What is a valve?

ValveMagazine

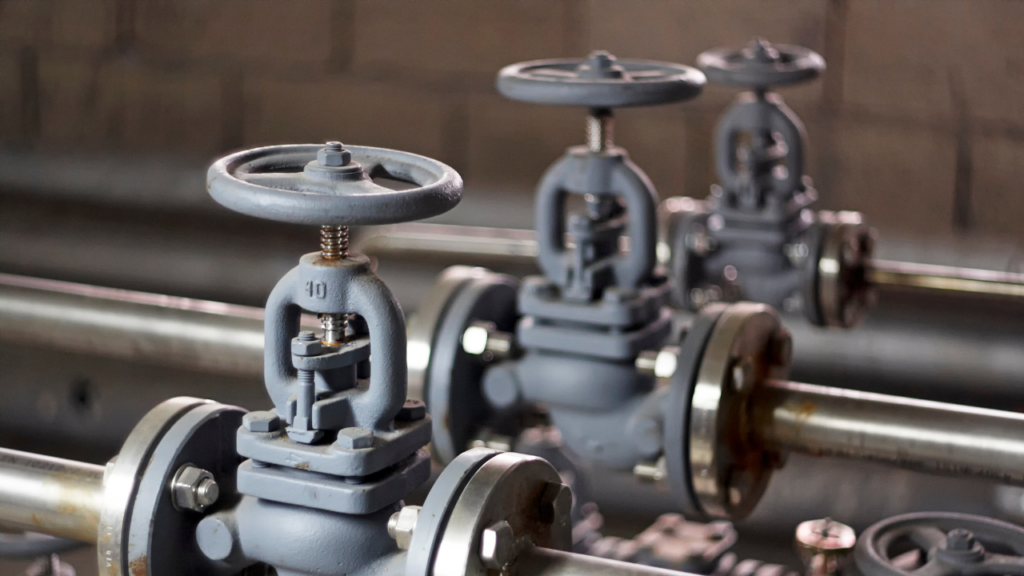

A valve is a product that is rarely noticed by the average person, yet it plays a very important role in the quality of our life. Each time you turn on a water faucet, use your dishwasher, turn on a gas range, or step on the accelerator of your car, you operate a valve. Without them, there would be no fresh pure water or automatic heat in your home. There would be no public utilities, and beyond wood and coal, almost no energy of any kind. Plastics would be unheard of, as would many inexpensive consumer products.

By definition, a valve is a device that controls the flow of a fluid. Today they can control, not only the flow, but also the rate, the volume, the pressure or the direction of liquids, gases, slurries or dry materials through a pipeline, chute or similar passageway. They can turn on and turn off, regulate, modulate or isolate. They can range in size from a fraction of an inch to as large as 30 feet in diameter and can vary in complexity from a simple brass valve available at the local hardware store to a precision-designed, highly sophisticated coolant system control valve, made of an exotic metal alloy, in a nuclear reactor.

They can control flows of all types, from the thinnest gas to highly corrosive chemicals, superheated steam, abrasive slurries, toxic gases and radio active materials. They can handle temperatures from cryogenic region to molten metal, and pressures from high vacuum to thousands of pounds per square inch.

The valve is one of the most basic and indispensable components of our modern technological society. It is essential to virtually all manufacturing processes and every energy production and supply system. Yet it is one of the oldest products known to man, with a history thousands of years old.

Common Types

There are 5 Common Types. They will be described further down below:

Multi-turn or Linear Motion Valves

Quarter Turn, or Rotary Valves

Self-Actuated Valves

Control Valves

Specialty Valves

Types of Actuators

Actuators are the triggering units for control valves, listed below are a few common types of actuators. They will be described further down below:

Manual Actuators

Hydraulic and Pneumatic Actuators

Electric Actuators

Multi-turn or Linear Motion Valves

Gate

The gate valve is a general service valve used primarily for on–off, non-throttling service. It is closed by a flat face, vertical disc, or gate that slides down through it to block the flow.

Globe

The globe valve effects closure by a plug with a flat or convex bottom lowered onto a matching horizontal seat located in the center of the valve. Raising the plug opens it, allowing fluid flow. It is used for on–off service and handles throttling applications.

Pinch

The pinch valve is particularly suited for applications of slurries or liquids with large amounts of suspended solids. It seals by means of one or more flexible elements, such as a rubber tube, that can be pinched to shut off flow.

Diaphragm

The diaphragm valve closes by means of a flexible diaphragm attached to a compressor. When the compressor is lowered by the valve stem onto a weir, the diaphragm seals and cuts off flow. It handles corrosive, erosive and dirty services.

Needle

The needle valve is a volume-control valve that restricts flow in small lines. The fluid going through it turns 90 degrees and passes through an orifice that is the seat for a rod with a cone-shaped tip. The Size of the orifice is changes by positioning the cone in relation to the seat.

Quarter Turn or Rotary Valves

Plug

The plug valve is used primarily for on–off service and some throttling services. It controls flow by means of a cylindrical or tapered plug with a hole in the center that lines up with the flow path of the valve to permit flow. A quarter turn in either direction blocks the flow path.

Ball

The ball valve is similar in concept to the plug valve but uses a rotating ball with a hole through it that allows straight-through flow in the open position and shuts off flow when the ball is rotated 90 degrees to block the flow passage. It is used for on–off and throttling services.

Butterfly

The butterfly valve controls flow by using a circular disc or vane with its pivot axis at right angles to the direction of flow in the pipe. It is used both for on–off and throttling services.

Self-Actuated Valves

Check

The check valve is designed to prevent backflow. Fluid flow in the desired direction opens it, while backflow forces it to close.

Pressure Relief

The pressure relief valve is designed to provide protection from over-pressure in steam, gas, air and liquid lines. It “lets off steam” when safe pressures are exceeded, then closed again when pressure drops to a preset level.

Control Valves

The control valve is designed to ensure accurate proportioning control of flow. It automatically varies the rate of flow based on signals it receives from sensing devices in a continuous process. Some valves are designed specifically as control valves. However, most types can be used as control valves, both linear and rotary motion, by the addition of power actuators, positioners and other accessories.

Specialty Valves

In addition to these standard products, many manufacturers produce custom-designed valves and actuators for specific applications. Valves are available in a broad spectrum of sizes and materials. Each design has its own advantages, and selection of the proper one for particular application is critical. The factors generally considered in the selection of a valve include:

- The substance to be handles and the required flow rate.

- The requirement that the valve control and/or shut off the flow in the manner demanded by the service conditions.

- The ability to withstand the maximum working pressure and temperature.

- The ability to resist attack by corrosion or or erosion.

- Actuator requirements, if any.

- Maintenance and repair requirements.

Types of Actuators

Manual Actuators

A manual actuator employs levers, gears or wheels to facilitate movement; while an automatic actuator has an external power source to provide the force and motion to operate a valve remotely or automatically. Power actuators are a necessity on valves in pipelines located in remote areas: they are also used on valves that are frequently operated or throttled. Valves that are particularly large may be impossible or impractical to operate manually simply by the sheer horsepower requirements.

Some valves may be located in extremely hostile or toxic environments, which preclude manual operation. Additionally, as a safety feature, certain types of power actuators may be required to operate quickly, shutting down a valve in case of emergency.

Hydraulic and Pneumatic Actuators

The hydraulic and pneumatic actuators are often simple devices with a minimum of mechanical parts, used on linear or quarter-turn valves. Sufficient air or fluid pressure acts on a piston to provide thrust in a linear motion for gate or globe valves. Alternatively, the thrust may be mechanically converted to rotary motion to operate a quarter-turn valve. Most types of fluid power actuators can be supplied with fail-safe features to open or close under emergency circumstances.

Electric Actuators

The electric actuator has a motor drive that provides torque to operate a valve. Electric actuators are frequently used on multi-turn valves such as gate or globe valves. With the addition of a quarter-turn gearbox, they can be utilized on ball, plug, or other quarter-turn valves.

Related Articles

Hydraulic Valves - Preventing Cavitation Damage

Troubleshooting Valves