Get Mechanical Seals Working Properly

Mike Sondalini, PWW EAM System Consultant, Equipment Longevity Engineer – with permission of BIN95 Business Industrial Network

Posted 9/19/2024

Get mechanical seals working properly. Mechanical seals are used to keep the bulk contents of rotating equipment such as pumps and compressors from escaping. They do this by sealing the shaft that protrudes from the casing. They require quality installation and operation conditions for a long life.

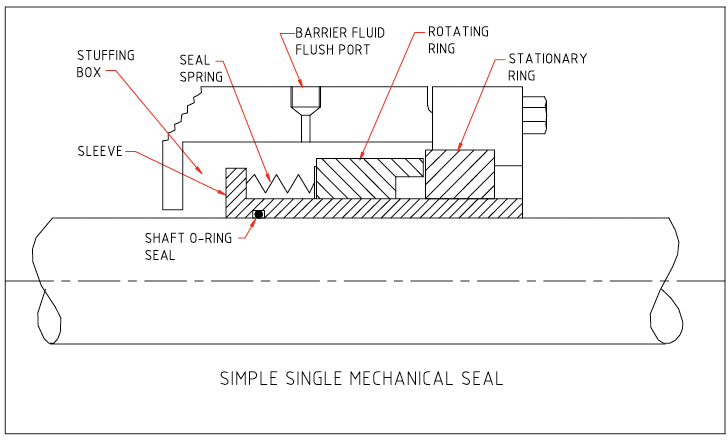

The sketch below shows the basic construction of a simple, single mechanical seal.

The harder stationary ring is held in place and the softer rotary ring rotates with the shaft. Springs or a convoluted bellows (rubber or metal) pushes the rotary ring against the stationary. With the faces sealed together as they turn, no path exists for the bulk contents to escape.

Between the seal faces an extremely thin layer of product or seal flush fluid develops and acts to lubricate and cool. This thin layer prevents rubbing contact of the surfaces, without which frictional heat would rapidly destroy the seal faces.

What Causes a Mechanical Seal to Leak?

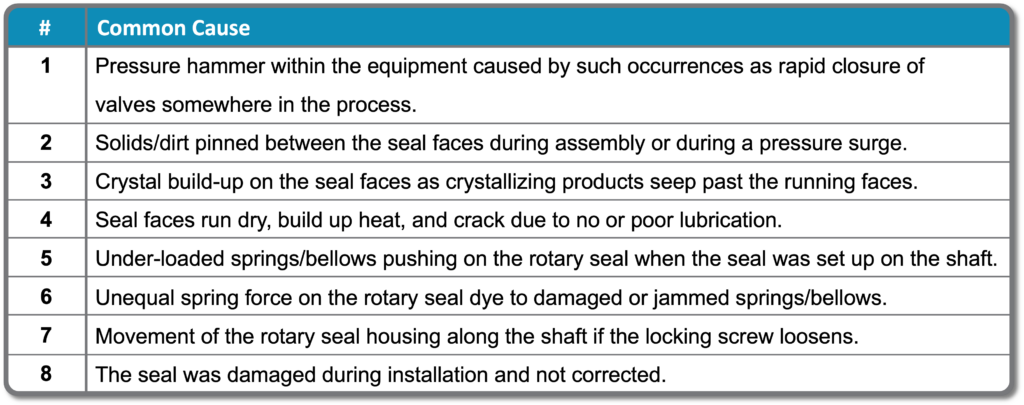

Mechanical seals leak when the faces are forced apart. If there is evidence of product leaking from a mechanical seal, then the faces have had cause to separate. The challenge to maintainers is to find the cause and rectify it. Below are some of the common causes of face separation.

Requirements for Long Seal Life

To get a long life, mechanical seal faces must be kept clean, cool, lubricated, square to the shaft and flat together.

ACHIEVE A HEALTHY LOCAL ENVIRONMENT

Use a barrier fluid to clean, cool and lubricate. These first three requirements are best achieved by pressurizing the spring/bellows chamber with a suitable clean, cool barrier fluid at a pressure higher than on the process side (stuffing box) of the stationary seal. The barrier fluid can be a liquid or gas depending on the service required of the seal. Usually a pressure difference of 100kPa is sufficient to guarantee slight weeping across the seal faces from the barrier fluid into the process. As a rough rule of thumb the stuffing box pressure is about two-thirds the discharge pressure.

An exception to use of a barrier fluid is when the fluid being pumped is itself clean and non-threatening to safety and the environment. Products such as clean water do not need a barrier fluid because the centrifugal action of the spinning seal will draw in minute amounts of water that will cool and lubricate the faces. This water escapes as vapor to atmosphere.

ACHIEVE PRECISION ASSEMBLY

Quality seal manufacture and installation achieve the last two requirements. Mechanical seal faces are manufactured to a flatness that is measured using wavelengths of light. Such fine tolerances imply high precision equipment. This is why seals reconstructed in maintenance workshop conditions never last. Precision manufacture requires a precision environment.

High precision is normally only possible at the time of manufacture. Mechanical seals installed by the pump manufacturer tend to last longer than seals installed in the same pump when on-site. The growth in the use of cartridge seals reflects a growing awareness of the importance of precision in the construction and installation of mechanical seals.

ACHIEVE PRECISION RUNNING

The alignment between the centre lines of motor and pump, for 4 pole motor speeds and less, must be perfect to within 0.050 mm (0.002”) from the end of the motor shaft to the end of the pump shaft when at operating temperature. There must be no vibration of the mechanical seal due to poor balance, poor tolerances, poor operation, wrong usage practices or poor installation.

Everything must be done to keep the mechanical seal faces together. The seal faces must be always square to the shaft. The shaft can only deflect a maximum of 0.025-mm (0.001”) at the mechanical seal face. The shaft and seal centerlines must be concentric to 0.025-mm (0.001”). If the entire shaft rocks and sways the seal must move with the shaft. If necessary, mount steady bearings close to the seal to ensure the shaft and seal remain concentric. Shaft overhang must be kept small and if that is not possible a thicker shaft or one made of stiffer materials or design is required.

Alternatives to Mechanical Seals

Other options are now available to use in place of a mechanical sealed pump. For example, if pumping clean liquids, magnetic drive pumps are now available that totally encloses the process. In these pumps a rotating magnet drives the shaft attached to the pump impeller. Similarly ‘canned motor’ pumps operate without mechanical seals. In these pumps the motor is encased within the pump body and cooled by the process contents.

On-going seal failures lead to high life cycle costs. The cost justification to use seal-less pumps on clean liquids is easily achieved once the $2,000 plus cost of the first mechanical seal replacement is added to the purchase price of the mechanically sealed pump. If a pump continues to suffer numerous seal failures then a seal-less pump may totally remove the problem.

What to do to Extend Mechanical Seal Life

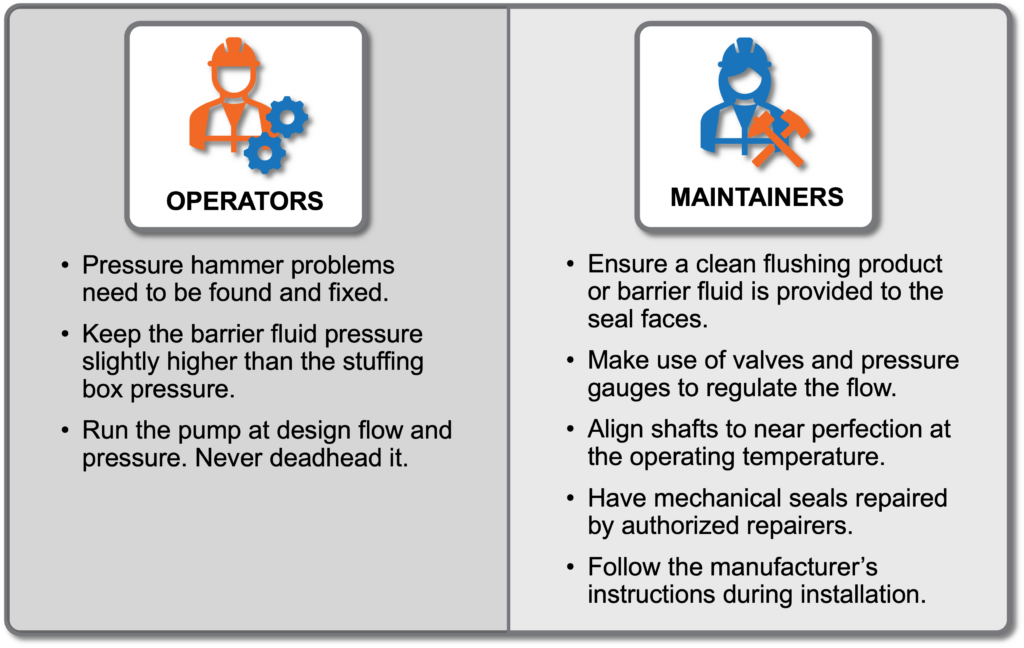

The working life of a mechanical seal should be at least three to five years. Lives of ten years have been achieved in clean, carefully controlled and monitored applications. People involved in the operation of equipment with mechanical seals need to be aware of the following:

Mike Sondalini

Mike Sondalini is a Senior Consultant at PWWEAM System-of-Reliability. BEng(Hons), MBA, CPEng. As a consultant and trainer, Mike was able to present his insights to his clients, suggesting innovative approaches to plant and equipment reliability. Their feedback was resoundingly positive. Efforts which earned him an international reputation for articulate, out-of-the-box articles on plant and equipment reliability, life-cycle EAM, maintenance management, work quality assurance, and team building. After decades of dedicated research, Mike authored “Industrial Manufacturing Wellness: The Complete Guide to Successful Enterprise Asset Management” a revolutionary approach on how maintenance and physical asset management systems should be run, the book detailed who, what, where, when, why, and how outstanding reliability could be achieved. Each step based in scientific and mathematical understanding to ensure repeatability of results and optimal outcomes.

Related Articles

OEE: Overall Equipment Effectiveness

What the Pump Was Designed to Do and Why it Doesn't Do it

What is Wrong with the Modern Centrifugal Pump?

Digging Up Savings: Go with the Flow

Chain Drive Design Recommendations

Classifying Chemicals to Assure Effective Sealing