IDCON Talks: Christer Idhammar

Greg Mecomber and Christer Idhammar

Posted 06/01/2023

Christer Idhammar is recognized as a maintenance guru across the world in the maintenance and reliability community. As the recipient of numerous awards and speaking invitations, he has established himself in his field through engaging and often hands on demonstrations and as founder of IDCON INC he has taught thousands of students his refreshingly simple common-sense approach to reliability best practices.

On what’s great about the M&R field

Greg: Good morning, Christer. I watched your latest webinar and I always enjoy watching you speak because your points really resonate with me and my experience which is very similar to yours, I hear. We both started out doing the grunt work turning wrenches, getting grimy and sweaty in environments in which no rational human being would be. So, what drew you into this field?

Christer: I’m on my 62nd year in this field and I realize why I still like it so much is because it is really about people. I still meet so many people today that when I talk about very basic maintenance management principles, they come up and say, “THAT was a great idea”.

And I like working with people on the front line – you know supervisors, planners, mechanics, electricians, and operators. They have so many good ideas, but they are often not listened to by management for many reasons and that’s really why I like to work with people in maintenance. Especially if you work in a medium-sized maintenance organization of up to about fifty people because you really get to know people and it’s less about politics. Whereas if you come into a maintenance organization with over five hundred people then it is more difficult to get the message through – people don’t know each other or work together and so forth.

I’ve been in this field for a long time, and I’ve met a whole assortment of characters. Do you know the television show Undercover Boss? Where the CEO or boss goes out and meets and talks to people in their organization and they find those employees that are absolutely excellent. And I think that is such a wonderful thing because when I go out and do assessments or provide support I go out and meet with these people and I find so many really fantastic employees and they are often not recognized.

Greg: What you said about basic maintenance management principles being a revelation to some, it seems that there are quite a few hyped solutions or methodologies that really just complicate the whole process. I think about a couple of times when I was working as a maintenance tech, and I over thought a solution when really it was quite straight forward.

Christer: And I am the other way, I have the ability to simplify things – I’ve noticed that in life. People can talk and talk and over complicate things and then finally I say, “really the way I understand it is…”. For example, I was in a meeting where we talked a lot about digitalization of maintenance: what is it, how do we do it, etc. but really it is just automation using new technology. That’s all it is.

Greg: Sounds very simple.

Christer: Yes, it IS very simple.

On influences and mentors

Greg: Before you got into consulting, did you have many mentors?

Christer: I did. We all remember good teachers; they are so important in life. I had a couple of them that really inspired me in many different ways, I learned a lot from them. And you know teachers who show enthusiasm for what they are teaching, you tend to remember them.

One in particular was Dr. [W.E.] Deming. There is no doubt he had a big impact on IDCON’s philosophy and when you read his philosophy you realize: “Okay. That’s what I always knew and have been thinking but I just couldn’t express it!” Another one was [Eliyahu] Goldratt and his book The Goal and, of course, [James] Collins, of the Good to Great fame. I discovered “Hey, you were going the right way, Christer. It was just that they expressed it so much better” in the way of examples and so forth.

Greg: Was there any advice that they gave that was particularly helpful?

Christer: Oh yeah! One idea that I repeat very often is from Deming’s work and that is that people cannot be more efficient than the system allows them to be. You can be a very good mechanic, but if you work in a reactive system, you are not allowed to do a good job because everything is urgent and unplanned. And that hit right home, for me. Another is the reason why so many improvement initiatives don’t work out, not just in maintenance and reliability but in many fields, it’s because of the mobility of top management. Deming writes a lot about that; how we never really get to the point where you can see the results from the initiatives we start before someone new starts a different initiative.

He also talks about “constancy of purpose”, as he says which to summarize means that you decide to do this and you stick with it if really believe that it is the right thing to do (such as continuous improvement) – you don’t give up on it, you don’t keep on changing. Another of Deming’s concepts was that you have to have the right people on board. People are not your most valuable resource… it’s the RIGHT people. Because in my opinion if you have the wrong people, well… that’s not really an asset, is it?

Greg: Yeah. A lot of times that can end up being a challenge for an organization.

Christer: They might be very very good in another position in the company and are just in the wrong one right now. Goldratt wrote about how they installed robots in a plant, and they didn’t see any results because they focused on the wrong places in the manufacturing process; they should have focused on the bottlenecks. He talked about many things like that, and you still discover things when you read and listen to people, right?

Greg: Right. My grandmother told me many times, “Shh. You never learn anything from talking”.

On writing his book Knocking Bolts

Greg: Speaking of books, I have a copy of your book Knocking Bolts right here.

Christer: Yeah (chuckling).

Greg: No how did you come up with this title?

Christer: Oh, we thought of a LOT of titles and then I was in the lobby at a conference up in Seattle some years ago and some lady said “Hey! Are you Christer Idhammar?!” and I said “yes”. The lady said, “Oh, I remember you! You were in our plant [15 or 20 years ago] and you talked about ‘knocking bolts’. I still remember that.” People remember that – when I talked about knocking bolts as an example of basic basic maintenance inspections.

The term “knocking bolts” comes from something they did to railroad cars back in the day. They had maintenance people walking around knocking on the bolts and listening to the sound to tell if everything was still tight and in good condition. “Knocking bolts” became an expression we still use in maintenance today and is synonymous with checking equipment. It’s really about a basic preventive maintenance inspection procedure that I didn’t understand the point of when I first started out. This showed me that we really need to talk about WHY we do things.

Greg: Being a maintenance guru, do you get recognized a lot when you go out?

Christer: Oh, it happens. You know I have a name and a level of recognition in this field and in maintenance and reliability in industry. Actually, yesterday I was named “Reliability Hero” by an organization in Australia.

Greg: Congratulations. Getting recognized all the way across the globe.

Christer: So yeah, if I go to a conference there or in Europe or here in the United States a lot of people recognize me. It happens at the airports too, but not as much.

Greg: Well with all that going on how did you find the time to write Knocking Bolts?

Christer: (Laughing) I was pushed so many times to write a book because Torbjörn, my son, had heard all the stories – which are now called the “grandpa stories” – from my traveling of the world. I think I started about thirty-five years ago and I wrote two and a half pages and I stopped. Then some time went by, and I was working part-time, and I said, “you know I really should write this book”, but in order to do so I will need a ghostwriter – and that is Majsan Bostrom. So, I wrote the content and she, of course, took care of the language and the outline of the book and such. But I wrote a lot in the evenings and sometimes between jobs and sometimes I just took several days and just sat down to get it done.

Because you know… it’s not what you do that stresses you, Greg… it’s what you haven’t done.

Greg: Hmm…

Christer: So, it was kind of a relief. I found the time and I did it.

On teaching maintenance and reliability abroad

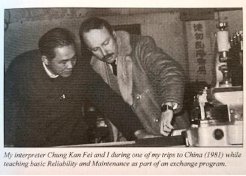

Greg: I found a photo of you in your book, and it says it is from a reliability exchange program in China in 1981. What’s going on in this photo?

Christer: This is me and my interpreter. I was visiting China five or six times doing two-to-three-week training seminars. And what they wanted was for us to go out and do what you were teaching. At the time I was teaching metalock which is a method of repairing cast iron because you can stitch pieces of metal together with a certain alloy and a certain key that you hammer in. Well, I explained it and showed videos, but we had to go out and do it because they had some broken pieces in the workshop. He talked about the lathe and how to measure and make sure that everything is within tolerance. So, I learned a heck of a lot because I had to go out and do it.

Greg: Well sure! That’s a good way to learn – at least it is for me.

Christer: Yeah, and there was a lot going on. It was a lot of fun. You know, I was using an overhead projector and all the transparency slides were in Mandarin. Well, of course I had memorized the slides and could explain the concepts on them, and I would point at the diagrams and Chung Fei would repeat it to the group in Mandarin. Many attendees came up to me surprised and said “Idhammar… you can read Chinese!” No, I just recognized a few of the characters like the one that meant “people”.

On finding one’s niche in this field

Greg: How did you get started in the maintenance and reliability field?

Christer: It was absolutely coincidence. I was several years at sea in the engine room. I’m still fascinated by those machines. There was a lot of maintenance on those big diesels. They were thirty feet tall, enormous giants also boilers and pumps and everything. Well, I had just gotten out of college, and I wanted a job offshore. Later I saw an advertisement for a Norwegian company that was setting up maintenance systems aboard ships and that was just right for me.

So, I applied for it, and I got the job immediately and I was sent out on a tanker for six weeks, but after that I started working more in industry; especially pulp and paper, steel, automotive, food and so on. So, it was kind of coincidence that I got into it. Then after five years there I decided to go out and do this on my own because the company ran out of contracts.

Greg: There is a chapter in your book Knocking Bolts where you talk about finding your niche. I wonder if you would expand on that a bit and maybe offer some guidance to those that may be trying to find the maintenance role where they are “the right person” like you mentioned earlier.

Christer: You mean in their professional life?

Greg: In their professional life… And I’d like to mention for our readers that IDCON has a YouTube series detailing the different roles within maintenance and reliability too.

Christer: I guess you could say “finding your calling” because it’s almost religious in a way, you know? I think I found mine because there was something I had no problem doing and that was speaking in from of large audiences. I remember I was once called to do that, and I stood up in front of people and I did not have any fear at all because I had a story to tell. If you’re going to be a good consultant, I think it is very important that you like the stage. Whether that is in front of a big group or online like we do now, you have to feel like you have a message to give them and you feel that that message is important.

And I think also if you are going to be a good consultant you need to get your name out there and build recognition otherwise, you’ll never get called in, you know? A maintenance manager isn’t going to call in someone that is totally unknown he or she is going to call in someone that has a good reputation and name recognition. You have to have a bit of an ego, and I’m not ashamed to say that, because otherwise you will shy away from that.

And you know, so many people are retiring, and we have to find the next generation. I’m sure they are out there, but they haven’t been taught that there are good jobs in maintenance and industry; there’s just not a culture there anymore.

Greg: Like an apprenticeship or like in my case just a patient older maintenance tech that wanted to help me learn. And he probably learned the same way from someone else.

Christer: I hope apprenticeships come back because they are a good way to get into industry.

Greg: Oh, they are. I’ve seen plenty. The skills gap isn’t going to be an issue much longer and I think fortunately for a lot of the green maintenance techs, there will be more open doors and opportunities for those with little experience than when I started out.

Thank you, Christer, for your time. It is always a pleasure speaking with you and getting insights from your years of experience.

Christer Idhammar

Christer Idhammar started his career in operations and maintenance 1961. Shortly after, in 1985, he founded IDCON INC in Raleigh North Carolina, USA. IDCON INC is now a TRM company. Today he is a frequent key note and presenter at conferences around the world. Several hundred successful companies around the world have engaged Mr. Idhammar in their reliability improvement initiatives.

Awards:

- He received the coveted EUROMAINTENANCE Incentive 2002 award during the biannual EUROMAINTENANCE 2002 conference in Helsinki in June 2002. Among 19 member European countries he was nominated and received the award from EFNMS – European Federation of National Maintenance Societies – for outstanding achievement and worldwide accomplishments in the field of reliability and maintenance.

- In 2008 he received the Salvetti Foundation Best Speaker all categories award among 154 speakers at Euromaintenance 2008 in Brussels, Belgium

- In 2013 he received the “Best presentation award” among 120 speakers at Reliability 2.0 conference in Las Vegas.

Related Articles

Can You Really Justify Reliability Centered Maintenance (RCM)?

Justification of Planners

90% of all Training is Wasted!

Can Operations Manage Maintenance?

Creating a Culture of Manufacturing Reliability