CMMS: Integrating Real-Time Information for Condition-Based Maintenance

Freiter Gord

Introduction

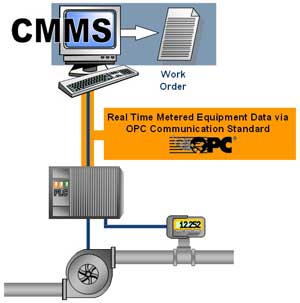

Industry pacesetters use real-time equipment data to prioritize and optimize their maintenance resources. The process is straightforward in concept: use real-time data to determine the equipment health, but only inform the Computerized Maintenance Management System (CMMS) when maintenance is actually necessary. From there, the CMMS automatically produces the work order and uses the workflow that is already familiar to all maintenance personnel.

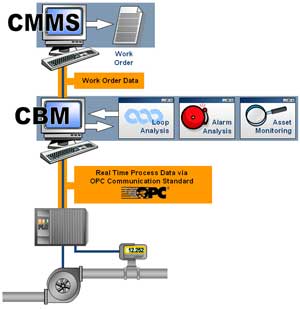

Pacesetters take two steps to achieve this goal. First they acquire and store real-time process data from their automation system (sometimes called SCADA or DCS). This automated data acquisition enables the Pacesetters to consistently have access to timely and accurate measurements. Second, the Pacesetters establish a Condition-Based Maintenance (CBM) system that uses the stored data to determine equipment health. The CBM system makes intelligent decisions regarding work orders, thus enabling maintenance to focus on activities that have the most impact on their operation.

Automated Data Acquisition Provides Timely and Accurate Measurements

Pacesetters use their existing automation systems to collect real-time equipment data at regular intervals using standards-based software. OPC is the de facto communication standard for acquiring real-time data and is based on industry-tested Microsoft technology. In fact, every automation system that is able to communicate with the outside world can be retrofitted with OPC. Available since 1996, OPC has spread to every industry.

Software applications use OPC to acquire real-time data, and to make the archived information available to external systems. By automating the data collection, Pacesetters eliminate the slow and error-prone manual labor that is typically required. For example, reading metered data from one computerized system or measuring equipment health with stand-alone instruments, recording it, and then entering it into a computerized maintenance system. Consequently, Pacesetters can access the latest data on demand. They are also comforted by the fact that the data was recorded exactly as it was in the original automation system, including all values and time stamps. The precision and frequency of data acquisition enables organizations to use a true CBM program.

Condition-Based Maintenance Uses Real-Time Data

Once they capture real-time data, Pacesetters implement a Condition-Based Maintenance (CBM) program that enables them to optimize their preventative maintenance efforts. The problem with traditional preventative maintenance is that all maintenance is scheduled on a periodic, regular basis regardless of equipment usage and operating condition. Thus, equipment that is rarely used receives the same amount of maintenance as frequently used equipment. As well, equipment that is used under harsh operating conditions is maintained as little as equipment that operates under ideal conditions. Consequently, some equipment is maintained too often, thereby increasing maintenance costs unnecessarily, and yet other equipment suffers undue wear-and-tear while waiting for its scheduled maintenance. This results in expensive repair costs that could have been avoided, and more importantly, ignores required maintenance activities that should be performed immediately. CBM helps with the prevention of unscheduled downtime because Maintenance can handle problems proactively, before they grow into more serious issues.

Pacesetters understand the key measurable factors that influence their equipment performance, and therefore, condition. Because these factors can be measured, software applications can automatically monitor them and alert maintenance only when the equipment condition necessitates action.

Getting Started with CBM

The most obvious factor to measure is equipment runtime (or running) hours. By acquiring the real-time data, the CBM system can determine when the equipment is running and automatically count the runtime hours. Once the count reaches the manufacturer-specified limits, the CBM system can immediately alert the CMMS.

The CBM system can then be augmented by considering other factors such as vibration analysis, temperature readings, fluctuating flow rates, and others. That is, if the operating conditions are especially harsh, these factors will alert Maintenance long before the runtime hours are exceeded, which will prevent premature damage. Furthermore, equipment that operates under optimal conditions may be able to operate long past its prescribed runtime hours, thus saving undue maintenance. While these factors provide an excellent basis for CBM, software applications can use measurement from the process itself to determine equipment health.

Process Alarms can Pinpoint Malfunctioning Instruments

The CBM system can incorporate alarms from the automation system to help identify malfunctioning instruments. Initially, the alarms slowly stream out of the Automation system, that it takes keen observation (and considerable time) for the operators to recognize the pattern of repeating alarms, especially if they span multiple shifts.

By capturing these alarms, the CBM system can quickly determine is the number of alarms for a specific instrument has exceeds a preset limit over a period of time. The CBM system can then inform the CMMS that the instrument should be inspected, automatically triggering a work order generation. This enables maintenance to recalibrate or repair the instrument even before operations is fully aware of the problem, thus eliminating potential hazardous operating conditions and urgency associated with unscheduled shutdowns.

Complex Equipment Benefits from Monitoring of Multiple Factors

The CBM system can associate multiple metered equipment values to calculate an overall equipment health factor. For instance, a feedwater pump might require the lube-oil pressure to be at a different reading when it idles than when it is at full capacity. Consequently, placing high and low alarm points on the lube-oil pressure may not be accurate at different operating conditions. Process analysis software determines the relationship between the various metered equipment values and their interactions. A normal relationship between the values indicates a good health factor. Whereas, an abnormal relationship indicates a poor health factor, and is a warning that maintenance is required.

Pacesetters use their CBM system to monitor the equipment health factors in real time and to inform the CMMS when an abnormal relationship is detected such as when the feed-water pump operates at quarter capacity, but the lube-oil pressure is still at full capacity levels). This issue is typically overlooked by busy operators and frequently causes unscheduled downtime, production loss, or both.

Control Loops can be Maintained Like Traditional Assets

The CBM approach to automation assets treats control loops as though they are physical assets, which enables maintenance to trigger instrumentation work orders based on the health of the control loop. Industry studies show that although 80% of control loops could use some maintenance, only 20% are critical enough to significantly impact the process operation and demand immediate maintenance. Unfortunately, most organizations take a reactive approach and the control loops are left to perform inefficiently, or turned to manual operation, which defeats the purpose of the automation system altogether.

By implementing continuous health monitoring of critical control loops, Pacesetters significantly reduce the work load of instrumentation personnel. The CBM system notifies the CMMS to focus instrumentation’s efforts on the worst actors that have the most impact. This maximizes production while simultaneously reducing maintenance workload and costs.

CBM Enables Maintenance to Prioritize Activities

It takes Pacesetters two steps to optimize their maintenance efforts. First, they automate their real-time data acquisition and storage using standards-based software applications. Second, they implement CBM systems that assess equipment health based on timely and accurate information. This enables Pacesetters to prioritize their maintenance efforts by moving human and capital resources away from well functioning equipment to areas that urgently require early attention.

Although it might seem that Pacesetters’ accomplishments are currently out of reach, most corporations are surprised to find out that these steps are easier to complete than initially perceived. Using commercial off-the-shelf software and standards-based applications, such tasks can be completed economically and provide exceptional add-on value to the CMMS installations.

For More Information

For more information about real-time data via the OPC communication standard, condition-based maintenance, or computerized maintenance management systems, please e-mail your requests to [email protected] or visit the following Web site links:

Condition-Based Maintenance: www.Matrikon.com

Real-time OPC Communication Standards: www.MatrikonOPC.com

OPC Multimedia Tutorial: www.MatrikonOPC.com/tutorial

Copyright © 2005 Matrikon, Inc. All rights reserved. The information contained in this document is proprietary to Matrikon, Inc. No part of this document may be reproduced, stored in a retrieval system, translated, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permission from Matrikon, Inc.

Freiter Gord

Related Articles

Too Small for a CMMS? Think Again

The Role of Information Technology in Plant Reliability

The Future of CMMS