Brinelling of Bearings

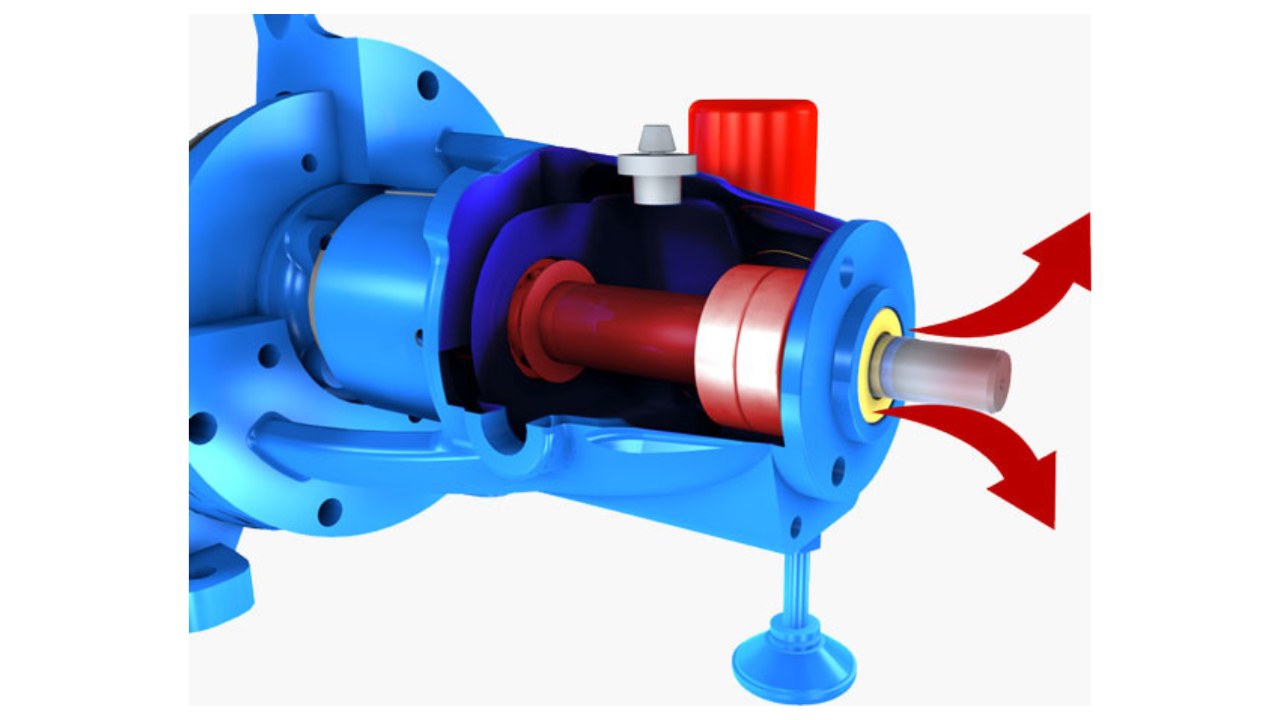

Impact or oscillatory damage (brinelling), how many of us think about these when we are storing, handling and installing bearings or even during the repair or aligning of machines/equipment with rolling element bearings?

Drop a bearing (oops!), impact an interference fit hub, coupling etc., that seized onto a shaft (hammer time oops!), beat a bearing onto a shaft or into an housing, hit the machine with the big hammer to move it (no jacking bolts oops!), let that spare machine sit on the warehouse shelf or in the field for months or even years with no rotation (oops!)? And the list could go on and on…we’ve all probably been guilty of at least one or more of these infractions at some point.

“What’s the big deal anyway?”

Well, quite often we talk about bearing failures as if they are simply normal and should be expected, while there are plenty of normal/end of service life/fatigue type failures in the bearing world, there are also times when we should take a closer look, especially when the failure is premature.

In fact two very common bearing damage types that are responsible for many of these failures are easily preventable or can at least be minimized by simply doing “the right things”.

“What’s the big deal”?

What kind of issues are we creating with improper handling, installation and storage?

We could be brinelling the bearing surfaces in a manner not evident right away.

What are the two types?

There are basically two types, true and false brinelling.

True Brinelling

True brinelling is indentation damage caused by impact, metal is displaced usually by the rolling element striking the raceway surface. Of course when the bearing is placed in service the damaged areas will spall/flake.

False Brinelling

False brinelling is rubbing action of metal to metal contact, usually between the rolling element and the raceway surface. False brinelling is caused by vibration or an oscillatory source acting on the bearing or machine while it is stationary. Here the vibratory action between the rolling element and the raceway surface creates axial lines and if remaining in that position long enough hollow spots. Again when in service the damaged area will start to spall.

When a bearing fails prematurely, the first questions asked should be “what caused it to fail and how can we not have this same failure recur?” In the case of brinelling, it is avoidable and/or the risk can be minimized greatly.

Preventing True Brinelling

– Minimize impacts to bearing or machine

– Use precision installation techniques

– Use correct installation tools

– Careful handling practices

Preventing False Brinelling

– Avoid vibration while bearing/machine is stationary

– Secure during transport

– Periodically rotate stored spares

– Periodically rotate field spares in/out of service

In addition to saving equipment, there are also many financial benefits of reliability.

Related Articles

Bearing Repair: An Alternative to Replacement

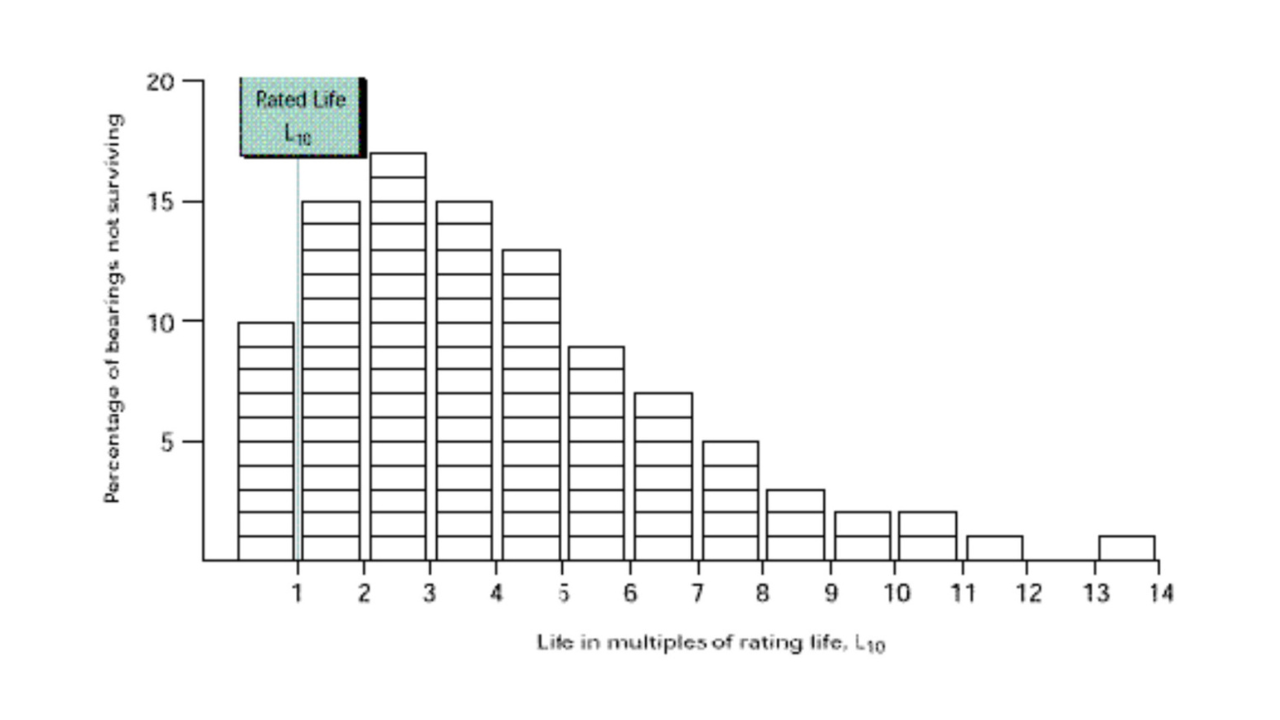

Basis for Bearing Life Calculation

Troubleshooting Premature Bearing Failure

Brinelling of Bearings

How to Extend Bearing Life

The Meaning of Bearing Life