Who Should Decide the Right Frequency for Preventive Maintenance Tasks?

www.reliabilityplant.com

Routine, time-based preventive maintenance is a fact of life for production-critical equipment. But, who should decide how often these tasks are performed? Should it be the maintenance team (led by the maintenance manager) or the production manager and the operations group? While the question may seem odd (maintenance people should decide when its work gets done, right?), many plants allow production to define maintenance scheduling by default.

Let me explain. In many plants, production occurs 24/7, 52 weeks a year, perhaps with the exception of a one- or two-week maintenance shutdown. Under these circumstances, careful planning needs to occur so the backlog of maintenance tasks that can’t be done with machines running can be completed in the allocated outage period. But when it comes to lubrication, many tasks simply can’t wait a year (or longer) between intervals. Take, for example, regreasing bearings. With the exception of small and/or low-speed element bearings, logic dictates that bearings be regreased more frequently – in some cases, as often as once per shift. But unless the bearing is accessible during normal operation, as opposed to being hidden behind guards or machine interlocks, the only time the bearing will be greased is when production makes the machine available to maintenance. In this case, production schedules drive maintenance decisions.

The same logic applies to oil changes. Consider a small yet critical centrifugal pump. Many pumps of this type contain just a few gallons (or less) of oil. But, changing oil can be a real problem if the pump can’t be shut down without taking down production; and while some may advocate doing an oil change “on the fly”, it’s not recommended or the preferred course of action. Of course with circulating systems, larger oil volumes coupled with the ability to “sweeten” the oil through bleed and feed (draining a small amount of oil from the reservoir and replacing it with an equal volume of new oil) makes this less of a problem.

What about filter changes? Most circulating systems have inline filters on the supply side and, in some cases, return line filters. But unless these filters are arranged in a duplex configuration with the ability to valve off one of the filters with the machine running, filter changes won’t be determined by oil analysis or differential pressure as best practice dictates, but instead by machine availability as determined by production schedules.

So, how can we avoid these problems? We’re not about to advocate modifying production schedules except in the most exceptional cases. Instead, we must modify the way we maintain our machines.

The place to start is during the design and installation phase. In past columns, I’ve talked about “maintainability” – having machines designed and installed in such a way that tasks like regreasing bearings or changing filters can be done without the need for intrusive system access. Maintainability needs to be built in from the outset, during equipment design. While it’s possible to modify in-service equipment to allow better intrinsic maintainability, it often takes significantly more time, effort and money to do this after the fact than it does from the start.

The second consideration is in the selection of lubricants and accessories (filters, breathers, etc.). If accessibility to a machine is limited to a year (or longer), the plant should consider using premium lubricants such as synthetics that will generally last longer than conventional mineral-based lubricants and may indeed last a year or longer without the need for an oil change. Where contamination is the driving force for a shortened PM interval, consider using better breathers, mechanical seals or large filters with greater dirt-holding capacity. Or, perhaps equipping the machine with quick connects to allow a portable filter cart to be used to decontaminate the oil while the machine is running is all that’s required.

The final consideration is in efficient planning and scheduling. When outages and production schedules dictate PM intervals, resource requirements will fluctuate from periods of low demand to “all hands on deck” when the machine becomes available for maintenance. But when maintainability is used, coupled with the appropriate use of premium products and accessories, the highs and lows of maintenance resource scheduling are less pronounced. Likewise, through the use of appropriate software tools that provide for options such as job kitting, dynamic job planning and current machine operating status, maintenance can take advantage of “golden opportunities” – times when the machine is unexpectedly down for production.

A common complaint I hear from maintenance people is: “Production won’t let us have the machines in order to properly maintain them.” While there’s a measure of truth to this statement, there’s plenty we can do to insure that the maintenance team fulfills its mandate to deliver reliability and availability to the operations team.

Related Articles

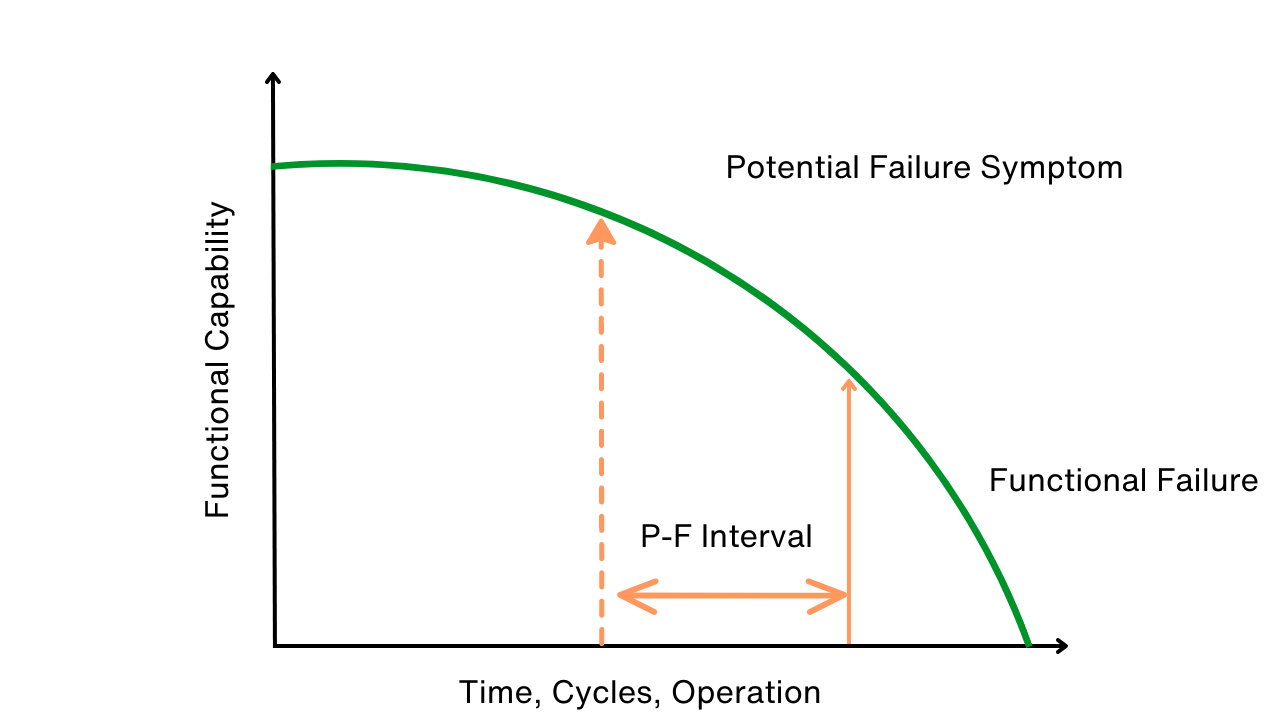

Use P-F Intervals to Map, Avert Failures

The RCM Trap

Can You Really Justify Reliability Centered Maintenance (RCM)?

Design for Maintainability