How to Build Your ISO 55001 Asset Management System Quickly and make ISO 55001 Certification Easy

Lifetime Reliability Solutions

ISO-55001-Standard-Certification-Plant-Wellness-Way

Click here to download the full pdf.

Lifetime Reliability Solutions

Related Articles

Keys for Effective Troubleshooting

Expert troubleshooters have a good understanding of the operation of electrical components that are used in circuits they are familiar with, and even ones they are not. They use a system or approach that allows them to logically and systematically analyze a circuit and determine exactly what is wrong. They also understand and effectively use tools such as prints, diagrams and test instruments to identify defective components. Finally, they have had the opportunity to develop and refine their troubleshooting skills.

Expert troubleshooters have a good understanding of the operation of electrical components that are used in circuits they are familiar with, and even ones they are not. They use a system or approach that allows them to logically and systematically analyze a circuit and determine exactly what is wrong. They also understand and effectively use tools such as prints, diagrams and test instruments to identify defective components. Finally, they have had the opportunity to develop and refine their troubleshooting skills.

Analyzing Semiconductor Failure

Semiconductor devices are almost always part of a larger, more complex piece of electronic equipment. These devices operate in concert with other circuit elements and are subject to system, subsystem and environmental influences. When equipment fails in the field or on the shop floor, technicians usually begin their evaluations with the unit's smallest, most easily replaceable module or subsystem. The subsystem is then sent to a lab, where technicians troubleshoot the problem to an individual component, which is then removed--often with less-than-controlled thermal, mechanical and electrical stresses--and submitted to a laboratory for analysis. Although this isn't the optimal failure analysis path, it is generally what actually happens.

Semiconductor devices are almost always part of a larger, more complex piece of electronic equipment. These devices operate in concert with other circuit elements and are subject to system, subsystem and environmental influences. When equipment fails in the field or on the shop floor, technicians usually begin their evaluations with the unit's smallest, most easily replaceable module or subsystem. The subsystem is then sent to a lab, where technicians troubleshoot the problem to an individual component, which is then removed--often with less-than-controlled thermal, mechanical and electrical stresses--and submitted to a laboratory for analysis. Although this isn't the optimal failure analysis path, it is generally what actually happens.

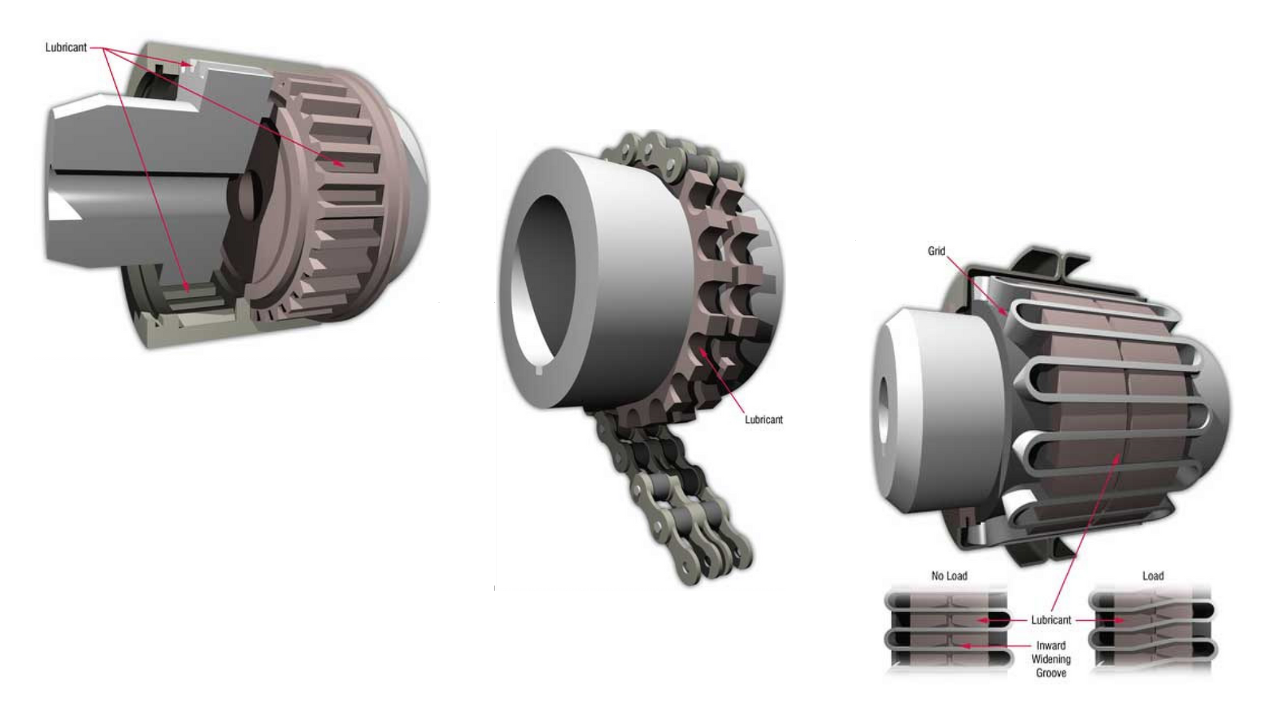

The Lubrication Requirements of Couplings

In an ideal world, multiple components could be produced in a single piece, or coupled and installed in perfect alignment. However, in the real world, separate components must be brought together and connected onsite. Couplings are required to transmit rotational forces (torque) between two lengths of shaft, and despite the most rigorous attempts, alignment is never perfect. To maximize the life of components such as bearings and shafts, flexibility must be built in to absorb the residual misalignment that remains after all possible adjustments are made. Proper lubrication of couplings is critical to their performance.

In an ideal world, multiple components could be produced in a single piece, or coupled and installed in perfect alignment. However, in the real world, separate components must be brought together and connected onsite. Couplings are required to transmit rotational forces (torque) between two lengths of shaft, and despite the most rigorous attempts, alignment is never perfect. To maximize the life of components such as bearings and shafts, flexibility must be built in to absorb the residual misalignment that remains after all possible adjustments are made. Proper lubrication of couplings is critical to their performance.

What is the True Downtime Cost (TDC)?

The key to realizing greater savings from more informed management decisions is to predetermine the "True" cost of downtime for each profit center category. True downtime cost is a methodology of analyzing all cost factors associated with downtime, and using this information for cost justification and day to day management decisions. Most likely, this data is already being collected in your facility, and need only be consolidated and organized according to the true downtime cost guidelines.

The key to realizing greater savings from more informed management decisions is to predetermine the "True" cost of downtime for each profit center category. True downtime cost is a methodology of analyzing all cost factors associated with downtime, and using this information for cost justification and day to day management decisions. Most likely, this data is already being collected in your facility, and need only be consolidated and organized according to the true downtime cost guidelines.

Improvement: What Comes First?

I use the term RCPE because it is a waste of good initiatives and time to only find the root cause of a problem, but not fixing it. I like to use the word problem; a more common terminology is Root Cause Failure Analysis (RCFA), instead of failure because the word failure often leads to a focus on equipment and maintenance. The word problem includes all operational, quality, speed, high costs and other losses. To eliminate problems is a joint responsibility between operations, maintenance and engineering.

I use the term RCPE because it is a waste of good initiatives and time to only find the root cause of a problem, but not fixing it. I like to use the word problem; a more common terminology is Root Cause Failure Analysis (RCFA), instead of failure because the word failure often leads to a focus on equipment and maintenance. The word problem includes all operational, quality, speed, high costs and other losses. To eliminate problems is a joint responsibility between operations, maintenance and engineering.

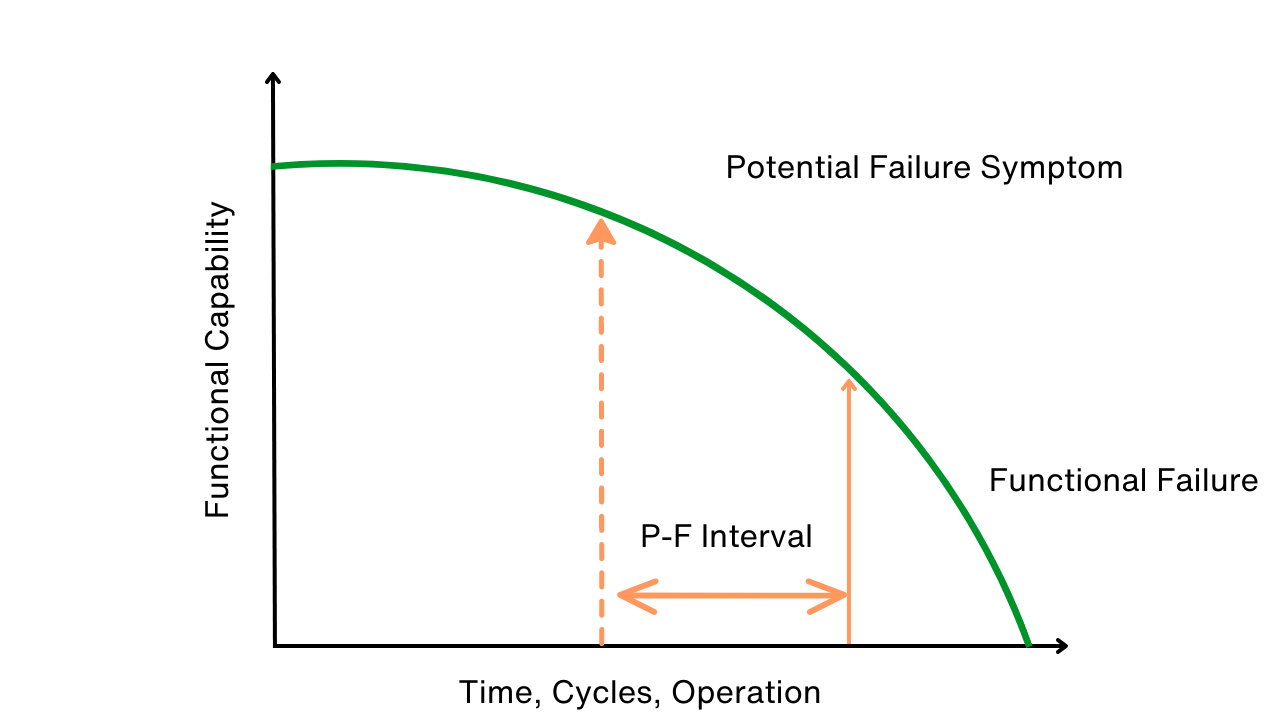

Use P-F Intervals to Map, Avert Failures

The potential-to-functional failure interval (P-F interval) is one of the most important concepts when it comes to performing Reliability-Centered Maintenance (RCM). Remarkably, the P-F interval is also one of the most misunderstood RCM concepts. The failure mode analysis becomes even more complicated when you are dealing with several P-F intervals for one failure mode. This paper will help clarify the P-F interval and the decision-making process when dealing with multiple P-F intervals.

The potential-to-functional failure interval (P-F interval) is one of the most important concepts when it comes to performing Reliability-Centered Maintenance (RCM). Remarkably, the P-F interval is also one of the most misunderstood RCM concepts. The failure mode analysis becomes even more complicated when you are dealing with several P-F intervals for one failure mode. This paper will help clarify the P-F interval and the decision-making process when dealing with multiple P-F intervals.

Use this Game Plan to Justify an Investment in Maintenance and Reliability

As many of us strive to improve the reliability of our plants, several comments bemoan how challenging that is to do in an era of continuous deep cost cutting. They say that in their operation, maintenance is seen as a cost, and is one of the first things to arbitrarily cut. Some think their operations have cut too far! What they seek is a way to justify a strong maintenance capability. I submit that one approach is to speak of maintenance as an “investment in capacity.” Use the language that plant managers, controllers and senior management understands: capital investment and return on investment (ROI).

As many of us strive to improve the reliability of our plants, several comments bemoan how challenging that is to do in an era of continuous deep cost cutting. They say that in their operation, maintenance is seen as a cost, and is one of the first things to arbitrarily cut. Some think their operations have cut too far! What they seek is a way to justify a strong maintenance capability. I submit that one approach is to speak of maintenance as an “investment in capacity.” Use the language that plant managers, controllers and senior management understands: capital investment and return on investment (ROI).