Top 10 Ways Not to be World Class at Machinery Lubrication

Jim Fitch, Noria Corporation

This article includes 10 ways to NOT be World Class at Machinery Lubrication. Achieving world class machinery lubrication at your organization takes lots of time, effort, education, and training.

1. Begin by not reading this editorial. Most “old school” lube programs like to hold to the status quo. Editorials like this one threaten their comfort zone. After all, change takes guts . . . it takes imagination . . . it takes commitment. Who’s got the time (and courage) for that?

2. Oil is oil. Use the one that’s near and convenient. Don’t waste your time worrying about whether a particular lubricant is “perfectly suited” for a machine. What does it matter? Relax . . . if the machine fails it will take a while, and then, who could prove it was associated with the lubricant?

3. Pretend to be saving money by buying your lubricants from the lowest bidder. Management will label you as being cost conscious. Ignore claims from higher priced lubricant suppliers of their more robust basestocks and higher quality additive packages. Such claims are just hype and jive anyway . . . right?

4. Keep your lubrication technicians on the lowest pay scale. Don’t encourage them to aspire to that of a “skilled” worker or a member of the trade. This only rocks the boat and leads to an increase in labor cost. After all, anyone who can walk and chew gum at the same time can lubricate a machine, right? These kinds of people should be the lowest paid.

5. Don’t develop procedures and guidelines on how to lubricate your machinery. If there’s no procedure, there’s no documented right or wrong way of doing it. This keeps things flexible, allowing technicians to customize their work to suit themselves. Who wants the hassle of having to conform to someone else’s “best practices” anyway?

6. If it ain’t broke don’t fix it. Even if machines fail repeatedly, don’t change anything. After all, why change what’s better left alone? And, what do others know about how to lubricate your machinery anyway? Your old-timers have decades of knowledge and experience about lubrication. If there was a better way of lubricating machines they would be the first to tell you. There’s really nothing to worry about.

7. Don’t waste money on oil analysis. It’s a gimmick cooked up by lubricant suppliers to sell oil changes . . . and pad their pockets. It’s better to just change oil according to a rigid schedule, whether it needs to be changed or not. And, don’t believe the claims of some labs that oil analysis can alert you to impending machine failure. Only vibration analysis can really do that.

8. Ignore the warnings that contaminated oil harms your bearings, pumps and other component surfaces. These people are just alarmists and don’t know what they are talking about. Who could believe that dirt in oil so small and low in concentration could cause a problem to a big, powerful machine of steel? …

… If filters were needed, the equipment manufacturer would have included them in the design (regardless of the date it was designed). And, for those machines that have filters, don’t bother to upgrade them.

9. If you want improved reliability, buy better gears and bearings. When bearings fail repeatedly, it’s not the fault of the lubricant. Everyone knows that all machines wear out eventually. You hire mechanics and millwrights for the purpose of fixing these routine problems. That’s their job.

10. Don’t waste your money on education. When it comes to lubrication and oil analysis there’s really nothing new. Besides, if you provide your lubrication technicians with education, they would just come back and do things the same way. We all know that seminars and conferences are just an excuse for not working. Don’t be foolish. Give them a book to read instead. And, by all means, don’t get them certified in the areas of lubrication and oil analysis. It just feeds their egos.

Jim Fitch, “Top Ten Ways Not to be World Class at Machinery Lubrication”. Practicing Oil Analysis Magazine.

