Guide to 2024 Reliability and Maintenance Conferences

Elizabeth Ruiz

Posted 12/20/2023

It’s the end of the year and we are all starting to look at our calendars for 2024. Industry professionals know that attending, sponsoring, and presenting at reliability and maintenance conferences is a fantastic way to learn about new technology and advances in manufacturing, network, and get your company’s name out there. 2024 will offer many conferences covering a variety of different topics and industries, giving you the opportunity to do all the above. Maintenance World has put together a list of 2024 reliability and maintenance conferences we think our readers will benefit from in the coming year. Check them out in this week’s newsletter!

January:

AIAA SciTech Forum and Exposition (AIAA 2024)

International Conference on Educational Assessment, Reliability and Validity (ICEARV 2024)

70th Annual Reliability and Maintainability Symposium (RAMS 2024)

PowerGen International Destination 2050 Conference

February:

Worldwide Advanced Manufacturing Symposium (WAMS 2024)

Facilities Maintenance & Management (February Expo Events)

Plant Facilities Maintenance Association (2024 PFMA Expo)

March:

Join us at the 28th Annual Maintenance and Reliability Conference (MARCON 2024) for a Unique Learning Experience

Are you ready to dive into the world of maintenance and reliability? Look no further than the 28th Annual Maintenance and Reliability Conference (MARCON 2024), hosted by The University of Tennessee Reliability and Maintainability Center. This exceptional conference will take place from March 4-7, 2024, at the Knoxville Convention Center in Knoxville, Tennessee. Prepare yourself for an unforgettable experience that goes beyond typical workshops and presentations.

Collaborative Learning and Networking Opportunities

Unlike other conferences, MARCON 2024 focuses on fostering collaboration and personal connections. While attending, you’ll have the chance to interact one-on-one with presenters, exhibitors, and fellow attendees. This interactive environment encourages knowledge sharing and provides a valuable opportunity to learn from others’ experiences. Engage in meaningful conversations, exchange ideas, and build lasting professional relationships that can benefit your career.

Sharing Best Practices and Emerging Technologies

MARCON 2024 is the perfect platform for companies to showcase their best practices and share insights on new emerging technologies in the field of maintenance and reliability. The conference will feature a wide range of presentations, workshops, and exhibits that highlight innovative approaches to optimize asset management, increase reliability, and enhance operational efficiency. Stay ahead of the curve by learning about the latest trends, strategies, and tools shaping the industry. Click here for more information!

National Facilities Management & Technology (NFMT 2024)

Central Valley Facilities Expo

International Conference on Reliability Engineering and Maintenance (ICREM 2024)

Ultrasound Users Bootcamp by UE Systems

April:

Maximo Utility Working Group (MUWG 2024)

Learn Maximo efficiency and best practices from the best in the business, while building lasting partnerships. The MUWG conference is dedicated to providing a collaborative environment for all attendees.

The Maximo Utility Working Group (MUWG) provides a forum for utility members to exchange information, methods and experiences.

The MUWG is an industry group representing over 200 utility companies, counties and cities throughout the world that exchange information related to the implementation and application of the MAXIMO asset management system.

Two conferences are held each year, one in the Spring/Summer, the other in Fall/Winter. If you are a licensed MAXIMO user and meet the criteria of the charter you can attend a conference.

IEEE-IAS/PCA Cement Conference

Food Automation and Manufacturing (FA&M) Symposium and Expo 2024

May:

The Reliability Conference (TRC 2024)

The RELIABILITY Conference (TRC) 2024, co-sponsored by Reliabilityweb.com® and Uptime® bookazine, is not just another industry event—it’s a call to action for those who are serious about mastering reliability, asset management, and condition monitoring. Taking place from May 14-16 in Bellevue, Washington, this conference has been the cornerstone of operational excellence since 2005.

Our mission? To fuel innovations that protect and elevate the people driving the reliability and asset management sector.

Stagnation is the enemy of reliability. That’s why we’ve tirelessly canvassed the globe to bring you an arsenal of leading-edge methodologies straight from the pioneers—subject matter experts, distinguished practitioners, and acclaimed authors—in our field. Your time is valuable, and we make it count.

Our robust lineup includes compelling main stage presentations that challenge the status quo, practitioner case studies that dissect real-world applications, and a plethora of short courses and workshops designed to deepen your skillset. Beyond the conventional, we offer a 3-day professional certification program, adhering to the Uptime Elements Reliability Framework and Asset Management System—because transformative leadership begins with transformative knowledge.

But we don’t stop there. Step into the RELIABILITY Expo, a nexus for the world’s top solution providers in reliability and asset management. Over 50 vendors await you, each one a catalyst poised to launch your organization into the realm of high-performance reliability.

Don’t merely attend—participate, engage, and lead. Mark the date; this is your opportunity to transcend from status quo to status go! Let’s write the future of reliability, together.

Why Attend?

Are you ready to challenge the status quo and rewrite the future of asset management, reliability, and operational excellence? Then buckle up—because the RELIABILITY Conference is the fuel your career has been yearning for. We’re not just selling tickets to an event; we’re offering an experience that transforms professionals into pioneers. Here’s why this isn’t just another conference—it’s a revolution!

Leap Ahead, Don’t Just Step: Dive into leading-edge methodologies, transformative technologies, and innovative approaches that make up the playbook of the world’s best-run companies. With over 6,000 organizations relying on the Uptime Elements Reliability Framework and Asset Management System, you’re stepping into a tried-and-true ecosystem for success.

Ignite Passion, Not Just Interest: Our lineup of world-renowned subject-matter experts, bestselling authors, and seasoned practitioners isn’t here just to lecture—they’re here to awaken a fire within you. When you’re engaged at a visceral level, learning transforms into mastery.

Empowerment, Not Just Education: Knowledge is power, but applied knowledge is superpower! Our 3-day professional certification program, guided by the principles of the Uptime Elements, turns you into the supercharged reliability leader your organization needs. The future doesn’t wait. Why should you?

Network & Thrive, Not Just Survive: Connect with a community that includes the world’s best-run companies that share your unwavering commitment to reliability and asset management. Imagine the synergy when hundreds of driven professionals pool their insights, experience, and energy. This isn’t networking; it’s a collaborative brain trust that lifts everyone higher.

Solutions, Not Just Theories: At our RELIABILITY Expo, touch, feel, and interact with the technologies and solutions that are shaping our industry. Over 50 vendors await, ready to offer tools that translate your visions into reality.

Actionable Insights, Not Just Data: Our program is designed to be a goldmine of actionable strategies. You won’t leave with vague ideas; you’ll walk away with a strategy and tactical blueprint to propel your organization into the realm of high-performance reliability and asset management.

The Leading Reliability Conference provides all participants with a great opportunity to learn more about maintenance and reliability by attending live presentations, workshops, and trainings. In addition, you are also provided with ample opportunity to socialize and make connections – allowing you to build relationships with influential professionals in maintenance and reliability around the country!

The ability to share ideas and perspectives with industry experts is ALWAYS a great thing and will only be beneficial as we continue to work our way back to a normal way of business. You can expect to learn a lot, have fun, and take valuable ideas home with you to your very own facility!

2024 Offshore Technology Conference

Association for Iron & Steel Technology (AIST) AISTech 2024

International Conference on Reliability, Safety and Security Engineering (ICRSSE 2024)

Advanced Semiconductor Manufacturing Conference (ASMC 2024)

Facility Fusion – an IFMA Conference & Expo

June:

SAP Sapphire & ASUG Annual Conference

Reliable Plant Conference 2024

Electrical Apparatus Service Association Convention (EASA 2024)

Southeastern Electric Exchange Annual Conference & Trade Show

July:

ASQ Reliability, Maintenance & Managing Risk Conference (RMMR 2024)

August:

The MaximoWorld Experience is empowering TEAMS for asset management transformation.

- Bring your team and cover over ten tracks of IBM® Maximo®, asset management and digitalization learning zone sessions.

- Meet leading-edge technology vendors and top-ranked system integrators at the MaximoWorld Expo.

- Participate in the hand’s-on experience labs for “show and tell” sessions.

- Participate in Maximo Best Practices Benchmarking.

- Connect with your Maximo User Group (MUG).

- Meet authorized IBM Maximo Partners.

- Meet IBM Executives.

- Join Women in Reliability and Asset Management (WIRAM) for a special gathering (pre-registration is required).

- Participate in the Reliability Leadership Foundation (RLF) Reliability Sustainability Hackathon.

Vibration Institute 47th Annual Training Conference and Expo

About the Vibration Institute:

Our mission is to disseminate practical information on evaluating the behavior and condition of machinery without commercial interest.

The Institute offers a variety of programs, including education, training, certification, and opportunities for technical knowledge exchange. Our members share information, procedures, and cutting-edge data through formal training, networking, meetings, and publications.

If you would like to join our network of esteemed colleagues, improve your skills, and expand your education in the study of machine vibration, contact us directly, and get started as a member.

September:

International Manufacturing Technology Show (IMTS 2024)

2024 Offshore Structures Reliability Conference – American Petroleum Institute

Maintenance, Reliability and Asset Management Conference (MaintTrain 2024)

Turbomachinery & Pump Symposia (TPS 2024)

National Mining Association (NMA) MinExpo 2024

Women in Steel Conference (Look out for next year’s dates!)

October:

Society for Maintenance & Reliability Professionals (SMRP 2024)

Association for Manufacturing Excellence (AME Conferences 2024)

Electric & Hybrid Vehicle Technology Expo

Food Processing ProcessExpo 2024

November:

Empowering Pumps & Industry Conference

The Empowering Pumps & Industry Conference is where the industry can come to connect with manufacturers, distributors, end users, associations, and students in one place. The two-day event will feature presentations from subject matter experts, roundtable discussions, exhibits, and tours.

Topics discussed will include:

- Engineering & Design

- Maintenance & Reliability

- Pumps & Operations

- Industry Innovation & Infrastructure

- Sustainability

- Workforce Development

This conference is for:

Pump & Equipment: Engineers, Operators, Maintenance and Reliability professionals across industry.

Leadership: Marketing and Management professionals looking to grow their leadership skills.

Manufacturing & IoT: Manufacturing and IoT professionals who work in the industry, including operators and supervisors.

Generis American Food Manufacturing Summit 2024

BEMAS Asset Performance Conference & Exhibition

December:

38th International Maintenance Conference (IMC 2024)

Step forward into the era of optimized performance at IMC-2024: The 38th International Maintenance Conference, where the vanguard of reliability and asset management converge to empower your organization’s success. Here, we’re not just about maintenance—we’re about creating an ecosystem of reliability that synchronizes people, leadership, processes, data, and technology.

Unearth the transformative potential of Uptime Elements, as you collaborate and network with visionaries from the world’s best-run companies. Experience a curated journey that fuels not only your assets but your most vital resource—your people. Elevate your management strategies to create an engaged, informed, and synchronized workforce that seamlessly automates asset knowledge, unlocking exponential value for your organization.

Don’t merely adapt; lead. Engage with actionable insights, dynamic workshops, and groundbreaking solutions that align with the tenets of the Uptime Elements Reliability Framework and Asset Management System. Harness the collective intelligence that will shape the future of safe, sustainable, and profitable operations.

Your path to leadership in creating resilient and high-performing workplaces starts here at IMC-2024.

Join us, and let’s make the quantum leap from reliability to reliability leadership.

23rd Annual Shutdowns Turnarounds Superconference

Rocky Mountain Electrical League – Multiple Events

American Fuel & Petrochemical Manufacturers (AFPM) – Multiple Events

UPDATE 1/8/2024 – More Conferences for the list! – Check out these additional 2024 Reliability and Maintenance Conferences and Manufacturing Conferences:

Cyber Security Training at SANS Orlando 2024

Shared Services and Outsourcing Week Conference

12th American Food Sure Summit

ISPE 2024 International Society for Pharmaceutical Engineering Annual Meeting and Expo

Health Care Facilities Innovation Conference 2024

North American Manufacturing Excellence Summit (NAMES 2024)

MUEW Electric Operations Conference & Expo 2024

Additive Manufacturing Strategies 2024

Additive Manufacturing Users Group (AMUG 2024)

Generis American Manufacturing Summit 2024

International Conference on Precision Engineering and Mechanical Manufacturing (PEMM 2023)

IEEE Applied Power Electronics Conference and Exposition (APEC 2024)

Gartner Supply Chain Symposium/Expo

International Conference on Mechanical & Production Engineering (ICMPE-24)

International Conference on Lean Systems and Manufacturing Practices (ICLSMP 2024)

International Conference on Material and Manufacturing Technology (ICMMT 2024)

Institute for Supply Management (ISM World 2024)

International Conference on Green Manufacturing and Product Design (ICGMPD – 24)

We hope this list of 2024 Reliability and Maintenance Conferences is useful and that you have a happy holiday season!

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you by the Maintenance World Crew.

Related Articles

Safe Use of Clamps Through Proper Selection

The Cost of Doing Nothing

Spare Parts Management Indicators

Properly Aligning Projects to Corporate Strategy

People Management - Workforce Shortage: Acceptance is the First Step

Novozyme Leverages Results Oriented Maintenance and Highly Motivated Staff to Win the North American Maintenance Excellence (NAME) Award 2000

Mechanical Quality Assurance: The Next Progression of Reliability

Maintenance Key Performance Indicators (KPIs)

The Building Blocks to Creating an Effective Lubrication Program

Maintenance Training - The Backbone of Cultural Change

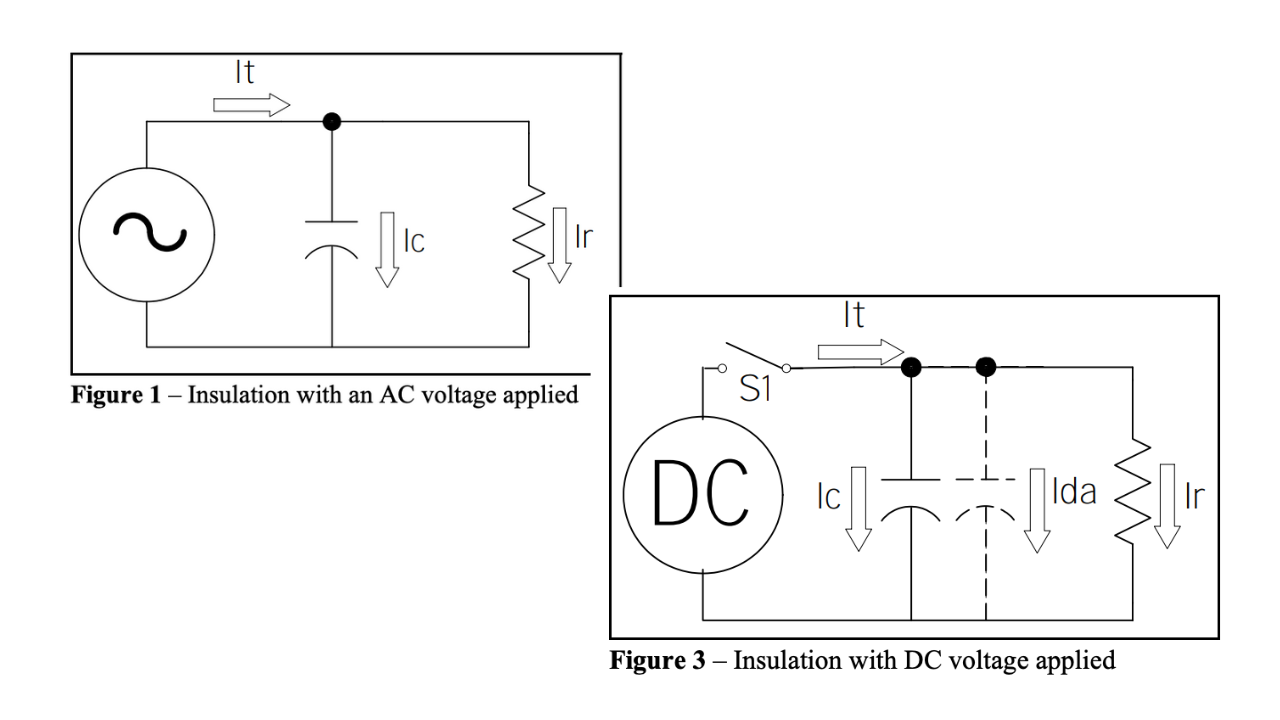

Principles of Insulation Testing

Corrective Maintenance Task Generation

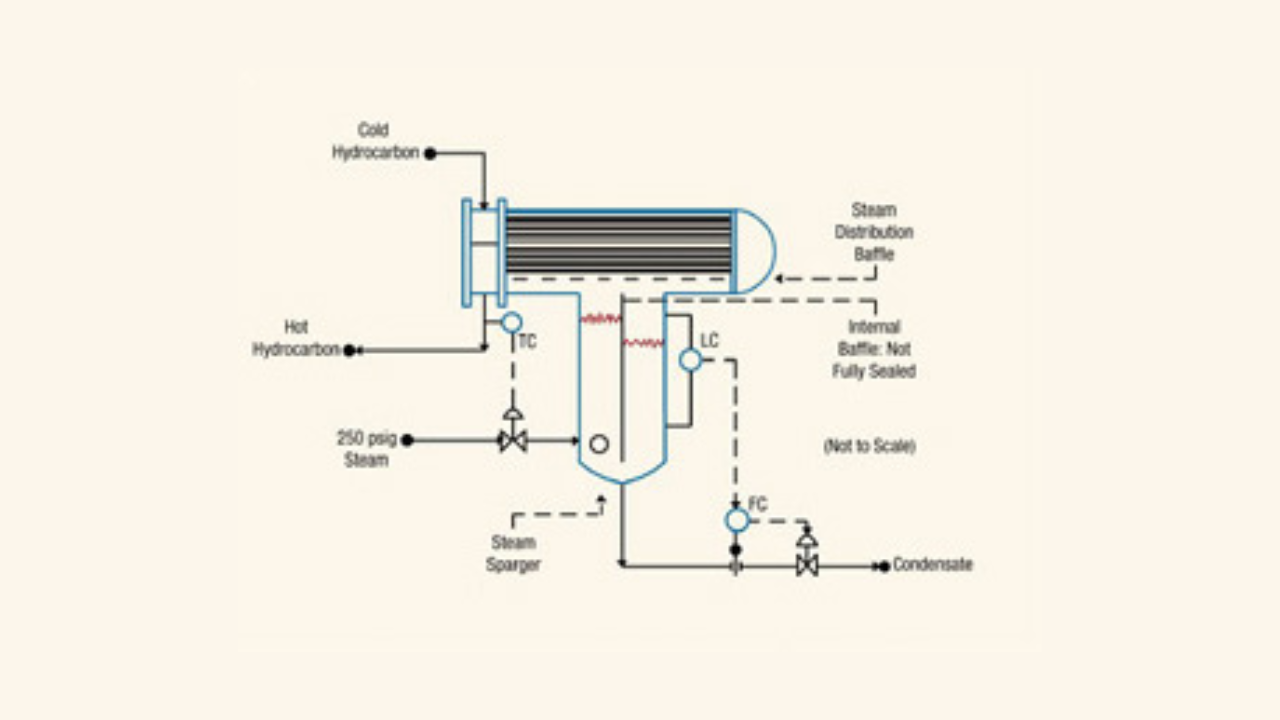

Preheater Points Out the Value of Cooling Off

Maintainability Design Checklist

The Cost of Producing Electricity

Why Planned Maintenance?

The What, Why, How of Wrench Time

What is Vibration?