How to Achieve Results Using Infrared Technology

Austin Dunne

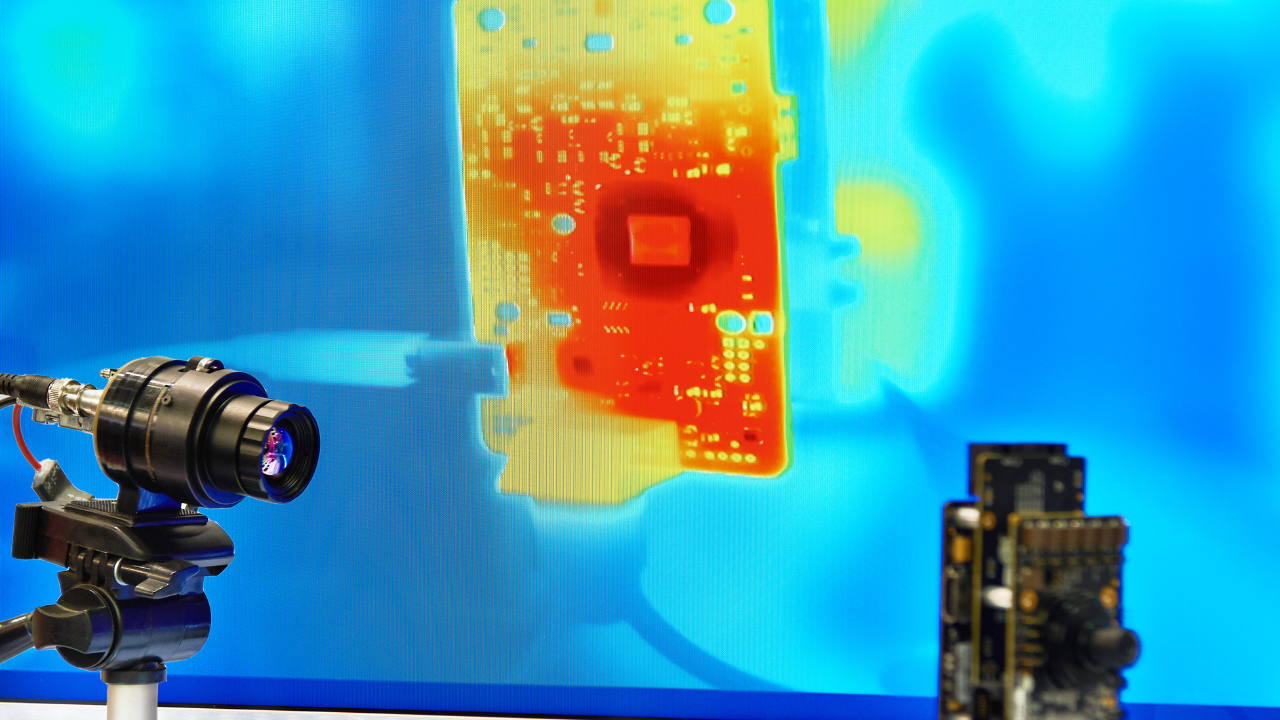

The Importance of Infrared Technology

The author, from a background as a full time infrared thermographer in industry, understands the benefits of running an in-house programme, and acknowledges that success was due to the experimental exposure gained over many years working with infrared technology to the exclusion of any other duties, plus the support of senior management which allowed time to conquer a steep learning curve. It is easy to buy equipment, but quite another matter to find an effective person able to provide quality data that will enhance a maintenance programme. As with many condition monitoring techniques, infrared thermography is a skilled art form that requires technician and engineeers to be educated in infrared physics, have a thorough understanding of applications and be able to develop their knowledge with continual field experience.

Over the years many individuals have joined courses ‘just to get a certificate’. In reality, most technicians and engineers are shocked to learn that the methods they have employed in the past do not provide accurate temperature measurements. The infrared camera is a scientific instrument and is designed to give a data output based on a known condition, in this case it is usually set to measure objects which have a 100% efficiency to emit infrared radiation. In reality, this is theoretical as no such object exists. This is where the skilled technician excels; their awareness will lead them to alter the instrument to the correct parameters. Both emissivity and reflectivity have to be inputted correctly, as one of the initial stages to correct the instrument’s mathematical calculation with the aim of achieving quantitative analysis. Several other factors are required in order to achieve correct temperature measurements. When introducing an in-house programme, product training on cameras only covers the basic operation of the instrument and often fails to convey the complexity of using infrared instruments in the field.

Historically, infrared thermography certification was usually based on ASNT SNT TC 1A, the American standard which provides a guide or outline of the course content. This is a second party certification scheme usually operated by training providers who deliver a course and end of course examination, often requiring field work from the students to complete the process. The certificate is given to the student by the training provider on behalf of the company that employs the individual.

