Fatigue Failure 101

The beginning of this article answers the question: What is Fatigue Failure? It also dives into some of the basic causes and technical aspects of what a failure is, but be sure to read to the end as Gregory Mecomber from IDCON INC adds in his personal experience with fatigue fracture analysis. Have any questions? Feel free to reach out to Greg on LinkedIn or join the MaintenanceWorld Discussion group on LinkedIn.

What is Fatigue Failure?

Fatigue Failure is when cracks form due to repetition/cyclic load. Once the cracks form, they will continue to grow and eventually will produce a complete fracture.

Causes

Metal fatigue is caused by repeated cycling of the load. It is a progressive localized damage due to fluctuating stresses and strains on the material. Metal fatigue cracks initiate and propagate in regions where the strain is most severe.

The process of fatigue consists of three stages:

- Initial crack initiation

- Progressive crack growth across the part

- Final sudden fracture of the remaining cross section

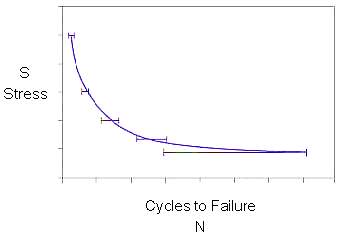

Schematic of S-N Curve, showing increase in fatigue life with decreasing stresses.

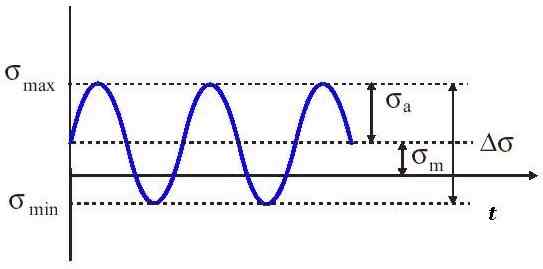

Stress Ratio

The most commonly used stress ratio is R, the ratio of the minimum stress to the maximum stress (Smin/Smax).

- If the stresses are fully reversed, then R = -1.

- If the stresses are partially reversed, R = a negative number less than 1.

- If the stress is cycled between a maximum stress and no load, R = zero.

- If the stress is cycled between two tensile stresses, R = a positive number less than 1.

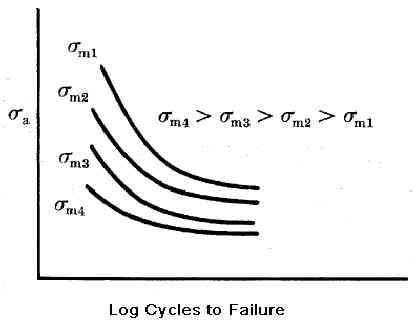

Variations in the stress ratios can significantly affect fatigue life. The presence of a mean stress component has a substantial effect on fatigue failure. When a tensile mean stress is added to the alternating stresses, a component will fail at lower alternating stress than it does under a fully reversed stress.

Preventing Fatigue Failure

The most effective method of improving fatigue performance is improvements in design:

- Eliminate or reduce stress raisers by streamlining the part

- Avoid sharp surface tears resulting from punching, stamping, shearing, or other processes

- Prevent the development of surface discontinuities during processing.

- Reduce or eliminate tensile residual stresses caused by manufacturing.

- Improve the details of fabrication and fastening procedures

Fatigue Failure Analysis

Metal fatigue is a significant problem because it can occur due to repeated loads below the static yield strength. This can result in an unexpected and catastrophic failure in use.

Because most engineering materials contain discontinuities most metal fatigue cracks initiate from discontinuities in highly stressed regions of the component. The failure may be due the discontinuity, design, improper maintenance or other causes. A failure analysis can determine the cause of the failure.

Quick Guide to Fatigue Fracture Analysis

The simple truth is that fatigue failures leading to broken bolts or shafts result commonly from excessive loading often from a shearing force. It is possible for us to get a general, but quantifiable idea of the failure mechanism and thus an objective step towards diagnosing root cause through unaided visual inspection of the bolt, shaft, etc. – though many of us may need to put on our readers for this process.

Often fatigue fractures, especially those from a shearing force initiate at a point on a single plane at the circumference of the bolt or shaft. If the fracture is the result of a single overload event, the fracture will be rough or jagged and often uneven.

If the fracture is the result of slight but repetitive overloads, the fracture will typically be smooth with the point of catastrophic failure (termination point) being smaller but jagged much like the single overload.

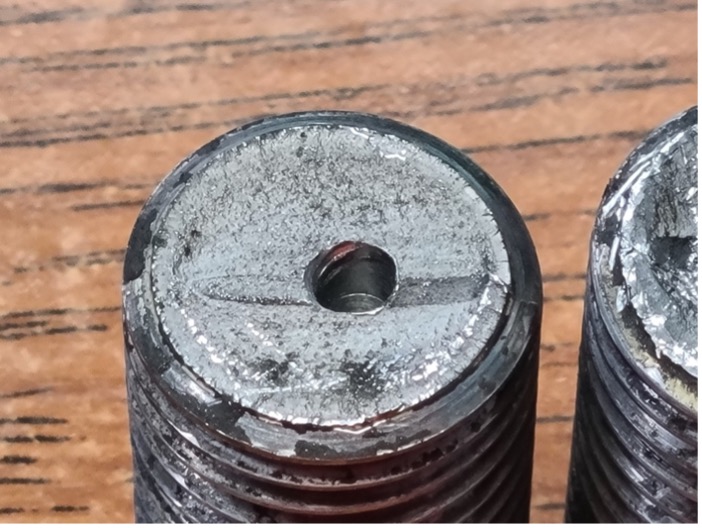

Typically, the termination point is opposite from the direction of overload (or strain) though sometimes it may end up being in the center of the bolt as is the case in the image below.

