France Struggling with Nuclear Reactor Maintenance

Natalie Johnson

Posted 05/03/2023

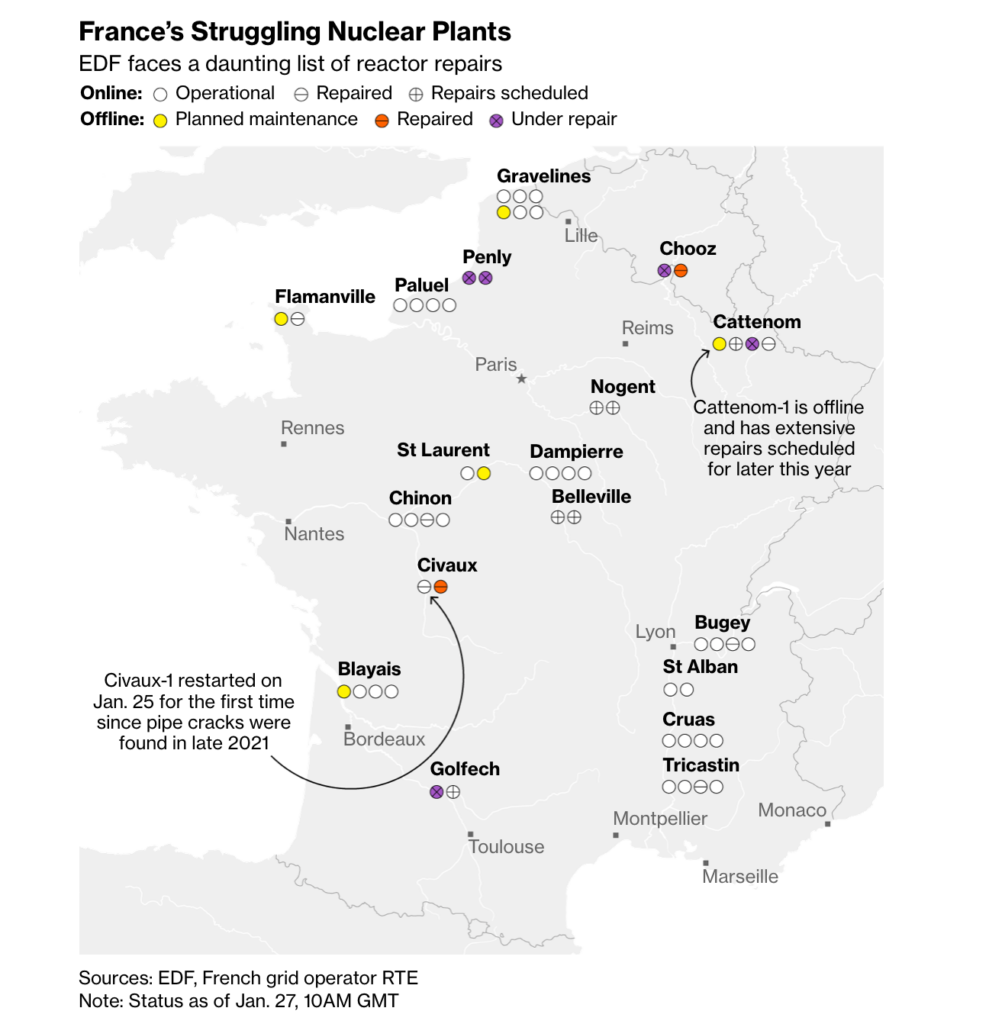

Électricité de France (EDF), a French energy group, is facing a severe maintenance crisis. In 2022, half of their nuclear reactors were down due to maintenance issues and the repairs continue to be pushed back, meaning some plants will remain shutdown well into 2023.

The trouble initially began when a 10 year inspection was conducted on a reactor at Civaux Nuclear Power Plant. Ultrasound machines found defects near the elbows of pipes in the cooling system that didn’t appear to be thermal fatigue. Maintenance workers cut the 3cm steel pipes to examine the defects and found stress corrosion.

After this discovery EDF began to inspect their profile of fifty-six nuclear reactors in France and discovered sixteen were affected by stress corrosion. Four N4-series 1450MWe reactors and twelve P4-series 1300 MWe reactors. Overall, half of all the nuclear reactors were shut down from May to October of 2022 due to maintenance work and repairs.

Burdensome Repairs

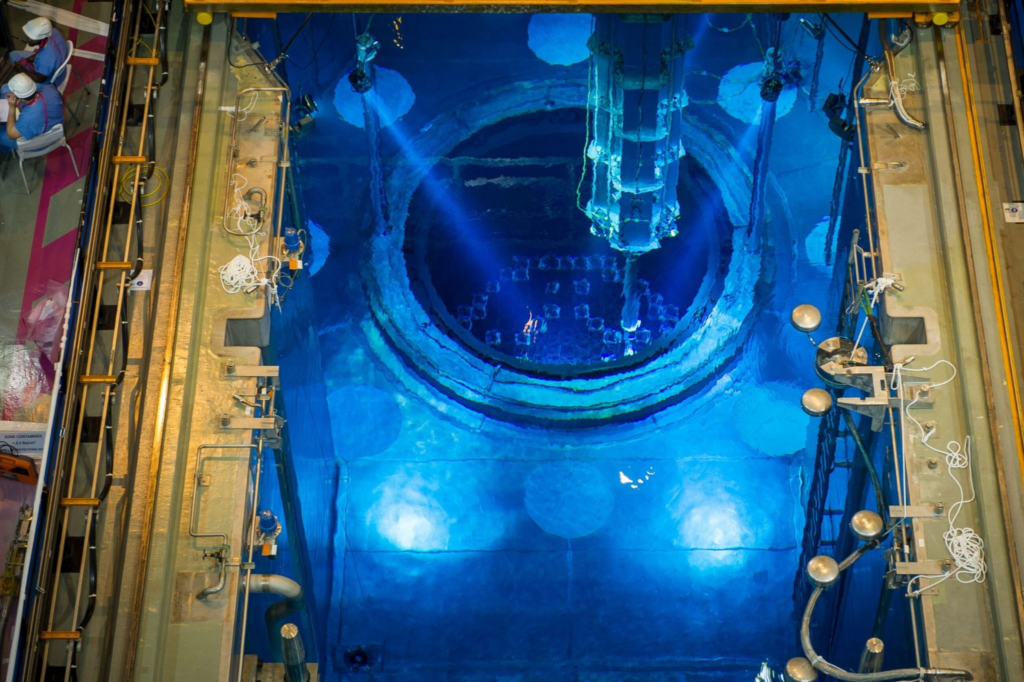

The emergency repairs necessary to fix the corroded pipes require highly skilled crews that must work in cramped spaces while wearing protective gear. Teams of highly-specialized welders and engineers were recruited from several North American and French companies to assist with maintenance and repair initiatives.

One of the most severe cases of corrosion was found at the Penly Nuclear Plant, where two reactors had to be taken offline for extensive repairs. A six inch long and one inch deep crack was discovered in the cooling tower. The crack doesn’t pose an immediate threat as the pipes are only used to protect against a reactor meltdown.

Welding the pipes is an extremely difficult task. Welders must crawl on their hands and knees, shift to their back, and even use mirrors to view pipes located close to the wall. Some facilities where repairs are ongoing have set up designated workshops for welders to practice before they are expected to repair the pipes under harsh conditions. Each day after welding is completed, ultrasound images are taken to ensure each layer of the weld is up to standard.

Heavy radiation suits must be worn at all times, which only makes it more difficult to maneuver the tight spaces. Some contractors have relaxed their rules on radiation exposure, one shifting their annual exposure limit from 12 millisieverts/year to 14, although the new limits are still well below the French legal limit of 20 millisieverts/year for nuclear workers.

Laurent Marquis, a manager at Altrad Group-Endle which was contracted out to perform some repairs at Penly shared his thoughts, “These are complex situations, in a noisy and radioactive environment. Workers can sometimes only hold their position for just a few minutes before they need to be replaced.”

Sourcing spare parts for the repairs also proves to be challenging as most must be imported from Italy and fitted to ensure they will support the installed tubes. Tools must be modified to fit into tight spaces and welders are frequently exchanged due to the radiation exposure limits and difficult positions they must maintain.

The tough working conditions and processes necessary to obtain the proper welders and supplies have increased shutdown times. The two reactors at Penly should be complete by June of 2023, but this is far beyond their initial January deadline. Month long delays extend to many other reactors facing similar types of repairs.

Shutdowns Across France

As of February 2023, twelve reactors are still shut down, eight of which are related to corrosion. The French government is urging EDF to stick to its maintenance schedule as the country is highly dependent on nuclear energy.

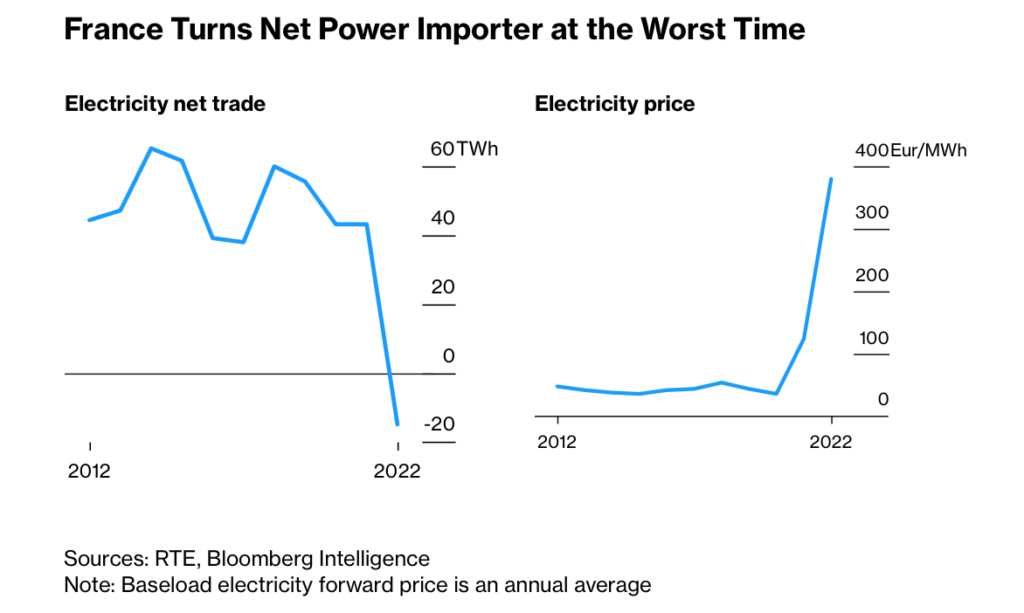

In 2022, the shutdowns caused France to become an importer of electricity for the first time in decades. Nuclear power plants typically produce 70% of the country’s electricity, but in 2022 the country only produced 279 terawatt-hours, a drastic drop from the 361 TWh produced the year prior.

EDF is estimating it will recover and produce 300+ TWh in 2023, but with continual setbacks and a history of deferred maintenance, the country may continue to import a significant amount of electricity this year. Most of EDF’s reactors were built in the late 20th century and require extended maintenance and lengthy periods of downtime, the corrosion repairs are just one part of the broader maintenance work that needs to be done.

Midweek with Maintenance World

Looking for a midweek break? Keep up with the latest news brought to you every Wednesday by the Maintenance World crew.

Natalie Johnson

Natalie Johnson is the previous editor/website administrator for MaintenanceWorld.com, and is currently a student at Campbell University Norman Adrian Wiggins School of Law.

Related Articles

Cardinal Manufacturing, Helping to Bridge the Manufacturing Skills Gap

South Carolina Ranked as the #1 State for Manufacturing

The Decade of American Reshoring

Lost Radioactive Capsule Proves Preventive Maintenance is as Important as Ever

HBD Condition Monitoring Devices at the center of Ohio Derailment

Failure Analysis Uncovers the Cause of the Keystone Oil Spill