Spare Parts Management Trends and Essential Tips

Elizabeth Ruiz

Posted 10/25/23

Introduction

In the manufacturing industry, having the right spare parts in the right place when you need them is key to making sure your facility is operating efficiently. Developing technology such as vision picking, predictive analytics, and more are rapidly transforming the way spare parts management programs function across industries.

Storeroom and spare parts organization is typically an area where we see opportunities for improvement in many organizations. What does a good storeroom look like? What are best practices in spare parts management? How can we use new technology and trends to organize and optimize the storeroom?

Essential Tips for Storeroom and Spare Parts Management

There are 8 elements to consider when organizing a storeroom:

1. Master Data: The information available about parts in the storeroom. This includes detailed descriptions, manufacturer specifications, primary vendor information, and manufacturer/vendor part numbers.

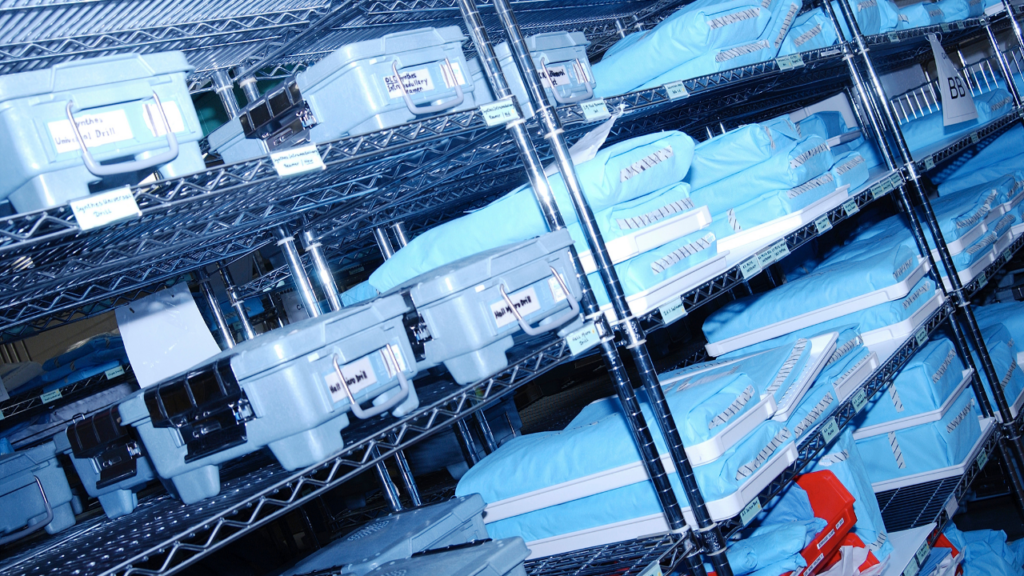

2. Storeroom Organization: Anybody should be able to find any part. Each part should have a designated location. Parts should be made easy to locate by placing the same types of components together and/or storing parts by equipment. Make sure all personnel know how to locate equipment in the CMMS and how the storeroom is organized.

3. Storeroom Operation: Organized and efficient parts issuing (dispatch), parts receiving, and parts return.

4. Inventory Control: Ensuring that a part identified as available is present, properly identified, in the correct bin location, in good condition (not used, broken, defective, substandard, or malfunctioning), clean and free of dust, stored in the proper environment, complies with all specifications, and that the storeroom is secure.

5. Quality Program: Inventory Record Accuracy (IRA), or Cycle Count – this procedure verifies that the number of parts in the CMMS is equal to the number in stock. It checks quantity accuracy, if the part is in the correct location, if the bin is labeled, if the part is labeled, and the condition of the part (completeness, new or rebuild, and physical condition). If all these conditions are met, the record is accurate.

6. Preventive Maintenance Program: Learn 8 Steps to Build an Effective Preventive Maintenance Program here – free download.

7. Reports, KPIs, and Data Analysis: Which Key Performance Indicators should you use, and when? Find out in this article.

8. Inventory Optimization: Organizations typically focus on and count the highest priced items. These items account for 80% of the total inventory cost, and usually have close to a 100% cycle count. Identify whether parts are fast movers, slow movers, or very slow/non-movers. The time frames for each depends on the organization. Using a spreadsheet with macros can assist with keeping track of the counts.

Now that we’ve covered the basics, let’s dive into the latest trends in spare parts management.

New Technology and Trends in Spare Parts Management

Keeping up with new technology is vital in all aspects of business – and life! Many advances in spare parts management are emerging and can be implemented to help move your organization forward.

Low Code Development Platforms and IoT: RT Insights has observed that it is advantageous to use a low code development platform to create an application joining MRO system insights with an ERP system designed for parts ordering. This application allows more efficient use of existing parts; it ensures that specific parts are in stock when needed, that parts are not overstocked, and that parts in stock are not outdated.

Predictive Analytics: According to Fiix, predictive analytics eliminates unpredictability in maintenance. This is possible because the data is based on real-time information. The data is used to predict equipment failure and when maintenance is needed. This makes deciding which spares to keep in stock much easier.

3D Printing: 3D spare parts production is on the rise. Learn more here.

Vision Picking: Clear Spider defines vision picking as the efficient selection of items from the inventory to fulfill an order. Vision picking is an example of applying augmented reality (AR) in the supply chain – it employs a headset that allows personnel to communicate with the warehouse software to locate items. This technology can be applied to MRO service teams and maintenance personnel using storeroom CMMS systems.

Cybersecurity – A Necessary Trend for Safety: The increased use of digital technology in maintenance has increased the vulnerability to cyberattacks causing expensive downtime and damage. Make sure maintenance software is guarded with firewalls, encryption, access controls, and other security measures. Personnel should be trained to recognize suspicious activity with an established response plan.

Conclusion

Effective spare parts management is indispensable for streamlined manufacturing operations, and the integration of emerging technologies and trends presents promising opportunities for improvement. The essential tips provided serve as a comprehensive guide for optimizing storeroom organization. New technologies offer innovative solutions, enhancing accuracy in parts ordering and minimizing downtime through predictive maintenance.

However, organizations must prioritize cybersecurity measures to safeguard against digital threats in this evolving landscape. By staying attuned to these trends and implementing recommended strategies, organizations can not only maintain well-organized storerooms but also ensure responsiveness to the dynamic demands of modern manufacturing, positioning themselves for operational excellence and competitive success.

Do you want your team caught up on the latest trends in spare parts management? Do you need to optimize and organize your storeroom? IDCON INC can help. Sign up for training today.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you every Wednesday by the Maintenance World Crew.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill