Understand Your Goals with New Maintenance Technology

Alan Friedman, Cat IV, CRL, CMRP, Author; Founder/CEO of Zenco Vibration Experts

Posted 5/9/2024

It’s common for people to think that the next new maintenance technology will solve all of their problems. Just recently, someone complained to me that they were looking for another provider for remote monitoring services using wireless vibration sensors. When I asked what the problem was, the person said it was because the wireless sensors kept falling off the machine. I noted that this was not an issue with the remote services provider but rather with sensor mounting. Any new sensors would also need to be mounted on the machine.

The reply was a blank stare. We tend to look for solutions without properly defining the problems we are trying to solve. The solutions often come in the form of quick fixes, new products (new pills!), something we can buy. And when the new fix doesn’t solve the problem we jump to the next new shiny object and hope that it will fulfill our undefined needs.

Defining Goals

Why are you buying those sensors? Why are you buying that new maintenance technology? What are you hoping to achieve? How will you measure success (or failure) both in technical terms and in terms of a return on investment? Although these questions are straightforward and obvious, my experience in the field suggests that many people cannot answer them adequately. They have some vague idea that a tool or technology will somehow solve their problems but they are not clear on what these problems are.

When it comes to vibration monitoring, one of the goals is to help planners plan better. If you know well in advance that a machine is developing problems, you can order the spare parts and schedule the repair in a way that makes best use of available labor and maximizes uptime. These benefits can be measured, quantified, and calculated in dollar terms. What I see in the field (still, after 30 years) is people using vibration in a reactive mode. Which is to say they identify a problem at a late stage and then they do the repair a few days later.

This does prevent catastrophic failure – which is a valid goal to have – but it does not achieve the other, more economically salient goals of being able to plan better.

How We Make Decisions

I would say that if a tool is good, it will change how you make decisions. It will change your processes and procedures and it will change the culture. A good tool enables you to do things differently. What I often see in the field is that we adopt new tools but we do not change our processes and procedures to make the best use of these tools. We do not use them to improve our operations.

Why is this? Because we are not clear about our goals and because we inherently don’t like change. A common scenario is that an operator tells a maintenance person that there’s a problem with one of the machines. The maintenance guy grabs a vibration data collector, confirms the suspicions and a repair is done a few days later. We just used a high-tech tool to tell us something we already knew. How is it supposed to work? The vibe guy is supposed to detect the impending defect months before the operator notices it and the repair should be scheduled well in advance. Click here to find out why you should be come a certified vibration analyst.

What are your Goals with New Maintenance Technology?

Maybe you are in the market for some new maintenance technology. Perhaps you are considering installing wireless sensors on more of your assets. What are your goals? How will you measure success? How will you calculate the return on your investment?

Reliable Plant Conference Chicago June 3 – 6

Exciting news! Get trained and certified Cat 1 at Reliable Plant and you also get to network with industry experts and see the latest technology. The best of both worlds!!!! Price includes access to exhibition hall, group meals, evening receptions, entertainment, and networking opportunities.

Website: www.ZencoVibrations.com

Email: [email protected]

LinkedIN: https://www.linkedin.com/in/alanfriedmanvibe/

Mailing List: mailing list

YouTube: https://www.youtube.com/channel/UCSWbScnX0Bnb6iXbvtWAOSA

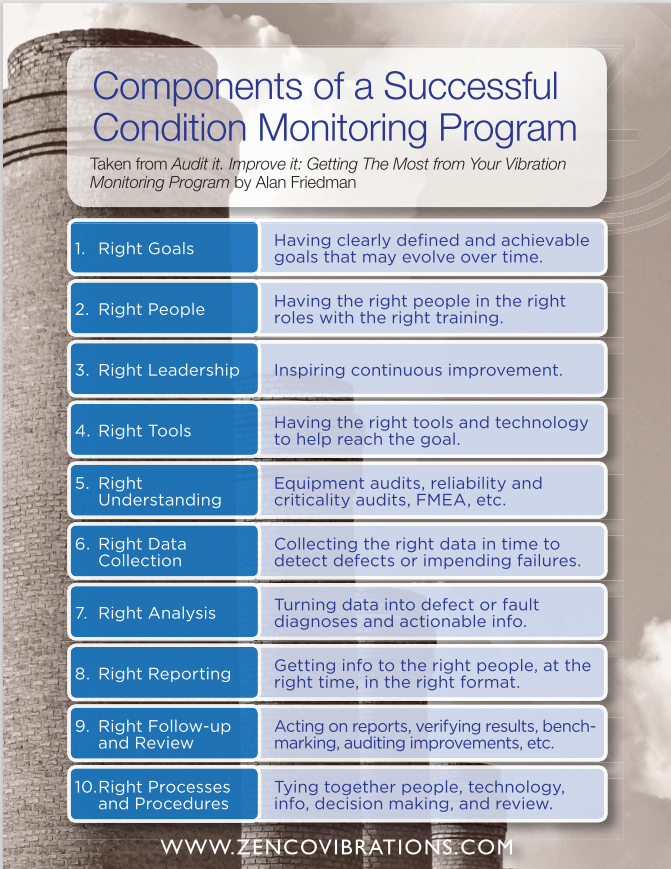

My Book: Audit It Improve It

Alan Friedman

Alan, aka the Vibe Guru, has over 30 years of vibration analysis experience, He has trained 1000’s of students around the world up to Category IV. One of the things that makes Alan a great teacher is his ability to teach people where they are at. Whether you are a math challenged millwright, an engineer or a PhD, Alan will challenge you without overwhelming you. If you are interested in condition monitoring you can also check out his book: Audit It. Improve It! Getting the Most from your Vibration Monitoring Program or hire him for an on-site program audit.

Related Articles

OEE: Overall Equipment Effectiveness

"Lean" on your Maintenance Materials

Can You Really Justify Reliability Centered Maintenance (RCM)?

The Achilles Heel of Modern Electronics

What is Vibration?

Web Based Vibration Analysis Programs

Vibration & Ultrasound Technologies: A Possible Integrated Inspection Tool?

Vibration Pen, Shock Pulse Measurement (SPM), & Vibration Analysis - What's the Difference?

Vibration Analysis Reveals Poor Motor Mounting Structure