Troubleshooting Mechanical Seals | Coking | Part 7

Chesterton

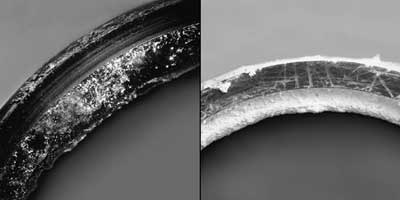

Coking

| SEAL FACE – COKING | SEAL FACE – CRYSTALLIZED |

SYMPTOMS:

- Coking or crystallized product

CAUSES:

- Excessive temperatures (both)

- Dirty or contaminated fluid (coking)

- Operating outside of the temperature envelope of the fluid (both)

- Small clearances in the seal chamber

- Pump cooling jacket not efficient

- Fluid evaporation between the seal faces (crystallization)

FAILURE MODES:

- Inadequate environmental controls

- Product harden, set-up or coked

- Exceeded limits (speed, temperature, pressure)

SOLUTIONS:

- Proper use of environmental controls

- Operate within seal limits

- Understand the temperature envelope of the fluid being sealed

This is a 9 part series. Click to view each article: 1 : 2 : 3 : 4 : 5 : 6 : 7 : 8 : 9

Related Articles

Causes of Overheating in Cartridge Mechanical Seals

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

How Can I Extend the Performance Range of Standard Cartridge Mechanical Seals?

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

In today's global environment, the "one size fits all" approach is used for so many products that we expect it to apply to just about everything. In the mechanical seal industry, one problem with that philosophy is the definition of the word all. Mechanical seals must live in literally every environment under the sun-from extreme hot to extreme cold, wet to dry, solid to gas, acidic to caustic and so on. Until relatively recently, a vast variety of cartridge mechanical seals were needed to accommodate these pump applications.

The Process of Troubleshooting Mechanical Seals - Part 1

The 9 articles in this series will outline common issues with mechanical seals, how to notice them, and troubleshooting tips. The series addresses: wide wear track, centered/miscentered, even/uneven wear track, scoring, chipping, coking, heat cracking or checking, and blistering.

The 9 articles in this series will outline common issues with mechanical seals, how to notice them, and troubleshooting tips. The series addresses: wide wear track, centered/miscentered, even/uneven wear track, scoring, chipping, coking, heat cracking or checking, and blistering.

Troubleshooting Mechanical Seals | Wide Wear Track | Part 2

Part 2 of 9 on Troubleshooting Mechanical Seals: Wide Wear Track - symptoms, causes, failure modes, and solutions.

Part 2 of 9 on Troubleshooting Mechanical Seals: Wide Wear Track - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Centered/ Miscentered | Part 3

Part 3 of 9 on Troubleshooting Mechanical Seals: Centered/Miscentered - symptoms, causes, failure modes, and solutions.

Part 3 of 9 on Troubleshooting Mechanical Seals: Centered/Miscentered - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Even/Uneven Wear Track | Part 4

Part 4 of 9 on Troubleshooting Mechanical Seals: Even/Uneven Wear Track - symptoms, causes, failure modes, and solutions.

Part 4 of 9 on Troubleshooting Mechanical Seals: Even/Uneven Wear Track - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Scoring | Part 5

Part 5 of 9 on Troubleshooting Mechanical Seals: Scoring - symptoms, causes, failure modes, and solutions.

Part 5 of 9 on Troubleshooting Mechanical Seals: Scoring - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Chipping | Part 6

Part 6 of 9 on Troubleshooting Mechanical Seals: Chipping - symptoms, causes, failure modes, and solutions.

Part 6 of 9 on Troubleshooting Mechanical Seals: Chipping - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Heat Checking or Cracking | Part 8

Part 8 of 9 on Troubleshooting Mechanical Seals: Heat Cracking or Heat Checking - symptoms, causes, failure modes, and solutions.

Part 8 of 9 on Troubleshooting Mechanical Seals: Heat Cracking or Heat Checking - symptoms, causes, failure modes, and solutions.

Troubleshooting Mechanical Seals | Mechanical Seal Blistering | Part 9

Part 9 of 9 on Troubleshooting Mechanical Seals: Mechanical Seal Blistering - symptoms, causes, failure modes, and solutions.

Part 9 of 9 on Troubleshooting Mechanical Seals: Mechanical Seal Blistering - symptoms, causes, failure modes, and solutions.