Glasses on, Troubles Gone: Augmented Reality Takes Flight in Maintenance

Natalie Johnson

Posted on 9/27/23

Augmented reality (AR) is emerging as a solution to enhance maintenance programs and mitigate the maintenance technician shortage. AR for maintenance has the potential to transform organizations’ maintenance programs by improving maintenance efficiency and accuracy in a time when skilled technicians are in high demand.

Maintenance technicians are the backbone of the aviation industry. Without their work, planes would not be able to leave the ground. However, a combination of factors has led to a shortage of workers available to fill this vital position. Oliver Wynman’s forecast on the global fleet and the MRO market noted the importance of modernization in attracting younger generations to the aviation maintenance field. Gen Z grew up surrounded by technology, and they want to utilize it in their workplace. As the aviation technician shortage continues, companies are turning towards augmented reality (AR) to improve their maintenance programs and expand the workforce.

Read more details about the shortage in a previous article.

Maintaining an aircraft is a demanding task that requires extensive knowledge of thousands of individual parts. Lugging around paper or PDF manuals is often impractical and difficult for those working in the hangars. Augmented reality (AR) is making it possible for aviation technicians to access technical manuals, 3D models, and consult other skilled professionals while simply wearing a headset. The technology has multiple benefits that can enhance the efficiency and accuracy of inspections, routine maintenance, and training efforts.

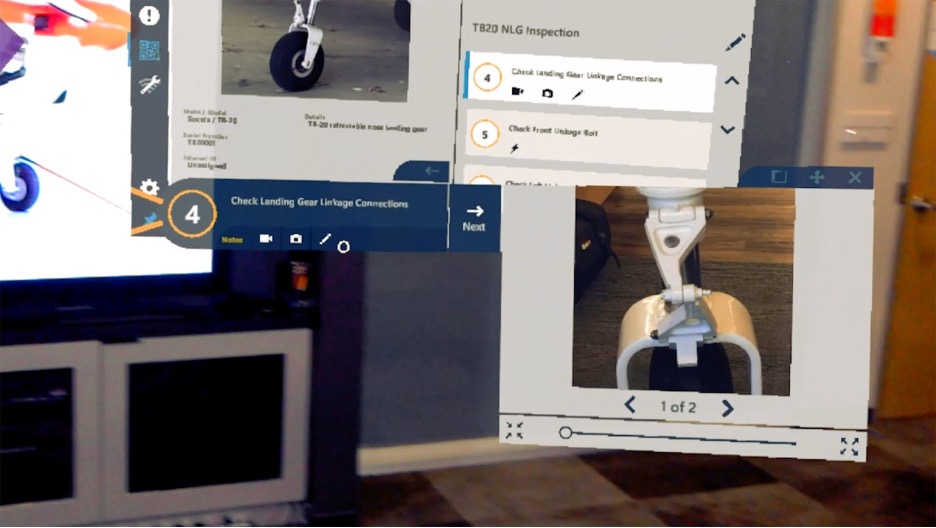

Upon landing, all commercial passenger planes undergo a thorough inspection by an MRO engineer. The inspection covers everything from the engines to the onboard Wi-Fi. It is a repetitive, yet crucial task that requires engineers to carry a paper-based job card with multiple pages throughout the entirety of the inspection; some planes are so large it takes over 200 steps just to circle the aircraft. Utilizing AR glasses allows engineers and maintenance technicians to work hands free while simultaneously accessing work instructions, editing and reorganizing their job list, capturing evidence to log job details, and accessing multimodal sources.

Harvard Business Review shared one MRO engineer’s thoughts, “Combined with [artificial intelligence], the AR glasses can make our job a lot easier. I can now point my fingers to a place, for example a lubricating oil cap, and it automatically recognizes the object or the key parts and tells me that it’s open but should be closed. It also can show me, in a picture or a short video, how the object looked in normal condition or in its last service.” Once the task is complete, engineers can sign off using a simple hand gesture since tarmacs are often too noisy to hear voice commands.

Another benefit of the AR for maintenance is the potential to standardize job performance. AR glasses can guide engineers through the inspection process, allowing them to seamlessly move from one task to the next without worrying about where they placed their papers. The technology can even allow maintenance teams to practice inspections without the physical aircraft present to improve their efficiency when it comes time to perform a real inspection.

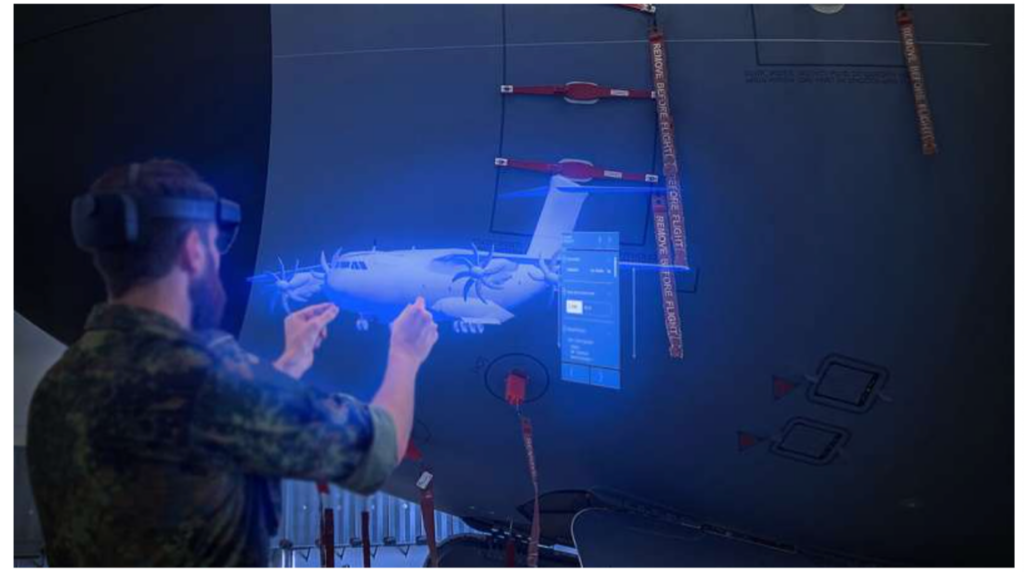

AR glasses can be especially useful for maintenance tasks beyond the tarmac. Modern aircraft contain thousands of mechanical and electrical components. In an Airbus A400M the engine alone is composed of 10,000+ individual parts. Servicing aircraft requires extensive knowledge of all components and often leaves mechanics constantly referring to different manuals with 2D depictions. AR glasses allow technicians to access a wide range of professional multimodal sources. Virtual elements can be accessed as 3D immersive experiences. These step-by-step instructions overlaid in the user’s field of vision safely and accurately guide technicians through tasks.

Once a task is complete, technicians must document the work completed for future reference. Record-keeping and communication tools are integrated into AR glasses so note-taking can easily be done with simple commands and voice instruction. Techs can log all details, and evidence from their jobs and performance is stored in the job board for review from any device.

Perhaps the most critical need AR glasses have the potential to address is the lack of experienced professionals available to train the younger generation of aviation technicians. As we saw in a previous news story, the airline industry’s rapid growth has led to the need for nearly 10,000 new aviation technicians every year for the next 20 years. However, the training capacity in the US can only produce 7,000 graduates each year, assuming there is full enrollment.

The US Air Force has found that utilizing AR technology reduced the need for trainers to be physically present to train new workers. Trainees using AR glasses can consult experienced professionals through voice interactions and the professionals can instantaneously provide access to the necessary manuals, videos, instructions, etc. They can also guide technicians through tasks in real time.

In addition, AR for maintenance allows techs the opportunity to interact with hundreds of different aircraft parts from a variety of planes in highly realistic simulations. Trainees have the chance to learn how to properly inspect and repair aircraft in an environment nearly identical to the physical world.

This application of AR glasses makes it easier, quicker, and cheaper, to train new technicians. While the technology is still being tested, it is clear that AR for maintenance has the potential to transform maintenance efforts in the aviation industry. The US Air Force found that when their technicians utilized the technology there were 53% less errors. Those still using traditional methods to install parts, incorrectly installed parts 57% more often than technicians using AR glasses.

Augmented reality (AR) is transforming aviation (and other industrial) maintenance by improving efficiency, accuracy, and training. AR glasses enable hands-free access to manuals and expert guidance, as well as standardizing procedures, therefore reducing errors. AR for maintenance also addresses the technician shortage by enhancing training capabilities and making maintenance processes easier, quicker, more cost-effective, and more attractive to a younger workforce. AR for maintenance can revolutionize industry, promising a brighter future for both experienced professionals and the next generation of maintenance technicians.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you every Wednesday by the Maintenance World crew.

Natalie Johnson

Natalie Johnson is the previous editor/website administrator for MaintenanceWorld.com, and is currently a student at Campbell University Norman Adrian Wiggins School of Law.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill