Data Analysis Tip 3 – Compare Identical Machines

www.dliengineering.com

Tip #3: Compare Identical Machines

When troubleshooting a machine or using vibration analysis in a Predictive Maintenance program it can be useful to compare identical machines to each other. This is often the best method to diagnose a problem – especially if you suspect a problem exists in one or more of the machines.

When vibration data is collected on a bearing housing using an accelerometer, one is not only measuring vibration forces, but also the effect of the structure on these forces. There is no vibration severity guide in existence that accommodates for the effect of the structure and this is one reason guides are only just that “guides”. Not only that, the effect of the structure is different at every frequency.

Some small machines normally vibrate “a lot” and some large machines barely vibrate at all. In either case, they all produce unique patterns. Therefore, the best comparison one can make is between two identical machines, or between reference data from the same machine but at an earlier test date. You should always be. sure to test the machines in the same locations and under the same conditions (speed and load). “Normalize” the data and compare them. If troubleshooting, note the test conditions and save the data for later use, remember we just discussed past reference data can be useful!

Did you enjoy this tip? Be sure to Tip #1 and Tip #2 if you missed them!

Do you have a tip you’d like to share with the Maintenance World community? Submit it to [email protected] today to be featured in your favorite publication!

Related Articles

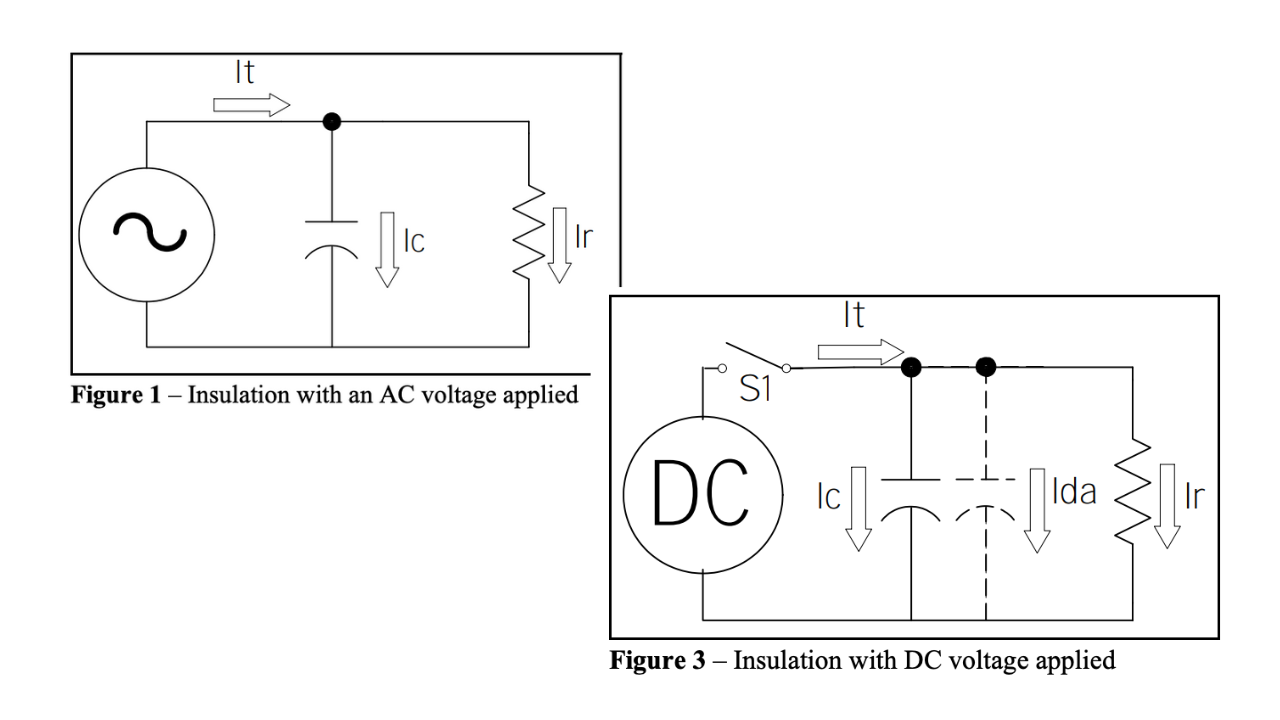

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

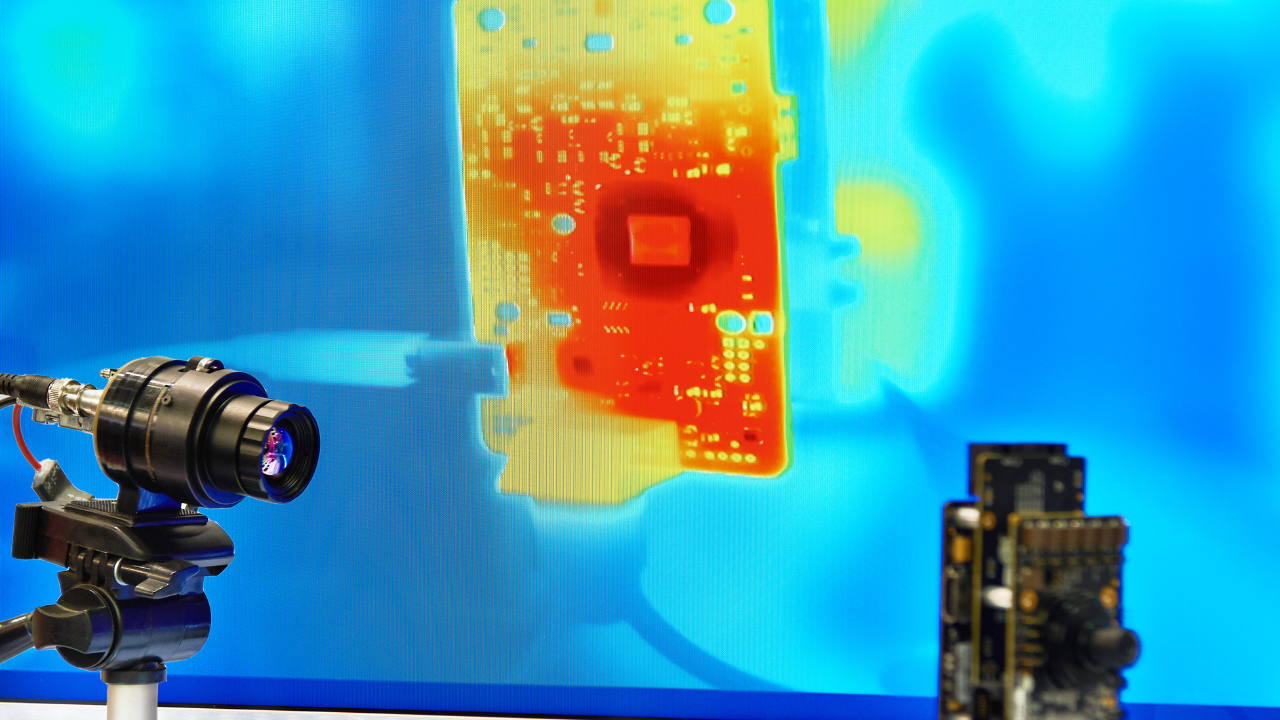

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera