Steam Maintenance: Inspect Steam Traps for Efficient System

Alan Bandes & Bruce Gorelick

Why is Steam Maintenance so Important?

Unfortunately, when it comes to steam traps, people often ignore them. There’s a complacency about them that is costing steam users much more than they realize. The hard reality of a plant maintaining its boiler and forgetting about the rest of the steam system can be a horribly wasteful proposition. Losses can include not only wasted energy but replacement of damaged equipment and misuse of man-hours. It is not uncommon to discover system losses in the hundreds of thousands of dollars.

Fortunately, much of these potential losses can be averted by a vigilant steam management system that includes a program for steam trap surveys. A steam trap survey creates a window into a steam system. Once a maintenance engineer can see what is going on, he or she can take corrective action. Corrective actions can add substantially to a company’s bottom line as “found money.” In some business circles, it has been estimated that $10.00 in-house savings is the equivalent $1,000 in sales. In other words, if a steam system generated $10,000 in savings, it would be the same as achieving $1 million in sales for that company.

In order to create savings by producing steam system efficiencies, it is important to understand the basics of a steam system. Steam loss can occur in both the supply and return side. Such elements as pipe layout, slope angles, sizing and trap type all contribute to the effective use of steam. Many plants have personnel who work on and understand steam systems including traps. Unfortunately, there are also many facilities that do not. These facilities should seriously consider assigning some personnel to be trained in steam system function or obtain the services of steam system experts for advice.

What is a Steam Trap?

Simply put, steam traps are automatic valves that release condensed steam (condensate) from a steam space while preventing the loss of live steam. They also remove air and non-condensables from the steam space. Steam traps are design to maintain steam energy efficiency by performing specific tasks such as heating a building or maintaining heat for process. Once steam has transferred and becomes hot water, it is removed by the trap from the steam side as condensate and either returned to the boiler via condensate return lines or discharged to atmosphere (a wasteful practice).

There are many types of steam traps because there are many different types applications. Each type of trap has a range of applications for which it is best suited.

Some steam trap professionals tend to describe steam trap types in terms of their properties such as “mechanical density,” “thermostatic/temperature” or “kinetic energy.” To the uninitiated, it is best understood to describe traps in terms of their generic operation modes, such as “continuous flow” and “intermittent flow”.

Continuous flow traps will, to one degree or another, continuously discharge condensate. These are float, thermostatic and fixed orifice traps. The thermostatic trap is a hybrid. It can be considered either a continuous flow or an intermittent flow, depending on the condensate load. Under heavy condensate load or at start-up, it will tend to have a continuous discharge.

Intermittent traps will cycle open and closed. They have a pattern of hold-discharge-hold. These traps are the thermodynamic, inverted bucket and bimetallic.

Trap Characteristics

Float and thermostatic traps consist of a ball float and a thermostatic bellows element. As condensate flows through the body, the float rises or falls, opening the valve according to the flow rate. The thermostatic element discharges air from the steam lines. They are good in heavy, and light loads and on high and low pressure, but are not recommended where waterhammer is a possibility.

When these traps fail, they usually fail closed. However, the ball float may become damaged and sink down, failing in the open position. The thermostatic element may also fail and cause a “fail open” condition.

Fixed orifice traps contain a set orifice in the trap body and continually discharge condensate. They are said to be self-regulating. As the rate of condensation decreases, the condensate temperature will increase, causing a throttling in the orifice and reducing capacity due to steam flashing on the downstream side. An increased load will decrease flashing and the orifice capacity will become greater.

There is the possibility that on light loads these traps will pass live steam. There is also a tendency to waterlog under wide load variations. They can become clogged due to particulate buildup in the orifice and at times impurities can cause an erosion and damage the orifice size, causing a blow-by of steam.

Thermostatic traps have, as the main operating element, a metallic corrugated bellows that is filled with an alcohol mixture that has a boiling point lower than that of water. The bellows will contract when in contact with condensate and expand when steam is present. Should a heavy condensate load occur, such as in start-up, the bellows will remain in a contracted state, allowing condensate to flow continuously. As steam builds up, The bellows will close. Therefore, there will be moments when this trap will act as a “continuous flow” type while at other times it will act intermittently as it opens and closes to condensate and steam, or it may remain totally closed.

These traps adjust automatically to variations of steam pressure but may be damaged in the presence of waterhammer. They can fail open should the bellows become damaged or due to particulates in the valve hole, preventing adequate closing. There can be times when the tray becomes plugged and will fail closed.

Inverted bucket traps have a “bucket” that rises or falls as steam and/or condensate enters the trap body. When steam is in the body, the bucket rises closing a valve. As condensate enters, the bucket sinks down, opening a valve and allowing the condensate to drain.

Inverted bucket traps are ideally suited for waterhammer conditions but may be subject to freezing in low temperature climates if not insulated. Usually, when this trap fails, it fails open. Either the bucket loses its prime and sinks or impurities in the system may prevent the valve from closing.

While most traps operate with back pressure, they’ll do so only at a percentage of their rating, affecting everything down the line of the failed trap.

Thermodynamic traps have a disc that rises and falls depending on the variations in pressure between steam and condensate. Steam will tend to keep the disc down or closed. As condensate builds up it reduces the pressure in the upper chamber and allows the disc to move up for condensate discharge.

This trap is a good general type trap where steam pressures remain constant. It can handle superheat and waterhammer but is not recommended for process, since it has a tendency to air-bind and does not handle pressure fluctuations well.

A thermodynamic trap usually fails open. There are other conditions that may indicate steam wastage, such as “motor boating,” in which the disc begins to wear and fluctuates rapidly, allowing steam to leak through.

When a Trap Fails

Most traps fail in the open mode. When this occurs, at times, a boiler may begin to work harder to produce the necessary energy to perform a task which, in turn, can create high back pressure to the condensate system. This inhibits the discharge capacities of some traps, which may be beyond their rating, and cause a system inefficiency. While most traps operate with back pressure, they’ll do so only at a percentage of their rating, affecting everything down the line of the failed trap. Steam quality and product is affected.

A closed trap produces condensate back-up into the steam space. The equipment will not produce the intended heat. As an example, if there are four coils in a dryer and only three are operating, it will take longer for the dryer to dry a product, which will have a negative effect on production.

Excluding design problems, two of the most common causes of trap failure are oversizing and dirt. Oversizing causes traps to work too hard. In some cases this can result in blowing of live steam. As an example, an inverted bucket trap can lose its prime due to an abrupt change in pressure. This will cause the bucket to sink, forcing the valve open.

Excluding design problems, two of the most common causes of trap failure are oversizing and dirt.

Dirt is always being created in a steam system. Excessive build-up can cause plugging or prevent a valve from closing. Dirt is generally produced from pipe scale or from over-treating of chemicals in a boiler.

How Failure Affects Equipment

When steam traps cause a back-up of condensate in a steam main, the condensate is carried along with the steam. It lowers steam quality and increases the potential for waterhammer. Not only will energy be wasted, equipment can be destroyed.

Waterhammer occurs as slugs of water are picked up at high speeds in a poorly designed steam main or in pipe coils or where there is a lift after a steam trap. In some systems, the flow may be at 120 feet per second, which is about 82 m.p.h. As the slug of condensate is carried along the steam line it reaches an obstruction, such as a bend or a valve, where it is suddenly stopped. The effect of this impact can be imagined. It is important to note that the damaging effect of waterhammer is due to steam velocity, not steam pressure. It can be as damaging in low pressure systems as it can in high. This can actually produce a safety hazard, as a valve or a strainer can be blown out by the force of waterhammer.

Condensate in a system is destructive. It can cause valves to become wiredrawn and unable to hold temperatures as required. little beads of water in a steam line can eventually cut any small orifices the steam normally passes through. Wire-drawing will eventually cut enough of the metal in a valve seat that it prevents adequate closure, producing leakage in the system.

Testing Methods

Before testing a steam trap, inspectors should be familiar with the particular function, review typical types of traps and know the various pressures within the system. This can help avoid misdiagnosis and allow proper interpretation of trap conditions.

There are three main categories of online trap inspection: visual, thermal and acoustic. Visual inspection depends on a release valve situated downstream of certain traps. An inspector opens these valves and looks to see if the trap is discharging condensate or steam. Thermal inspection relies on upstream/downstream temperature variations in a trap. It includes pyrometry, infrared, heat bands (wrapped around a trap, they change color as temperature increases), and heat sticks (which melt at various temperatures). Acoustic techniques require an inspector to listen to and detect steam trap operations and malfunction. This method included various forms of listening devices such as doctors’ stethoscopes, screwdrivers, mechanical stethoscopes and ultrasonic detection instruments.

The ideal listening device will allow users to listen to the sounds of steam trap operations while ignoring most ambient pipe sounds. This is where ultrasonic listening devices excel. Since they are sensitive to high frequency (short wave) signals, they tend to ignore most stray pipe signals. Also, they are very directional in their pick-up. For this reason, they will allow users to hear and see on meters the exact operations of steam traps.

Ultrasonic detectors usually have a stethoscope module, which contains an ultrasonic transducer attached to a metal rod that acts as a “wave guide”. The wave guide is touched on the downstream side of a trap to determine trap condition such as mechanical movements or steam and condensate flow. Most ultrasonic detectors amplify the signals and translate them into the audible range where they are heard through headphones or seen as intensity increments on a meter. Some include frequency tuning to allow users to tune into desired trap sounds.

Record-keeping

Good record-keeping is essential. It is one thing to just inspect traps, another to be able to determine costs, efficiencies, inefficiencies and trouble spots. To begin with, traps should be tagged and mapped. All too often many traps in a system are forgotten. A mapping and tagging system will assure that these traps are maintained.

There are many ways to systematize data and to keep records. The result should be useful records such as cost analysis of the work performed. Also, analytic ability is needed to determine the status of all the traps within a system including those failed, blocked, leaking, out of service or operating well. Here a computer can be invaluable. Rather than trying to “reinvent the wheel,” take advantage of commercially available software packages that can help successfully implement a good steam management system.

In-house Survey Ideal

Ideally, a survey will be conducted by in-house trained inspectors who will routinely inspect their steam traps. How- ever, even in plants that have trained inspectors, steam traps often are neglected. This is because, in many plants, maintenance departments have been scaled back to where they’re putting out fires and do not have the time or manpower for surveys. In these situations, plants can benefit from using professional services.

Professional services can conduct surveys and issue reports without involving in-house staff. Or in facilities with large staffs, an expert can be brought in to set up a program and train personnel. In-house staff can be trained to maintain and inspect traps while the professional can assure that the program runs effectively.

In summary, any plant with a steam trap system should set up a comprehensive survey program. Whether it has 50 traps or 5,000 traps, substantial savings can be generated in the energy, equipment, manhours and product by keeping on top of the system.

Related Articles

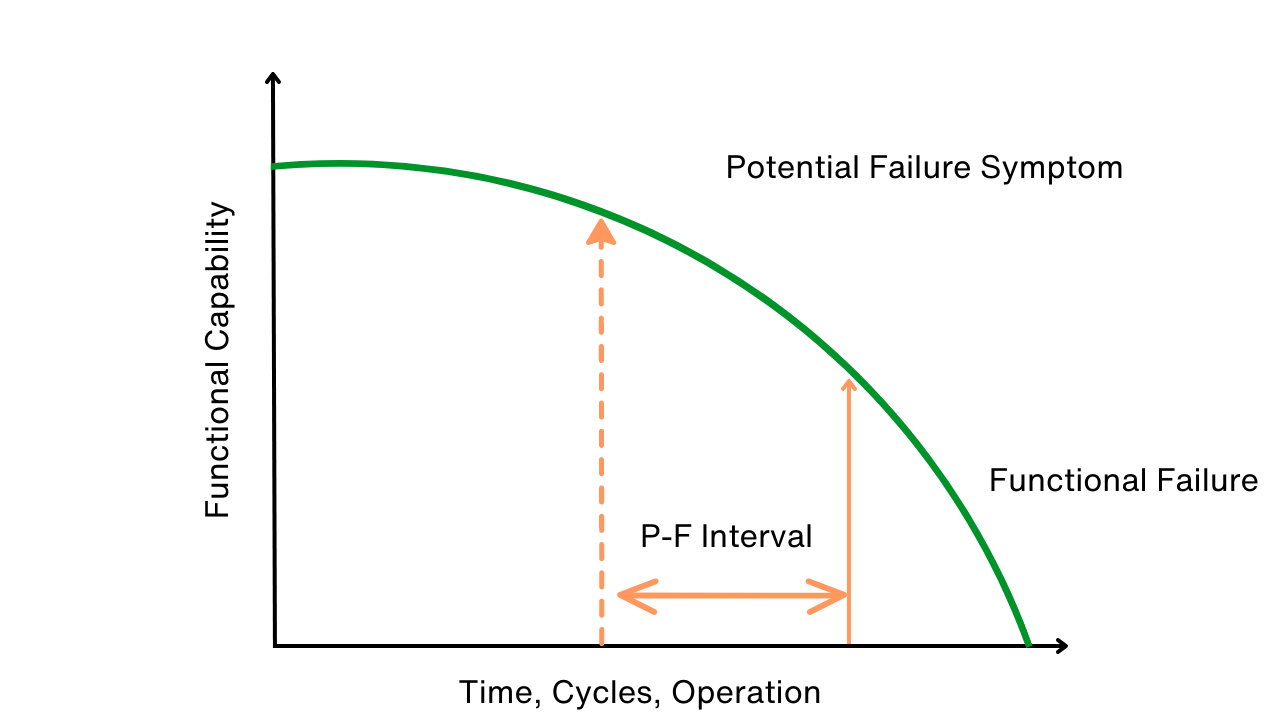

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability