belt PM are essential for reliable conveyor operation. Most importantly, prioritizing worker safety and building a strong safety culture further ensures efficient and secure conveyor belt operations in your organization.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you every Wednesday by the Maintenance World Crew

Related Articles

Machine Safety: Machinery Friend or Foe?

Quality Control of the Inspection Process

The Totally Responsible Individual: Dealing with Chaotic Events

Reliability Improvements Drive Down Maintenance Costs

OEE: Overall Equipment Effectiveness

Tips for Maintenance Planning

Fixing Maintenance