Practical Guide to Equipment Hierarchy

John Sewell, Consultant, IDCON INC

Posted 01/19/2023

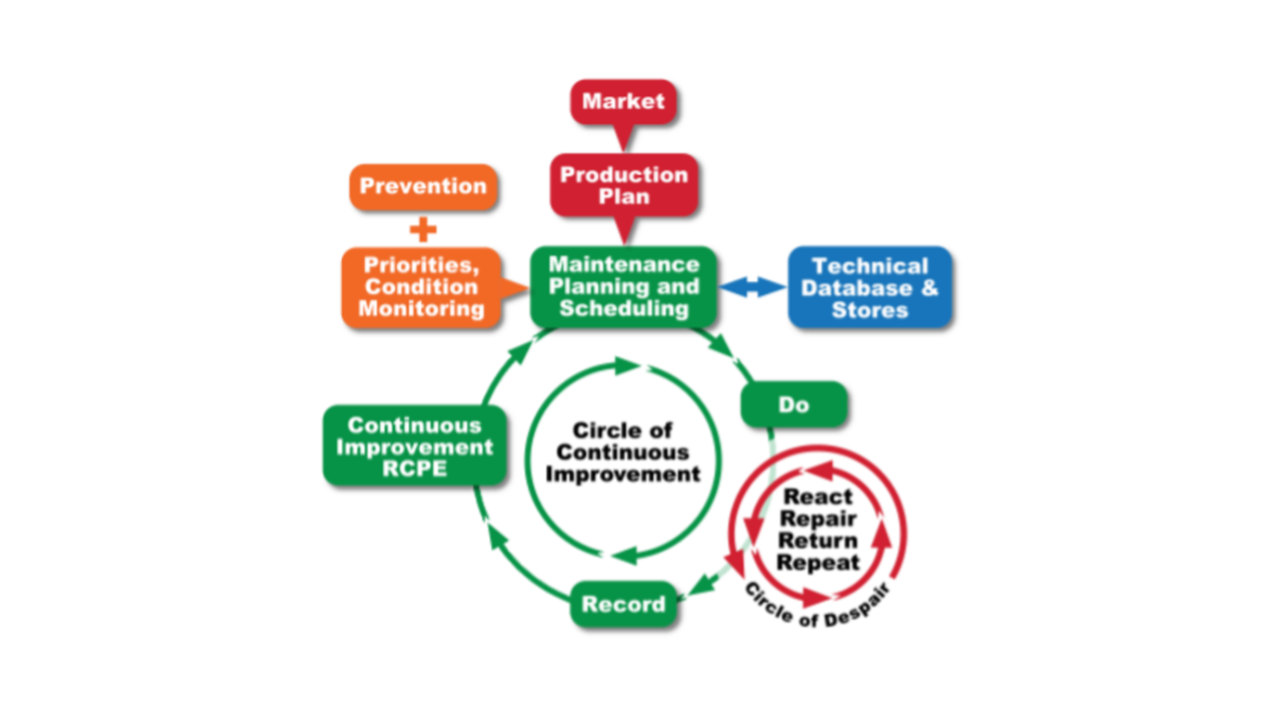

Equipment hierarchy is the foundation on which the technical database is built. Since the technical database is a key element in allowing efficient planning and scheduling, the equipment hierarchy is a building block of the entire work management system. Nearly every business unit from accounting to purchasing and from operations to maintenance will benefit from a well-organized and complete equipment hierarchy.

Benefits of a complete equipment hierarchy include:

- Accurate work identification by operations and maintenance

- Detailed work instructions from planners

- Easier identification of like equipment for leveraging standard job plans, criticality, or spare parts

- Record of nameplate data allows for fast and accurate application to predictive maintenance tools

- Faster contact with original equipment manufacturers when questions arise

- Parent/child relationships allow for efficient scheduling during outages

- Accurate accounting of costs allows for easy Pareto analysis

- Work history can be recorded to specific equipment and used to plan upgrades in capital projects

What is the Equipment Hierarchy?

The information in the technical database is built on a framework that matches the organization of the manufacturing process. All equipment should be represented in the hierarchy and have associated spare parts lists where appropriate.

The equipment hierarchy is a grouping of equipment locations or numbers structured to match the manufacturing process such that each level progresses in increasing detail down to individual equipment and associated parts lists.

While often focused on the computerized maintenance management system (CMMS), the equipment hierarchy can be used in other areas of the technical database. Drawings and manuals may be stored in paper copies that match the hierarchy. A best practice is to file electronic records (like pictures and standard job plans) with the same structure. Anyone trained in writing notifications to the correct level of the hierarchy can then find other relevant technical data.

Developing the Equipment Hierarchy

The basic steps to develop the equipment hierarchy are shown below.

- Form Team: The size and makeup of the team will vary based on the scope of the project. Consider the following resources when developing the team:

- Operations can offer insight about the purpose of equipment and help identify relationships between the levels.

- Maintenance is an end user of the hierarchy that understands the equipment functions and needed spare parts.

- Process Engineering can assist with how levels of the hierarchy fit together and define parent/child relationships.

- Purchasing and Accounting ensures the data is set up correctly so work orders will have correct charge codes and are linked to payment systems.

- Computerized Maintenance Management System experts are familiar with specifics of the computer system related to character limits and available fields to input data.

- Original Equipment Manufacturer Representatives can Provide Equipment Data and Spare Parts Lists

- Establish Structure: Determine the overall structure that will be used for the hierarchy. If starting from scratch, consider standards like ISO 14224; otherwise use existing standards from corporate resources.

- Define Naming Convention: Document a naming convention for each level of the hierarchy. This is most critical for spare parts. There may be character limits in the CMMS.

- Document the Process: Outline the manufacturing process and set boundaries for each area. Divide the plant in increasing detail down to the individual equipment level. Identify parent/child relationships for each level. Follow the agreed-upon structure and naming convention.

- Create Parts Lists: Work with equipment manufacturers and maintenance to develop parts lists for all equipment.

- Train End Users: Conduct initial training on the computerized maintenance management system. Instruction should be tailored to each job role and to typical tasks. Have a plan for training new employees and periodic refreshers for all users.

- Plan for Change: Changes to equipment are inevitable. Build steps to update the equipment hierarchy in the Management of Change (MOC) process.

- Monitor and Improve: To achieve the full value of the equipment hierarchy, the system must be used consistently. Conduct assessments of the equipment hierarchy to ensure that goals are being met. Check that work notifications are being written to the correct level and that any changes in the field are being reflected in the hierarchy.

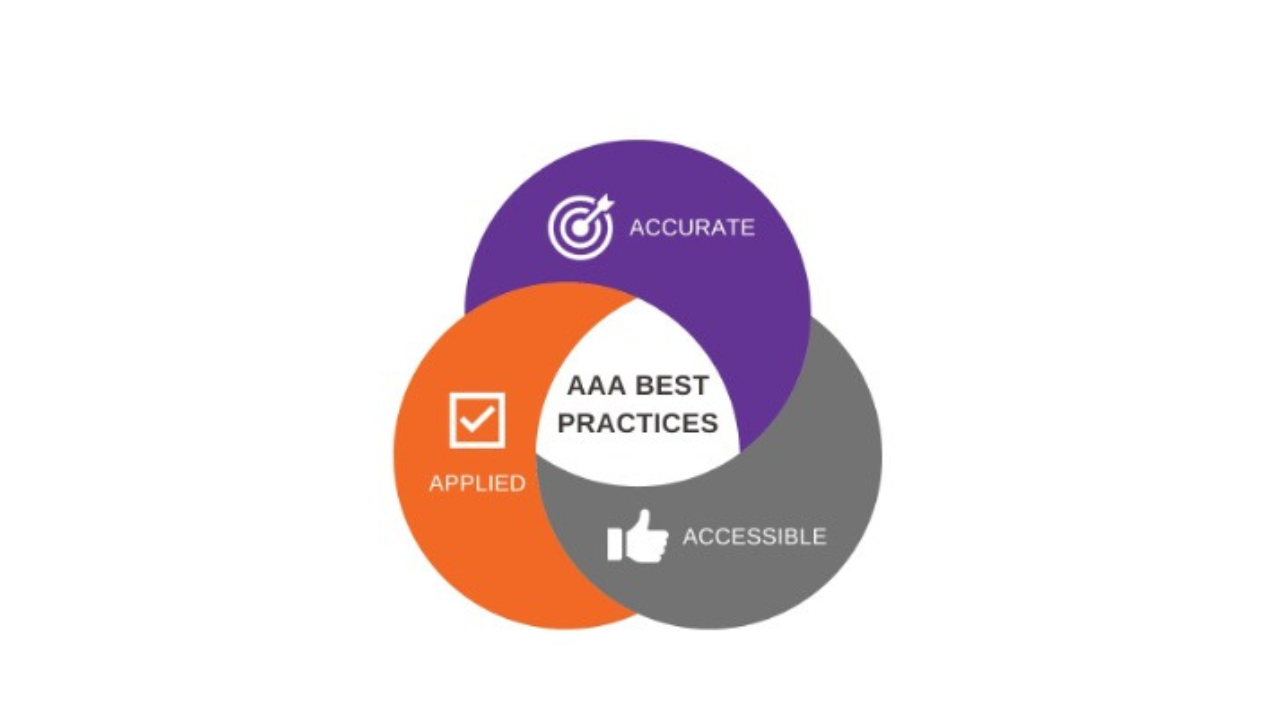

What are Best Practices?

When developing your equipment hierarchy, focus on three best practices:

- Accurate

- Accessible

- Applied

Accurate – Ensure the asset hierarchy covers all the equipment and contains appropriate details. For greenfield projects, having a cross-functional team to build the hierarchy will help ensure nothing is missed. A documented, communicated, and understood Management of Change process will cover updates to the hierarchy and associated equipment properties.

Accessible – Issues with accessibility arise more with training than with permissions in the plant computerized maintenance management system. In many plants, most personnel can create a work notification in the CMMS. In theory, they have access to the complete depth of the equipment hierarchy and can write the notification to the correct level of detail. In practice, it’s not uncommon to see notifications for specific pieces of equipment written to areas or departments. This can be due to a lack of training for end users, especially new employees.

Applied – To reap the benefits of an accurate and accessible equipment hierarchy it must be used. To ensure the full depth of the equipment hierarchy is being used, do routine checks. Look at what level recent work notifications are written to. Run account reports and see if costs are being charged to the appropriate pieces of equipment. Check that job plans include the right equipment and are being applied to similar equipment.

Example of Hierarchy Development

As an example, imagine you’ve been tasked with developing the asset hierarchy of a substantial addition to an existing plant. The equipment will primarily be existing technologies, but some key equipment will be new for the plant.

- Start by forming a team of operations, maintenance, and process engineers. Engage purchasing and accounting representatives as needed. Seek input from the computerized maintenance management system representatives for information on character limits or best practices they’ve seen work at other facilities. These resources may be internal or from the computer system vendor. Have project engineers write equipment specifications to require equipment manufacturers’ supply parts lists.

- Next, establish the overall structure that will be used for the equipment. Since this is an addition to an existing facility, the new hierarchy structure will be built to match the same logic. If there is not a documented standard, determine how to best match the existing structure. For example, ensure the area level in the new facility will have the same meaning as the current hierarchy.

- The naming convention for spare parts will use the same standard as the existing equipment.

- Work with process and project engineers to outline the system at a high level. Use process and equipment specific drawings to break down the facility into areas and equipment groups. Work from the plant level down to individual pieces of equipment. Use a branching tree structure to show the parent/child relationships. Record equipment nameplate information in the system.

- Review spare parts lists from equipment manufacturers. Leverage existing parts that are already set up in your storeroom to the new equipment. New equipment will require new part numbers be created. Ensure these are set up appropriately with clear descriptions. This step will take a significant amount of time but is necessary to keep duplicate parts to a minimum, making efficient maintenance possible.

- Train end users on the proper use of the hierarchy including work identification at the correct level of detail. Early involvement from operations and maintenance personnel will gain buy-in for maintaining data integrity. Record training with screen capture or short videos to help training in the future.

- Update the plant’s Management of Change system so changes in the field are reflected in the hierarchy. Work with equipment installers and project engineers to capture as-built information to ensure the hierarchy matches the equipment at start up.

- Identify a hierarchy owner who will ensure accuracy is maintained. Conduct audits of the data on a frequency to monitor compliance. Review training records. Conduct simple interviews with operations and maintenance to check if the process is communicated and understood.

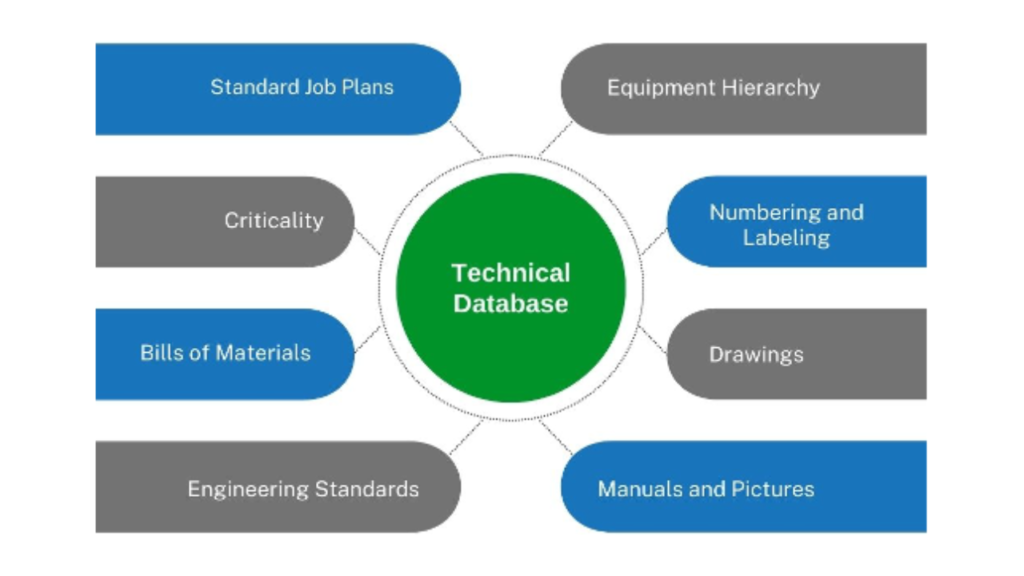

How Does Equipment Hierarchy Fit in the Technical Database?

Having an accurate, accessible, and applied equipment hierarchy is the foundational aspect of the technical database.

Other aspects of the technical database are often organized around the asset hierarchy structure. Taking the time to carefully set up the equipment hierarchy with your team is worth the effort involved. Setting clear expectations and training end users on the use of the hierarchy is vital to fully achieve all the benefits of a hierarchy. A robust management of change system will ensure that the integrity of the hierarchy is maintained over the life of the plant.

The technical database is made up of eight components, if you’re interested in learning more about each component follow along with the series as it is updated each month.

- Equipment Numbering and Labeling

- Drawings, Manuals, and Pictures

- Engineering Standards

- Bill of Materials

- Criticality

- Standard Job Plans

John Sewell, CMRP

John Sewell, CMRP is a Consultant with IDCON INC, a specialized management consulting firm in the field of reliability and maintenance management. As a consultant, John works with clients in any industry to improve reliability and lower manufacturing and maintenance costs through hands-on coaching and training.

Related Articles

What is the Technical Database and How Does it Affect Planning and Scheduling?

How to Label and Number Equipment for Easy Identification

Put Your Equipment Drawings, Manuals and Pictures to Work for Cost Savings

Engineering Standards to Help Lower Cost