New Generation IR Cameras

Alan Thomson

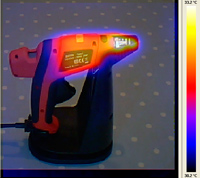

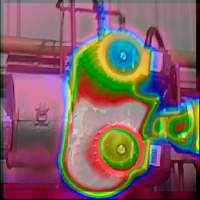

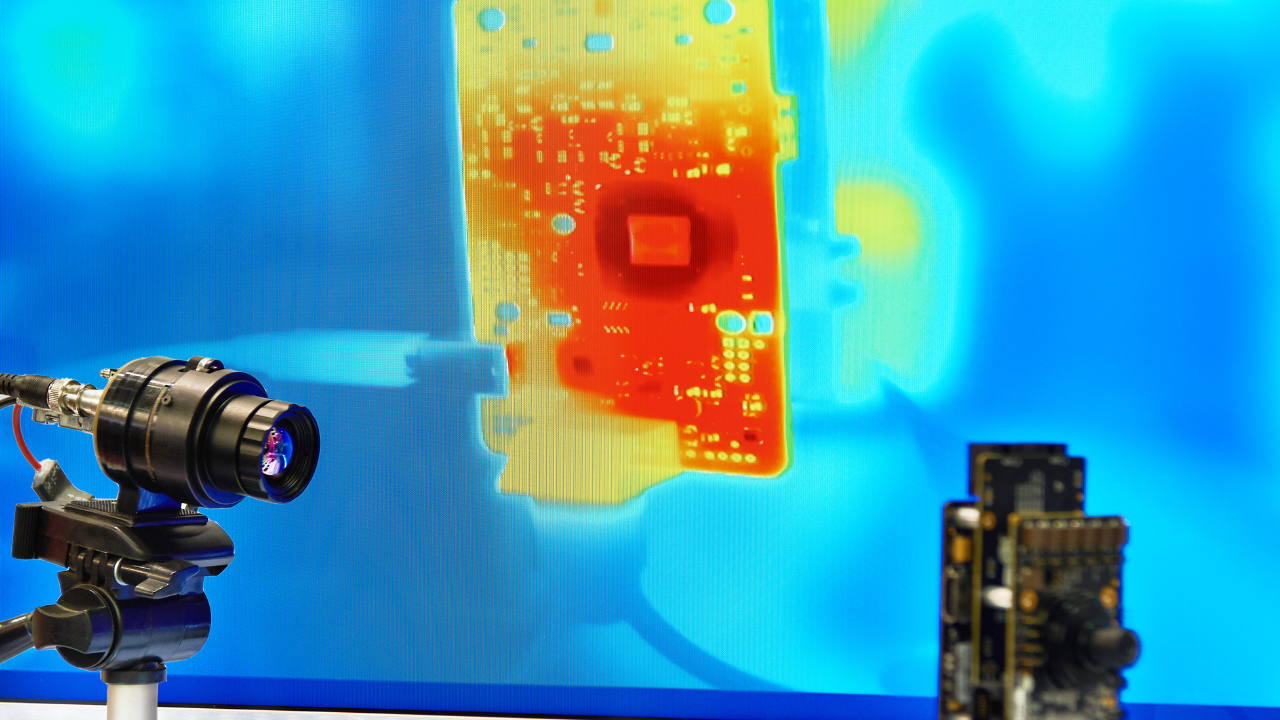

Three years ago the markets were hit by the first low cost, high resolution IR cameras that have revolutionised the use of thermography and vastly enhanced the appreciation of the benefits of the technology. They have been responsible for bringing thermography to the attention of a wider public through thought provoking images of large, well recognised buildings that have been published in media worldwide seeking to illustrate energy conservation issues. They have revealed previously unknown heat loss through roofs, windows and doors, in buildings ranging from local housing developments to the most prestigious of national edifices. At the same time they have been used increasingly to identify ‘hot spots’ in plant and machinery, giving maintenance engineers the opportunity to take corrective measures before a heat problem becomes a disaster.

The demand for this equipment will undoubtedly continue, but many users – particularly plant engineers and the increasing number of new energy surveyors – have been calling for affordable and user-friendly IR cameras which previously had only been available to specialist thermoraphers due to cost and complexity of use. This market-led demand has resulted in a new generation of IR cameras that combine thermal imagery with digital photography. They are ideally suited for close up inspection work on items such as window frames, doors and identification of insulation gaps, rather than the more panoramic images to be obtained from those with higher resolution.

Manufacturers, including Irisys, have developed a variety of models that offer digital and thermal images. Naturally they all vary, and in some cases the two images can be superimposed to give the operator a precise location for the interpretation of the ‘hot spot’ identified by the thermography process.

Voice annotation has also been built in, enabling operators to make verbal notes of each image taken, thereby enhancing reports generated later on a pc by positive identification of all aspects of the images. The audio facility has been combined with an alarm regime that offers engineers the opportunity to pre set the IR camera to give audio as well as on-screen visual warning when temperatures outside the defined parameters are identified. This will be a significant asset to plant engineers undertaking routine checks on large numbers of electrical control panels, wiring or fuses, as a pre-determined temperature limit can be set to trigger the alarm to alert the user that there are areas that require closer inspection. Engineers involved with mechanical equipment incorporating bearings will be equally delighted with the new IR cameras as they will give early warnings of bearings that are overheating and therefore likely to fail because they have begun to disintegrate. And we all know how much more expensive it is to replace equipment that has been damaged by a failed bearing than pre-emptive bearing replacement.

Some of the new IR cameras on the market meet IP54 requirements for outdoor use, where extreme temperatures, dust and the like could be a problem while others incorporate two cursors which enable the display of Delta T temperature differences without the need to capture two images. Through built in hot and cold tracking the cursors will also automatically identify hottest and coldest points, or both.

The mix of thermal and digital technology contained in an easy to use package that takes the guess work out of thermal imaging for less than £2,000 must offer the most economical and efficient way forward.

Related Articles

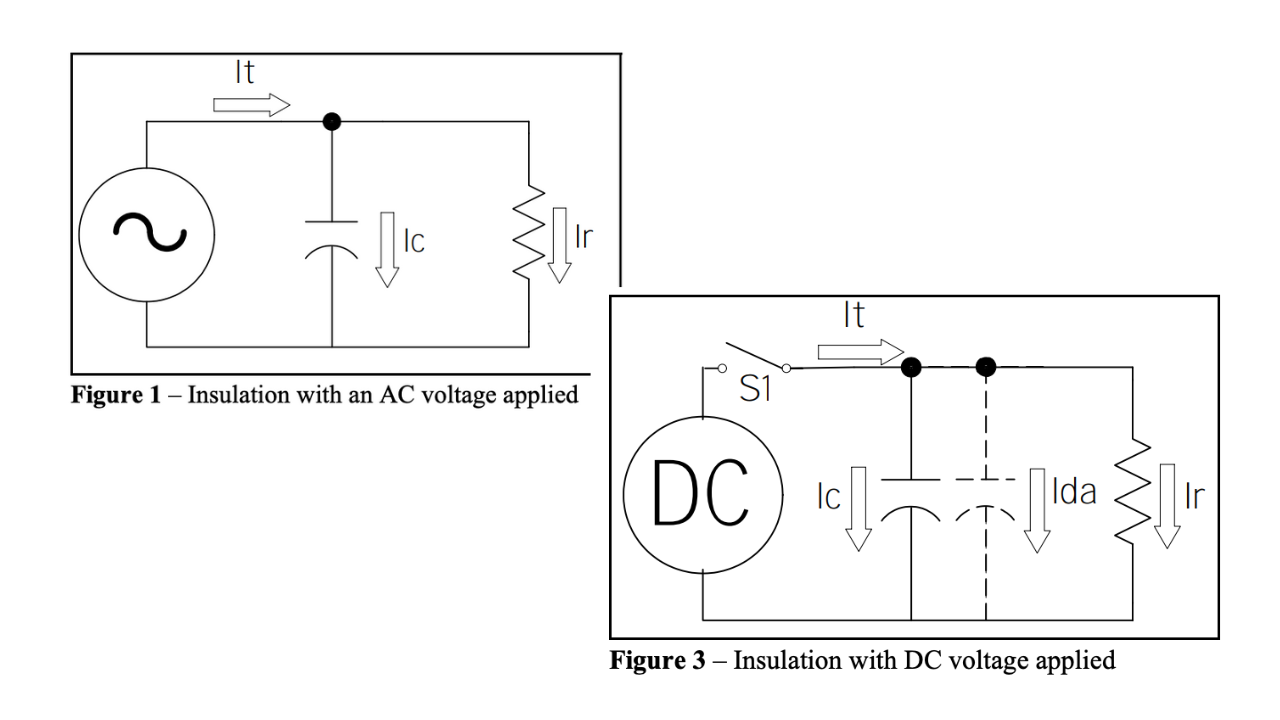

Principles of Insulation Testing

Top Tips for Selecting Pressure Measurement Transmitters

Gearbox Diagnostics Fault Detection

What is Vibration?

Why Record? Infrared Video

What You Should Know Before you Buy – A Guide to Buying an Infrared Camera