Balasore Train Crash: Urgent Need for Maintenance and Safety Upgrades

Natalie Johnson

Posted 06/21/2023

A recent train crash in Balasore, India has resulted in hundreds of casualties and injuries, highlighting the critical need to ensure robust maintenance practices and safety measures are in place. While the investigation is still underway, the Ministry of Railways has identified the root cause of the incident and made recommendations to prevent future accidents.

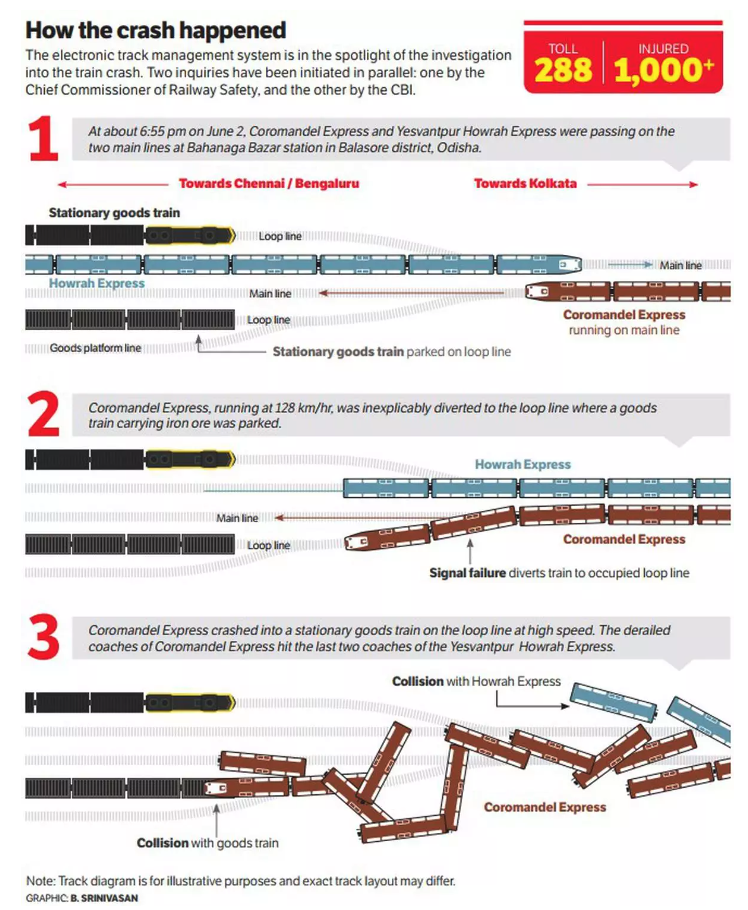

The tragic collision occurred in Balasore, Odisha injuring over 1,200 people and claiming 292 lives thus far. Three trains were involved in the accident: the Bengaluru-Howrah Superfast Express, the Coromandel Express, and a freight train.

The root cause of the incident was determined to be improper changes to the electronic point machine. This machine operates turnouts, allowing a train to be directed from one track to another via point blades. The electronic interlocking system is meant to ensure conflicting signals are not sent to multiple trains. A signal failure led to the Coromandel Express diverting to an occupied loop line and colliding with a freight train. The derailed cars then interfered with the last 2 cars of the Bengaluru-Howrah Superfast Express. Seventeen coaches from the two passenger trains were derailed due to an improper change in the electronic interlocking system.

There are many possible causes that led to this accident including human error, mechanical failure, and track defects. The Central Bureau of Investigation is performing an investigation to determine which errors were involved in this crash to implement corrective measures.

Among the factors contributing to the accident, maintenance-related issues have come to the forefront. Reports from the Comptroller and Auditor General of India (CAG) indicate ¾ of 217 train accidents occurring between 2017-2018 and 2020-2021 were caused by derailments, which are often linked to the inadequate maintenance of tracks. The decline in funds allocated for track renewal works and underutilization of available funds has exacerbated these maintenance challenges.

Recognizing the urgency to enhance safety, Indian Railways has taken action to address maintenance-related issues and prevent future accidents.

Anil Kumar Lahoti, the Railway Board Chairman, has directed general managers and senior engineers to prioritize interacting with their staff to address maintenance, safety-related issues, and daily monitoring. Encouraging such interaction will allow for more visibility as those on the front lines have first-hand knowledge of the strengths and weaknesses of assets in their jurisdiction. In addition, senior officials must inspect all aspects of maintenance and educate their employees on the correct and safe execution of work.

When field officials are deployed for maintenance activities on the railways, they must only be utilized for those activities and spend the maximum amount of time at work sites to ensure safety and reliability. These initiatives aim to ensure constant vigilance and timely resolution of maintenance concerns.

The key areas the railways must focus on were outlined by IRCTC News:

Infrastructure Maintenance: Regular inspections, maintenance, and repairs of tracks, signals, and bridges must occur promptly.

Utilization of Technology: Advanced technologies such as automatic braking systems, improved signaling systems, and condition monitoring systems can improve safety.

Training and Education: Continuous education programs for all staff (conductors, engineers, maintenance personnel) are essential to ensure they have the proper knowledge and skills to operate and maintain railways.

Safety and Public Awareness: The public must be educated about safety measures, emergency procedures, and responsible behavior while onboard to ensure their safety.

The Balasore train accident serves as a somber reminder of the ongoing challenges faced by Indian Railways. While the number of accidents per million train kilometers has decreased over the last decade, it is evident that additional efforts are needed to address maintenance issues, enhance existing infrastructure, and optimize staff resources.

Poor maintenance of tracks and overstretched staff are the two main problems Indian Railways must address. Following the accident, The Ministry of Railways is addressing maintenance-related issues, infrastructure improvements, technological advancements, comprehensive training programs, and stringent safety regulations in an effort to improve the safety and reliability of their railway network.

Natalie Johnson

Natalie Johnson is the previous editor/website administrator for MaintenanceWorld.com, and is currently a student at Campbell University Norman Adrian Wiggins School of Law.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill