Hydraulic Pump Life Cut Short by Particle Contamination

Insider Secrets To Hydraulics

Do you know what Particle Contamination is? Not everyone does.

I was recently asked to conduct failure analysis on a hydraulic pump that had an expected service life of 10,000 hours. The pump had been removed from its machine after achieving only 2,000 hours in service. Further analysis revealed that this pump hadn’t actually failed – it had been ‘worn-out’ through abrasion caused by contaminated fluid.

So, what is ‘Contaminated Fluid’?

Contaminants of hydraulic fluid include solid particles, air, water or any other matter that impairs the function of the fluid.

How does Contamination Affect a Hydraulic Pump?

Particle contamination accelerates the wear of hydraulic components. The rate at which damage occurs is dependent on the internal clearance of the components within the system, the size, the quantity of particles present in the fluid, and the system pressure.

Particles that are larger than the component’s internal clearances are not necessarily dangerous. Particles the same size as the internal clearances cause damage through friction. However, the most dangerous particles in the long term are those that are smaller than the component’s internal clearances.

Particles smaller than 5 microns are highly abrasive. If present in sufficient quantities, these invisible ‘silt’ particles cause rapid wear, destroying hydraulic pumps and other components.

How can this type of Failure be Prevented?

While the type of failure described above is unusual in properly designed hydraulic systems that are correctly maintained, this example highlights the importance of monitoring fluid cleanliness levels at regular intervals.

As in this case, if the high levels of silt particles present in the hydraulic fluid had been identified and the problem rectified early enough, the damage to this hydraulic pump and the significant expense of its repair could have been avoided.

Trying to Extend the Life of your Pump?

Related Articles

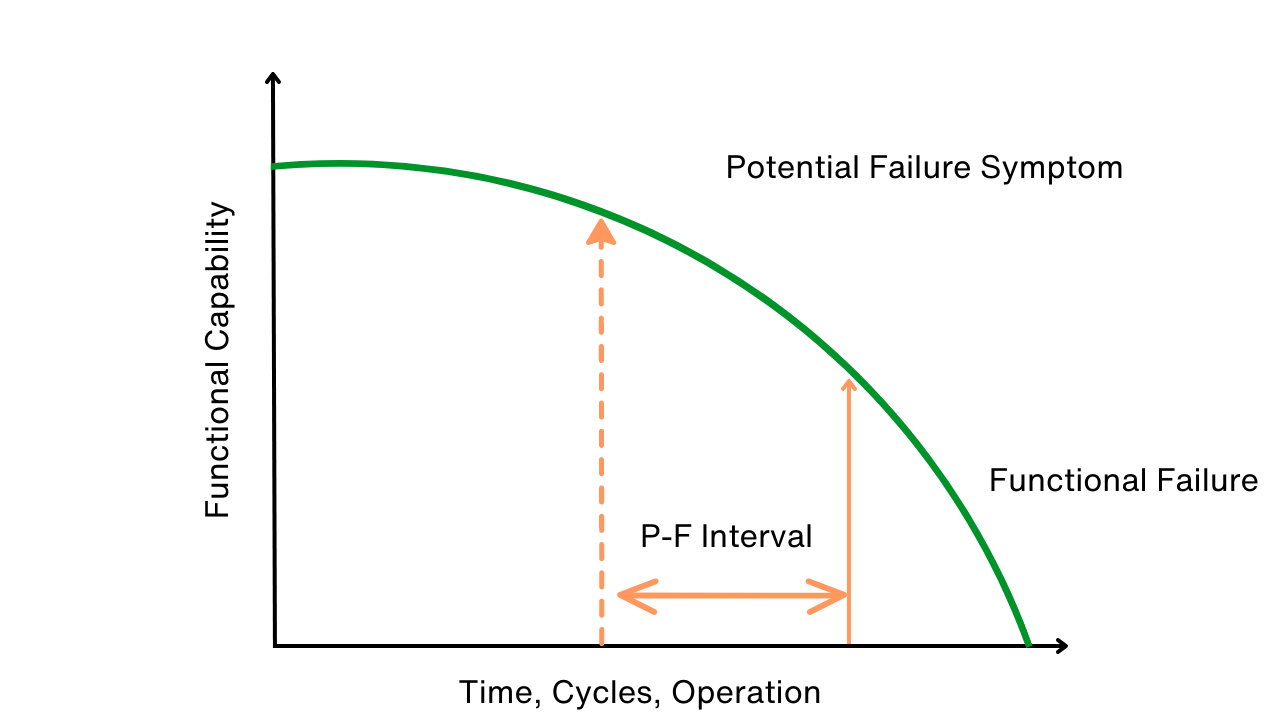

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability