10 Steps to Getting More From Your Equipment Lubricants

Greg Mecomber, IDCON INC

Posted 11/16/2022

Give Your Lubricants a Long and Happy Life…or turn your lubricants into “lubri-cans”

Just like everything else, lubricants have a shelf-life. If you treat them right, this can be anywhere between six months to three years depending on the type. However, lubricants will only reach their max life expectancy if they are stored and cared for properly.

What effects does improper storage have on lubricants?

The primary and most significant effect of improper storage is Contamination. Contaminants such as metals, moisture (in the form of liquid or humidity), air, process chemicals or even other lubricants can cause a lubricant and its additives to oxidize and degrade rapidly – losing its protecting and lubricating properties (Thompson, 2007). “Dirt” is not typically responsible for the breakdown of lubricants, but it does result in accelerated wear on contact parts within machinery as well as reduced oil flow.

As a result of their contamination control program, Smoky Canyon Mine was able to defer AU$280,000 in spending for the first quarter of 2003 alone (“Contamination Control”, n.d.).

Second is Temperature Extremes – unless you’ve made some very poor and also strange storage decisions, it isn’t likely your lube storage will reach or exceed roughly 400°F, however if they do and they are not rated for high-temperatures, the molecules of both the lubricant and additives can begin to break down and the lube viscosity may be permanently altered (Barnes, 2003). The same is true for cold extremes also – typically below -5°F. Cold temperatures, in contrast to hot temperatures, cause additives and oils to separate which will reduce their effectiveness and shelf-life.

Finally, and related to both contamination and temperature extremes is Temperature Fluctuation. Unsealed containers, leaving the contents exposed to the elements should be considered a lubrication “worst practice”, but even sealed containers, such as drums, can become exposed to the elements through a process known as “thermal siphoning”. This occurs when the air contained within the headspace of the container expands and contracts and causes the container to “breathe” air – and all the contaminants therein – into the container despite it being sealed. If there is rainwater, condensation or other build-up around the seals, these too can be pulled into the container to some extent.

Any and all contamination that enters your lubricants will also enter your equipment. Better lubrication practices are often an easy solution to many issues at manufacturing facilities.

What can you do to extend the life of your lubricants?

1. Make sure all storage containers are closed/sealed properly after each use and covered with an appropriate cover such as a drum cover for extra protection

2. Often organizations store and (sometimes) use an excessive amount of lubricant types. 25-40 is a common number of different lubricant types at facilities that have not optimized their lubrication strategy. Consult with an expert to help reduce the number of lubricants to a more manageable number that is truly necessary.

3. Add desiccant breathers and filters to the bulk storage containers that are currently being used.

4. Ensure oil handling tools are clean. This means clean of lubricant residue (to avoid cross contamination) as well asl dirt and other debris.

5. Store lubricants indoors and in a climate-controlled area if at all possible.

6. If a lubricant must be stored outside, use drum covers to protect the top of the drums at the very least. A tarp or lean-to type structure in addition to the covers is advisable to reduce the exposure to the sun and rain.

7. Store metal containers on blocks or other supports to protect the bottom from ground moisture and prevent corrosion of the container. Note: This may also be a factor indoors. Containment reservoirs are often a requirement and would satisfy this consideration.

8. Drums, if possible, should be stored horizontally with bungs at the 9 and 3 o’clock positions. This reduces thermal siphoning and if the caps do happen to spring a leak, only 50% of the oil will escape instead of potentially all of it.

9. Drain and flush gearboxes regularly. Performing oil analysis is recommended to determine the required frequency. All this effort will be in vain if all you’re doing is adding clean oil to pre-existing sludge.

10. Educate and hold people accountable for doing their part in maximizing the useful life of your lubricants. Following these simple steps will reduce costs, lubricant degradation and equipment downtime due to lubrication issues. Your organization will without a doubt benefit from improving lubrication storage, but for other lubrication related issues, IDCON also conducts training on Root Cause Problem Elimination – a common-sense and actionable process that can be used by anyone at all levels of your organization to identify and eliminate problems at your facility.

References

Barnes, M. (2003, May). The Lowdown on Oil Breakdown. Practicing Oil Analysis.

Contamination control. techenomics.net. (n.d.). Retrieved November 11, 2022, from https://www.techenomics.net/case-studies/contamination-control/

Livingstone, G., Wooten, D., & Thompson, B. (2007, January). Finding the Root Cause of Oil Degradation. Practicing Oil Analysis.

Greg Mecomber

Greg Mecomber is a reliability and maintenance consultant. He has years of maintenance and reliability experience with both “turn-around” and start-up companies as well as experience in varied industries such as brewing, medical devices, glass fabrication, airfield maintenance and food & beverage.

Related Articles

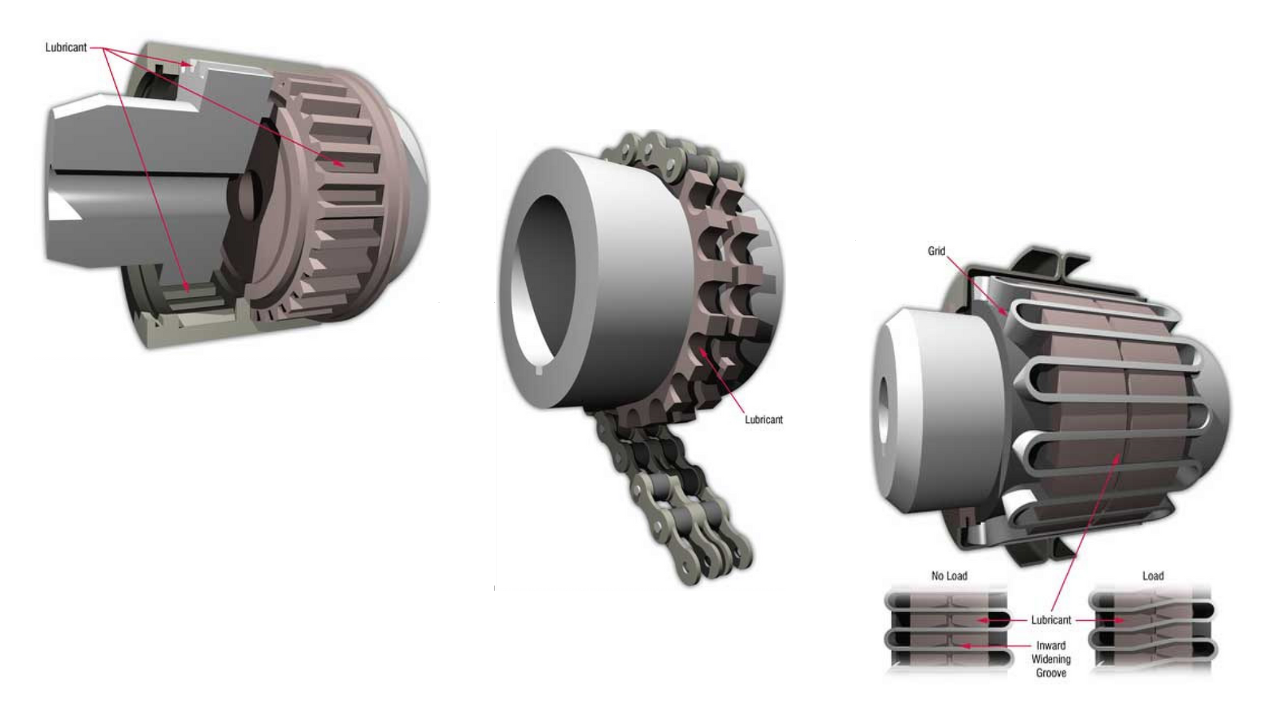

The Lubrication Requirements of Couplings

The Building Blocks to Creating an Effective Lubrication Program

Does Lubrication Belong in the CMMS?

Water Contamination

Ultrasound for Better Lubrication

Top Ten Ways Not to be World Class at Machinery Lubrication