Cleanliness is Indicative of Quality

Chris Felix, Production Machining

Outward appearance is often considered a strong indication of what can be expected of the final product. That’s why this shop goes the extra mile to look good in all areas of its business especially cleanliness.

A first impression is a lasting one. The folks at H&R Screw Machine Products (Reed City, Mich.) understand the impact of this axiom when their parts are delivered to customers. If oil is soaking through the box or parts are dirty, the customers are going to be much more skeptical about what they are paying for. The company produces millions of parts a year and sends a majority of them through its aqueous cleaning system to ensure that the customers like what they see.

But it’s not all about the appearance. A shop needs to follow that up with consistent quality to prove the value of its parts. It can’t be smoke and mirrors. So this shop also devotes a lot of energy toward high-end productivity and lean methods of efficiency to get the most from its processes.

Look and Feel

Visitors quickly get a sense of the importance of appearance to the folks at H&R. From the well kept landscaping on the outside of the building to the overall cleanliness of the shop floor, employees here make sure they are portraying the image of quality. The current construction in the front of the building is merely an indication of the company’s continued growth.

Founded in 1976 with single-spindle Brown & Sharpes, H&R now has 26 multi-spindle machines including New Britains, Wickmans and Davenports as well as Doosan and Daewoo CNCs. The company also does centerless grinding and has index tables and a host of other secondary equipment.

The company has been conservative in its expansion through the years, adding only what it has immediately needed, instead focusing on providing quality parts. “If we could get by with adding 500 square feet, we didn’t add 501,” says Vice President Tom Halladay, who helps run the business with his brother, Tim (general manager), as well as their father, Dave (president), who started the company with his father-in-law 35 years ago. “Tim and I grew up in an environment of making due with what we had, so the decision to build a new plant 11 years ago was a big one.”

After a year and a half of planning, they moved about six miles down the road from a 12,000-square-foot facility to a brand new 38,000 square foot plant, opening on January 3, 2000. “But we’ve continued to stay lean,” Tom says. “We’re getting to a point where we’re relatively full again. Right now, we’re adding a couple of offices up front for our new controller and plant manager. Soon, we’ll have to consider adding on to the shop floor again, but we have acreage out back, and we have a pop-out wall, so we can extend easily. We’ll put it off as long as we can, but we also need to be thinking ahead.”

Operations

The company serves a range of industries, including military, material handling, medical and automotive. One of its stronger growth areas lately has been consumer products, which has included parts for heating and air conditioning systems, appliances, athletic equipment, fire suppression system components and furniture. Tom explains, “We try not to be dependent on any specific market. Some areas, such as those affected by the housing market, have declined in recent years, while we’ve tried to grow other areas. Our service and quality have helped us retain customers long term, though, including our first two, who have been with us for 35 years.”

Three shifts allow production around the clock. About half of the employees work the first shift with the other half split evenly between the other two shifts. Most of the setups are done during first shift. The second and third help to add flexibility for last-minute customer requests. “Almost every week we’ll have a customer call us needing something immediately,” Tim says. “We can almost always get it on a machine right away.” The brothers also see this as an indication that machine utilization can be increased, and they are developing ways to take advantage without losing flexibility.

Clean Parts, Happy Customers

Cleanliness is an important part of the business at H&R. “The first thing customers see when they open the box is the look of the part,” says Jarrod Lemasters, plant manager. “What do they think if they receive parts with chips or oil on them? If you don’t care enough to send a nice looking part, you probably don’t care about making a quality part. Customers don’t want to clean the parts after they receive them.” Many of the parts also go for finishing operations as well, so cleaning is an important step before these processes.

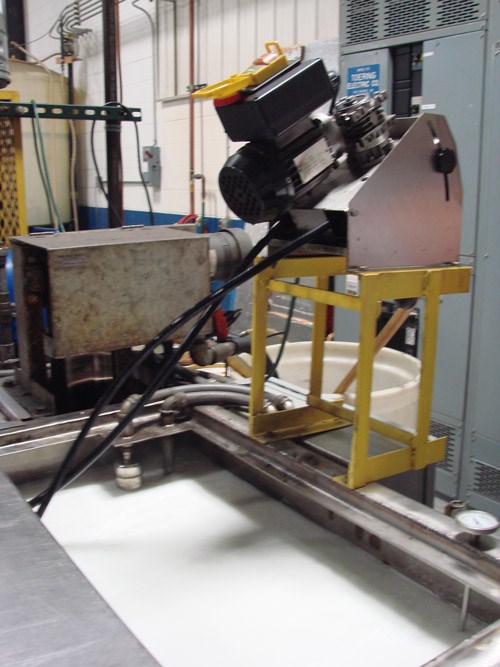

Before acquiring its current cleaning system, H&R did labor intensive mineral spirits washing. Some brass and aluminum parts were even shipped out for outsourced degreasing, which added considerable time to the production process. Now almost all of the parts go through the company’s Painter Design rotary basket aqueous wash system which ensures the cleanliness of parts.

“For some shaft work we’ll do a wash at the machine and then go to centerless grinding,” Tom says. “Beyond that and maybe some CNC parts that only need a quick hand wash, everything including all the screw machine work goes through the aqueous system. That’s 20 to 25 million parts a year.” The previous system was a less effective mineral spirits based, auger-type washer that required a lot of physical labor, loading and unloading parts and blowing them off.

The system has capacity for six baskets. During the wash cycle, the baskets can be rotated 360 degrees in addition to the carriage rotation (rotation within a rotation). The cycle includes complete immersion as well as continuous spray from a rotary head that flushes from the inside out. This additional pressure assists with deep, blind holes that can often present a challenge for any cleaning system. The cycle times for the wash, rinse and dry, as well as the rotation speed of the baskets, can be adjusted to fit the requirements of the parts to be cleaned. Delicate parts may require a slower rotation while more heavily soiled parts may require the additional agitation generated by faster rotation to ensure cleanliness.

H&R invested in a large supply of Buckhorn cleaning baskets that are used not only during the cleaning process, but also to transport parts throughout the shop to reduce labor through handling. The baskets have varying screen sizes to optimize the amount of flow during the cleaning process without allowing the parts to fall through. The height of the basket lids is adjustable to allow for varying quantities of parts and to limit the movement of parts during rotation of the basket. This is particularly important for more delicate parts.

The cleaning system includes two 500-gallon tanks to accommodate both the wash and the rinse. For steel parts, H&R skips the rinse process, but adds a rust inhibitor to the wash cycle. A skimmer removes the oil that has accumulated in the water. A couple of years ago, H&R switched from a belt skimmer to a tube skimmer. As the closed-loop tube floats across the water surface, oil adheres to the tube and is slowly drawn across the surface of the water and into the oil skimmer, where it is scraped off and deposited in a collection container.

“The cleaning system has been very effective for us,” Tim says. But the company is always looking for ways to improve its processes. “Although the system only runs during first shift, we’ve eliminated an hour or more of downtime by having our third shift heat up the system.” Sometimes efficiency comes in simple packages; other times it’s on a much bigger scale.

It’s bigger than just cleanliness

The people at H&R don’t view appearance or cleanliness as a benefit only to the business. They see cleanliness as an ongoing philosophy that also helps the environment. Green operations are important to them, so they have implemented a number of programs to save energy and reduce the company’s environmental footprint. Last year, the company replaced the metal halide lighting fixtures in the shop with a six-bulb T8 fluorescent system that uses about half the power, but provides almost twice the brightness—good for the environment and good for the company as it allows employees to see their work better and costs less to operate.

The company recycles paper and cardboard, and Mr. Lemasters is initiating an effort to go to paperless with a lot of the company’s shared files, such as layouts for screw machines, process layouts and prints. They also use an evaporator to recycle the water from the parts washer and floor scrubber. Oil that is separated in the evaporator is sent for use in asphalt plants.

The company also recycles its oil through a scrap metal processing system that runs throughout the shop. The system is designed to handle both ferrous and nonferrous material, so the company uses it on all machines that are running either aluminum or steel. As it separates the materials, it also filters the oil through a magnetic microseparator—a centrifuge for fine separation of contaminants. The separated chips are then ready to be hauled off for recycling and the oil is reclaimed to be used again. All 26 machines can be fed by the 15,000 gallons of oil, but some are closed off for use on brass parts.

Tom sees the automated processing of chips as the biggest benefit of the scrap processing system because it reduces employee fatigue and reduces tooling consumption. “With the large amount of oil spread throughout the shop, it stays pretty cool,” he explains. “The result has been extended tool life and improved efficiency, which have easily paid for the system.”

Efficiency Breeds Results

H&R strives to be one of the best in the precision machining industry, and it uses its lean manufacturing and a strong commitment to quality and cleanliness to get there. Through continued efforts towards setup reduction, 5S, visual production and management, the use of tool counters and inspection systems, improved material handling and clamping systems, and other strategies to refine its operations, management sees a bright future ahead.

“We try to provide a comfortable place to work where employees can be proud of what they’re doing,” Tom explains. “Even the shop floor is air conditioned, which not only helps make the shop a nicer place to work, but also helps to prevent rust on steel parts.” The low employee turnover rate helps to demonstrate that the company is doing something right. But the influence these employees and their quality of work have on the growing base of satisfied customers is what will sustain the company long into the future.

Chris Felix

Chris Felix is the Editor-in-Chief of Production Machining. He is an experience Editor with a history of working in the publishing industry and holds an Associates of Science in Technical Writing and Editing.