How to Protect Bearings from Dust and Water

Mike Sondalini, PWW EAM Consultant, Equipment Longevity Engineer – with permission of BIN95 Business Industrial Network

Posted 6/26/2024

Protecting bearings from dust and water is essential for bearing durability and performance. Bearing protection methods like labyrinth rings, rubber seals, felt seals and shaft mechanical seals are described. Choice of the appropriate shaft seal and seal configurations to protect against dust and water ingress is critical. Numerous shaft seal designs suited to contaminated conditions are reviewed.

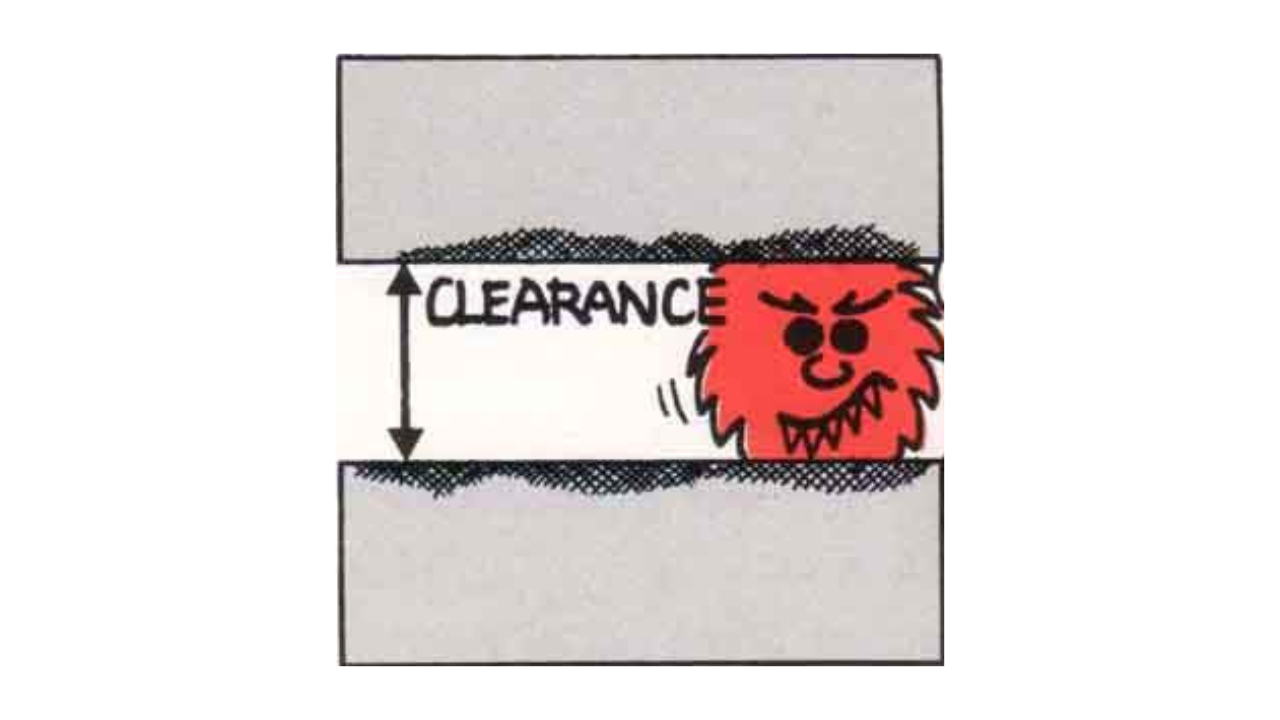

Dusty surroundings are one of the most difficult environments for bearings. In equipment handling powders or in processes generating dust the protection of bearings against contamination by fine particles requires special consideration.

Bearing Houses

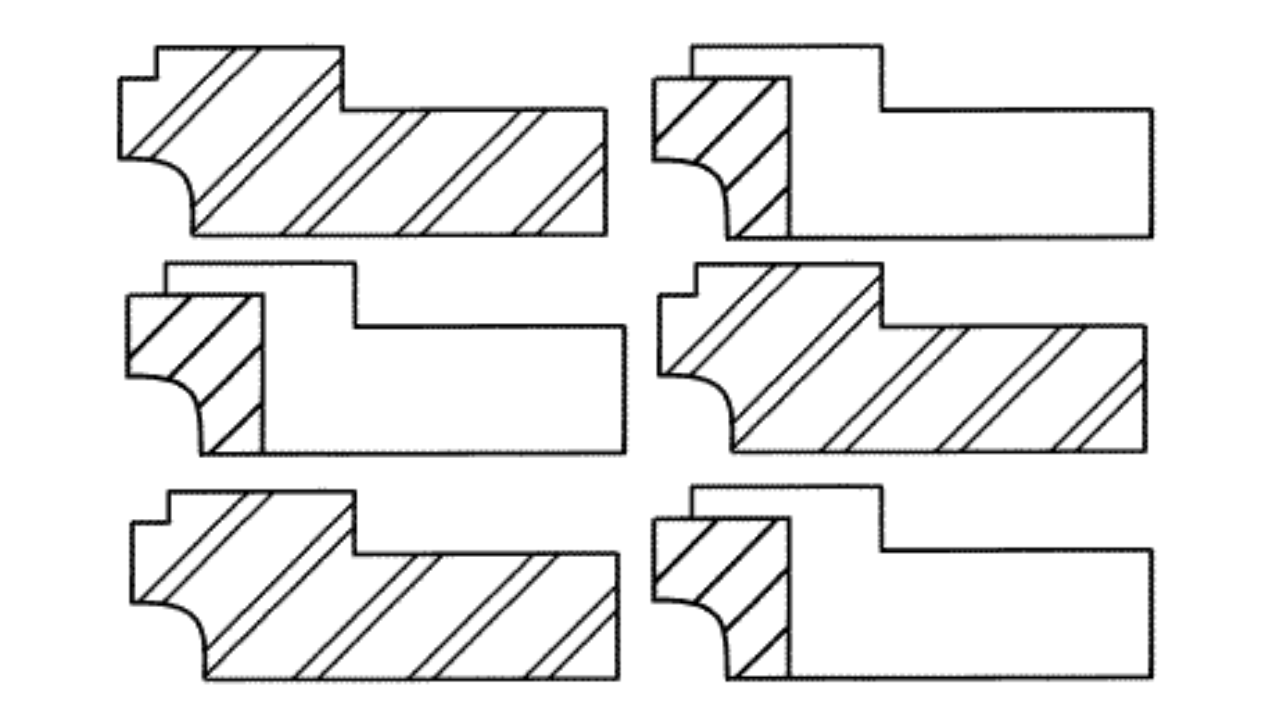

Bearings are contained within a housing from which a shaft extends. The shaft entry into the housing offers opportunity for dust (and moisture) to enter the bearing.

The shaft seal performs sealing of the gap between the housing and shaft. Choice of the appropriate shaft seal and seal configurations to protect against dust ingress is critical.

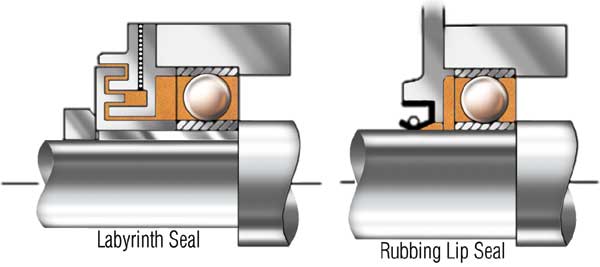

Figure No. 1. Shaft Bearing Housing Seals. Image courtesy Machinery Lubrication, a Noria publication.

Bearing housing seals for dusty environments may be either a labyrinth type or a rubbing seal type. The labyrinth type requires a straight shaft running true. Rubbing seals are the more common and allow for some flexing of the shaft. The sketches below are conceptual examples of each type of seal. When setting a lip seal into place to prevent dust ingress ensure the sealing lip faces outward.In situations of high dust contamination there may be a need to redesign the shaft seal arrangement for better dust protection than provided in standard housings.

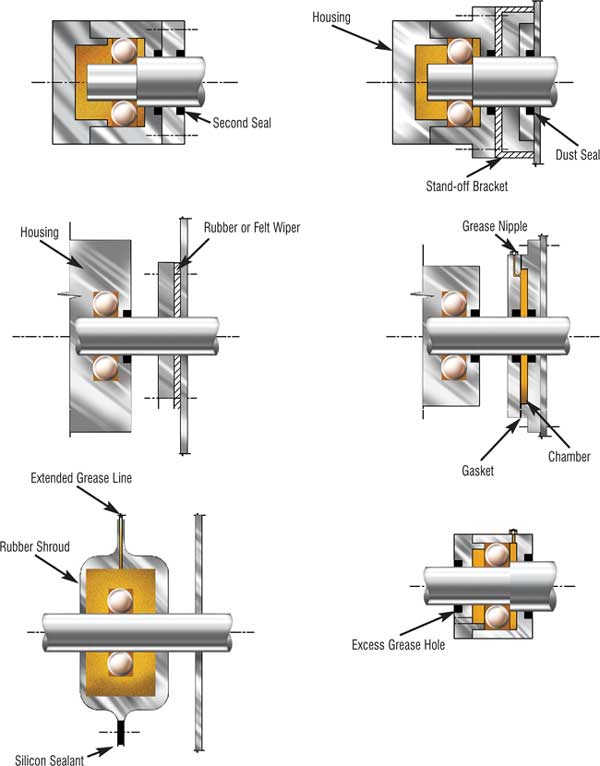

Some ideas which can reduce dust ingress into bearing housings are to:

- Retain the housing shaft seals but change from a greased bearing in the housing to one which is sealed and greased for life. If contamination were to get past the shaft seals, the bearing’s internal seals would protect it.