In Europe, some countries provide certification based on a third party principle, the training being delivered by a provider and the certification conducted by a separate organisation based on standards like EN473 or the Scandinavian equivalent. Third party examinations, being independent, provide a recognised competence level as the training organisation has no access to the examination questions, thus ensuring uniformity of minimum competences. Although considered to be superior to second party schemes, the process is fragmented and only operates in certain areas of the world and is not seen as a solution across continents.

Over recent years, the BINDT (British Institute of Non Destructive Testing) has taken the outline from an international standards group and used it as a platform for producing a certification scheme based on ISO 18436. They have developed this third party certification scheme using PCN (a well established accreditation body) to deliver a high quality process for qualifications in a range of condition monitoring techniques, including Infrared Thermography, Vibration Analysis, Acoustic Emission, Ultra-sound, etc. Industry should be seen to embrace a scheme designed to ensure the fundamentals are understood in each infrared technology, which promotes a minimum time requirement for practical experience prior to certification, whilst providing an independent assessment of each student. This scheme could grow rapidly and will ultimately be recognised as a world standard for training and certification in condition monitoring activities. Legislation on the use of infrared thermography is quite sketchy at the moment and it is not unusual to see a complete novice purchase these scientific instruments and offer services without any in-depth training or experience. This obviously allows a reduction in their charge-out rate and compromises consultants who compete in the field with high quality equipment, expert training and many years of practical experience. As more insurance companies now demand infrared inspections prior to the issue of their insurance certificates, it is essential that the survey is carried out by competent individuals. Industry must set standards to ensure consultants and practitioners obtain the required skills, training and experience to ensure the quality of data collected.

Footnote

The IIT is an Accredited Training Organisation for the BINDT and provides independent education, training and support to industry. Trainers are experienced thermographers who convey both the theoretical and practical aspects of infrared technology, and certification conforms to ISO 18436 and ASNT SNT TC 1A. The emphasis is to raise the awareness of thermography and develop skills in all industry sectors. Courses are offered in over 50 countries with training manuals in over 10 languages. IIT staff are always available to answer general enquires and questions on the certification processes

Related Articles

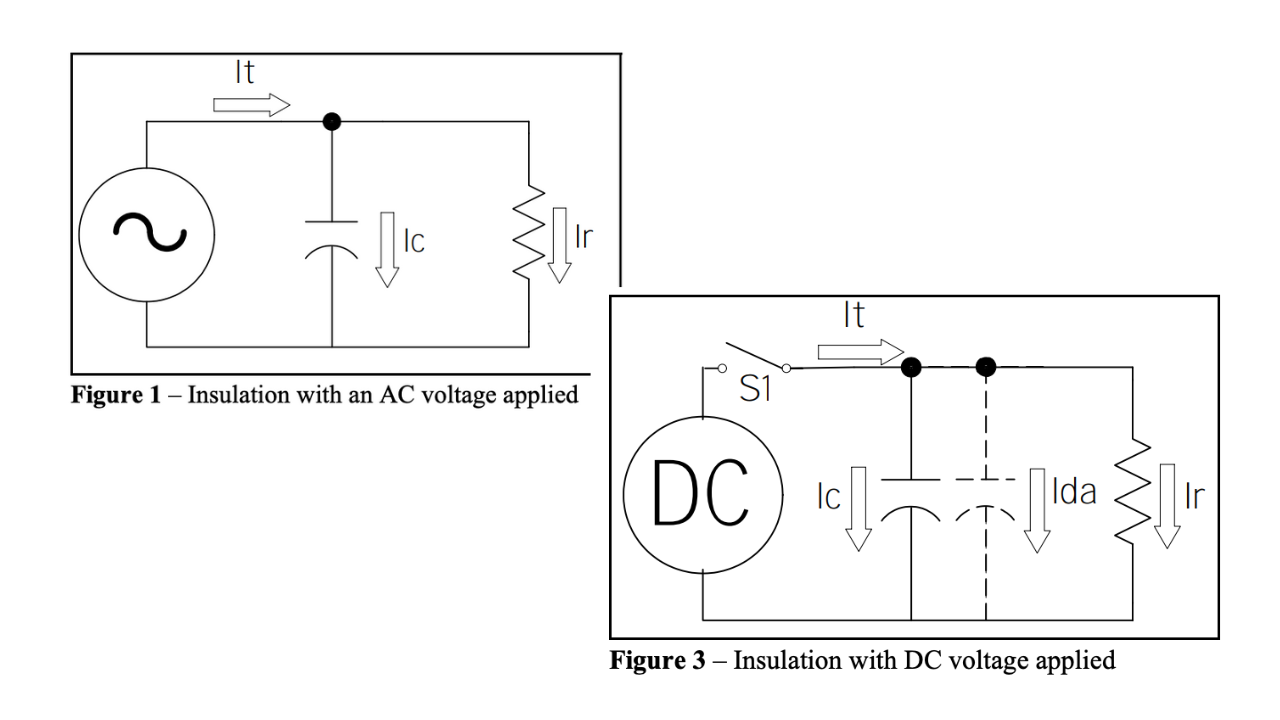

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera