Nondestructive Testing for Protective Coatings: Implementing a Lifetime Corrosion Prevention Program

Jim Deardorff, President of Superior Coatings

During the 20th century cheap and abundant energy made corrosion a manageable problem. This era is coming to an end. Soon, industry will find there is less funding available for corrosion prevention after adjusting for rising energy costs. At this time, management will be forced to decide whether to continue with traditional corrosion control practices or change to something new with a greater potential for energy savings. For many, this will be an extremely difficult decision to make. Nondestructive testing may be the solution.

Protective coatings nondestructive testing (PC/NDT) is a lifetime maintenance discipline that has been designed to provide a significant improvement in the maintainability of protective coatings. Protective coatings nondestructive testing is based on the application of permanent foundation primer coats over-coated with expendable finish coats. Maintenance focuses on the repair or replacement of the finish coats, leaving the primer coats intact.

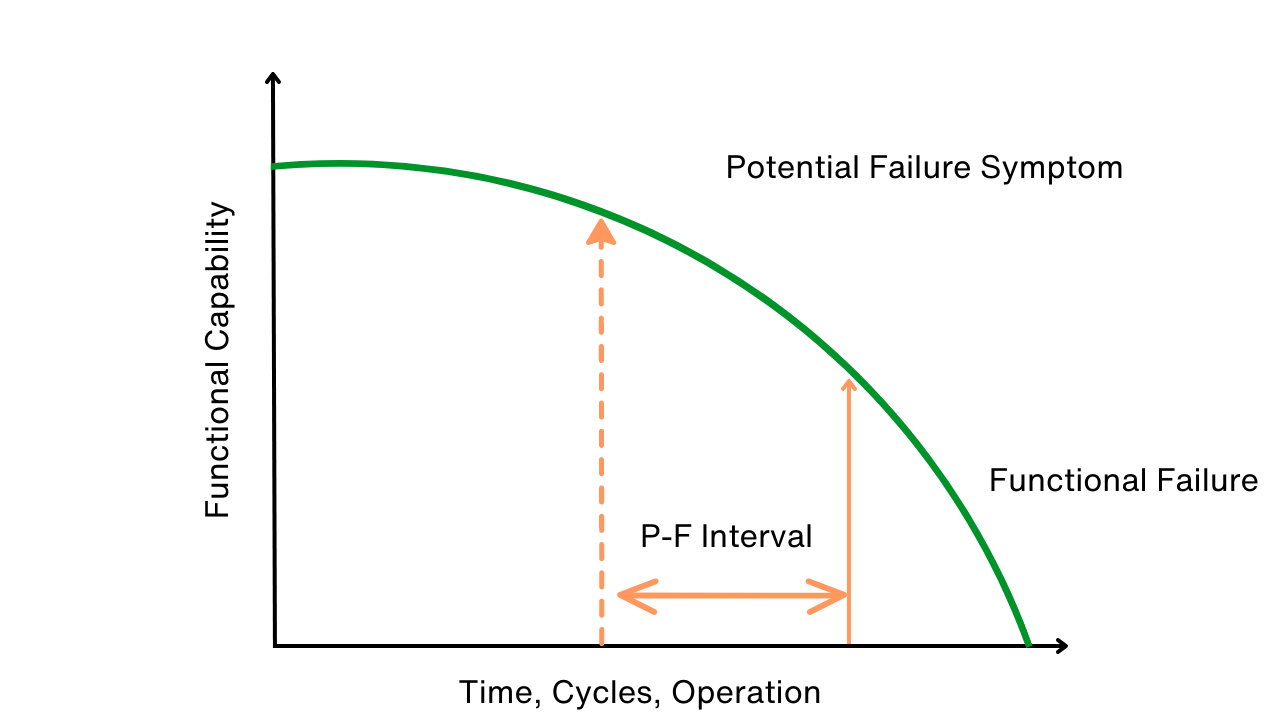

Recoating is scheduled by black light–activated fluorescence (a type of nondestructive testing). The integration of an early warning defect detection indicator (fluorescence) into the original coating formulation produces an enhanced visual signature (EVS) that allows workers to monitor large or complex surfaces in relatively short periods of time and determine the best time for coating repairs (Fig. 1). This allows maintenance to be performed before complete coating failure occurs and irreversible corrosion damage begins.

The Problem

Oil, the main source of energy in today’s world, is a product of buried biomass. Over a period of 200 million years, this raw material has been transformed by heat and pressure into an energy source that has no equal for its versatility, ease of transportation, and cost-to-benefit ratio. For example, the energy produced from one barrel of oil is equal to 12 people working 40 hours a week all year long, or 25,000 man hours of labor.

On July 12, 2008, oil reached a record price of $147 per barrel. This is a 488% increase over the 2004 price of $25 per barrel. Oil, coal, and natural gas are the fossil fuels that produce 85% of the world’s energy. Currently, the United States uses more than 20 million barrels of oil per day. This represents upwards of 25% of the world’s total production. When fossil fuels are converted into energy they produce carbon dioxide, a greenhouse gas. Each year, 6.1 billion metric tons of greenhouse gases are added to the earth’s atmosphere.

Since the discovery of massive oil deposits in the early 1900s, mankind has consumed more than 1 trillion barrels. Today, conservative estimates place global oil reserves at 1.1 trillion barrels that can be obtained by conventional means. In less than 100 years humans have consumed more than half the world’s oil reserves. The oil we have left will be harder to get and much more expensive to buy.

According to a 2002 report by the Federal Highway Administration, the annual direct and indirect cost of corrosion to the U.S. economy exceeds $500 billion. This represents 6% of the gross domestic product (GDP) valued at $8.76 trillion. Experts predict that energy costs will double in the next 20 years. This could easily cause corrosion costs to exceed one trillion dollars by 2050.

Maintainability is defined as the measure of time and effort required to return an asset to a predetermined state of performance after a failure event has occurred. Designed maintainability is performed during the concept phase and is used to incorporate durability, inspection, and serviceability into new products. This is done to improve the efficiency and effectiveness of subsequent maintenance operations.

Traditionally, the coating industry has limited its use of engineered maintenance programs due to the complexity and high labor costs involved with the inspection and evaluation of aged coatings. Another problem is the fact that modern coatings are not specifically designed for planned maintenance programs.

Protective coatings nondestructive testing has been developed to remove the cost, production, and technical barriers that have historically limited industry’s acceptance of coating maintenance. Protective coatings nondestructive testing is designed to prevent the conditions that produce corrosion rather than dealing with its effects. By dealing with corrosion elements on an individual basis, Protective coatings nondestructive testing reduces the number of major coating operations and the volume of recoat materials required over an asset’s lifespan.

To better understand the problems with coating maintenance it is important to understand how maintenance programs have evolved over time.

Maintenance Background

Since the beginning of the industrial revolution more than 100 years ago, the evolution of maintenance programs can be traced through three distinct generations.

First Generation (1840 to 1940): “Fix it when it breaks” (reactive maintenance)

At the beginning of the industrial revolution, machinery was simple and robust. Industry still relied heavily on manual labor for the production of goods and services. Maintenance focused on simple parts replacement, oiling, and cleaning. Painting was performed by hand using brush-applied, linseed oil–based coatings.

Second Generation (1940 to 1960): “Fix it before it breaks” (preventive maintenance)

The nature of maintenance changed dramatically during World War II. The war effort dramatically increased the demand for planes, ships, and other war-related products. At the same time, manpower reserves dropped dramatically. This placed a higher importance on machines. To reduce downtime, companies began servicing and over-hauling machines at fixed time intervals. This was the beginning of preventive maintenance practices. Painting moved to compressed air spraying to increase production for manufactured products. Lead-based coatings were still widely used for industrial applications. Water-based “latex” paints were introduced during this period.

