AAA Best Practices Make the Difference

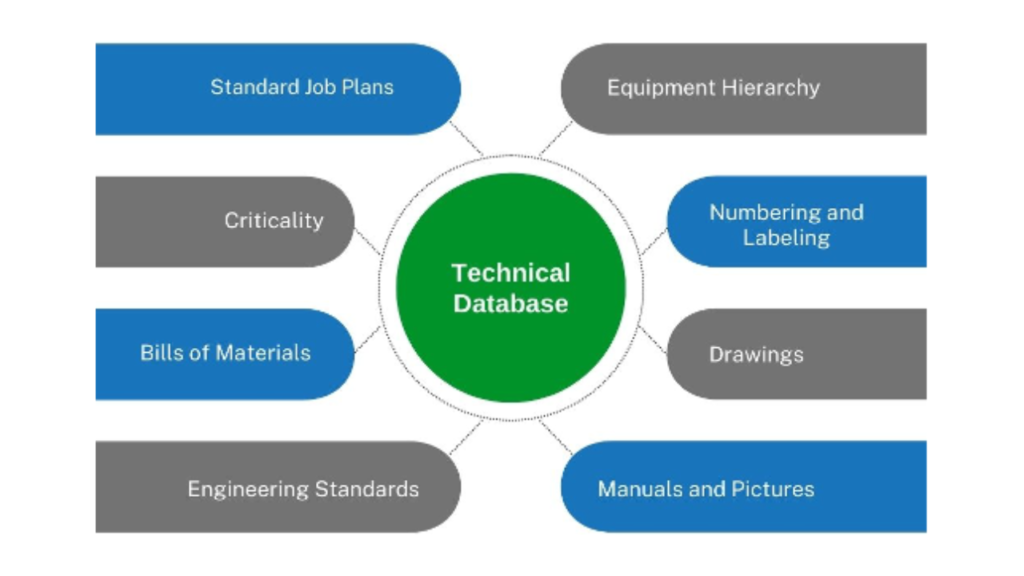

The technical database is all the information needed to plan and schedule efficiently and effectively. Having the eight components of the technical database in place will allow quick determination of the what, how, how long, who, and when of a maintenance job. Application of three simple best practices will generate the most value from the technical database. Focus on developing a technical database that is accurate, accessible, and applied.