- Stand the bearing off the equipment to create a gap between the end of the equipment and the bearing housing while sealing the shaft at the equipment.

- Put in a felt seal wipe between the housing and the wall of the equipment to rub the shaft clean. Install of a mechanical seal in very harsh environments.

- Install a grease barrier chamber sandwiched between two seals. This barrier is separate to the bearing housing and acts as the primary seal for the bearing. Grease pumped into the chamber will flush out past the seals.

- Replace the grease barrier chamber instead with an air pressurized chamber.

- Shield the bearing housing from dust with use of a specially fabricated rubber shroud encapsulating the housing and wiping the shaft or fit a rubber screen with a hole wiping the shaft over the opening emitting the dust.

- Flush the bearing with grease by pumping excess grease into the housing and allowing the grease to be forced past the shaft seals or through a purposely drilled 15mm hole in the housing. The hole must be on the opposite side of the bearing to the grease nipple, at the bottom of the bearing housing when in service and between the bearing and seal.

- Mechanical seals can be fitted to the shaft with the stationary seal sitting toward the machine and the rotating seal mounted back along the shaft. Combinations of other seals and wipers can also be used in conjunction with the mechanical seal. Mount the auxiliary seals so they see the dust/water first and keep the mechanical seal as the last line of protection.

Assembly

The process of assembling a bearing into the housing must be spotlessly clean. If contamination occurs at the time the housing is assembled no amount of external protection will stop the bearing from premature failure.

When assembling bearings into housings make sure that:

- Your hands have been washed.

- The work bench is clear and wiped down clean.

- No one creates dust or grinds nearby during assembly.

- Fresh, clean grease is used to pack the housing.

- The components are clean and all old grease has been thoroughly removed.

Breathers

When protecting bearings from dust you want to always consider another important area. A breather is used to let hot air out of a confined space and then to let the air back in when it cools down. Enclosed bearings get hot when operating and cool down to ambient temperature when not in use. The air drawn back into the space needs to be clean of dust and moisture. A breather on a bearing housing or bearing housing enclosure allows ingress of moisture and dust into the bearings causing premature life failure.

Often a breather is insufficient and should be replaced with a low micron air filter that removes dust particles two micron and greater in size. Protect the breather or filter from water spray and damp conditions (ban hosing down if possible) with a shroud or by using an extension tube going into a clean, safe environment. Make sure the breather tube cannot be crushed closed by accident.

Protect Bearings: Conclusion

Protecting bearings from dust and water is essential for their durability and performance. Effective methods include using labyrinth rings, rubber seals, felt seals, and shaft mechanical seals. Choosing the right shaft seal and configuration is crucial. Additionally, proper assembly practices and using breathers or low-micron air filters help maintain cleanliness and prevent contamination. Implementing these measures ensures the longevity and reliability of bearings in dusty environments.

Mike Sondalini

Mike Sondalini is a Senior Consultant at PWWEAM System-of-Reliability. BEng(Hons), MBA, CPEng. As a consultant and trainer, Mike was able to present his insights to his clients, suggesting innovative approaches to plant and equipment reliability. Their feedback was resoundingly positive. Efforts which earned him an international reputation for articulate, out-of-the-box articles on plant and equipment reliability, life-cycle EAM, maintenance management, work quality assurance, and team building. After decades of dedicated research, Mike authored “Industrial Manufacturing Wellness: The Complete Guide to Successful Enterprise Asset Management” a revolutionary approach on how maintenance and physical asset management systems should be run, the book detailed who, what, where, when, why, and how outstanding reliability could be achieved. Each step based in scientific and mathematical understanding to ensure repeatability of results and optimal outcomes.

Related Articles

Carbon in a Metal Holder

Classifying Chemicals to Assure Effective Sealing

A Guide to Matching Electric Motors with Hydraulic Power Units

Anatomy of a Boiler Failure—A Different Perspective

Anatomy of a Hydraulic Pump Failure

Are We Willing to Hear What “Failure” Has to Say?

Causes of Overheating in Cartridge Mechanical Seals

Centrifugal Pump Troubleshooting

Electrical Troubleshooting in 7 Steps

Reduced Wear and Failure of Machine Components: Failure Analysis of Mechanical Components

Gearbox Diagnostics Fault Detection

Water Contamination

Vibration Pen, Shock Pulse Measurement (SPM), & Vibration Analysis - What's the Difference?

Ultrasonic Leak Detection in Heat Exchangers

Using Corrective Maintenance Work Plans to Improve Plant Reliability

Understanding The Basics Of Balancing & Measuring Techniques

Understanding Shaft Alignment: Thermal Growth

The Case of Successful Filtration and Oil Analysis Implementation

The Basics of Lubrication PM Procedures

Standard Practices vs. Right Practices