Third Generation (1970 to present): Prevent the conditions that would cause a part to break in the first place. Develop a maintenance program for the part or learn how to make it better (predictive and reliability-centered maintenance programs)

By the 1970s machines were expensive to buy and operate. It was critical that machines run as long as possible with minimum downtime. This led to the development of reactive and reliability-centered maintenance programs.

Predictive maintenance is based on the actual condition of a component part for the scheduling of repairs or replacements. Reactive maintenance can virtually eliminate catastrophic failure events, but it is expensive. Testing equipment can cost tens of thousands of dollars, plus there is the added expense of training personnel to perform reactive maintenance operations.

Reliability-centered maintenance (RCM) is defined as a process that determines the optimum maintenance requirements of an asset in its operational environment. RCM is different from preventive maintenance in that it uses root cause analysis to determine what causes an asset to fail in the first place and what design changes or modifications can be performed to prevent a similar problem in the future.

During this current era, industry has moved from oil-based coatings to high-performance epoxy/urethane systems, whereas lead-based paints were banned due to health concerns. Airless paint pumps were introduced during the 1960s, and airless spraying provided a dramatic increase in painting production and lowered painting costs for large steel structures.

The Protective Coating/Nondestructive Testing System

Protective coatings nondestructive testing mirrors the performance levels of predictive and RCM maintenance programs and is designed to match coating life with asset life, even if the asset’s life exceeds 50 to 100 years or more. Protective coatings nondestructive testing is designed with durability and maintainability in mind. Protective coatings nondestructive testing divides the responsibility for lifetime corrosion management between the corrosion engineer, the coating manufacturer, the painting contractor, and the facility owner. Each has an important role in the Protective coatings nondestructive testingprogram.

- The corrosion engineer develops specifications for the Protective coatings nondestructive testingcorrosion management program.

- The coating manufacturer formu- lates and manufactures the coatings to meet the engineer’s specification requirements.

- The painting contractor installs the new coating system and may contract for maintenance work.

- The facility owner has the ultimate responsibility for the program. Management schedules maintenance, develops asset inventory, and documents all painting work.

Protective coatings Nondestructive Testing Program Advantages:

- Increased service life for equipment and infrastructure.

- Reduced corrosion-related repairs, downtime, and early replacement costs.

- Improved performance and operational readiness.

- Increased worker safety and morale.

- Reduced waste and disposal costs.

- A reduction in VOCs, HAPs, and other types of greenhouse pollutants.

- Improved recycling and remanufacturing potential.

- Lean engineering (a reduced need to over-design assets to resist corrosion).

- Significant energy savings for corrosion prevention by protective coatings.

Protective Coatings Nondestructive Testing is Based on the Following Component Steps:

- Improved surface preparation standards.

- Special purpose maintenance coatings.

- Advanced black light nondestructive testing quality control.

- Post-application cleaning and recoating.

- Failure analysis: black light EVS provides workers with a better understanding of why coating failure occurs and what can be changed to prevent future problems.

Surface Preparation for Nondestructive Testing

Surface preparation is the foundation for the Protective coatings Nondestructive testing maintenance program. It is critical that the bare-metal substrate be completely cleaned and conditioned to prevent under-film corrosion activity and provide a sound base for later maintenance recoat operations.

Under-film corrosion is a condition that develops at the metal/coating interface and is impossible to correct by traditional maintenance operations. Under-film corrosion requires the complete removal of existing coatings, the re-establishment of surface preparation standards, and the reapplication of a complete new coating system.

The cleaned metal must also be free of chemical contamination, including soluble salts—a type of contaminant that includes chlorides, sulfates, and nitrates. Salts react with moisture and oxygen and produce a chemical reaction that causes internal pressure and loss of coating adhesion. After blast cleaning, salts should be removed by recommended industry standards before new coatings are applied.

The effectiveness of any extended maintenance program can be severely limited due to a condition known as high-energy surface profile. This occurs when metal is cleaned by high-pressure abrasive blasting that produces an extremely rough surface. The increased surface area exposes more molecules to the environment. Molecules have a net attraction to other molecules in bulk. The molecules next to the surface are highly energized and instantly attract moisture, oils, and oxides from the atmosphere. Coatings that are applied over contaminated surfaces can produce under-film corrosion and result in premature system failure.

To eliminate this problem, a second abrasive blast is performed to further clean and condition the metal substrate. The second blast uses a special blend of hard, dense, abrasive materials that are delivered to a target surface at a uniform angle and air pressure. This reduces surface energy levels and lowers the potential for under-film corrosion activity. If it is not possible to perform a second abrasive blast over the total surface area, it is recommended that the second abrasive blast be performed, at least, at primary corrosion sites (welds, edges, joints, and other irregular surfaces).

Special Purpose Maintenance Coatings

Protective coatings nondestructive testing is designed to extend coating life based on the application of permanent primer foundation coats over-coated with expendable intermediate and finish coats. The primer has high adhesion to the metal substrate and is resistant to abrasion, chemicals, and ultraviolet light. The intermediate and finish coats are formulated to degrade slowly over time. This allows removal of damaged areas while leaving the primer coat intact.

Black Light Quality Control

The permanent primer coat is formulated to produce black-light–activated fluorescence. The finish coat is not reactive to black light. This allows workers to verify coverage, saturation of profile, and proper dry film thickness (DFT) of each coat by black light.

Black light EVS is the only coating inspection process that can match the speed of modern spray applications. Line-of-sight inspections can be performed as fast as the hand can move the black light and as fast as the human eye can follow.

Note: The average worker with 20/20 vision can locate a coating defect 50 microns in size in good light when they are allowed adequate time for a thorough visual inspection. The same worker, using black light EVS, can locate the same defect even in low light conditions or during production painting operations.

Electromagnetic Energy

There are tree types of energy: kinetic, potential, and electromagnetic. Kinetic energy is energy in motion, such as a person riding a bicycle. Potential energy is energy held in reserve: for example, an archer’s pulled bow string waiting for release. Electromagnetic energy is energy that radiates from a single source and travels at the speed of light, such as light bulbs, radio, or television signals (Fig. 2). Electromagnetic energy makes possible TVs, computers, and cell phones.

The type of electromagnetic energy is determined by wavelength. Wavelength is defined as the distance between the crest of one wave to the crest of the next. Wavelength is measured in nanometers, with a nanometer being equal to one-billionth of a meter.

Frequency is the number of waves that pass a point in one second. For example, the frequency of visible light is 4 to 800 trillion waves per second. As the length of a wave increases the energy level decreases. Conversely, as the length of the wave decreases the energy level increases. A packet of light or electromagnetic energy is called a photon.

Types of Electromagnetic Wave Energy

- Radio waves

- Microwaves

- Infrared waves (also known as heat waves)

- Visible light

- Ultraviolet light (black light)

- X-rays

- Gamma rays (also known as cosmic waves)

Fluorescence

More than 3,000 natural and man-made substances can transform invisible electromagnetic energy into longer visible wavelengths that produce fluorescence. Theses substances react because they are composed of easily excitable molecules. When exposed to black light illumination, this energy—in the form of photons—causes one or more electrons to be “kicked up” into a higher energy state. In this state, electrons are extremely unstable and will eventually release this excess energy and return to their original ground state. This release of excess energy is what we see as fluorescence.

Fluorescence Coating Formulation

Currently, protective coatings can be modified to produce fluorescence in two ways. Fluorescent dyes can subsequently be added to conventional coatings at the recommended levels. Fluorescent pigments can be added during formulation to replace or mix with traditional color pigments. It is important to select paint and coating colors that work best with fluorescent properties.

Black Light

Black light—also known as Wood’s light, long-wave UV, or UV-A—is a form of electromagnetic energy that occurs just beyond the visible end of the light spectrum. This low-energy wavelength covers the range between 320 nanometers (nm) and 400 nm.

Unlike ordinary light bulbs that produce visible light by moving electricity through a filament wire, black light is created by sending electricity though a tube filled with an inert gas (such as argon) and a small amount of mercury. As an electric spark passes across an electrode, this makes the mercury atoms move at a high velocity. As these atoms slow down, they release excess energy at 365 nanometers, or black light electromagnetic energy (Fig. 3).

Solid-State Black Light Inspection Lamps

Historically, a major problem with the use of black light inspections has been the inability to produce a strong fluorescent response in normal light. This problem has been virtually eliminated with the introduction of new solid-state black light models. These lamps use transistorized power supplies and micro-discharge (MDL) bulb designs for increased power and intensity (Fig. 4).

Advantages:

- Produce 10 times the power and intensity of traditional black light lamps.

- Produces a minimum of 40,00 µW/cm at one meter

- Lightweight

- Cool running

- Impervious to magnetic fields

Solid-state lamps provide a significant advantage for nondestructive testing inspections due to their expanded coverage area. As the solid-state lamp begins scanning an area, coverage defects 4 to 8 feet from the focus point will begin to fluoresce. Solid-state models reduce production costs for the inspection of large or complex structures.

Black Light Laser Sight

Solid-state black lights have a projection range of 25–50 ft. At this distance it can be difficult for workers to determine exactly where the black light energy is focused (black light is virtually invisible until it comes into contact with a fluorescent material). One solution is a laser sight mounted directly onto the black light inspection lamp. This allows workers to perform long-range inspections by laser guidance.

LED Black Light Flashlight

Many coating applications require that workers inspect large, complex structures or reach elevated work sites. New LED flashlight black lights provide excellent nondestructive testing inspections at ranges of 4–8 ft (Fig. 5). The LED lamp is only 8 inches long and comes with a handy belt holster. This allows workers hands-free access to remote inspection sites. The lamp uses rechargeable batteries that provide up to 90 minutes of operation time.

Protective Coatings Nondestructive Testing Costs

The cost for the Protective coatings nondestructive testing initial application is slightly higher than traditional coatings systems. Because fluorescence is only added to the primer coat, this makes the formulation cost very reasonable. The major expense comes from the higher surface preparation standard and the use of two separate abrasive blasting operations. However, increased coating life and reduced maintenance costs justify the added expense.

Safety

Safety precautions should be followed with any high-energy illumination source. Black light energy requires no protective clothing unless the individual is over-sensitive to bright sunlight. Protective clothing should be worn in these cases. It is recommended that protective eye wear be worn during nondestructive testing inspections. Black light–blocking safety eye wear makes coating defects easier to detect by increasing fluorescent contrast with non-reactive surfaces. A safety note: Do not point the black light beam directly into the eyes.

Black Light Coating Inspection Process

One-Coat System

When a fluorescent coating is applied over a prepared metal surface, workers will look for dark spots or shadowing of the non-reactive metal showing though the fluorescent coating (Fig. 6).

Two-Coat Systems

When a fluorescent primer coat is applied over a prepared metal surface and over-coated with a non-reactive finish coat, workers will look for fluorescent spots or shadowing showing through defects in the finish coats. Note: This is the most effective combination for the black light EVS process. (Fig. 7)

Three-Coat Systems

When a three-coat system is used over a prepared metal surface, the primer coat is formulated with an adequate amount of fluorescence to still be seen after the intermediate coat has been applied. Then, the finish coat is applied until the fluorescence is completely blocked out. Note: the primer coat and the intermediate coat should have definite color differences (Fig. 8).

Three-Coat Systems (with stripe coat)

When a three-coat system is selected, including a stripe coat, the stripe coat has fluorescent properties. The stripe coat is applied for added corrosion control to all welds, joints, cracks, crevices, corners, and edges. A standard non-reactive (NR) primer coating is applied to block out the fluorescence of the stripe coat. After the primer, a fluorescent intermediate coat is applied. Over the intermediate coat, a NR finish coat is applied until it completely blocks out the fluorescence of the intermediate coat. This system makes maximum use of black light EVS quality control and offers the highest level of performance and support for extended maintenance programs.

