Data Analysis Tip 2 – Create a Vibration Test and Analysis Guide

www.dliengineering.com

Tip #2: Create a Vibration Test and Analysis Guide

A vibration test and vibration analysis guide is a simple book or electronic document that contains a variety of information about the machine. Information should include: A simple schematic of the machine with test points identified, instructions for testing the machine (especially if loads and speeds must be manipulated or verified), name plate information and a simple schematic of internal components. This information is invaluable for conducting a proper diagnosis of the machine.

Access to testing instructions may lead the analyst to recognize bad data caused by improper test conditions. Test location information allows the analyst to determine what graphs to consult when looking for particular faults. A simple internal schematic of the machine is invaluable as one wouldn’t want to diagnose ball bearing wear in a machine with only sleeve bearings! (Believe me, it happens!) Additionally, faults present themselves differently depending on how the machine is configured. A common example is that unbalance in a fan with a supported rotor looks different than unbalance in a fan with an unsupported rotor. It is essential to have this information visually in front of you when conducting data analysis.

Did you enjoy this tip? Continue onto Tip #3 or if you missed Tip #1 find it here!

Do you have a tip you’d like to share with the Maintenance World community? Submit it to [email protected] today to be featured in your favorite publication!

Related Articles

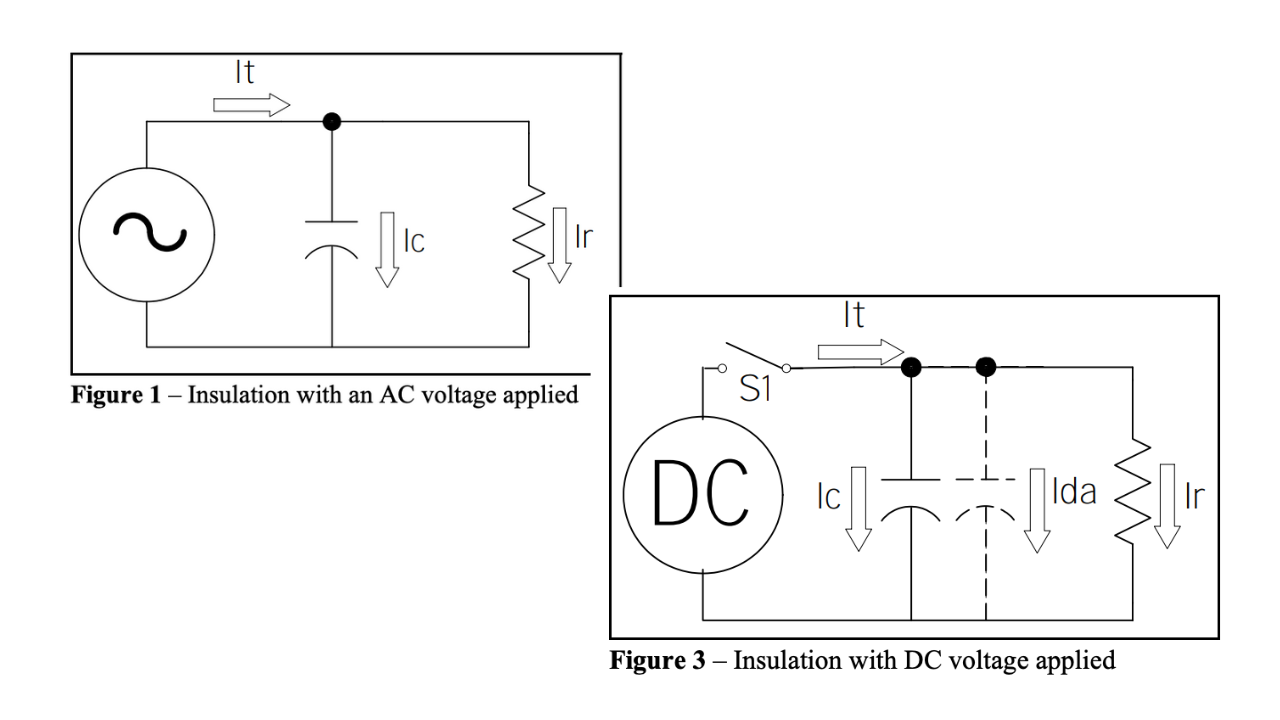

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

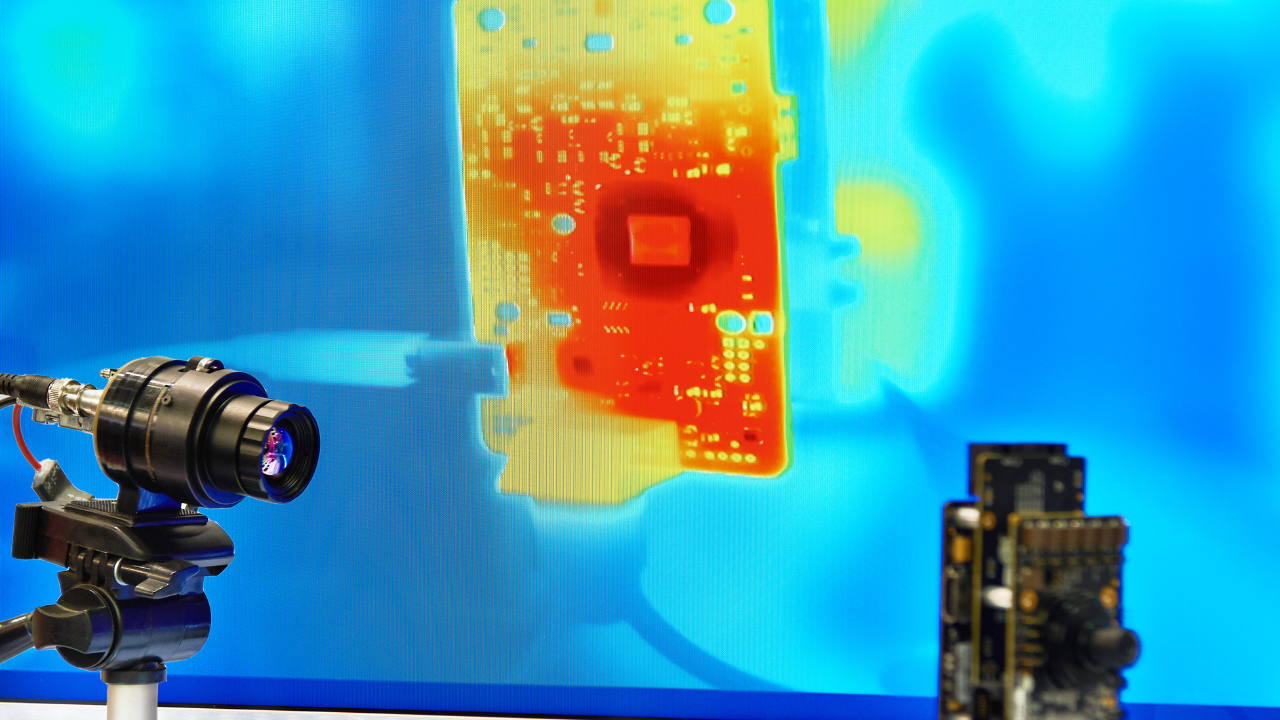

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera