Using Corrective Maintenance Work Plans to Improve Plant Reliability

Torbjörn Idhammar, IDCON INC

Preventive maintenance is generally considered to include both condition-monitoring and life-extending tasks which are scheduled at regular intervals.

Some tasks, such as temperature and vibration measurements, must be done while the equipment is operating and others, such as internal cleaning, must be done while the equipment is shut down.

There is another, often overlooked, type of preventive maintenance inspection which can not be scheduled at regular intervals. These inspections can and should be done in conjunction with corrective maintenance. Corrective maintenance is defined as maintenance work which involves the repair or replacement of components which have failed or broken down.

For failure modes which lend themselves to condition monitoring, corrective maintenance should be the result of a regular inspection which identifies the failure in time for corrective maintenance to be planned and scheduled, then performed during a routine plant outage.

When corrective maintenance is done, the equipment should be inspected to identify the reason for the failure and to allow action to be taken to eliminate or reduce the frequency of future similar failures. These inspections should be included in the work plan.

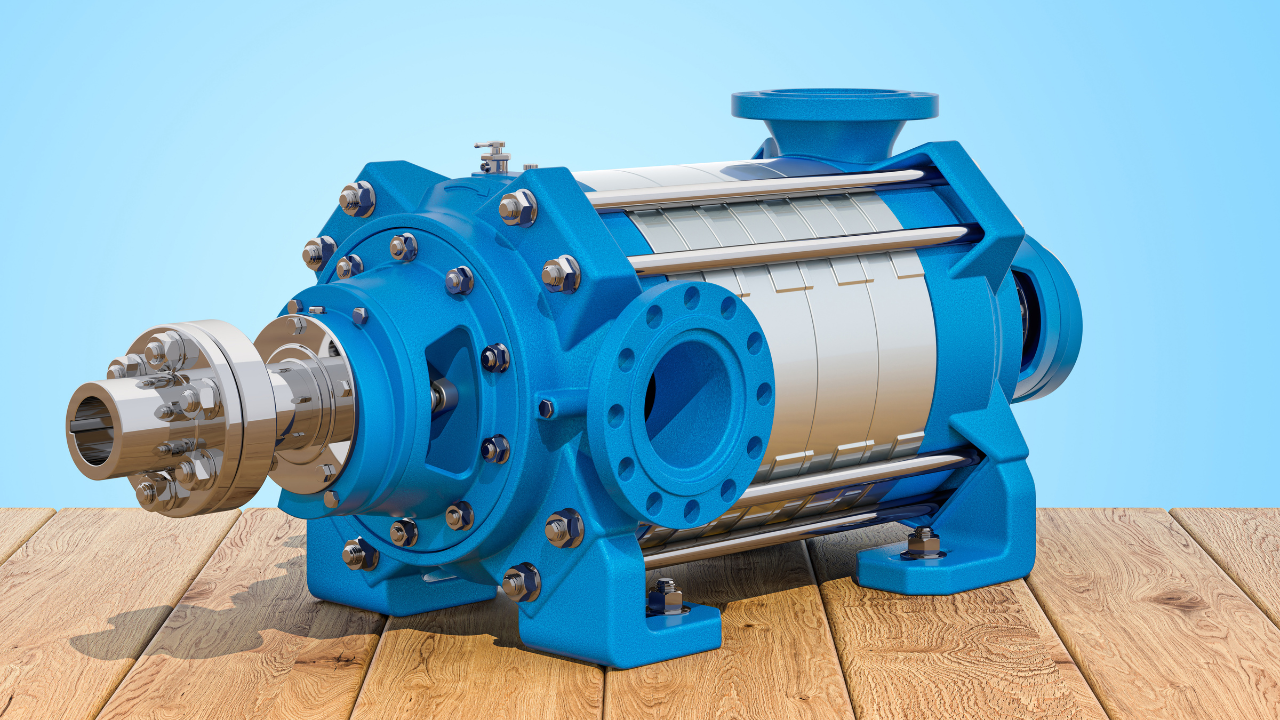

A good example is the failure of packing in a process pump.

Packing can be monitored by checking leakage and the location of the gland follower, so repacking should not normally be a fixed-time maintenance task. It should be done at frequencies which depend on the operating context.

During the process of repacking the pump, there are a number of simple inspections related to packing life which can be performed. These include:

- Using a padded pry bar to lift the pump shaft to check for a failed bearing

- Checking the condition of the shaft or sleeve for excessive wear or surface irregularities (using a small light that can be inserted deep into the stuffing box)

- Checking that the packing sequence is correct and that the lantern ring is in the right location

- Checking the throat bushing for wear

- Checking that the packing is cut to the correct length and properly seated

- Checking the packing used is the correct type

- Checking the clearance behind the impeller, especially if it has back pump-out vanes

- Checking shaft run-out

- Checking seal water pressure

- Confirming that seal and cooling water connections are correct

Many of these inspections would not normally be done on a regular scheduled basis and can only be done during repacking.

In a well-managed maintenance system, inspections that should be done during corrective maintenance for a specific failure mode (such as packing failures) should be listed, recorded and used.

So for any work order to repack a pump, the above check list should be attached to or included in the work order as a standard procedure.

The standard should include measurements appropriate to the specific equipment, such as the allowable sleeve wear and the impeller clearance in the case of the process pump packing.

A check list similar to the one for pump packing can be developed for many failure modes for common components, such as mechanical drives and hydraulic systems.

Integrating inspections that directly relate to failures into corrective maintenance work plans is a powerful tool to improve plant reliability.

Related Articles

Expert troubleshooters have a good understanding of the operation of electrical components that are used in circuits they are familiar with, and even ones they are not. They use a system or approach that allows them to logically and systematically analyze a circuit and determine exactly what is wrong. They also understand and effectively use tools such as prints, diagrams and test instruments to identify defective components. Finally, they have had the opportunity to develop and refine their troubleshooting skills.

Expert troubleshooters have a good understanding of the operation of electrical components that are used in circuits they are familiar with, and even ones they are not. They use a system or approach that allows them to logically and systematically analyze a circuit and determine exactly what is wrong. They also understand and effectively use tools such as prints, diagrams and test instruments to identify defective components. Finally, they have had the opportunity to develop and refine their troubleshooting skills.

See More

Corrective Maintenance Task. Generation is best performed by the. same personnel who perform corrective maintenance. The normal. technician’s time schedule does not. allow the time to document tasks in. detail. Some companies rely on the maintenance supervisor to document. and implement new preventative and corrective maintenance tasks.

Corrective Maintenance Task. Generation is best performed by the. same personnel who perform corrective maintenance. The normal. technician’s time schedule does not. allow the time to document tasks in. detail. Some companies rely on the maintenance supervisor to document. and implement new preventative and corrective maintenance tasks.

See More

Availability in a Supply Constrained Environment is the Number One Issue for Refinery Executives according to the EPI Center.

Availability in a Supply Constrained Environment is the Number One Issue for Refinery Executives according to the EPI Center.

See More

Let's suppose that we have recorded the time when each failure of a repairable subsystem has happened during a season. The arrangement of these failures (black points in Figure 1) along the time axis is called a stochastical realization of failure events.

Let's suppose that we have recorded the time when each failure of a repairable subsystem has happened during a season. The arrangement of these failures (black points in Figure 1) along the time axis is called a stochastical realization of failure events.

See More

Paul Maier, project manager of the NYSERDA study, states that "Pump sandblasting and coating should be a required step of any pump. refurbishment program." MCWA has also included interior pump coatings as a requirement in its new pump specifications. The goal is that. requiring coatings on the inside of. new pumps will eliminate, or significantly delay, the seemingly inevitable decline in pump performance and efficiency from internal corrosion and tuberculation buildup inside unlined pumps.

Paul Maier, project manager of the NYSERDA study, states that "Pump sandblasting and coating should be a required step of any pump. refurbishment program." MCWA has also included interior pump coatings as a requirement in its new pump specifications. The goal is that. requiring coatings on the inside of. new pumps will eliminate, or significantly delay, the seemingly inevitable decline in pump performance and efficiency from internal corrosion and tuberculation buildup inside unlined pumps.

See More

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

Too much heat can cause multiple problems with cartridge mechanical seals. Some heat problems are not seal design or seal installation related.

See More

You have four opportunities to trouble shoot centrifugal pumps and each opportunity can offer you a clue as to what is wrong with the pump. Let's take a look at each of these conditions:

You have four opportunities to trouble shoot centrifugal pumps and each opportunity can offer you a clue as to what is wrong with the pump. Let's take a look at each of these conditions:

See More