The Affinity Laws for Rotary, Positive Displacement Pumps 13-6

The McNally Institute

The affinity laws accurately predict the affect of changing the speed of a centrifugal or rotary pump, and they also do a fairly good job of predicting the affect of changing the diameter of a centrifugal pump. In another paper (02-01) we discussed the affinity laws as they apply to centrifugal pumps, but in this paper we will look at their use with rotary pumps.

Rotary pump designs include: gear, vane, lobe, progressive cavity, screw, etc. They are more commonly know as positive displacement (PD) pumps and act very different than centrifugal pumps:

- PD pumps do not have a best efficiency point (B.E.P).

- There is no impeller shape (specific speed) to consider.

- There is no system curve to match.

- Their capacity is a constant even if the head changes.

- Unlike a centrifugal pump, if you were going to fill a tank with a PD pump you would fill the tank from the bottom rather than the top to save energy costs.

Take a look at the following two curves. The one on the left describes a centrifugal pump curve with the curve shape determined by the “specific speed” number of the impeller. The curve on the right describes the curve we get with a typical Rotary Pump.

H = Head in feet or meters

Q = Capacity in gpm, or M3/hr

What happens when you change the speed of each of these type pumps? We will look at what happens when you double the speed and change from 1750 rpm to 3500 rpm. This is a drastic change in speed, but not uncommon.

If you are using a variable speed motor, pulley arrangement or gear box the speed change might not be as dramatic, but the formulas you will be using remain the same.

NEW SPEED/OLD SPEED = A NUMBER , or

3500/1750 rpm. = 2, or

1500/ 3000 rpm. = 0.5

First we will take a look at what happens with a centrifugal pump when you double the speed. In the metric system I will show what happens when you cut the speed in half:

The capacity or amount of fluid you are pumping varies directly with this number.

- Example: 100 Gallons per minute x 2 = 200 Gallons per minute

- Or in metric units: 50 Cubic meters per hour x 0,5 = 25 Cubic meters per hour

The head varies by the square of the number.

- Example : A 50 foot head x 4 (22) = 200 foot head

- Or in metric: A 20 meter head x 0,25 ( 0,52) = 5 meter head

The horsepower required changes by the cube of the number.

- Example : A 9 Horsepower motor was required to drive the pump at 1750 rpm.. How much is required now that you are going to 3500 rpm?

- We would get: 9 x 8 (23) = 72 Horse power is now required.

- Likewise if a 12 kilowatt motor were required at 3000 rpm. and you decreased the speed to 1500 the new kilowatts required would be: 12 x 0,125 (0.53) = 1,5 kilowatts required for the lower rpm.

The NPSH required varies by approximately the square of the speed

- Example 9 feet x 22 = 36 feet

- Or in metric 3 meters x 22 = 12 meters

Lets compare that to the rotary, positive displacement pump. Again we will double the speed, and in the metric units we will cut the speed in half:

The capacity or amount of fluid you are pumping varies directly with this number.

- Example: 100 Gallons per minute x 2 = 200 Gallons per minute

- Or in metric: 50 Cubic meters per hour x 0,5 = 25 Cubic meters per hour

There is no direct change in head with a change in speed. The pump generates whatever head or pressure that is necessary to pump the capacity.

The horsepower required changes by the number

- Example : A 9 Horsepower motor was required to drive the pump at 1750 rpm.. How much is required now that you are going to 3500 rpm?

- We would get: 9 x 2 = 18 Horse power is now required.

- Or in metric units, if a 12 kilowatt motor were required at 3000 rpm. and you decreased the speed to 1500 the new kilowatts required would be: 12 x 0,5 = 6,0 kilowatts required for the lower rpm.

The NPSH required varies by the square of the speed

- Example 9 feet x 22 = 36 feet

- Or in metric, 3 meters x 0,25 ( 0,52) = 0,75 meters

Rotary pumps are often used with high viscosity fluids. There is a set of Affinity Laws for changes in viscosity, but unlike changes in speed the change in viscosity does not give you a direct change in capacity, NPSH required, or horsepower. As an example: an increase in viscosity will increase the capacity because of less slippage, but twice the viscosity does not give you twice the gpm.

Since there are a variety of Rotary Pump designs operating over a wide range of viscosities, simple statements about changes in operating performance are hard to make, but the following relationships are generally true.

Here are the Viscosity Affinity Laws for Rotary Pumps:

- Viscosity 1>Viscosity 2 = gpm 1 > gpm 2

- Viscosity 1>Viscosity 2 = BHP 1 > BHP 2

- Viscosity 1>Viscosity 2 = NPSHR 1 > NPSHR 2

- Viscosity 1>Viscosity 2 = No direct affect on differential pressure.

Related Articles

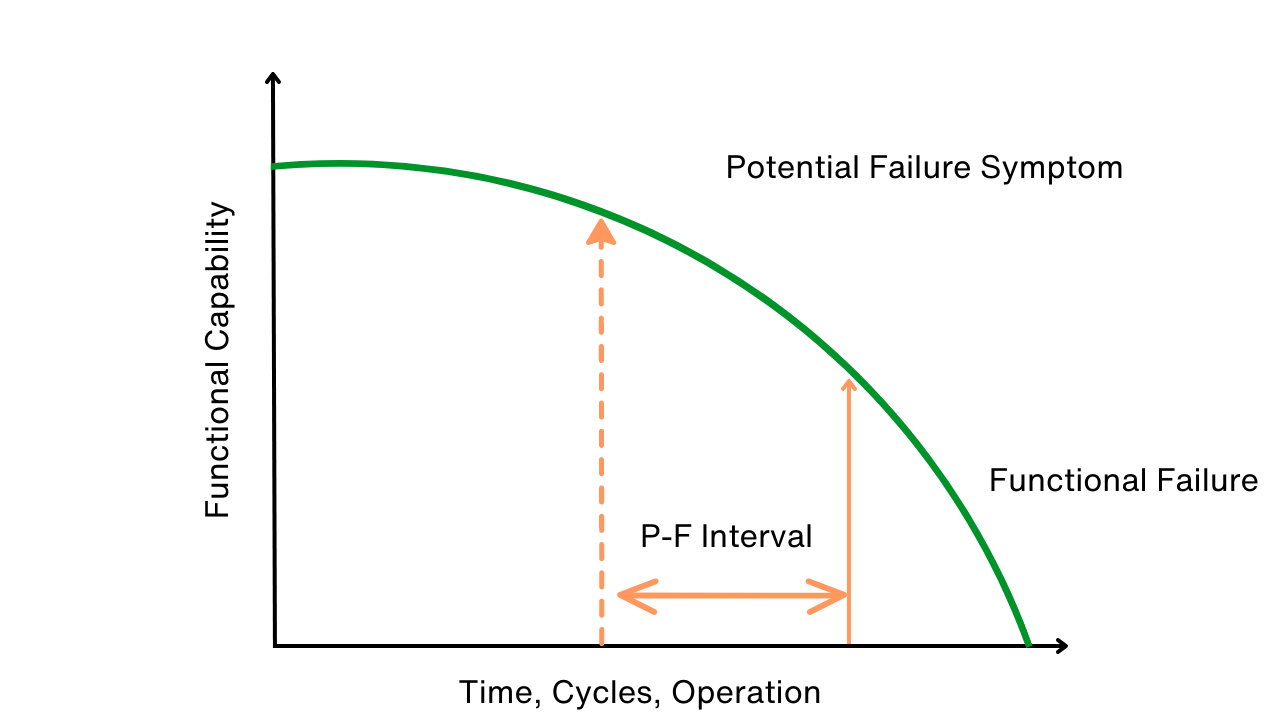

Use P-F Intervals to Map, Avert Failures

The RCM Trap

OEE: Overall Equipment Effectiveness

Can You Really Justify Reliability Centered Maintenance (RCM)?