Studying Fractures: Recognizing and Understanding Failure Modes

Shane Turcott, Steel Image

Posted 03/07/2023

Examining a failed part’s fracture surface is a great source of information as to why and how it failed.

To understand why a part or equipment failed, how it failed must be first diagnosed. Different failure modes such as fatigue, brittle, and corrosion all have very different causes and very different solutions. If an investigation were to guess at the failure mode and guess wrongly, the planned remediation may not address the true cause of failure and additional failures may occur.

The only way to diagnose how a part failed is by examining the broken part. The various failure modes form different features which in turn can be helpful for diagnosis. Some damage mechanisms such as complex corrosion cracking require lab-based analysis. Yet for mechanical failures such as ductile, brittle, and fatigue, a lot can be learned just by visual examination of the part. It is possible for reliability workers, mechanical engineers, and inspectors dealing with failures to learn how to diagnose mechanical fractures.

To demonstrate the importance of identifying how something failed, consider three failed chain links. All three are from automotive assembly plants’ conveyor chain systems. Their failures represented lost production costs and created safety issues for people assembling the cars. Although chain links are a simple part, they can fail in a variety of manners and for very different reasons. Identifying the failure modes was crucial to understanding why each chain link had failed and to develop effective solutions. With minimal training, the failure modes of all three failures would have been identifiable to engineers and metallurgists had they been properly trained in fracture recognition.

Or phrased differently, had someone not studied the links’ fractures, what are the odds that anyone would have guessed how to prevent repeat failures for all three? Remember, if even one guess were made wrong, people might have gotten hurt.

Case Study 1

The first chain link was from a line that suffered over a dozen failures in two years. Although each failure had been taken seriously, these historical investigations were conducted without study of the links themselves.

Examination of the most recent link’s fracture surface confirmed that the failure mode was fatigue (Fig. 1). With this diagnosis as to how the link failed, the next question is naturally, why did the link fail by fatigue? Fatigue failure only occurs when the repetitive loading exceeds the fatigue limit/durability of the steel. Once the link was shown to be of sound quality, the only way to cause fatigue failure of a perfectly good link was from excessive, repetitive loading.

Therefore, chain link failure was from cyclic loading higher than it could sustain. The remainder of the investigation could then be focused on considering the source of elevated loading (excessive line tension, small radius turns, and so on). Also, considering the entire chain had experienced the excessive loading, it was likely that numerous other links had already formed cracks. Therefore, the chain needed to be replaced after the source of elevated loading was removed/reduced.

After a dozen failures, had the latest link been simply replaced, the chain would have continued to suffer more failures. If the loading on the chain had been reduced yet the chain not replaced, links already cracked would have caused more failures. If the chain had been replaced without reducing the loading, the new chain would have eventually suffered failures, too.