Coating Types

EVS Control Coat System

Two-coat primer/finish systems are widely used by industry to provide short-term protection for manufactured products. EVS control coat systems use ultra-thin fluorescent coats applied in alternating layers with standard primer/finish coats. This allows verification of coverage and saturation of voids by black light.

Protective Coatings Nondestructive Testing Inspection Process

Coatings can be inspected by black light (EVS) in several ways. First, fluorescent coating can be applied to a surface, inspected, and then touched up while still wet, or the coating can be allowed to cure before inspection and then touched up.

The most productive inspection process would have an applicator apply the coating followed immediately by a second worker checking for defects by black light. If defects are found, the second worker can instruct the applicator to make on-the-spot repairs.

Post-Application Maintenance

After the initial coating application, extended service life depends on regular black light monitoring to determine coating wear. The scheduling for black light inspection depends on the type of coating and its service environment. For normal applications, black light inspections should be performed every two years for each surface area. For harsh chemical environments, it may be necessary to inspect coatings every six months to one year.

During black light inspections, if low-level fluorescence is detected then this means that maintenance can be put off until a later date. If high-level fluorescence is detected, then complete coating failure is imminent and recoating repairs should be performed as soon as possible. A better black light inspection system would incorporate one shade of fluorescence next to the metal substrate and another color shade in the intermediate coat. Workers would determine maintenance urgency by the detection of specific colored fluorescence.

In addition to the using black light to ensure coverage and saturation of surfaces with fluorescent coatings, it is also be possible to accurately measure dry film thickness (DFT) with the use of non-contact optical scanners. For over a decade, fluorescent coatings have been used to protect printed circuit boards against dust, moisture, and other airborne contaminants. When fluorescent intensity and inspection spot size are factored in, optical scanners can accurately measure film thickness based on microvolt readings.

Additional Program Advantages

Primary Corrosion Sites

Virtually all man-made structures contain areas know as primary corrosion sites. These points include: welds, joints, corners, cracks, nuts, bolts, fasteners, or wherever there is a dramatic change in surface contour.

Protective coatings nondestructive testing performs a dual function in reducing premature coating failures for primary corrosion sites. For welds and joints, black light ensures complete saturation of voids. For corners, edges, joints, nuts, bolts, and fasteners, black light shows where coatings have cured away from sharp edges and extra coats are needed to achieve proper DFT.

Even though primary corrosion sites may account for only a small percentage of total surface area, they may, in fact, be responsible for the majority of premature coating failures. Protective coatings nondestructive testing provides a quality control and maintenance advantage for these problem areas.

Permeability Control

Loss of impermeability is a leading cause of premature coating failure. This occurs when a coating loses its ability to prevent the migration of moisture, oxygen, and other reactive agents to the metal substrate. Protective coatings nondestructive testing is very effective for maintaining the impermeability of coatings. As the finish coat begins to degrade, black light will identify the location so maintenance recoating can re-establish effective moisture control.

Conditional Coating Failure Sites

In addition to primary corrosion sites, there may be other areas that are subject to a much higher rate of corrosion due to their service location. A good example would the $23 billion problem car owners have with deicing road salts. The impact of ice and snow in combination with salts dramatically increases the corrosion rate for car bodies. If manufacturers would incorporate black light EVS into automotive coatings, then owners could reduce salt damage though Protective coatings nondestructive testing maintenance cleaning and recoating.

Critical Components

Many structures have components that are critical to their operation. This includes: motors, pumps, electronics, pressure tanks, valves, piping, etc. Due to their importance, these components are checked and serviced on a regular basis. During these service checks, workers can also inspect coatings for excessive wear or damage. This dual maintenance operation saves time and money for facility owners.

Two-Component Mixing

Two-component coatings are widely used due to their increased chemical resistance and durability. For two-component materials to achieve their full performance capabilities, it is important that the Part A (base) be completely blended with the Part B (activator).

By adding the fluorescent additive to the Part B (activator), complete and uniform blending can be verified by black light. Note that complete blending produces a solid fluorescence color shade, whereas incomplete blending can produce a candy-cane effect.

Training

Protective coatings nondestructive testing can provide a valuable training tool for new painters learning basic techniques or experienced applicators making adjustments for new coating formulations, specification changes, or varied structural designs. One of the most effective training programs would involve workers applying fluorescent coatings in a total black light working environment. Under true black light there are only two specific color variations. Black, for non-reactive (NR) surfaces or standard NR coatings, and the particular fluorescence shade of the black light coating. A total black light environment would also be an extremely efficient way to apply ultra-high-performance coatings to critical surfaces where real-time quality control is important.

Many large companies employ corrosion engineers for coating maintenance. Corrosion engineers are college or university graduates and have completed the following courses:

- Fundamentals of electrochemistry

- Basic metallurgy and alloying systems

- Various corrodents and corrosive environments

- Cathodic protection basics

- Chemical treatments, coatings, and corrosion monitoring

Many users of paint and coatings do not have access to training or corrosion management information. Protective coatings nondestructive testing allows small companies or individuals to improve the performance of their painting work through simple-to-use black light quality control.

Reduced Surface Preparation Costs

Surface preparation can account for 40–60% of recoating costs. This is especially true when high-pressure abrasive blast cleaning is used to remove aged coatings and corrosion. Surface preparation costs for the original coating application are relatively low. New metal only requires the removal of mil scale, rust, and machining oils prior to coating application.

Maintenance recoating costs are much higher. When stringent surface preparation standards are called for, such as SSPC SP-10 near-white or SSPC SP-5 white metal abrasive blasting, up to 80% of the energy expended is involved with the removal of the last 20% of the previous coating, Because Protective coatings nondestructive testing only involves the repair or replacement of the finish coat, up to 80% of surface preparation costs can be eliminated. Additional savings are produced by reduced delivery and disposal costs for abrasive blasting materials.

Reduced Rework and Liability Costs

Coating defects can result in customer complaints and returns. In extreme cases, misapplied coatings can also increase liability exposure. Black light allows painted products to be checked for defects before leaving the manufacturer and again upon delivery by the customer for quality guarantee.

Reduced VOCs

The Clean Air Act was passed by the U.S. Congress in 1970 and then amended in 1990. This limited the use of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) in paints and coatings. Current regulations limit VOCs and HAPs produced per gallon, per application. Protective coatings nondestructive testing has been designed to reduce VOCs and HAPs produced per foot, per year, over a surface life.

New environmental laws passed to lower VOCs and HAPs in paints and coatings may have another and possibility more serious impact on extended maintenance programs. Waterborne and other types of low-VOC coatings may not respond to maintenance due to their chemistry.

Protective coatings nondestructive testing coatings are formulated to degrade slowly over time. This allows removal of damaged layers while leaving sound coatings intact. Maintenance cleaning prevents the excessive build-up of coating thickness, and thin-film recoating maintains the integrity of the original application.

Abrasion Control

For equipment or structures subject to harsh abrasion, Protective coatings nondestructive testing allows workers to easily locate damage points. Removal of damaged coatings by low-impact surface preparation and the application of a new finish re-establishes effective abrasion protection.

Maintenance Scheduling

Protective coatings nondestructive testing provides a tremendous advantage for scheduling maintenance. No longer is maintenance scheduled by the appearance of visible corrosion or at fixed time intervals. Recoating is based on black light evaluation of excessive coating wear (fluorescence rather than visible corrosion). This provides facility owners with sufficient lead time to schedule maintenance work, thereby making the best use of personnel, resources, and climate conditions.

Remote Failure Analysis

Failure analysis for traditional coatings is costly and time consuming and usually requires on-site visits by trained corrosion specialists. Black light evaluation of fluorescent coatings provides an enhanced visual presentation for early failure sites. With new digital camera technology and computer software, it would be simple to send pictures to coating experts for advice or repair recommendations.

OEM-Initiated Maintenance Programs

The most effective use of Protective coatings nondestructive testing programs would come directly from the original equipment manufacturer (OEM). New metal is never cleaner and in better condition than when it comes from the factory, and coatings are usually applied in a controlled environment. All the manufacturer would have to do is apply the fluorescent primer to a properly prepared surface and offer black light inspection lamps to service personnel or new customers.

Fluorescent Cleaning

Another way to reduce coating degradation is to keep painted surfaces clean. The use of fluorescent cleaners aids in the removal of surface contaminants (especially soluble salts) from equipment, structures, and vehicles subject to deicing road salts. First, the fluorescent cleaner is applied to a surface. Coverage and saturation is verified by black light. Then, the fluorescent cleaner is rinsed off until all fluorescence is gone. For example, fluorescent cleaning works like a light bulb. Black light activation of the fluorescent cleaner turns the light on. The removal of all visible and non-visible contaminants, verified by black light, turns the light off.

Cost to Prevent Corrosion

The cost of the initial Protective coatings nondestructive testing application is slightly more expensive than traditional coating systems. The modification for fluorescence is relatively small (usually less than 25 cents per mil, per coat, per gallon of coverage). The main increase is due to the higher surface preparation standard and the use of two separate blasting operations. However, the potential savings from extended service life more than justifies that added expense.

Corrosion Tax Credit Bill

Congress is responding to the environmental, safety, and economic impact produced by corrosion with the introduction of the Corrosion Prevention Act of 2008 (H.R. 491.3). If passed, this bill will provide a tax credit equaling 50% of the corrosion prevention expenditures for U.S.-based physical assets that are susceptible to corrosion damage.

Conclusions

President Obama promises to end Americans’ dependence on foreign oil in the next 10 years. This is an ambitious goal considering that the U.S. uses 25% of global oil production while being home to only 4% of the world’s population. To solve this serious problem, it is important to develop new alternative energy sources. Nevertheless, it is critical that we learn to conserve the energy we have left.

There is a simple economic and environmental advantage for proactive coating maintenance. It takes far less energy to maintain a coating than it does to repair or replace the surface it protects.

References

- Corrosion Costs and Preventive Strategies in the United States. U.S. Federal Highway Administration Highway Research Center, 2002.

- Brevoot, B. The coating consumer: understanding initial and long-term painting costs. Journal of Protective Coatings & Linings, Dec. 1993.

- Adamson, N.P. Performance of coating systems using numerical life predictions. Journal of Protective Coatings & Linings, July 1998.

- Black Light Measurement of NDT. American Society of Nondestructive Testing, 1983.

- Davis, L. Shedding light on UV test equipment. Quality Progress, Sept. 1992.

- Dullinghan, G. Surface energy explained. Precision Cleaning Magazine, April 2000.

- Our Dependence on Foreign Oil. Special Order Speech by Roscoe G. Bartlett, U.S. House of Representatives, April 20, 2005.

- Moubray, J. Introduction to Reliability-centered Maintenance. Industrial Press, 1997.

- Moshed, A. Asset corrosion management and the existing training gap. Materials Performance, Apr. 2009.

- Poncio, S., Adkison, P. Economics of a total maintenance coating program. Materials Performance, Aug. 1994.

- Cantor, S.E. Nondestructive inspection of coatings based on enhanced fluorescent response. Metal Finishing, April 2009.

- Rogan, M.N., Johnson, J.R. Soluble salts and their impact on corrosion. Presented at NACE International Western Conference, Edmonton, Alberta, Feb. 3–6, 1997.

James R. Deardorff is a NACE and SSPC member and the president of Superior Coatings, a contract painting company located in Chillicothe, Mo. With almost 20 years of experience in its field, Superior Coatings specializes in the application and maintenance of protective coatings for equipment, structural steel, and concrete. Deardorff is a distributor for protective coatings and NDT inspection equipment. He has also written more than 50 articles and papers on coatings, abrasive blast cleaning, and surface maintenance programs.

Related Articles

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability