The Trifecta of Motor Maintenance

Noah Bethel, VP Product Development, PdMA® Corporation

Posted 12/13/2022

The odds are against picking the first place winner of a horse race. The odds of picking the first, second, and third place winners are even less favorable, but when it happens the trifecta payday is big! In the world of horseracing, guessing the winners is pretty much a gamble. But imagine if a gambler knew in advance the trifecta of the race. It would be a no-brainer, and they would put everything they had on the race knowing they would see huge returns on the investment. Using the same concept of a trifecta (three factors for success), this article provides companies with the winning strategies of motor maintenance, focusing on the three reliability tasks for electric motor testing and the order in which they should be applied. Following these steps will drastically improve their odds in motor reliability and put a big payday at the end of their production goals.

Talmadge Ward, a senior engineering technologist with Duke Energy, believes that the trifecta of motor maintenance has saved his company both time and money. “Motor reliability is paramount in the electrical generating business,” says Ward. “Duke Energy has performed motor testing for more than 50 years.”

Electric motors

A basic understanding of the construction of electric motors is essential before discussing the trifecta of motor maintenance. Commonly, an AC electric motor would be a component of a fan, pump, or larger piece of equipment such as a mixer, conveyor or winder. Electric motors have three main parts: the rotor, the stator and the enclosure. The rotor and stator are the working parts of the motor. The enclosure serves to protect these working parts.

The stator is the part of the motor that doesn’t move. The core of the stator is made of thin laminations of metal. These laminations are arranged in a hollow cylinder, into which coils of insulated wire are placed. The rotor, as the name suggests, is the rotating piece in the motor. It is also made of thin metal laminations to form a cylinder, and a shaft is inserted into its center. The rotor is inserted inside the stator, but a small air gap ensures they do not physically touch. The enclosure holds the stator and rotor assembly. A yoke supports the stator and rotor assembly, while bearings mounted on the rotor shaft allow the rotor to spin. A cooling fan may also be attached.

Electric motors work on the basic principle of electromagnetism. When an electric current is passed through the insulated wire windings in the stator, it creates a rotating magnetic field. The magnetic rotor, working on the principal that opposite electric charges attract, spins as the electric field moves and pulls the south pole of the rotor toward the north pole of the field (and the north pole of the rotor toward the south pole of the field). This in turn spins the shaft, which allows work to be done, whether the shaft is connected to a pump, conveyor, or other piece of equipment.

Trifecta of Motor Maintenance – Part 1: Quality Control

The first piece of the motor maintenance trifecta is quality control (QC). QC is a general term that impacts a wide variety of people, assets, times, and locations. It’s both the asset being maintained and the environment in which it’s stored. Companies should ask several questions regarding their motors from delivery to installation. First, is the motor tested when it’s delivered, or do the employees in charge of receiving the equipment assume that all is well? Assuming the motor works as specified, a second consideration is how the motor is stored. Is the environment suitable in terms of temperature, humidity, protection from the elements, and easy accessibility? Third, the motor should be tested intermittently during storage. Just because the motor worked when delivered does not guarantee that problems won’t develop as the motor sits idle over time.

Additionally, motors should be installed in an overall system that is quality controlled. The electrical distribution system is a vital component. For example a voltage imbalance of 5-10 percent can cut the life of a motor in half. In this situation, replacing a motor isn’t solving a problem. Rather, it’s starting the failure cycle again. This leads to the old adage cited by veteran employees in work environments without adequate QC: “Let the new guy start it.”

Duke Energy’s Ward says that all motors are checked before storage or installation. “In the case of our most critical large motors we review the vendor test reports for both new and repaired motors as a quality check based on our purchase or repair specifications for motors.” Adds Ward, “For these motors, we also perform our own motor testing once they arrive at the generating station. All of the large stations have staff, and they are qualified to perform these tests and evaluate the data. These tests are also done once the motor is installed and ready for service.”

Trifecta of Motor Maintenance – Part 2: Trending

Once a motor is in place and operating, it’s not a good practice to leave well enough alone and assume there are no problems if everything seems to be running smoothly. While many motor failures are mechanical, nearly half are electrical in nature. A 1985 EPRI/GE study showed that 41 percent of motor failures were caused by bearings and 12 percent by “other” problems, while a whopping 47 percent of failures were caused by rotors (10 percent) and stators (37 percent).

Data collection is the key to preventing these failures. Machine operators often call a repair company with just one data point. Trending is a term that refers to taking data points on a regular basis, so that potential problems can be identified well in advance, and a detailed history of the problems can be assembled.

For example, it’s smart to monitor one’s health over time rather than wait until a problem develops which requires a visit to the doctor. Just like machines, as people age, certain problems are common. With regular visits, physicians can monitor indicators such as cholesterol levels or blood pressure over time. If the doctor sees a trend developing, for example, cholesterol levels steadily rising at each yearly checkup, the physician can advise the patient to take preventive actions such as modifying diet, increasing exercise, or taking cholesterol-lowering medications. Without these frequent data snapshots and preventive measures, the doctor may end up working with a heart attack victim in rehab—or worse.

What types of trending data should be gathered, and how often? When it comes to data collecting, “trend is your friend.” Using software and testing equipment that can analyze both dynamic and static data a detailed history can be obtained for a motor that shows potential problems before a catastrophic failure occurs. There are six fault zones that should be analyzed regularly to obtain trending data:

- Power Quality: Power quality relates to the quality of the voltage (which is determined by the power system) and the quality of the current (which is determined by the load). Factors that can be analyzed include low or high voltage, harmonic voltage factor, crest factor, and total harmonic distortion for both the voltage and current.

- Power Circuit: The power circuit fault zone contains everything from the test point down to the motor, including things such as circuit breakers, fuses, and disconnects. Measurements of voltage imbalance and resistive imbalance can be taken to analyze the power circuit fault zone.

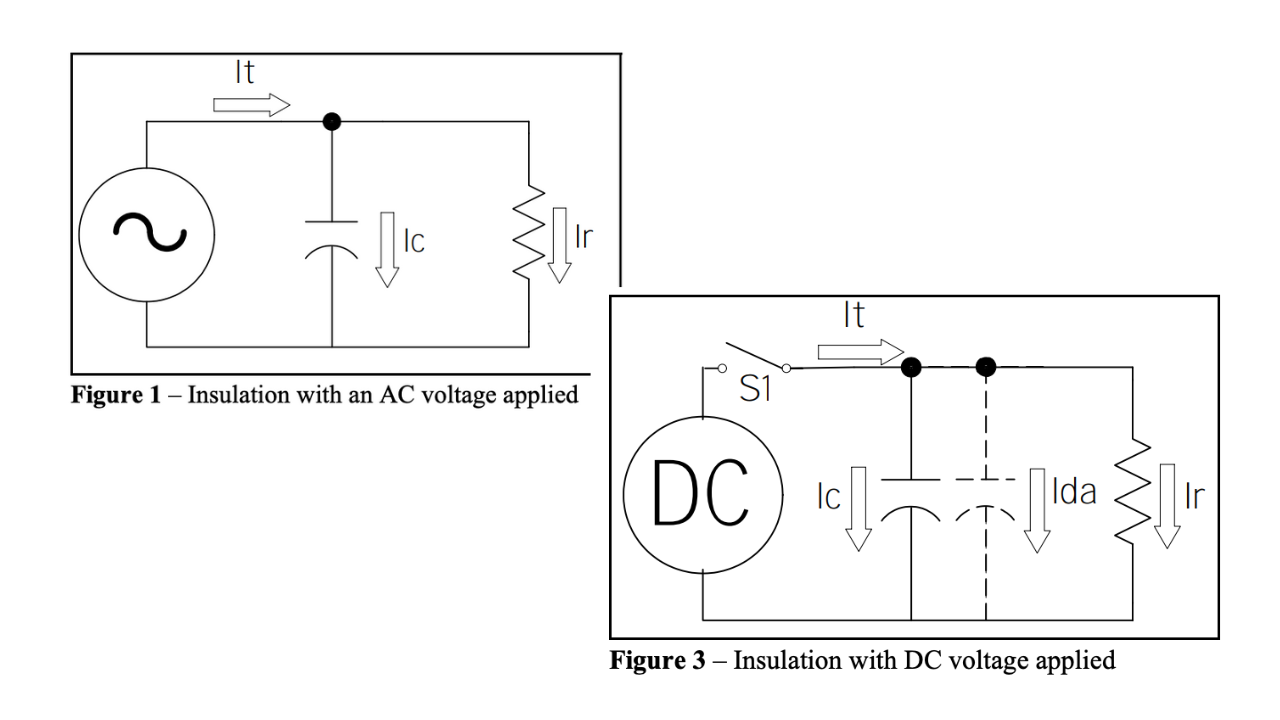

- Insulation: Insulation can be affected by old age, moisture, temperature, vibration, and other factors. In the insulation fault zone, appropriate hardware and software can measure resistance-to-ground, capacitance-to-ground, polarization index, and step voltage.

- Stator: In the stator fault zone, inductive and impedance imbalances are measured to indicate the health of the insulation between the turns of wire in the stator coils.

- Rotor: Current signature analysis (CSA), in-rush current, inductive imbalance, and a rotor influence check (RIC) test are performed in the rotor fault zone.

- Air Gap: In the air gap fault zone, CSA and RIC tests determines levels of static eccentricity and dynamic eccentricity in the shaft.

How often these tests are performed will depend on the type of motor being used, the frequency, intensity, and duration of use, and the company’s seasonal production patterns. Other factors may include the environment in which the motor is run. Whatever the interval, consistency is the key. Quarterly or semi-annual trends may be much more valuable than tests performed at random intervals or whenever the staff remembers to have the data collected.