Related Articles

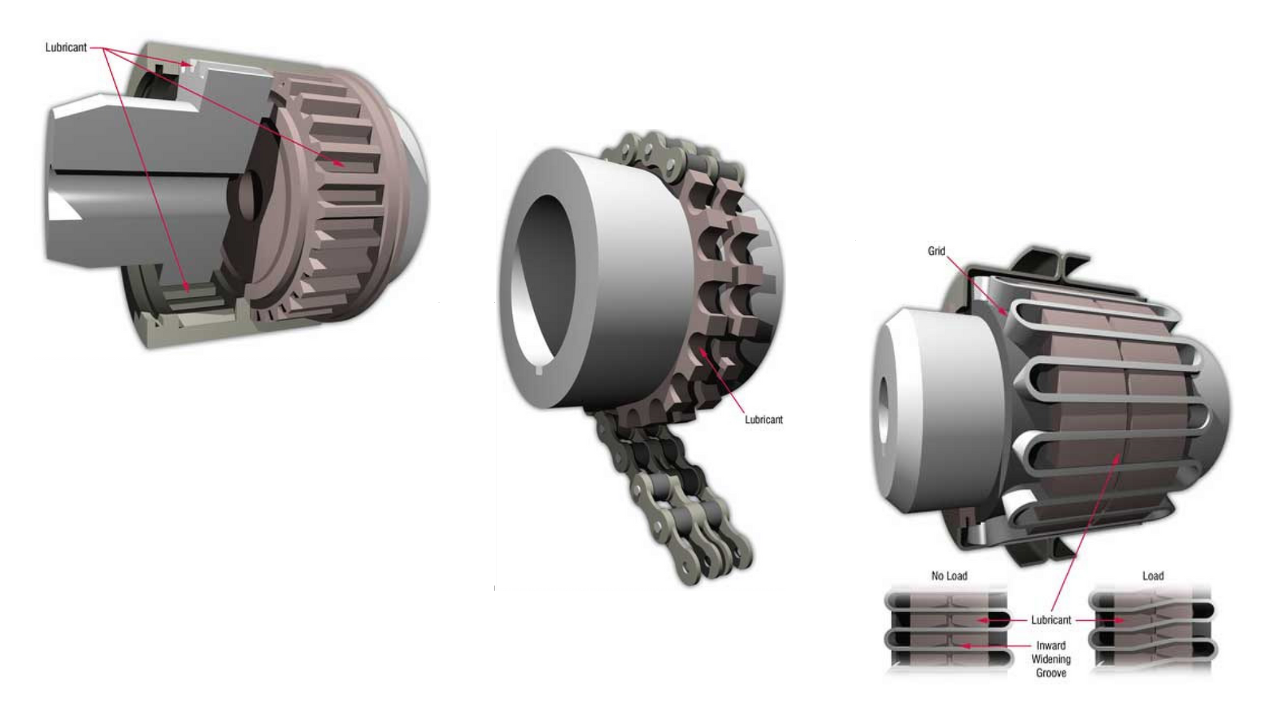

In an ideal world, multiple components could be produced in a single piece, or coupled and installed in perfect alignment. However, in the real world, separate components must be brought together and connected onsite. Couplings are required to transmit rotational forces (torque) between two lengths of shaft, and despite the most rigorous attempts, alignment is never perfect. To maximize the life of components such as bearings and shafts, flexibility must be built in to absorb the residual misalignment that remains after all possible adjustments are made. Proper lubrication of couplings is critical to their performance.

In an ideal world, multiple components could be produced in a single piece, or coupled and installed in perfect alignment. However, in the real world, separate components must be brought together and connected onsite. Couplings are required to transmit rotational forces (torque) between two lengths of shaft, and despite the most rigorous attempts, alignment is never perfect. To maximize the life of components such as bearings and shafts, flexibility must be built in to absorb the residual misalignment that remains after all possible adjustments are made. Proper lubrication of couplings is critical to their performance.

See More

The goal of every lubrication program should be to ensure that all equipment receives and maintains the proper levels of lubrication such that no equipment fails due to inadequate or improper lubrication. In order for this to happen, we must follow the 5R's of lubrication - right lubricant, right condition, right location, right amount, right frequency.

The goal of every lubrication program should be to ensure that all equipment receives and maintains the proper levels of lubrication such that no equipment fails due to inadequate or improper lubrication. In order for this to happen, we must follow the 5R's of lubrication - right lubricant, right condition, right location, right amount, right frequency.

See More

Most, if not all, companies use CMMS systems to oversee their maintenance activities. From home-grown systems to complete ERP systems, leveraging technology allows companies to more efficiently and effectively manage their maintenance, repair and operations activities. So as a core maintenance function, surely routine, lubrication-related preventive and predictive activities such as regreasing motor bearings, taking oil samples, and executing oil top-offs and inspections belong in the CMMS system like any other maintenance task, right?

Most, if not all, companies use CMMS systems to oversee their maintenance activities. From home-grown systems to complete ERP systems, leveraging technology allows companies to more efficiently and effectively manage their maintenance, repair and operations activities. So as a core maintenance function, surely routine, lubrication-related preventive and predictive activities such as regreasing motor bearings, taking oil samples, and executing oil top-offs and inspections belong in the CMMS system like any other maintenance task, right?

See More

Industry spends millions of dollars each year on improved filtration technology in an attempt to reduce particle contamination, with some of the more advanced companies reducing failure rates by up to 90 percent simply by controlling fluid cleanliness. However, in some industries and environments, water is a far more insidious contaminant than solid particles. Water contamination is often overlooked as the primary cause of component failure.

Industry spends millions of dollars each year on improved filtration technology in an attempt to reduce particle contamination, with some of the more advanced companies reducing failure rates by up to 90 percent simply by controlling fluid cleanliness. However, in some industries and environments, water is a far more insidious contaminant than solid particles. Water contamination is often overlooked as the primary cause of component failure.

See More

Ultrasonic technology (UT) has become widely accepted for the detection of leaks in both pressurized and nonpressurized systems. Most compressor service companies and several manufacturers own some type of ultrasonic sensor for pinpointing leaks. It is easy to cost-justify the purchase of an ultrasonic sensor based upon the high cost of energy loss due to leaks. However, there is another application for ultrasound that consumers, nondestructive testing (NDT) organizations, and even developers and manufacturers of ultrasonic sensors are often not aware of or overlook. UT can be used as a means to detect early wear of components such as bearings and gears due to lack of lubrication or overlubrication.

Ultrasonic technology (UT) has become widely accepted for the detection of leaks in both pressurized and nonpressurized systems. Most compressor service companies and several manufacturers own some type of ultrasonic sensor for pinpointing leaks. It is easy to cost-justify the purchase of an ultrasonic sensor based upon the high cost of energy loss due to leaks. However, there is another application for ultrasound that consumers, nondestructive testing (NDT) organizations, and even developers and manufacturers of ultrasonic sensors are often not aware of or overlook. UT can be used as a means to detect early wear of components such as bearings and gears due to lack of lubrication or overlubrication.

See More

Using lubrication and oil analysis to enhance machine reliability is really too simple. Behind the appearances of complexity and vale of high science are the most basic of concepts. We can try to make it difficult, but why? With the right tools and a generous amount of training, a seemingly challenging task can be transformed into something almost mundane, but still powerful.

Using lubrication and oil analysis to enhance machine reliability is really too simple. Behind the appearances of complexity and vale of high science are the most basic of concepts. We can try to make it difficult, but why? With the right tools and a generous amount of training, a seemingly challenging task can be transformed into something almost mundane, but still powerful.

See More