Mobile CMMS: The Future Maintenance Team’s BFF

Ashley Halligan

Maintenance management is an around-the-clock challenge. Equipment failure can (and does) happen at inconvenient times–times when maintenance managers may be off-site and must rely on communication from technicians to convey problems and act efficiently. A Mobile CMMS system and other applications provide live, synchronized status reports and other key features that can dramatically improve reaction time and efficiency.

However, some organizations have been reluctant to shift from traditional maintenance management systems to mobile operations. Some technicians are intimidated by the technology–both because it can be complex to use, and because they perceive a risk that these advancements will render their jobs unnecessary.

Furthermore, some organizations have been hesitant to make the financial investment in mobile devices for maintenance teams, along with the software upgrades that are sometimes necessary.

As a result, mobile CMMS have been slow to seep into the maintenance and asset management sector, but those who embrace them seem to quickly realize the benefits of doing so.

Leading CMMS software vendors like HippoFM and Upturn Solution’s Sprocket have introduced full-fledged mobile CMMS versions of their systems, while niche vendors offer function-specific applications accessible by mobile devices.

By automating core functionalities and providing real-time updates on equipment, maintenance tasks and upcoming alerts, current data is accessible organization-wide. Here are the most valuable features these systems and applications provide, the business challenges they address, and how they’re changing maintenance management.

Core Functions and Benefits

Paperless Work Order Management: Having the capability to manage work orders on- or off-site alleviates the need to collect and disperse paper work orders in-house. This saves time by eliminating the need to take notes in the field–then having to manually re-enter those same notes on-premise. Managers can instantly dispatch a work order to a technician–and the tech can acknowledge its receipt, provide job status updates, close completed work orders, and finalize tasks with mobile signatures.

Why this is valuable: Managers and technicians can communicate from different locations to update job statuses and verify completion, while existing work orders can be modified from afar when necessary. This significantly reduces the amount of time spent creating and managing current work orders and awaiting in-person approval, and allows immediate, organization-wide updates without having to visit the home office.

Inventory Management: Mobile CMMS systems give managers and technicians instant access to inventory records in the field. This enables, for instance, a technician to check parts inventory for upcoming jobs, or to issue a spare part to a remote location. Technicians and maintenance managers can also instantly update inventory records when returning or dispatching equipment to or from a job.

Why this is valuable: Even with a Web-based CMMS system, tracking inventory from a remote location was not instantaneous, which was problematic in the case of an immediate need for issuing spare parts. With mobile CMMS, the availability and location of parts and equipment is always current.

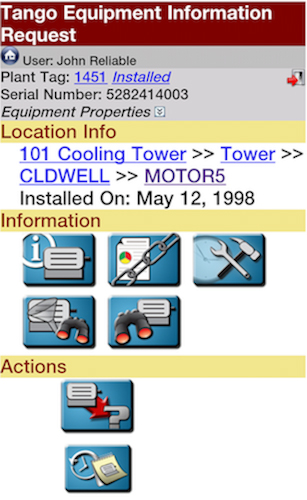

Asset Management and QR Codes for Maintenance Tracking: Maintaining accurate and up-to-date maintenance history for an asset can be a tedious and lengthy task. With barcodes and Quick Response (QR) codes affixed to an asset, its entire history–including past maintenance, upcoming maintenance, and malfunction reports–is accessible simply by scanning the code with a mobile device.

Maintenance updates are recorded via the same process, with updates being immediately integrated into the asset’s history. Some Web-based CMMS suites offer this functionality, though there are also vendors like Tango that provide QR scanning as a dedicated mobile application.

Why it’s valuable: While cloud solutions in maintenance management have the capability to store up-to-date and detailed asset records, having the added capability of accessing comprehensive maintenance data in the field is a valuable tool. This allows maintenance professionals to instantly update records, record condition entries, and flag necessary alerts.

Since almost all maintenance management tasks are performed in the field or on the floor, immediate mobile access allows status updates to be accessible by all levels of an organization. This bridges the communication gap between personnel and management and ensures the database is always up-to-date.

Overall, a mobile CMMS system lessens the amount of time needed to initiate work orders, update asset records, manage and issue inventory for jobs, and await job approvals and status updates.

Ashley Halligan

Has your organization recently shifted toward or implemented mobile or application-based CMMS? If so, what has your experience been like? Have you found the transition to be an efficient one? Feel free to share your experiences below or email me at [email protected].

Related Articles

Maintenance Apps for Smartphones

Sources of data for AI Empowered Maintenance – Manufacturing Execution System

How to Mitigate Risk with Your Mobile Solution Proof of Concept

New Challenges in Maintenance Management