How a CMMS Can Reduce Downtime

Dario Soric, WorkTrek

Posted 07/20/2023

In today’s fast-paced industrial landscape, minimizing downtime is crucial for businesses to maintain productivity and profitability. Equipment breakdowns, maintenance delays, and inefficient processes can lead to significant downtime, resulting in lost revenue and increased costs. However, with the right tools and strategies in place, such as a Computerized Maintenance Management System (CMMS), organizations can effectively reduce downtime and optimize their operations. This article will explore the benefits of using a CMMS to minimize downtime and improve overall productivity.

Downtime in industrial settings can occur due to various factors, including equipment failures, unscheduled maintenance, lack of spare parts, and inadequate communication between maintenance teams. These disruptions can have far-reaching consequences, affecting production schedules, customer satisfaction, and overall profitability. Implementing a CMMS can help organizations tackle these challenges proactively and reduce the impact of downtime on their operations.

Understanding CMMS

A CMMS is a software application that enables organizations to manage and optimize their maintenance activities effectively. It provides a centralized platform for scheduling and tracking maintenance tasks, managing work orders, monitoring equipment performance, and storing critical maintenance data. By digitizing and automating maintenance processes, a CMMS simplifies maintenance management, enhances productivity, and reduces downtime.

Preventive Maintenance Planning

One of the key features of a CMMS is its ability to facilitate preventive maintenance planning. Rather than waiting for equipment to fail, preventive maintenance focuses on scheduled inspections, routine servicing, and proactive repairs. By creating maintenance schedules and generating work orders automatically, a CMMS ensures that maintenance activities are performed at the right time. This proactive approach helps identify and address potential issues before they escalate into major problems, significantly reducing unplanned downtime.

Streamlining Work Orders

Efficient work order management is essential for minimizing downtime. A CMMS streamlines the work order process by providing a centralized platform for creating, assigning, and tracking work orders. Maintenance technicians can access work orders, view instructions, and update their progress in real-time. This real-time visibility improves communication and enables faster response times, ensuring that maintenance tasks are completed promptly and reducing equipment downtime.

Efficient Inventory Management

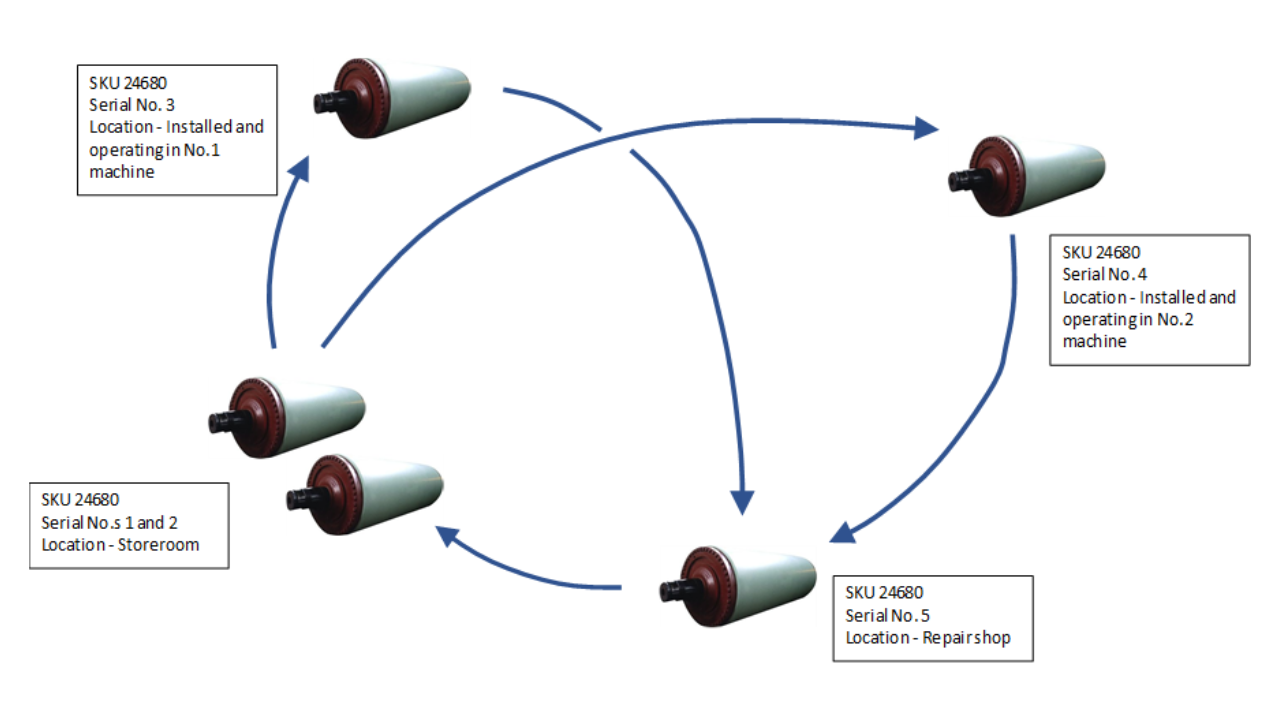

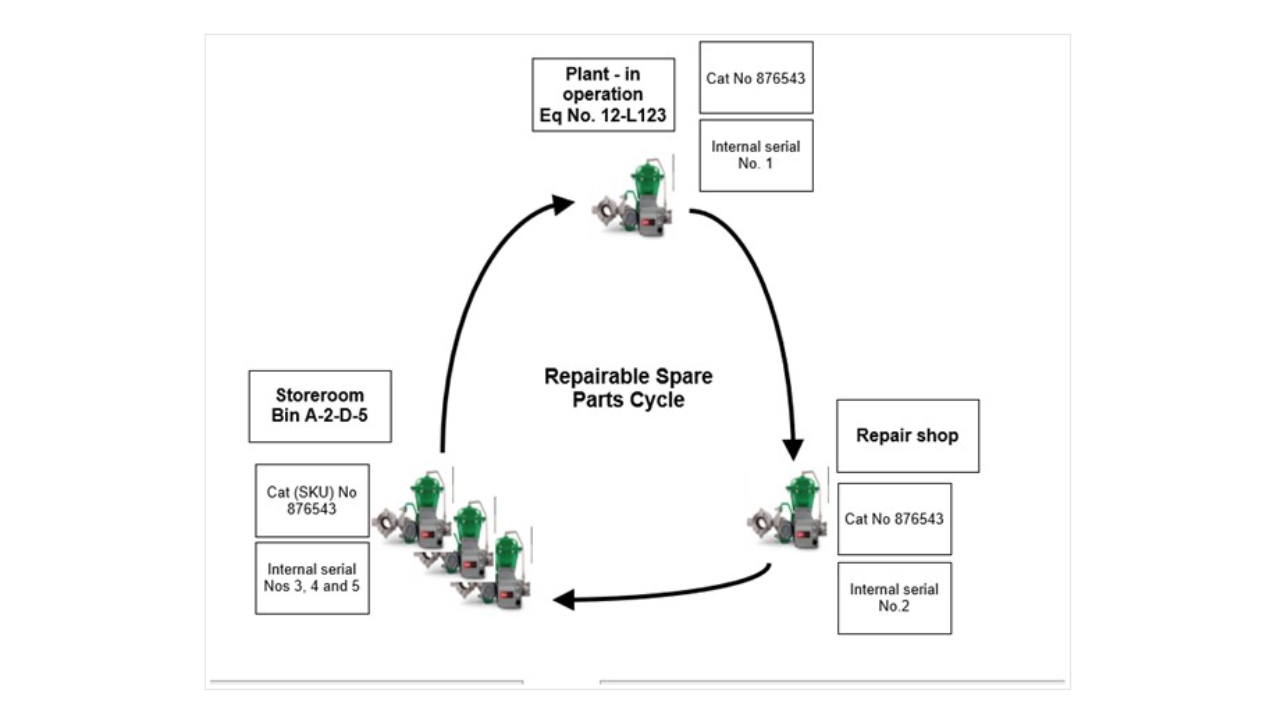

Inventory management plays a critical role in minimizing downtime caused by parts unavailability. A CMMS enables organizations to track spare parts inventory, automate reordering processes, and generate alerts when stock levels are low. By ensuring that the right parts are available when needed, organizations can significantly reduce equipment downtime associated with waiting for spare parts.

Real-Time Monitoring and Alerts

With a CMMS, organizations can monitor equipment performance and receive real-time alerts for any deviations or abnormalities. By integrating with sensors and Internet of Things (IoT) devices, a CMMS can capture real-time data on equipment condition, performance metrics, and predictive maintenance indicators. Timely alerts and notifications allow maintenance teams to take immediate action, preventing potential failures and minimizing unplanned downtime.

Data-Driven Decision Making

A CMMS collects and stores valuable maintenance data, which can be analyzed to drive data-driven decision making. By leveraging historical maintenance records, equipment performance data, and maintenance costs, organizations can identify patterns, trends, and areas for improvement. This data-driven approach enables proactive decision making, optimizing maintenance strategies, and reducing downtime.

Enhancing Communication and Collaboration

Effective communication and collaboration are vital for minimizing downtime. A CMMS provides a platform for maintenance teams to communicate, share information, and collaborate on maintenance tasks. Technicians can leave comments, upload images, and provide updates within the system, ensuring that relevant information is readily available to all stakeholders. This streamlined communication enhances coordination, reduces delays, and minimizes the potential for errors or miscommunication.

Integrating with IoT Technology

Integrating a CMMS with IoT technology can further enhance its capabilities in reducing downtime. IoT devices and sensors can provide real-time data on equipment performance, energy usage, and predictive maintenance indicators. By leveraging this data, a CMMS can enable predictive maintenance strategies, identifying potential failures before they occur. IoT integration empowers organizations to adopt a proactive maintenance approach, minimizing downtime and optimizing asset performance.

Increasing Equipment Reliability

Regular maintenance, facilitated by a CMMS, can significantly improve equipment reliability. By adhering to preventive maintenance schedules, conducting inspections, and performing necessary repairs, organizations can enhance the reliability of their assets. Reliable equipment reduces the likelihood of unexpected breakdowns, thereby minimizing downtime and maximizing productivity.

Training and Knowledge Base

A CMMS can serve as a centralized repository for maintenance-related information, including equipment manuals, standard operating procedures, and troubleshooting guides. This knowledge base provides maintenance technicians with easy access to critical information, enabling them to perform tasks efficiently and accurately. By empowering technicians with the right knowledge and resources, a CMMS contributes to reducing downtime caused by maintenance errors or delays.

Continuous Improvement Initiatives

A CMMS facilitates continuous improvement initiatives by capturing maintenance data and generating performance reports. Organizations can analyze these reports to identify bottlenecks, inefficiencies, and opportunities for optimization. By implementing corrective actions and process enhancements, organizations can continually refine their maintenance practices, minimizing downtime, and maximizing operational efficiency.

Ensuring Compliance and Safety

Compliance with regulations and safety standards is essential in industrial environments. A CMMS can help organizations ensure compliance by providing documentation of maintenance activities, inspections, and audits. By having a comprehensive record of maintenance activities, organizations can demonstrate adherence to regulations and mitigate potential risks. This proactive approach minimizes the chances of downtime resulting from compliance issues or safety incidents.

Cost Savings and ROI

Implementing a CMMS can result in significant cost savings for organizations. By reducing downtime, optimizing maintenance practices, and extending the lifespan of assets, a CMMS maximizes the return on investment (ROI) for maintenance activities. The cost savings associated with reduced downtime, improved labor efficiency, and optimized inventory management can contribute to the overall profitability of the organization. Downtime can have severe implications for businesses, impacting productivity, profitability, and customer satisfaction. However, by leveraging the capabilities of a CMMS, organizations can proactively reduce downtime and optimize their maintenance practices. From preventive maintenance planning and efficient work order management to real-time monitoring and data-driven decision-making, a CMMS provides a comprehensive solution for minimizing downtime and improving overall operational efficiency.

Dario Sorić

Dario Sorić is the marketing assistant and website administrator for Worktrek.com. He graduated with a Bachelor of Digital Marketing from the University of Algebra in 2023. Feel free to contact him at [email protected].

Related Articles

Why Might your Business Need a CMMS?

Making These 8 Simple Changes in Your CMMS Will Give You Surprising Results

Embracing the Power of Computer Aided Facility Management

Managing Repairable Spares