Semiconductor Industry Facing Worrisome Talent Shortage

Natalie Johnson

Posted 05/24/2023

Following the CHIPS and Science Act, semiconductor manufacturers have announced over $200 billion in investments for manufacturing. The United States currently produces 10% of all chips but hopes to increase production and account for 30% of global chip production by 2030. McKinsey predicts this aspiration will result in a deficit of 300,000 engineers and 90,000 skilled technicians.

Educational institutions and training programs tailored to the industry are struggling to attract, retain, and prepare the next generation of semiconductor technicians. A lack of awareness about the industry and large technology firms recruiting a majority of the workforce has made it difficult for companies to retain workers, mainly engineers and techs.

Engineers

Engineers are responsible for semiconductor research, design, and development. They test products, troubleshoot potential software problems, and interact with manufacturers to ensure quality production.

Many undergraduate engineering programs, such as electrical engineering, computer science, and software engineering equip students with the necessary knowledge to work in the industry. However, fewer than 50,000 students in the US graduate with a degree in electrical engineering or computer science each year. Upon graduation, students receiving these degrees are often recruited by large technology firms and fail to enter the semiconductor industry.

Technicians

Skilled technicians account for 38% of the semiconductor manufacturing workforce. One company, Intel labs, anticipates creating nearly 7,000 jobs over the next decade and 70% of those positions would be for technicians with two-year degrees.

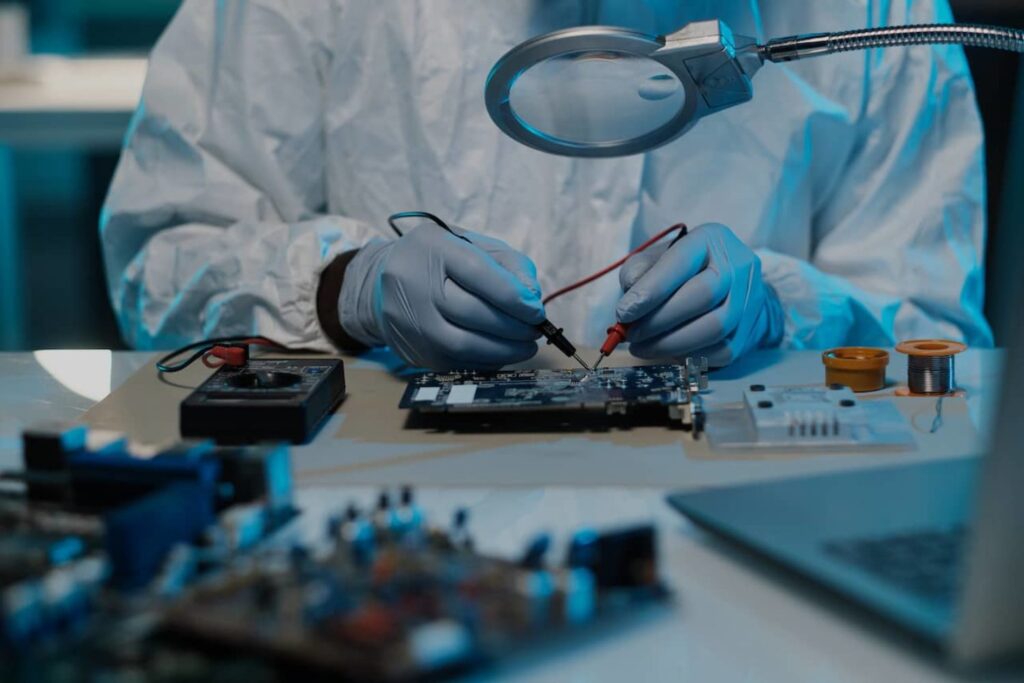

Technicians are integral in the manufacturing process and typically work in clean rooms while wearing “bunny suits” to minimize contamination of electronic components. They work with special furnaces, x-ray equipment, chemical baths and other equipment used to form circuitry and change conductive properties.

Techs are crucial to the overall operation of semiconductor manufacturing facilities as they are largely responsible for the operation and maintenance of equipment. This includes:

- Monitoring, maintaining, and repairing semiconductor fabrication equipment

- Performing preventive maintenance

- Installing, troubleshooting, diagnosing, and calibrating equipment

- Utilizing test and diagnostic equipment

- Proficiency in programmable logic controllers, microprocessors, control circuits, analog and digital circuits, and motor.

Tackling Training

To combat the shortage of skilled workers available, there are three main programs being unveiled in the states.

1. Quick Start Programs

Some community colleges have elected to swiftly equip students with the skills necessary to enter entry-level technician positions. These programs are typically several weeks long. In Arizona, Maricopa Community College has partnered with Intel to offer a 10-day training program that will prepare students to enter the industry as a semiconductor technician upon completion of the program.

2. Associate and Bachelor’s Degree Programs

Many community colleges and universities offer programs in electronics, microelectronics, computer science, and applied science. These educational institutions are attempting to increase enrollment and add programs specifically tailored towards the industry.

One such initiative, the Northeast University Semiconductor Network, was announced in April of this year. The network is a large partnership between over twenty universities and Micron Technology to maximize training opportunities for individuals hoping to enter the industry.

The partnership will allow Micron to strengthen the curriculum by sharing technical content, experiential learning programs, and research opportunities with students.

3. Workforce Hubs

The federal government has pledged to work with labor unions, companies, high schools, colleges, and workforce development organizations to expand apprenticeships and technical education related to the industry.

Cities can continue to apply to become technology hubs to build a diverse workforce. The five initial workforce hubs will be located in:

- Phoenix, Arizona

- Columbus, Ohio

- Baltimore, Maryland

- Augusta, Georgia

- Pittsburgh, Pennsylvania

Globally, more than 1 million additional skilled workers will be needed in the semiconductor industry by 2030. The United States isn’t the only country struggling to fill positions. In the next few years, training programs, educational institutions, and employers will have to increase workforce development initiatives to meet the growing demands of the industry. The United States is in a good position to equip a workforce as there’s an abundance of educational institutions, supported by private and public initiatives, available to train the next generation of engineers and technicians.

Natalie Johnson

Natalie Johnson is the previous editor/website administrator for MaintenanceWorld.com, and is currently a student at Campbell University Norman Adrian Wiggins School of Law.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill