Drying Your Compressed Air System Will Save Real Money

Power & Motion

The cost of replacement parts, labor, standby inventory, and downtime can have a devastating effect on a plant’s bottom line. Eliminating even one of them by drying a compressed air system will offset the cost of installing and operating the equipment.

When pneumatic components wear or become corroded as a result of moisture, they consume more compressed air – and lose energy efficiency. When this wear or corrosion becomes great enough, components must be repaired or replaced – increasing operating expense.

4 Types of Compressed Air Dryers

Dryers remove water vapor from the air, which lowers its dew point – the temperature to which air can be cooled before water vapor begins to condense. In broadest terms, there are four basic types of industrial compressed air dryers: deliquescent, regenerative desiccant, refrigeration, and membrane.

Dryers remove water vapor from the air, which lowers its dew point – the temperature to which air can be cooled before water vapor begins to condense. In broadest terms, there are four basic types of industrial compressed air dryers: deliquescent, regenerative desiccant, refrigeration, and membrane.

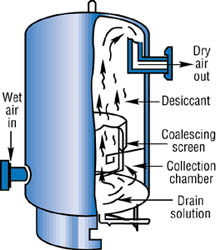

Deliquescent dryers contain a chemical desiccant which absorbs moisture contained in the air, whether the moisture has already condensed or is still a vapor. The desiccant is consumed in the water-removal process and must be replenished periodically. The solution that must be drained from these dryers contains both liquid water and the deliquescent chemical, so disposal may be a problem. Local environmental regulations should be checked before disposal of this solution.

Deliquescent dryers reduce the dew point of compressed air 15° to 25° F below the inlet air temperature. If the incoming air has a dew point of 90° F, it will leave a deliquescent dryer with a dew point of about 65° F. Depending on operating conditions, some deliquescent dryers can produce dew points as low as -40° F; new deliquescent chemicals may produce even lower dew points.

Two important points: desiccant level should not be allowed to fall below that recommended by the dryer manufacturer, and inlet temperature should be limited to 100° F or less to prevent excessive desiccant consumption.

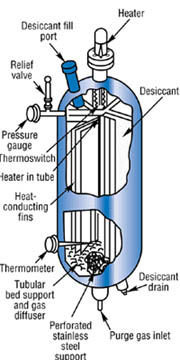

Heatless regenerative dryers use two identical chambers filled with desiccant. As wet air moves up through one chamber, a portion of the dry discharged air is diverted through the second chamber at close to atmospheric pressure, reactivating its desiccant. The moisture-laden purge air is vented to atmosphere. Some time later, air flow through the chambers is reversed.

Standard industry dewpoint ratings for these dryers is -40° F at pressure. By adjusting the flow rates and volume of purge air, -100° F pressure dewpoints can be achieved. These dryers, as with all desiccant dryers, should be supplied with oil-free air. Oil will greatly reduce the life expectancy of the desiccant.

Heat regenerative dryers also use two identical chambers. In this type, however, air flows through one chamber until its desiccant has adsorbed all the moisture it can hold. Then air flow is diverted to the second chamber. Internal heating elements or an external source of heat (steam or electricity) then dries the saturated desiccant in the first chamber. Because desiccant’s adsorption capacity decreases as temperature increases, the dried desiccant bed must be cooled from the temperature it reaches during regeneration before it can be used again. The regeneration cycle in these dryers usually lasts several hours – 75% heating and 25% cooling.

Regenerative desiccant dryers can produce pressure dew points as low as -100° F. The type of desiccant used has a definite effect on the final dew point.

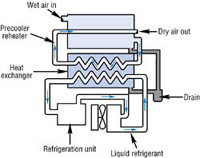

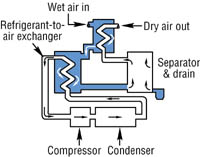

Refrigeration dryers condense moisture from compressed air by cooling the air in heat exchangers chilled by refrigerants. These dryers produce dew points in a range from 35° to 50° F at system operating pressure.

Most 20-scfm and larger refrigeration dryers reheat the cooled air after it has been dried, usually by routing it through heat exchangers in contact with the hot incoming air. Reheating the cooled air prevents condensation from forming on the exterior of air lines downstream from the dryer and also precools incoming air.

Standard refrigerating dryers should not be used where ambient temperature can drop below 40° F because lower temperature can freeze condensate. This will block air passages and could damage the dryer’s evaporator. Dryers may be equipped with heat tracing packages for operating in ambient temperatures as low as 50° F.

Refrigeration dryers should not be operated in conditions where the incoming air and ambient air heat load is 15 to 20% of the rating – a 100-scfm rated dryer (100° F inlet and ambient) can freeze up if operated at 20 scfm and 40° F.

Refrigeration Dryer Types

Tube-in-tube refrigeration dryers operate by cooling a mass of aluminum granules or bronze ribbon that in turn cools the compressed air. As the tube-to-tube refrigeration dryer cycles, a thermometer in the granule mass senses its temperature. As the temperature rises, a switch turns on the refrigeration unit. When the temperature drops to a cut-off point, refrigeration stops. These dryers are designed to produce dew points of 35° or 50° F.

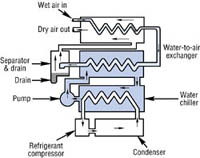

Water-chiller refrigeration dryers use a mass of water for cooling. An extra heat exchanger is needed to maintain chilled water flow through the condenser, as well as a water pump. Dew points can be between 40° and 50° F. Water-chiller dryers cycle as they operate.

Membrane-Type Dryers

Typically this membrane material is formed into bundles of thousands of individual fibers from one end of the dryer to the other. Water vapor escapes through the walls of the fiber to a sweep chamber from where it is continually vented to atmosphere as a gas. A fraction of the dried air is routed through the sweep chamber to continuously purge and exhaust moisture vapor.

Industrial-grade membranes can be used for years to dry air continuously. They respond spontaneously to any change in inlet conditions. They perform at temperatures between 40° and 150° F (ambient or inlet), and handle pressures from about 60 to 300 psig. They will deliver a consistent outlet dew-point reduction anywhere between these extremes. The inlet flow rate and pressure determine the outlet dew point suppression. In other words, membrane air dryers deliver a consistent level of drying protection that follows the rise or fall of the inlet dew point temperature, and can easily be sized to follow the ISA recommended 20° F pressure dew point suppression below ambient. Outlet pressure dew points can also be selected as low as -50° F. Flow capacities are relatively low, but modules can be installed in parallel for higher flows.

Prefilters mounted immediately upstream from the membrane dryer keep out liquids and solids to allow an almost unlimited service life. Because water vapor passes right through the membrane material, it does not accumulate there, so membranes do not become saturated and never need to be regenerated. Membranes have no moving parts to wear out. They are non-electric and suitable for most hazardous locations. They require no RF shielding or protection. They use no refrigerant gas or potentially dusty desiccants.

They make no noise. And, they can be mounted in any orientation. Their low-mass components are inherently vibration-resistant. Because they are static, inert devices, they never need service or adjustment and don’t require monitoring devices. Made of plastic and aluminum, they do not rust or corrode and don’t need painting. They have almost no pressurized volume, so most pressure code restrictions do not apply.

Note: membrane gas separators will remove other gases too. Some membrane-type compressed air dryers can reduce outlet oxygen concentrations (or not permeate oxygen at all). Consult the manufacturer to determine if membrane can be used for breathing air.

Importance of Knowing the Dew Point of Compressed Air

As pointed out earlier, wet air adds to plant operating expenses through the cost of:

- repair parts,

- repair labor,

- product damage, and

- production downtime.

The economic advantages of reducing or eliminating these detriments of moisture build a strong case for installing a dryer. Once the decision to install a dryer has been reached, two questions arise: how dry must the air be, and what type of dryer should be used?

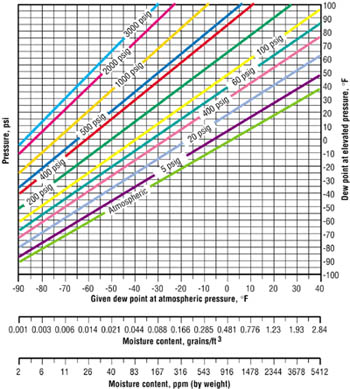

The most important criterion in choosing an air dryer is the pressure dew point that it must produce. The required dew point of an air system determines how dry the air must be and to a great extent, which type of dryer to use. Dew point varies with pressure. For example: the compressed air dew point chart at left shows that air at atmospheric pressure with a dew point of -12° F has a pressure dew point of 35° F at 100 psig. Dryer manufacturers may specify the dew point that a particular model can attain at atmospheric pressure or at a typical system pressure, such as 100 psig. If performance is specified at atmospheric pressure, use a chart like at left to find what the minimum dew point will be at the system’s operating pressure.

The required dew point varies with each application. If preventing condensation in compressed air lines is the main concern, then the lowest ambient temperature to which air lines will be exposed will be the controlling factor. However, for some applications, dew point requirements will be more stringent, possibly as low as -100° F at line pressure. An example might be the air used for spraying a powdery substance. Even the slightest trace of moisture in such air could condense and cause particles to stick together.

If all the compressed air will be used inside a building where temperature is maintained at a stable level, then the required dew point can be fixed within a few degrees. But if some or all of the compressed air is subjected to outdoor temperature variations, the required dew point can change from day to day, or even hour to hour.

Do not be too aggressive by estimating an unjustifiable margin for error. Stating a dew point much lower than that actually required wastes money. A rule-of-thumb margin for error is about 20° F maximum.

Extremely low dew points may be required at only a few isolated locations. If this is the case, consider using individual small heatless regenerative dryers at locations requiring pressure dewpoints below 35° F. A less-expensive dryer to dry the air to less-stringent requirements can then be installed for the rest of the air system.

Evaluating Flow Capacity

An air dryer not only must dry compressed air to the required dew point, but also must be able to handle the required air flow without causing excessive pressure drop. Flow capacity of a dryer depends on:

- operating pressure,

- inlet air temperature,

- ambient air or cooling water temperature, and

- required dew point.

When any of the above conditions changes, flow capacity of the dryer also changes. Dryer manufacturers can supply performance curves that show the relationship of their dryer’s flow capacity to these four factors. Evaluating characteristics of the different types of dryers will help indicate which is best for a particular application. This is where cost finally can be considered. Purchase price of the dryer is only one factor to evaluate when choosing an air dryer. A deliquescent chemical dryer, for example, has a relatively low initial cost, but its chemical must be replaced periodically, adding to the operating cost. This cost is offset somewhat because the deliquescent chemical dryer requires no external power source.

Other dryer types may cost more initially, but have lower operating costs because they can run for long periods with little or no maintenance required. It should be clear, then, that cost analysis should be conducted based on manufacturers’ specifications as they relate to an individual application’s physical and economical requirements.

Installation and Maintenance

Location can affect how well an air dryer performs. The site for an air-cooled dryer should be well ventilated, so heat can be carried away, and readily accessible to aid maintenance. The maximum ambient temperature for a refrigerated dryer is about 100° to 120° F. Higher temperatures prevent the dryer from exchanging heat with its surroundings and keep it from operating properly. Dryers with water-cooled condensers can tolerate higher ambient temperature because they transfer heat to the cooling water instead of to the surrounding environment. Refrigerant dryers, whether air- or water-cooled, should not be exposed to ambient temperature below 32° F unless optional low-ambient-temperature controls are installed.

If a deliquescent dryer is used in a central compressed-air system, bypass piping should be installed around the dryer to maintain air supply whenever the dryer is taken off line to add desiccant. There should also be no set of operating conditions that permit system pressure to drop low enough to allow high, turbulent air flow through the dryer that might carry chemicals into system air lines. It is important to shut off the water in water-cooled aftercoolers when the air system is shut down. A leak in the aftercooler could flood the deliquescent dryer and fill downstream piping with desiccant, making all pneumatic components inoperable.

Refrigeration and deliquescent dryers should be drained regularly, depending on the volume of liquid accumulated. Most refrigeration dryers have automatic drains, at least as an option.

It should be noted that dryers remove water vapor, while filters remove liquid water. A good drying system always has a filter with an automatic drain installed upstream from the air dryer. Air dryers of all types are not stand-alone components. The cost of adequate prefilters, both particulate and oil coalescing, is a wise investment to protect the more expensive dryers. Postfilters are necessary for several reasons. For refrigerated dryers, a coalescing filter can catch any oil from a refrigerant leak. For deliquescent dryers, a particulate filter downstream will catch any carryover of the corrosive desiccant. For regenerative dryers, a 0.5-µm postfilter is necessary to catch desiccant dust, which is common to all adsorptive desiccants.

Related Articles

OEE: Overall Equipment Effectiveness

What the Pump Was Designed to Do and Why it Doesn't Do it

What is Wrong with the Modern Centrifugal Pump?

Digging Up Savings: Go with the Flow

Chain Drive Design Recommendations

Classifying Chemicals to Assure Effective Sealing