LubeRight: A New Tracking System for Manual Greasing

ASSALUB

ASSALUB has introduced a new technology to help track manual greasing. This technology can help improve your lubrication program and ensure the practices you aim to implement are being completed. The LubeRight is a computer aided manual greasing system that offers the following advantages when compared to traditional manual greasing:

- LubeRight identifies each grease point and shows the exact amount of grease to be fed to the bearing. An accurate amount of lubricant extends bearing life overtime.

- LubeRight confirms and checks that each grease point has been greased.

- LubeRight enables historical reporting on every single lubrication point so data can easily be recorded and past data can be reviewed or compared with current data.

All lubrication points are equipped with a transponder (a chip baked into a washer-like envelope). The chip holds a unique identification number enabling the system to recognize each grease point. The amount of grease to be fed into a grease point is stored in the memory of the grease meter and is shown on the display. The grease meter registers the actual amount fed the grease point. When the grease route is completed, the results are transferred to a PC.

The computer program shows how much grease has been fed into every grease point and any potential deviations to the set value. For example, the software clearly displays a missed grease point. The LubeRight system gives the user an easy-to access overview of all manual grease points and therefore enables improve equipment reliability. It effectively reduces the risk of unscheduled production stops.

LubeRight is a tool that makes manual lubrication reliable. Greasing will become a high-tech activity!

For more information contact: Pär-Olof Funck at +46 120 35841. Please note Sweden is 6 hours ahead of Eastern Standard Time in the United States. You may also contact us by email at [email protected].

Related Articles

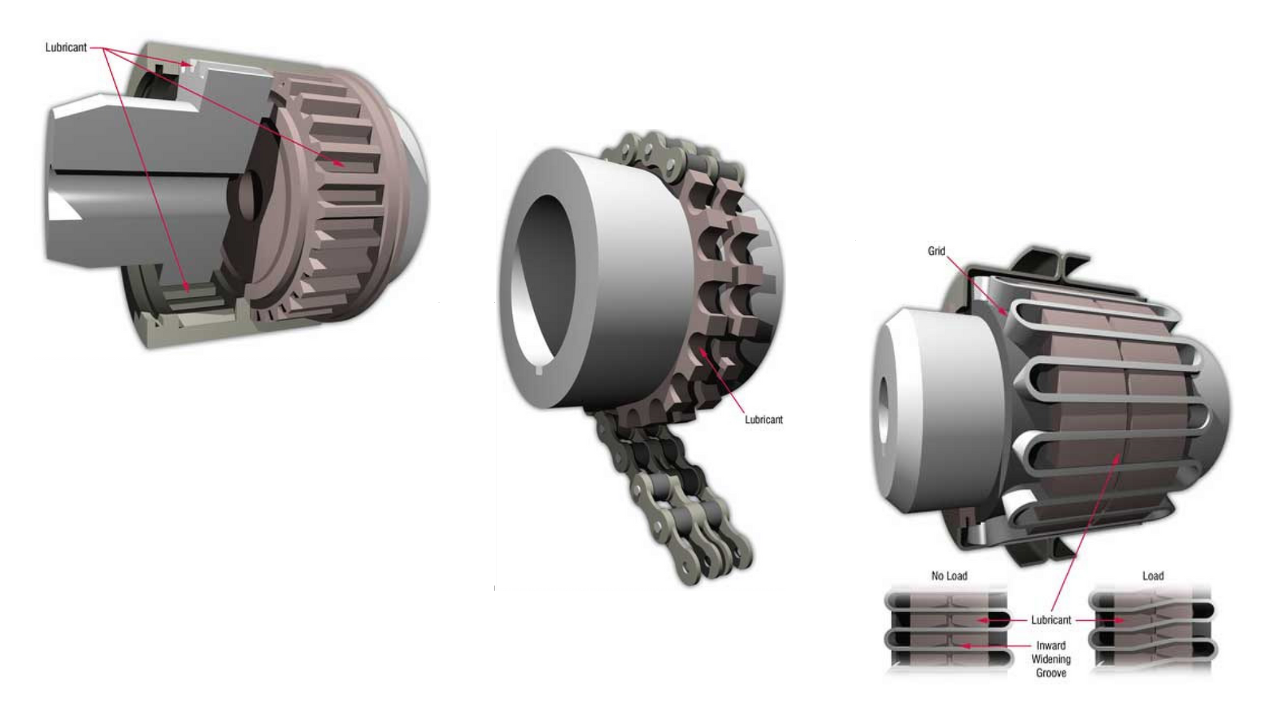

The Lubrication Requirements of Couplings

The Building Blocks to Creating an Effective Lubrication Program

Does Lubrication Belong in the CMMS?

Water Contamination

Ultrasound for Better Lubrication

Top Ten Ways Not to be World Class at Machinery Lubrication