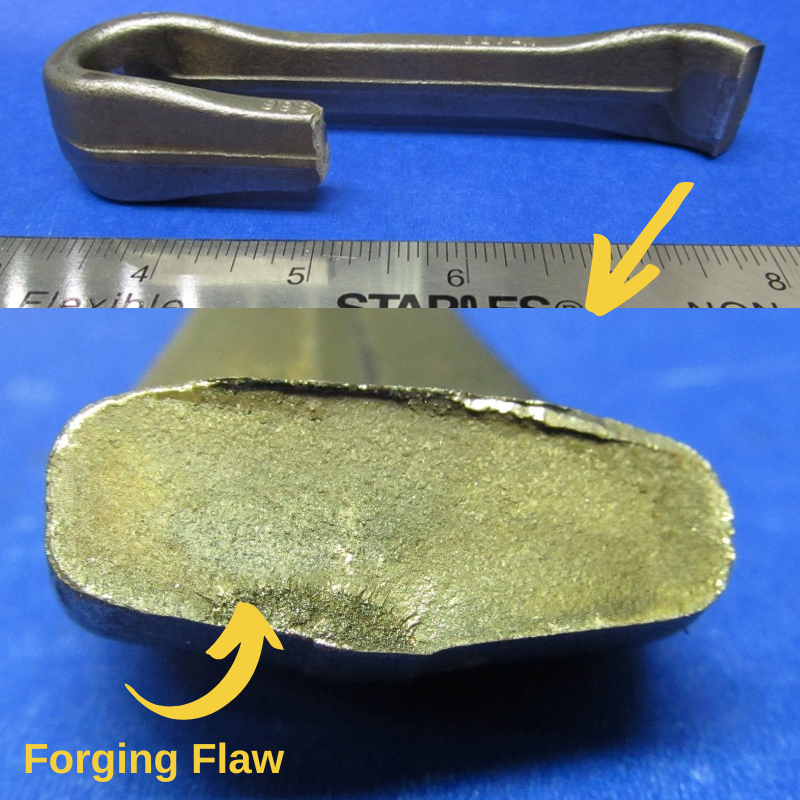

Case Study 2

In addition to studying fracture features to identify the failure mode, it is critical to locate and examine where the cracking initiated. The initiation site sometimes provides critical information relevant to how and why a part failed. In the case of this second chain link failure (Fig. 2), the fracture features were also fatigue, indicating the repetitive loading had exceeded the strength of the steel. Yet looking at the initiation region, cracking had started from a forging flaw. This pre-existing, cracklike feature had increased the local stresses, which then caused fatigue cracking. Ultimately, this link failed because of a quality issue with the link from original manufacture.

Understanding how the part failed from study of its fracture often includes additional information relevant to why it failed. If the broken link had not been studied, it was unlikely that anyone would have guessed its failure was due to a forging quality issue.

Case Study 3

The fracture features of the third chain link were distinctly different because it had failed by a different mechanism. Its fracture features were consistent with brittle failure, later found to be caused by embrittlement (Fig. 3). Due to a quality issue with the steel, it did not have the ability to sustain bending loading without snapping.

Although the diagnosis as possible brittle fracture is well within the skill limits that reliability/mechanical engineers should develop, to understand why something had been brittle requires metal testing. Yet upon recognizing the fracture features, at least the investigator would know what steps would be required to ensure that the case was solved. For this link, its embrittlement was determined to be from tempered martensite embrittlement, which is caused by tramp alloying and heat treatment, both associated with part quality.

Conclusion: Failure Modes

Components as simple as chain links can fail by numerous failure modes, each caused by different factors. One should never guess why something failed because, if they did, they would sometimes guess wrong. To understand why a part failed, one must first accurately identify how it failed. That can only be done by examining the failed part itself. For anyone involved with investigating or preventing equipment failures, learning to recognize the common mechanical failure modes is extremely helpful to equipment reliability efforts.

Note

This article is based on Decoding Mechanical Failures: The Definitive Guide to Interpreting Fractures by Shane Turcott, and is available in the ASM bookstore. This book introduces fractography and how to decode the fracture features of mechanical failures. It demonstrates how to visually diagnose and interpret ductile, brittle and fatigue failures using numerous examples. It then explains how each diagnosis is used to direct the investigation towards the root cause of failure. There are two additional chapters on advanced fatigue of rotating shafts and static fastener failures.

Shane Turcott

Shane graduated with his B.Eng and M.A.Sc. in Materials Engineering from McMaster University. He had performed failure analysis for various employers before founding Steel Image in 2009. Steel Image provides laboratory-based failure analysis supporting the maintenance and reliability efforts within the refining, petrochemical, mining, energy and manufacturing industries. He is a past Chair of American Society of Materials Ontario, author of “Decoding Mechanical Failures” and the recently released book, “Steel Isn’t Hard (To Learn)”.

Related Articles

Reduced Wear and Failure of Machine Components: Failure Analysis of Mechanical Components

Fatigue Failure 101

RCFA: How to Select the "RIGHT" Root Cause Failure Analysis