Technical Database Performance Survey: Get the Full Picture

John Sewell, CMRP

Posted 10/19/2023

Uncover the Value of the Technical Database

Are you looking for ways to improve maintenance work execution? Are your planning and scheduling processes not generating the desired results? Does it seem like a struggle to find the information you need to define the what, how, how long, who, and when of a maintenance job? Take a three-part technical database survey on the technical database to uncover what a poor system is costing you. As a token of our appreciation for completing all three surveys, you’ll receive a customized report and a free 20-minute consultation with an expert from IDCON.

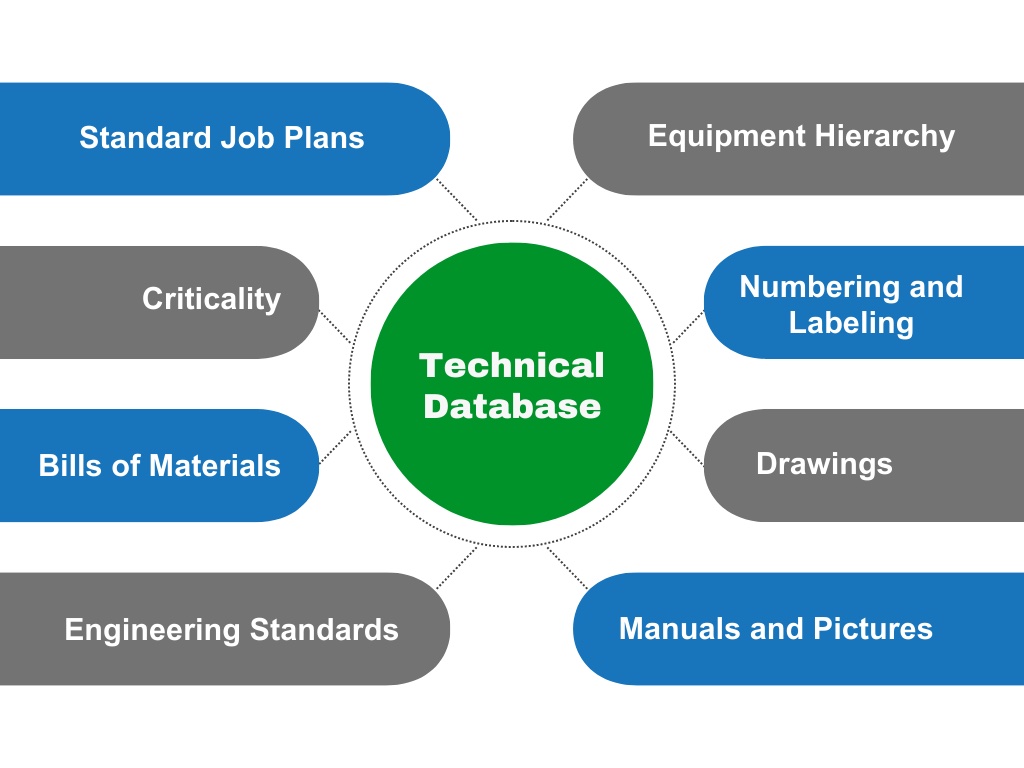

The technical database is a critical enabler of efficient planning and scheduling. The technical database includes eight types of various documents, standards, and instructions needed to plan and schedule a maintenance activity.

With a poor technical database planners spend more time looking for parts than field scoping jobs. Crews and forced to make their own arrangements for special tools and permits. Work consistently takes longer than it should. To function well, the technical database must be accurate, accessible, and applied.

Assessing your technical database can be a challenge. The information is usually spread across different departments so no single person has the full picture. Knowing questions that will uncover the current state of your technical database also presents a hurdle. To help you overcome these obstacles, IDCON has developed a three-part survey. The survey will enable you to gain a deeper understanding of your technical database and its impact on your work management system.

Ready to take the survey? Click here.

An Impactful Survey with Purpose

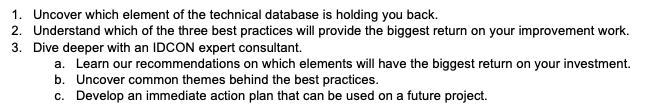

The survey goal is simple: to provide information that will improve your technical database and work management processes. To accomplish the goal there are three objectives.

With ongoing labor shortages, companies can’t afford to waste time or effort. Demand for qualified workers has risen with salaries necessary to attract new talent climbing. Supply chain disruptions have lengthened project timelines. Maintenance backlogs have continued to grow. Having a safe and engaged workforce that proactively meets new challenges is vital to asset intensive industries.

While the benefits of excellent work management are well understood, the impact of the technical database is overlooked. The technical database is often considered an unnecessary expense with little thought given to its content or organization. However, a poor technical database is a root cause of poor planning and inefficient work execution. In many plants, mills, and mines, improving the technical database represents a huge opportunity to fundamentally improve maintenance productivity.

Want to increase the productivity of your maintenance department? Take the three-part survey to learn how the technical database supports planning and scheduling.

Tangible Benefits with Immediate Result

IDCON has been in the business of improving maintenance performance for over 50 years. A key element of our success is a continued focus on developing industry insight. Your participation in the survey will lead to a better understanding of key factors that drive world-class planning and scheduling.

Help spread the word and encourage others to take the technical database survey. Compare results across areas or between different sites. Use a team-based approach and kick off your next strategy session with the survey. Discuss the questions with your teams to gain insight and value from the very beginning. Broadcast the survey to your network and help others succeed.

As an added benefit of completing all three surveys, receive a free customized report and a 20-minute strategy session with one of our IDCON expert maintenance and reliability consultants.

Ready to schedule a free 20-minute call with an IDCON expert consultant? Complete all three surveys and we’ll be in touch!

Take the Survey Now!

Ready to take the survey?

Click the above link to get started with the first survey. Answer questions based on the current performance at your plant, mill, or mine to uncover the factors that impact the accuracy of your technical database.

After completing all questions, fill in some basic information about yourself click “Next”. You’ll receive an email with your overall score and a link to the next survey. Complete the other two surveys to find out if your technical database is accessible and applied.

The three surveys comprise 64 questions that will help evaluate all eight elements of the technical database against three best practices. The three surveys will take less than 30 total minutes to complete which is a small investment for the insight produced.

Need more information on the technical database?

Click here for videos and full articles on each element.

After all three surveys have been completed, your scores will be reviewed. Then a customized report covering your exact situation will be developed. We’ll schedule a free 20-minute call to discuss your report and dive deeper into the results.

In today’s business climate, efficiency and effectiveness can’t be overlooked. The technical database supports work management and ensures smooth planning, scheduling, and maintenance work execution. Take the survey to benchmark your current performance and find areas to improve the productivity of your maintenance team.

Read more about the Technical Database:

- What is the Technical Database?

- Numbering and Labeling

- Drawings

- Engineering Standards

- Bill of Materials

- Criticality

- Standard Job Plans

- Equipment Hierarchy

John Sewell, CMRP

John Sewell, CMRP is a Consultant with IDCON INC, a specialized management consulting firm in the field of reliability and maintenance management. As a consultant, John works with clients in any industry to improve reliability and lower manufacturing and maintenance costs through hands-on coaching and training.

Related Articles

Reliability Improvements Drive Down Maintenance Costs

Reliability and Current Best Practices - An Educational Journey

Mechanical Quality Assurance: The Next Progression of Reliability

Maintenance Business: Managing Maintenance as a Business

Key Performance Indicators and Frontline Maintenance Leaders

Too Small for a CMMS? Think Again