A Driving Lesson for Plant Management

Torbjörn Idhammar, IDCON INC.

Picture this. Plant Management Personnel are driving along a road in an automobile. The maintenance manager is driving blindfolded.

Sitting beside the maintenance manager is the mill manager who is peering in the rear view mirror. In the back seat, the production manager is urging the maintenance manager to proceed at top speed while simultaneously warning him about a flat tire.

This situation is obviously out of control. In a plant setting, it is equally out of control.

Plant management frequently focuses on past data analysis rather than future improvements.

Maintenance is often “blindfolded” due to tight short-term cost control measures instead of long-term results.

Meanwhile, the operations group is becoming desperate and therefore dictates what maintenance should do.

The behavior described has many names—the circle of despair, unplanned maintenance, or reactive maintenance.

Whatever name you prefer, you must understand the point from a maintenance perspective.

Maintenance work needs management through good maintenance planning and scheduling. How does one start such an improvement?

From the thousands of possible ways to start, this article will discuss a starting point: “Maintenance and Operations 101.”

One key element of an operations and maintenance partnership is well-organized daily or weekly planning and scheduling meetings.

Although you may already have these meetings, are they as productive as they could be? The purpose of such meetings is finalizing a schedule and possibly finalizing minor planning.

The meeting objectives or agenda are the following:

- Review work from yesterday

- Update work for today

- Finalize work for tomorrow

- Finalize schedule for following week by 2 PM on Friday

- Track planning and scheduling of key metrics

- Schedule 100% of work force including contractors

- Resolve new work requests.

The meeting should be attended by the area or department operations representatives, maintenance supervisors, and planners. The operations liaison must have sufficient clout to set a schedule without overriding by others after the meeting.

Maintenance should represent both mechanical and E/I maintenance.

The meeting should occur mid-day and last no longer than 20 minutes. Keeping the meeting to this limit with effective results requires the following:

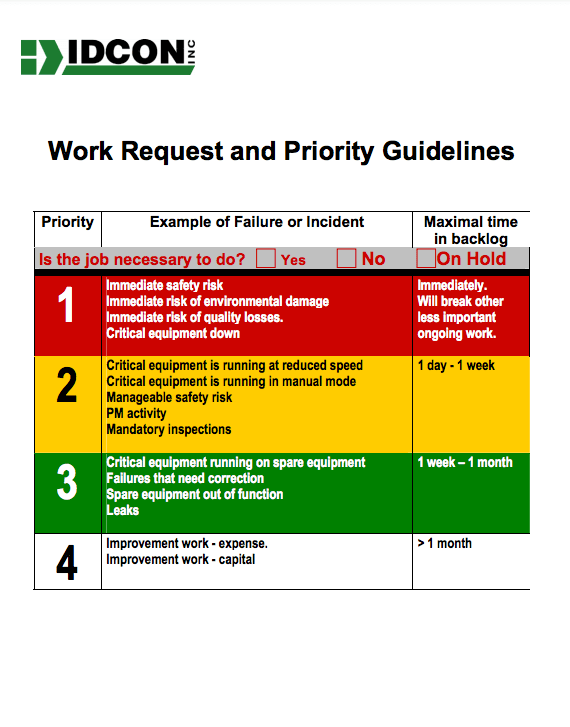

- Having a priority chart. An example is available here:

Planning for work in the backlog before the meeting - Knowing the availability of people

- Realizing that all meeting agreements are final—any change is break-in work.

Tracking the performance of these meetings is critical. Upper management must drive—not simply support—the planning and scheduling meetings.

A simple scorecard (available above) will help.

The scorecard tracks the following:

- Did all the proper people attend?

- Did attendees do their preparatory work?

- What is the level of unapproved work orders in the backlog?

- Was the first cut of the schedule for the following week posted on time?

In addition to the meeting indicators, the group should track the classic planning and scheduling indicators such as scheduling compliance, planning compliance, paper machine compliance, etc.

A major process plant in the United States recently implemented better planning and scheduling procedures. They achieved 7.7% average increased reliability in their bottleneck worth US $6 million in eight months.

Learn About IDCON’s maintenance planning and scheduling consulting and training

Torbjörn Idhammar

Torbjörn Idhammar is the president and CEO of IDCON INC., a Reliability and Maintenance Management Consulting Firm. Tor’s responsibilities include training IDCON consultants, product development, sales, and marketing. He gives advice to IDCON’s multi-site and international clients to ensure outcomes and deliverables are met.