This particular fracture was the result of the slight but repetitive overload shearing forces mentioned. Notice that all but the jagged horizontal strip through the middle is relatively smooth. The horizontal strip is the fracture termination point where it snapped all at once. The smooth surface was the result of gradual cracking from a forward and reverse shock load starting from both the top and bottom at once.

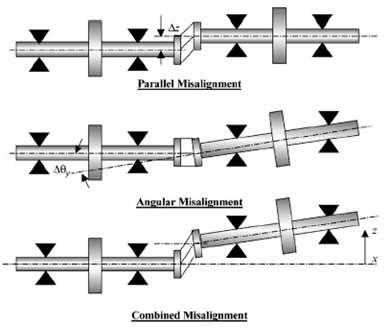

Some broken shafts will be quite uneven since they result from torsion forces, but even if the fracture is spiral shaped the surfaces still largely tell the same story as the bolt; a larger rough area indicates more of a shock load such that may result from a seized bearing. Occasionally, one might come across a shaft with the termination point being in the center only, which would result from the slight repetitive overloading due to angular misalignment.

Being able to distinguish the fracture initiation and termination points will give you reliable evidence of the direction and amount of overload.

Fractures due to metal fatigue can be reasonably minimized by:

- Using the correct bolt material and size.

- Torquing to the correct specifications.

- Ensuring bolt tightness periodically WITHOUT over tightening or over-torquing.

- Minimize extreme fluctuations in temperature

- Monitor for and prevent excessive corrosion.

- Eliminate shock loads where possible.

Read more about The Keys to Solving Fatigue: The Silent Killer

Greg Mecomber

Greg Mecomber is a reliability and maintenance consultant. He has years of maintenance and reliability experience with both “turn-around” and start-up companies as well as experience in varied industries such as brewing, medical devices, glass fabrication, airfield maintenance and food & beverage.

Related Articles

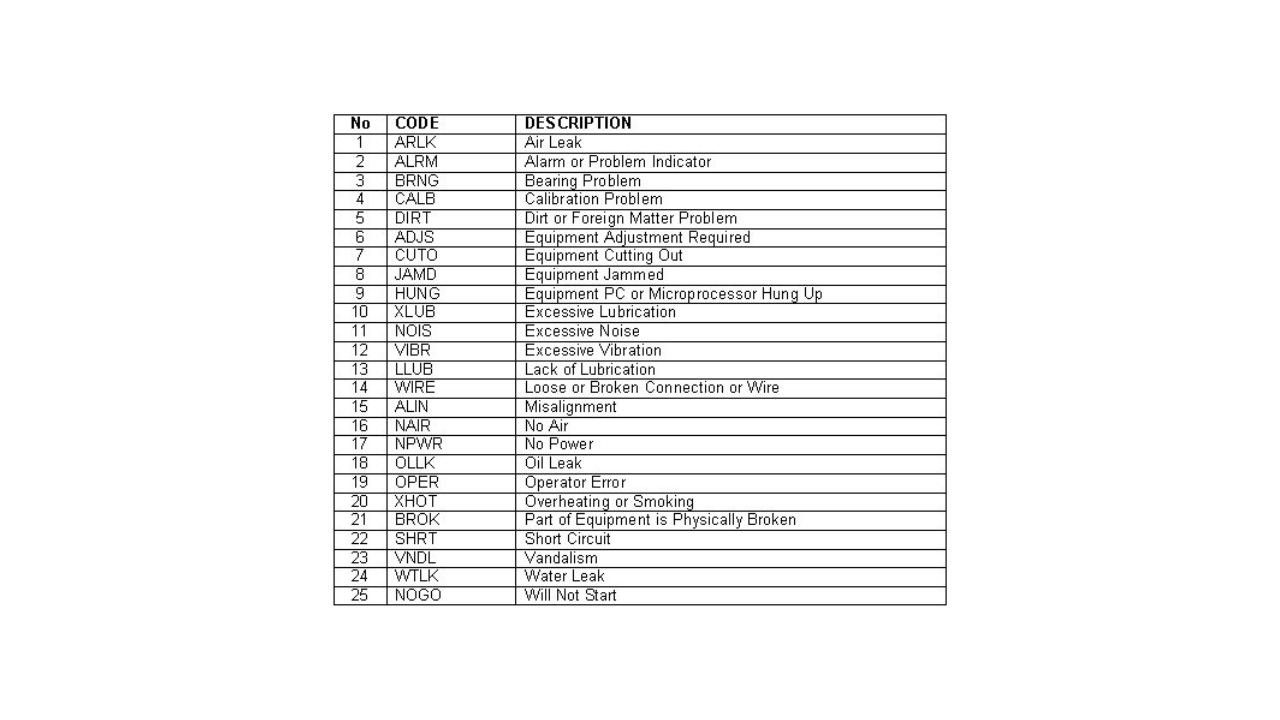

Failure Codes in Maintenance Systems - CMMS

Are We Willing to Hear What “Failure” Has to Say?

Reduced Wear and Failure of Machine Components: Failure Analysis of Mechanical Components

Internal Clearance & Its Effect on Bearing Fatigue Life

The Keys to Solving Fatigue: The Silent Killer