Duke Energy’s Ward has found that an annual interval works best for his company. “Testing motors for trending is done as frequently as every year for the most critical population of motors, but for less critical motors we use a scalable approach which we base on the probability and consequences of a motor failure. Our goal is to plan motor service rather than be forced to limit generation for motor repairs because they have reached end of life.”

Duke Energy’s trending data collection has paid off. “Recently we found a large difference in resistance in the circuit of a critical 125 HP AC induction motor during a routine off line test,” says Ward. “The cause was loose field cable connections. After the connections were properly torqued the follow up test showed only a 0.1 percent resistive imbalance verses the 9 percent imbalance first observed.”

Trifecta of Motor Maintenance – Part 3: Troubleshooting

All motors have a limited lifespan. Eventually, a motor will fail. What happens at this point is heavily dependent on whether or not the company has been diligent with parts one and two of the trifecta: quality control and trending. If so, the third part of the trifecta, troubleshooting, will be much easier. Troubleshooting refers to what happens when a motor fails or performs poorly enough that it causes a problem.

A good example is the case of the local coal mine that experienced trouble with a wound rotor motor…on a Saturday. The local electrical company was dispatched to the mine, where production had ground to a halt and dollars began to bleed from the operation. This motor type generally couldn’t be fixed in the field, but the mining company had the foresight to have a spare motor on hand. By Monday afternoon, a crane was in place to swap the motors, and by midnight, the new motor was installed and ready to start.

The miners waited with baited breath under the stars as the start button was pressed, and…a growl and a blown $1,000 fuse resulted. Adjustments were made, and another $1,000 fuse blew. By 4:30 in the morning on Tuesday, the third $1,000 fuse blew. At 7 pm Tuesday—more than four days after the initial failure—the electrical company prepared to remove the spare motor and take it to the shop for inspection. However, someone had the idea to use electric motor testing equipment and software to identify the problem. On Wednesday morning, testing revealed that two leads were reversed. The problem was quickly fixed and the spare motor started.

Needless to say, this scenario could have been avoided had the three parts of the trifecta been in place. QC would have detected faulty wiring in the spare motor at delivery or while in storage, trending would have identified problems in the original motor before it failed, and troubleshooting—what to do when a problem arises—would have saved the miners five days of downtime.

When it comes to troubleshooting, the first key is having written instructions, in a manual, that spell out the company’s policies on motor failures. This includes employee training. Second, the policy should require that the job site have the technology available to assist in diagnosing the problem. If the miners and the electric company had used the electric motor testing equipment on Monday morning, down time on Tuesday and Wednesday would have been avoided. The plan should also stipulate calling in outside experts when the scope of a problem exceeds the training or knowledge of the employees.

“Critical motor failures are very rare in our generating stations,” says Ward. “What is more common is to find a degraded motor and determine the cause and contribution factors. Then we develop an increased testing plan. Degraded motors require more frequent testing to understand the cause and understand the rate of degradation. With an understanding of both the cause and the rate of degradation we can have a high degree of confidence we will avoid an in-service motor failure.”

Management, Predictive Maintenance and the Bottom Line

Management also plays a key role in successful troubleshooting. Creating manuals takes time, which costs money. Training employees may result in reduced labor available, which may cause scheduling conflicts. Calling in experts is expensive. However, it’s much more costly to lose extra time due to fumbles and false starts than it is to do things correctly in the first place. For example, studies show that industrial rotating machinery failures cost $17 per horsepower of the motor per year for companies practicing only reactive maintenance—in other words, if it breaks, fix it. Compare that with $12 per hp for companies practicing preventative maintenance (regular maintenance without the benefit of data), and $8 per hp for companies using predictive maintenance. The maintenance trifecta is the very essence of predictive maintenance: using QC and regularly collected data to fend off and forecast problems before catastrophic failures occur. And the impact on the bottom line? Repair costs reduced by more than 50 percent over companies with a “close our eyes and hope it turns out okay” approach.

Predictive maintenance saves money in other ways, too. With predictive maintenance, there are fewer unexpected motor failures and less need to keep extra motors and parts on hand, resulting in less costly inventory and need for storage space. And repairs and maintenance can be scheduled during the company’s slow periods—not at peak production on a Saturday.

“In the last 20 years we have secured the support of senior management. With this support we have developed specification, procedures, motor alliances with repair shops, budgets for purchase of motor test equipment, and what we consider to be a solid motor maintenance program,” Ward reports.

Winning the Trifecta of Motor Maintenance

All business involves risk. Some risk, such as entrepreneurial risk, is beyond anyone’s control. But other types of risk can be alleviated and mitigated with best practices. By putting their money on the trifecta of motor maintenance—quality control, trending, and troubleshooting—companies can “hedge their bets” and increase their chances of a big payday.

Noah Bethel

Noah Bethel, CMRP, is vice president of product development for PdMA Corporation, Tampa, Florida, a leader in the field of predictive maintenance, condition monitoring applications, and development of electronic motor test equipment for motor circuit analysis. For more information, call (800) 475-6463.

Related Articles

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera