Hydraulic Ram Leak Caused by Operator Error

www.insidersecretstohydraulics.com

A client recently asked me to explain a seal failure on a hydraulic ram. The ram had been removed from a hydraulic lift due to a leaking rod seal, but upon inspection, both the rod seal and the surface of the rod were found to be in serviceable condition.

What is a hydraulic ram?

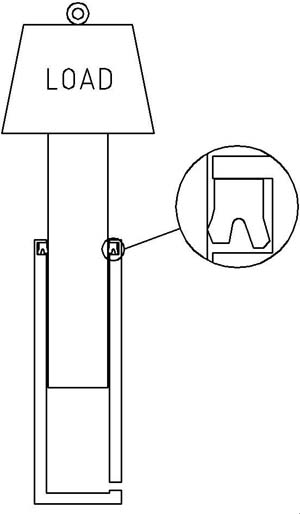

A hydraulic ram is a single-acting hydraulic cylinder in which fluid pressure acts on the cross-section of the rod i.e. it has no piston (Figure 1).

Figure 1. Hydraulic ram sectional view showing U-cup seal profile.

Failure investigation

Because inspection of the rod seal (U-cup type) and the rod’s surface didn’t reveal any obvious cause of failure, I asked the operator to describe the nature of the leak. He explained that during his morning inspections he had noticed that there was always a trickle of hydraulic fluid down the side of the ram.

Further investigation revealed that the current operator had only been assigned to the machine several weeks earlier. So I asked the operator to explain how he left the hydraulic lift at night. He advised that after shutting down he always relaxed the hydraulics (released the load off the hydraulic ram). This revealed the most likely explanation for the nuisance leak.

Seal energization

To seal effectively, a U-cup seal relies on hydraulic fluid pressure to energize the lips of the seal against the rod and seal groove (Figure 1 inset). Releasing the load-induced pressure from the hydraulic ram after shutdown effectively de-energizes the seal. Once the seal is de-energized, a gradual increase in the volume of fluid in the ram due to thermal expansion can result in fluid leaking past the seal. This gradual loss of fluid prevents development of sufficient pressure to effectively energize the seal, so the leak continues until the temperature, and therefore volume, of the fluid in the hydraulic ram stabilizes.

Root cause of failure

I advised my client that the practice of taking the load of the hydraulic ram after shutdown was the most likely cause of the leak. This being the case, there were two possible solutions. Discontinue the practice or change the seal profile to an energized U-cup (a U-cup that has an O-ring fitted in the ‘U’ to pre-energize the lips of the seal).

The root cause of the problem was confirmed when, without changing the seal profile, rod seal leakage was eliminated by discontinuing the practice of unloading the hydraulic ram. Warning! In certain situations, leaving loads suspended on hydraulic equipment can pose a safety hazard. For this reason, it is recommended that a safety risk assessment be carried out on a case-by-case basis before adopting this practice.